Softgel Machine:The Complete Buying Guide In 2025

In today’s age vitamins and minerals have become an important component of everyone’s life. They are important for the growth and well-being of mankind. These vitamins come in different forms like tablets, pills, effervescent tablets, capsules, and syrups. One of the most important and commonly used forms of vitamins is in the form of softgel capsules. These are the special form of capsules made from the softgel machine.

Softgel machine has gained immense importance in the recent age because of the widespread use of encapsulated capsules. It is only because of softgel machines that industries can produce almost 529,920 capsules in a minimum time of one hour. These machines have very high precision and efficiency, and they guarantee that each capsule will have an equal and right amount of softgel.

In this blog, you will be going to learn about the components of a softgel machine as well as the working of each component in detail. I will also explain the different types of the softgel machines, the advantages, and the drawbacks of softgel machines. I will also discuss the industrial applications as well as technical specifications of the softgel machine.

Let’s start with the understanding of a soft gel machine.

1.What is a Softgel Capsule?

They are the special form of oral medicines that are composed of gelatin shell in which active ingredient in the form of liquid or gel is present. They are made by the softgel machine through a forming, filling, and sealing process taking place in coordination in the machine.

Softgel Capsules- Image Courtesy: theinsightpartners

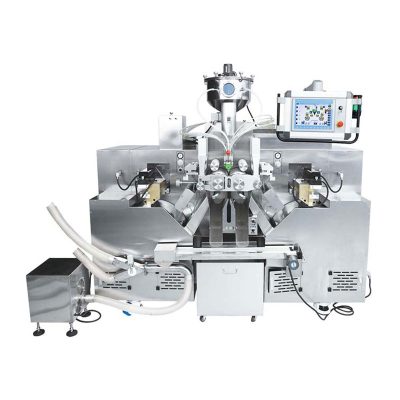

2.What is a Softgel Machine?

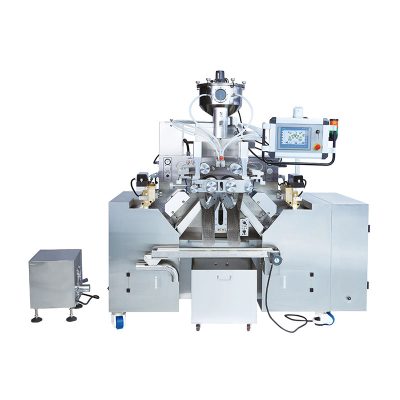

AIPAK Automatic Softgel Machine

It is a machine that fills the empty capsules of soft and hard gelatin with the active ingredient in the form of liquid, powder, semi-solid, or granules. The machine can fill capsules of various sizes. The active ingredient may be some pharmaceutical drug or any other multivitamin or food supplement. The term encapsulation stands for the filling of substances in empty capsules. The machine is actually a mechanical device that uses electrical energy to fill the capsules. The whole process is an electromechanical process.

3.What are the advantages of a Softgel Machine?

The softgel machine has a wide range of uses in different industries and is an important part of pharmaceutical as well as other industries. The main advantages of softgel machine include:

- The machine has very high efficiency and precision and capable of making a big mass of encapsulated capsules in a short time.

- The encapsulation of drugs through softgel machine in gelatin capsules has improved the drug availability, and it has also reduced the unpleasant taste of the drug.

- The safety of the drug has been ensured through encapsulation by softgel machine.

- The dose of the drug has been rightly measured using the softgel machine.

- The encapsulation of drugs has also eased the process of swallowing of the drugs.

- It has also provide protection against heat, light, and other environmental factors that may affect the drug formulation and availability.

- Softgel machine has also reduced the chances of drug oxidation by offering a protective cover.

- The storage and transportation of encapsulated drugs are much convenient than the non-encapsulated ones so softgel machine has played an important role in the proper storage of drugs.

- Without the softgel machine, it will be impossible to produce the encapsulated drugs and other vitamins and supplements.

4.What are the disadvantages of a Softgel Machine?

The machine has some limitations that you should be aware of before going to make a final decision of purchasing the machine.

- The softgel machine is quite expensive and needs a great investment.

- The installation of the softgel machine requires high assistance.

- The softgel machine is very heavy and it is very difficult to move the machine from one place to another. Also, it needs a lot of space thus suitable only for big-scale industries.

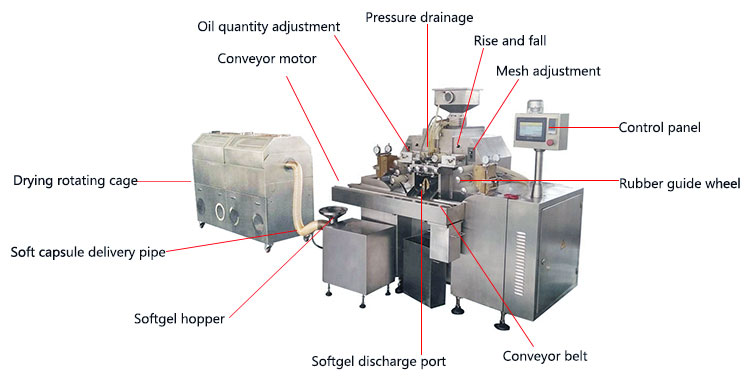

5.What are the essential components of a Softgel Machine?

The machine is made up of a large number of different parts and you need to know every part to obtain the maximum benefit from the machine.

The parts of the machine include:

- Medicine Hopper

- Operation Panel

- Gel Box

- Die Roll Mold

- Electric Cabinet

- Cooling Drum

- Fan Blower

- Conveyer

- Tumbler Dryer

- Air Compressor

- Gelatin Melting Tank

- Water Chiller

- Lubrication System

Medicine Hopper:

Medicine Hopper of Automatic Softgel Machine

It is the main feeding system of the machine that is located above the frame of the machine and below the material tank. In this way, it is easier for the machine to transport the material from one unit of the machine to another. The filling material in the form of a drug or other active ingredient that will be filled in the capsule is loaded in this tank. This tank can provide the necessary heat through the hot water jacket to the filling material and thus it prevents the solidification of the filling substance. The machine can hold a big load of filling material up to 5kg and is made up of heavy steel material to hold the mass of the filling material. The filtering of large and hard particles of the filling material is also carried out in this tank to avoid any kind of blockage in the pumps.

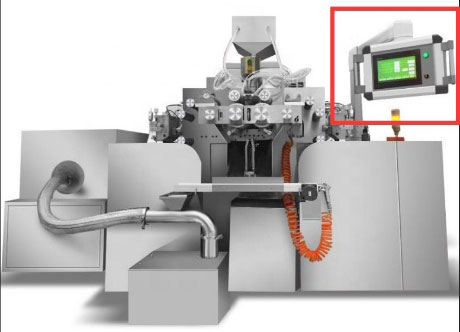

Operation Panel:

Operation Panel of Automatic Softgel Machine

This is a PLC control system in which all the instructions and parameters regarding the encapsulation of products through the softgel machine are set by the operator. Since the machine is fully automatic so once you adjust the parameters the machine will automatically perform the required action. An LCD is attached to it where you can see all the commands and can choose the parameters. The main point is a well understanding of all the parameters to avoid any confusion later on.

Gel Box:

This is also known as the spreader box. This part of the machine holds the molten gel solution. This part is responsible for the transport of the gel after the melting and mixing of the gel. This component of the machine keeps an eye on the temperature and liquid consistency of the gel. Thus it controls the volume and consistency of the material. The thickness of the gelatin ribbon is also controlled through this part to improve the overall performance of the machine. It has size variations depending upon the type of the softgel machines.

Gel Box of Automatic Softgel Machine

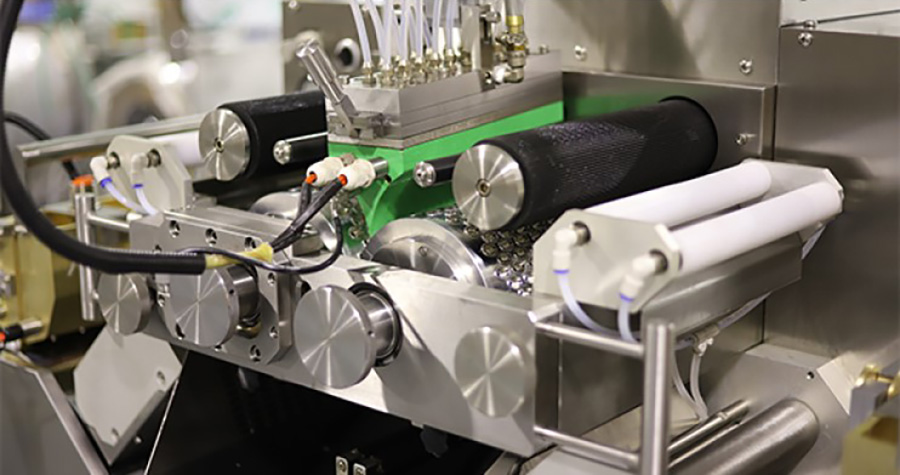

Die Roll Mold:

It is a major component of the softgel machine as it is responsible for the final shape, size, design, and cutting of the encapsulated capsule. It has a direct impact on the overall appearance and quality of the final product. There are different shapes, sizes, and cavities of die rolls depending upon the requirement of the manufacturer, they are made up of aluminum thus the pressing of gelatin is very handy.

Electric Cabinet:

This unit of the machine has all the electrical requirements of the machine, and it is regarded as the powerhouse of the softgel machine. All the switches, breakers, fuses, wiring are placed inside this stainless steel box. You should be very careful of this part and only an expert electrician must be allowed to check and maintain this component.

Electric Cabinet of Automatic Softgel Machine

Cooling Drum:

This part of the machine is located inside the gelatin box and it functions to form the gelatin ribbon from the liquid gelatin material by lowering the temperature of the gelatin mixture. This system can lower the temperature of the machine by cooling the drums and gel dies.

Cooling Drum of Automatic Softgel Machine

Fan Blower:

Once the encapsulation is done by the softgel machine and capsules are moved towards the tumbler dryer for cooling purposes. But the difference in height between the conveyer belt and tumbler dryer affects the cooling process. Thus, here comes the use of a fan blower, it dries the capsules and transports them to the cooling baskets.

Fan Blower of Automatic Softgel Machine

Conveyer:

This component of the softgel machine work as the transport system. It moves the materials from one part of the machine to the other. The movement of materials is managed by the PLC control system and it is necessary for the drying, sorting, and checking of the softgel capsules. The softgel capsules are moved from the discharge unit to the tumbler dryer in a to and fro movement. Thus, this part of the machine is important in the transport of encapsulated substances from one system to the other during the processing operations.

Tumbler Dryer:

This part of the machine is located right after the conveyor system, the major function of this part is to dry the encapsulated material coming from the conveyor system. The material stays there for some time and then is passed on to the drying trays.

Tumbler Dryer of Automatic Softgel Machine

There are different sizes and weights of tumblers depending upon the type of machine. The power consumption of each tumble is also different. So you must account for this parameter before purchasing the machine.

Air Compressor:

These are present alongside the gelatin melting tank and its function is to make the uniform consistency and flow of the gelatin.

Air Compressor of Automatic Softgel Machine

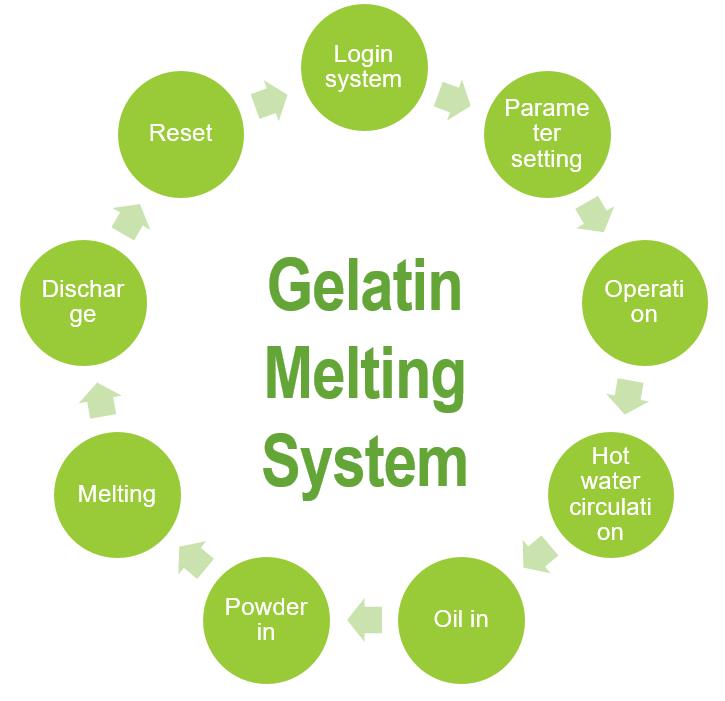

Gelatin Melting Tank:

The outer shell of the capsule is made from gelatin, water, pacifier, and glycerin. All these materials are poured into the stainless steel tank for mixing to make a homogenous mixture for making the outer shells of the encapsulated capsules.

Gelatin Melting Tank of Automatic Softgel Machine

Water Chiller:

The water cooler is attached to the cooling system inside the main body of the machine. It lowers the temperature of the melting gelatin as soon as it is poured down into the main machine.

Water Chiller of Automatic Softgel Machine

Lubrication System:

The machine has a lubrication system for the oiling of different parts of the machine. It is very important to avoid friction between the parts. You need to be careful regarding the nature of lubrication oil that it must not be harmful to the soft gel encapsulation ingredients.

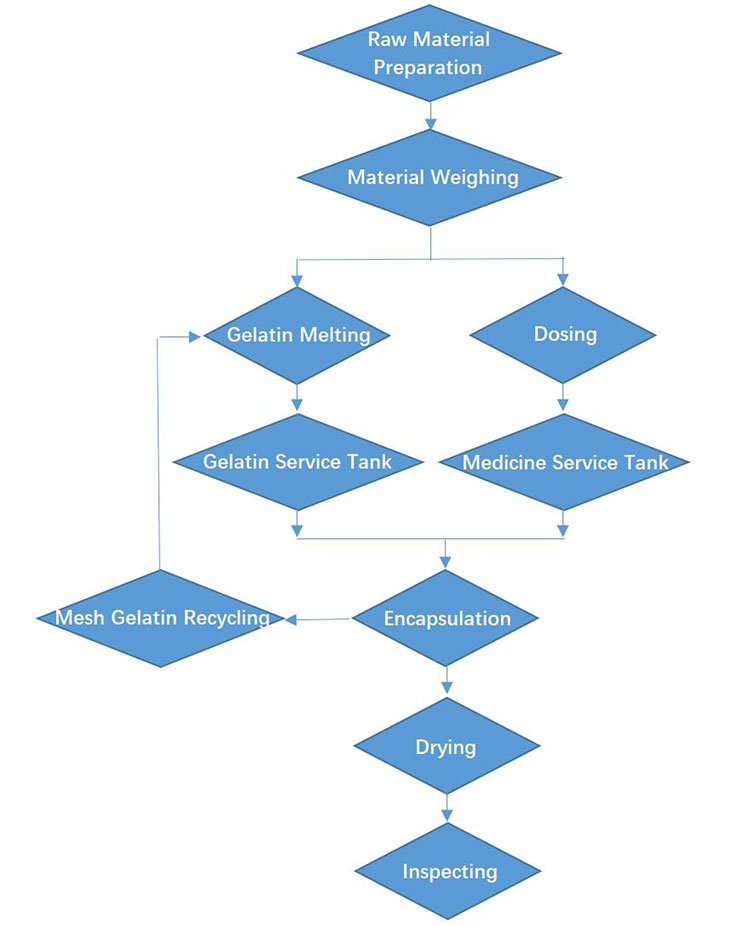

6.How does the Softgel Machine work?

The machine works in a coordinated manner with all the parts to form the gelatin mixture for the outer covering of encapsulation, and then the liquid medicine is filled inside these capsules. I will break down the whole process of making the softgel products into different steps for your better understanding.

Making of Gelatin Shells:

As you know that the outer cover of the encapsulation is made of soft and hard gelatin. The ingredients needed for the making of gelatin shells are gelatin powder, water, plasticizer, and some coloring agents. The gelatin in the form of powder is dissolved in the hot water, it will form the soft gel as it cools down. This gel is then melted by adding water and plasticizer to the water tank. After melting the gel the mixture is stirred at 65-75 °C by adding gelatin granules to make the soft gel mass. During this process, you must avoid bubble formation by removing the extra air from the mixture. You need to be very vigilant regarding the amount of water in the mixture. The water may loss during the removal of air to avoid bubble formation. To compensate for this you need to add some extra water to the mixture.

Pictorial Representation of Gelatin Melting Process in an Automatic Softgel Machine

When you feel the homogenous consistency of the mixture and the gelatin has a transparent glass-like appearance you will shift the mixture in the holding tanks at 60 °C and coloring agents are added to the mixture. The plasticizer in the form of glycerol or sorbitol solutions is mixed with the mixture too hard the mixture.

Make sure the mixture is well set with no bubbles inside before moving it to the next step of encapsulation.

Drug Preparation:

After the processing of the gelatin mixture next step is the preparation of the filling material in liquid, semi-liquid, or any other required form. The filling material may be of some medicine drug in nature or some food supplement like fish oil etc.

Transfer of the Gelatin and Medicine in the Hopper:

The gelatin and the mixture of the drug are transferred into the gelatin melting tank, the filling medicine is filled through the medicine hopper, and gelatin is loaded in the respective gel boxes.

Encapsulation Process:

This the most important part of the mechanism of the softgel machine. Once the gelatin is moved through the tubes in the gel boxes through the action of compressed air it will assume the shape of thin film also called a gelatin ribbon. This ribbon will move to the cooling system through the action of conveyor belts. The gelatin ribbon will become more flexible and after cooling, it will roll down to the lubrication system where the friction is removed between the gelatin ribbon and different parts of the softgel machine.

The gelatin ribbon will run smoothly through the machine and the lower side of the capsule will be sealed and the medicine will be injected into the gelatin ribbon from the open end. After the filling of medicine, the capsule is also sealed from the upper end.

This whole process is very important because two major tasks are being carried out in this step i.e. the sealing of the capsule and the filling of the medicine.

Cooling of the Soft gel:

The encapsulated capsules are then passed on to the tumbler dryer system where the cooling of the encapsulated capsules takes place through the rotatory action of the fans. It is necessary to hard the encapsulated capsules and for the removal of extra moisture.

Tray Drying:

In this step, all the encapsulated capsules are shifted to the trays where they are cool down for 1-2 days.

Sorting of the Capsules:

After drying you will check for the quality of the capsules before packaging. All the damaged capsules are sorted out and the extra oil on the capsules is being removed by the use of cotton cloth.

This is the whole working process of the Softgel Machine, and it is very important for you to completely understand the whole working process before operating the machine by yourself.

7.What are the industrial applications of a Softgel Machine?

With the widespread use of gel tablets, the softgel machine finds its uses among the cosmetic, pharmaceutical, food, chemical, and recreational industries.

Pharmaceutical Industry:

In the pharmaceutical industry, the softgel machine is used to produce aesthetically appealing capsules that mask the unpleasant taste of the drugs and make the swallowing of drugs easy for the consumer.

Pharmaceutical Softgel Capsule products

The bioavailability of many drugs and related products has also been improved in the gel form. The storage and transport of drugs are easy in this form. Also, the manufacturing of many oil-based drugs has become convenient using the softgel machine.

Healthcare Industry:

In the healthcare industry, the use of the softgel machine is very prominent for the production of different nutraceuticals and food supplements. Many vitamins are being administrated in softgel form. The case of medical marijuana has also been justified in the form of softgel capsules.

Softgel Nutraceuticals-Image Courtesy: sirio-europe

Cosmetic Industry:

In the cosmetic industry, the softgel machine plays an important role in the making of many skincare pills. It makes the handling and use of these pills very convenient by converting them into soft gel form.

Softgel Hair Vitamin Capsules-Image Courtesy: megiohealth

Recreational Industry:

In the recreational industry, the softgel machine has gained immense importance for the production of paintballs. These balls are a source of joy and ultimate pleasure for the people and the shooting of paintballs is a popular game of the modern world.

Painball

8.What are the different types of Softgel machines?

When we talk about the types of a Softgel Machine you will be surprised to know that all the softgel machines are fully automatic and you don’t need to have human labor for the production of the softgel capsules. The machine is classified based on its production capacity into the following categories.

Small Scale Production Capacity:

AIPAK small scale softgel machine

They are small, very handy, and portable gel machines that are good enough for the production of small-scale soft gel capsules. This type of machine is widely used in small laboratories and research units.

Medium Scale Production Capacity:

Their production capacity is not too large and is suitable for small-scale manufacturers. They are easy to move from one place to another.

Large Scale Production Capacity:

AIPAK large scale softgel machine

This is the type of soft gel machine that you will find in the pharmaceutical and big-scale food industries. They have a production capacity of tons and are very large for the movement from one place to another. Thus, once they are installed at a place it is very difficult to move the machine.

9.What quality assurance standards are necessary for the Softgel Machine?

Before buying the machine you must be aware of the quality standards that are necessary for the safety and high performance of the machine.

A good manufacturer will show you the following quality standards of the softgel machine.

- cGMP

- CE Certificate

- FAT

- IQ Standard

- OQ Standard

- ISO Certification

You must ask the dealer for these certifications before buying the softgel machine.

10.What are the common problems with the Softgel Machine?

Here I am explaining to you some problems that you may face during the operation of the softgel machine. These problems include:

- The thickness of the gelatin ribbon is not even, due to insufficient lubrication or the presence of any outside material in the gelatin solution. You need to check for the proper lubrication of the machine before the operation, also the material mixture should be free of foreign substances.

- The presence of any foreign particle in the mixture may lead to the shorter-length gelatin ribbon.

- The texture of the gelatin mixture has dents on its surface and is not as smooth as it should be.

- Sometimes the ribbon may be stuck between the rolling die because of incorrect positioning.

- The shape of the gelatin ribbon may be deformed because of the uneven thickness of both sides of the soft gel capsule.

11.How to maintain the Soft Gel Machine?

The soft gel machine requires regular maintenance and cleaning for better quality results.

- The power supply to the softgel machine must be following the requirements of the machine model.

- The lubrication of different parts of the softgel machine must be checked regularly to avoid damage from friction.

- The screws of the machine should be checked and if any part of the machine needs tightening of its screws it should be done immediately.

- You should always clean the machine once you are done with the production at the end of the day. This is important to clean the medicine residual and other dust from the machine.

- The machine should be leveled properly on the ground, also the medicine plate must be placed horizontally to avoid any damage.

- The machine must be kept safe from direct sunlight, water, and harsh environmental conditions.

12.What techniques are used to print on the Softgel Capsules?

The printing on the softgel capsules can be done through three techniques namely:

Inkjet Printing:

This is the modern and most efficient method used for printing softgel capsules. The letters or numbers are entered on the touch screen of the control panel and as soon as the sensor detects the presence of a softgel capsule it will automatically eject the required amount of the ink to print on the capsules.

Mold Printing:

It is an old method of printing on the softgel capsules in which single color and simple pattern can be printed with the food graded ink.

Laser Printing:

This is the most advanced technology to print any pattern or letters on the softgel capsule with colorful variations.

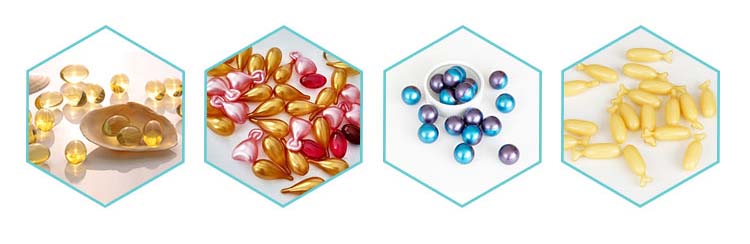

13.How different types of capsules are made from the Softgel Machine?

The size and shape of the capsules always depend upon the die roll. You can either choose the traditional oval shape capsule to die or can opt for the custom-made designs. These designs will need the adjustment of the rolling die. The most commonly used designs include:

Different Shapes of Softgel Capsules-Image Courtesy: Philadelphia.edu.jo

- Oval shape

- Oblique shape

- Oblong shape

- Round shape

- Tube shape

14.Which parameters play an important role in the making of Softgel?

The production of the softgel machine depends upon many factors depending upon the type of the machine and some of the environmental factors. I will briefly explain some of the parameters that play an important role in the production of soft gel.

- The type of the softgel machine being used is one important factor, a high capacity machine will give you a high production rate.

- The speed of the softgel machine is also very important in the production of the gel high-speed machines will produce a big mass of the soft gel.

- The most important step in the production of the softgel is gelatin formation. So, if you have mixed the right amount of ingredients in the process of gelatin formation you will have better results.

- You need to have a trained operator who will run and monitor the whole process of the soft gel formation, an untrained operator will create chaos and affect the capacity of the softgel machine hence the production rate.

- You also need to have a proper arrangement of supporting equipment for the production of softgel.

- The drying of the product also affects the quality of the soft gel production because different products dry at different temperatures.

15.What type of supporting equipment works with the Softgel Machine?

Some equipment plays a supporting role in the line of the softgel production machine. This equipment has a direct effect on the production quality and quantity of the machine.

Supporting Equipment for Softgel Machine-Image Courtesy: JSPharma

Here are some of the important supporting equipment.

Melting Tank:

This tank is needed for the mixing, heating, and melting of the gelatin solution.

Material Filling Tank:

In this tank, you will be made the filling materials for the capsules.

Material Storage Tank:

This tank is used to store the gelatin mixture at a stable temperature for quite a period.

Gelatin Holding Trays:

They are the PP trays that are used to hold the softgel capsules before they get transported to the cooling system.

Grinder:

This is used to grind all the fine granules during the process of making gelatin.

Polishing Machine:

The softgel machine is used to give a clean finish to the gelatin capsules, it makes them look luscious.

Inspection Machine:

The softgel machine is used for sorting off any d-shaped, disoriented, and broken capsules. The excess oil on the capsules is also removed through the softgel machine.

16.What is the future of the Softgel Machine?

The increasing demand for softgel products has directly impacted the market of softgel machines. The nutraceutical industry is rapidly growing with the use of the softgel machine for the production of food supplements and vitamins in encapsulated form.

The high precision and efficiency of the softgel machine have made it popular in the pharmaceutical industry, especially in the international market.

The revival of traditional Chinese medicine products has also uplifted the market of the softgel machine because swelling of those unpleasant taste tablets is very difficult.

The softgel machine is a great addition to your pharmaceutical industry and will help you flourish every day.

Conclusion:

Now that we have discussed all the major points of a soft gel machine, and you have also become aware of its importance, you can now go for the buying of the softgel machine by just a single click on our website.

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine