Softgel Encapsulation Machine:The Complete Buying Guide in 2025

To maintain a happy and healthy lifestyle you must take vitamins and nutritional supplements as per your daily requirement. Thus, a Softgel encapsulation machine made it possible to provide high-standard supplements. Softgel encapsulation machines assure you that each capsule contains an accurate amount of dose.

An enhanced nutritional bioavailability is one of the most extensively recognized advantage of softgel capsules. Due to this property consumers expect to get perfect nutrients consumption with a fast delivery as well as the onset of action.

The softgel capsules are elegant looking with exceptional drug delivery and easy to swallow. Their attractive colors and intentionally added flavors make them easily acceptable to adults and children.

To achieve all the above-mentioned targets, a softgel encapsulation machine is of prime importance. Softgel Encapsulation Machine is also characterized as Softgel encapsulator. It has a specialized layout to manufacture soft gel capsules utilize for gel encapsulation across the globe.

In this blog, we will try to provide extensive details that may assist you to know about softgel encapsulation machines.

Let’s get into it.

1) What is a softgel Capsule?

Softgel capsules

Softgel capsule is a soft sealed capsule available in different shapes, sizes, and colors containing active ingredients in the form of granules, paste, oil, or suspension.

They are made up of gelatin, glycerin, and other associated pharmaceutical ingredients that helps in the firmness and toughness of capsules.

Gelatin is mainly protein that is extracted from the skin of chicken, fish, or some non-animal derived sources. The protein gel is capable to digest by the action of enzymes present in the intestinal region ultimately release the active ingredient which is being absorbed and enters into the bloodstream.

2) What are the benefits of softgel capsules?

The benefits of softgel capsules are as follow:

#1. A softgel capsule offers to deliver a highly pure substance and preserve its originality without incorporating unwanted preservatives.

#2. You will get an excellent dosed volume of active ingredients via softgel capsules.

#3. A softgel capsule can protect your active substance from chemical and physical reactions. They are hermetically sealed that protect the active from oxidation and keep it safe.

#4. A softgel capsule sealing assures a temper evident pharmaceutical drug delivery.

#5. A softgel capsule is made up of 100% biodegradable shell in an oil medium that protects the mucosal lining of the gastrointestinal tract.

#6. Most often consumers prefer taking softgel capsules due to their color, shapes, and masking the bad taste.

#7. You can safely dispense natural ingredients with help of softgel capsules.

#8. Softgel capsules are easy to swallow therefore, it is preferred by adults and children.

#9. A softgel capsule may provide quick and better absorption on specified active sites. They have fast disintegration time, therefore, provide quick therapeutic action.

3) What is a Softgel encapsulation machine?

Softgel encapsulation machine is also termed as capsule fillers, capsule encapsulator, or capsule filling machines. This is a mechanical device that is extensively used in pharmaceutical or other industries to fill empty gelatin capsules that could be soft or hard available in various shapes, colors, and sizes.

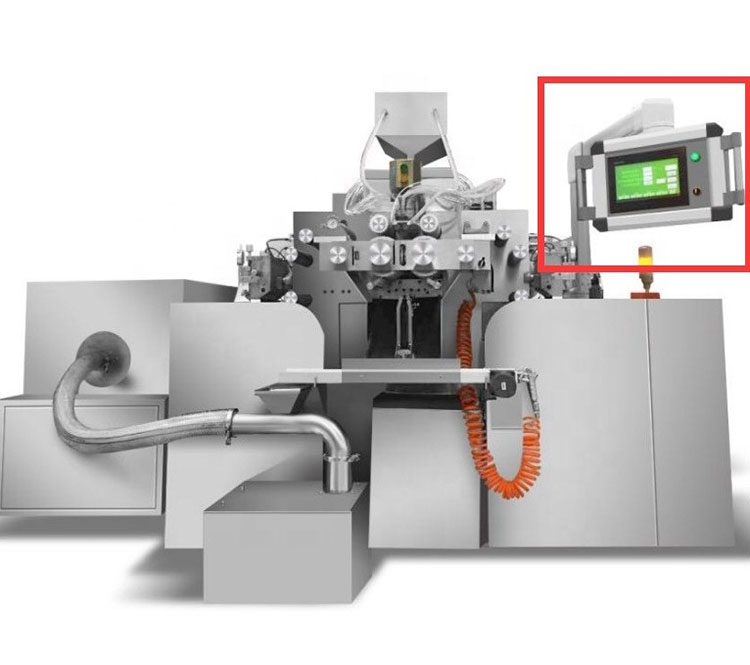

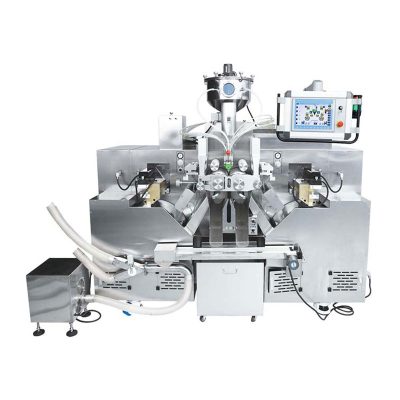

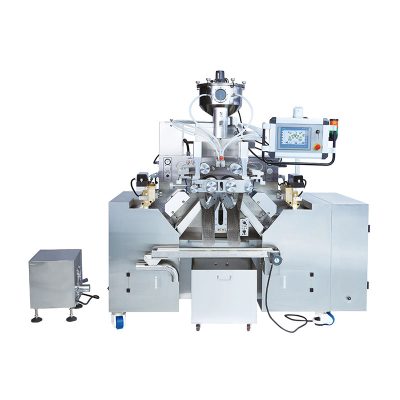

AIPAK Softgel Encapsulation Machine

These capsules are commonly filled with powders, oils, semi-solid or solid granules that contain a single or combination of active pharmaceutical ingredients along with a set of excipients.

The process of filling capsules with the pharmaceutical or chemical substances known as ‘Encapsulation’.

4) How Softgel encapsulation machine works?

The following guidelines will help you to provide a clear understanding manufacturing of Softgel encapsulation via machine.

Before the process encapsulation, two sub-processes are often carried out which yields a Softgel.

These sub-processes are

- The gel mass that ultimately provides a Softgel shell.

- Filling of material.

#1 Rectification

This is the first and fundamental step that is involved in the selection of the right formulation for the gelatin.

In this process, it is important to choose the right formulation for the gelatin. In many cases, the gelatin composition consists of a selection of plasticizers from shells and elastic, colorants, and good quality gelatin which is obtained from animal sources.

Gelatin is extracted from animal sources by boiling the skin bone and tendons. This gelatin is of prime importance as entire capsule making based on it, so correct choice is mandatory.

Soft Gelatin Capsules

All ingredients are amalgamed with the help of the universal blending vehicle ‘water’. Water plays an exceptionally important role in the preparation process of the Softgel capsule that covers the entire formulation of capsules to form a good blend.

You are required to heat and mix all the ingredients continuously till you get a viscous syrup. The viscous syrup is the gel mass that forms a vital component for the process of encapsulation.

Once everything is ready you can begin to flow the syrup into the spreader box. This spreader box will uniformly allow the mixture before entering the cooling and die roller chamber.

#2. Separation of Capsule Caps from Bodies

In the manufacturing of Softgel capsules, this process is very simple and easy. This step is accompanied by the preparation of filling material depend upon your formulation.

For this you will be required to:

- Add oil or paste-like substance depending upon the nature of the material. Similarly, you may also use a hammer mill, process tank, dryer, or fluid bed granulators.

- After combining the filling material according to your formulation. Now, the material will smoothly flow from a hopper to an injection wedge via a tube.

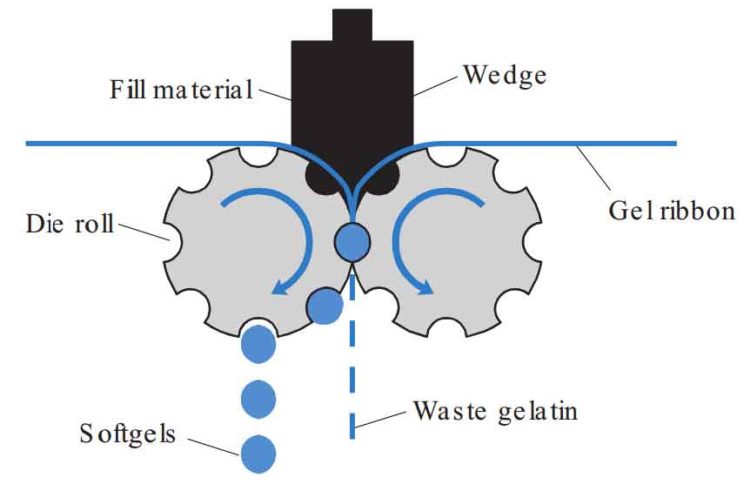

Filling of the mixture into the die roll from an injector wedge

#3 Gel Encapsulation

This is a very important and technical step that involved a Softgel encapsulation machine.

This step required two units of material

A) gelatin

B) mixture of ingredients

A hot gel mass (melted under 80⁰C) is supplied to the Softgel encapsulation machine with the help of heated transfer pipes using a casting method which results in two distinct 150mm wide gelatin ribbons.

Their thickness is monitored throughout the process of manufacturing. These ribbons are brought out of rollers toward a rotary die of encapsulation tool.

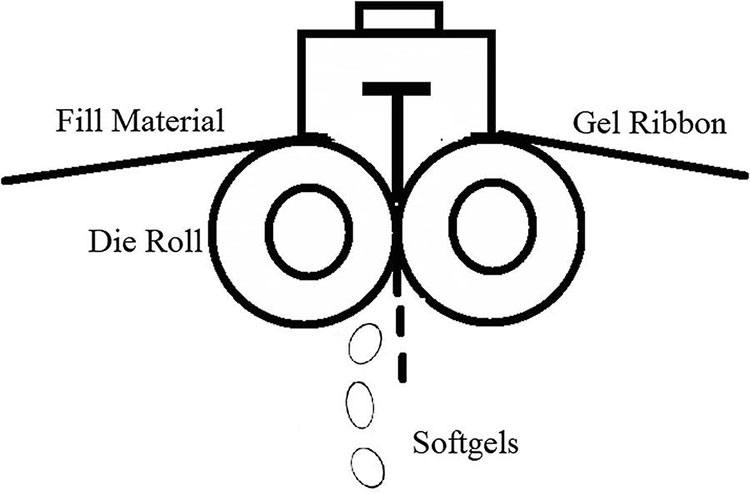

Softgel encapsulation machine- rotary die process

Each ribbon forms one-half portion of the Softgel. Therefore, it is possible to create a bicolored Softgel capsule using a ribbon of two distinct colors.

During this, you may add the filling material into the Softgel encapsulation machine that incorporates in the middle of the gelatin ribbon.

The process continues within the rotary die rolls. Now, the gelatin will wrap up the filling material to develop a capsule. The shape of the capsule is determined by the type of die roll cavities.

Soon after the machine will allow the capsule to leave via a discharge chute. During this process, there is the probability of sticking capsule particles on a die roll. Therefore, a brush is constantly sweeping and removing the presence of an excessive particle.

Besides this, a stripper roller may also help to remove any capsule particle that glues onto the gelatin web.

#4 Rejoining and Inspection of Capsule

The strips of ribbon continuously passing through a heated wedge system, and then hard-pressed between die’s rolls.

At this time, two halves of the capsule are sealed together with the help of heat and pressure.

In meantime, these capsules are being cut from gel ribbons automatically with the help of a rim available at each die roller.

For complete drying, these capsules are passed through a tumble dryer spread onto a tray and complied in a tunnel dryer which supplies air with 20% relative humidity.

The tunnel drying process may take 2-3 days that may exceed up to 2 weeks which is depending upon the nature of Softgel formulation.

Then Softgel capsules are inspected and packed into a bulk container to prevent their interaction with environmental factors such as light, air, and humidity.

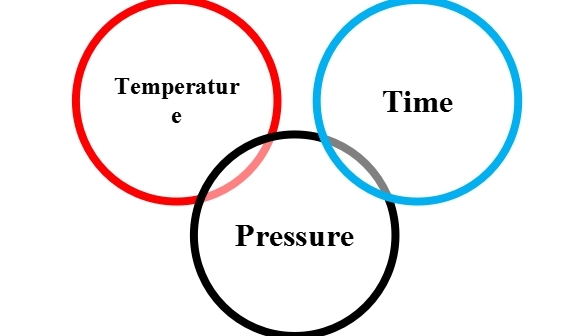

5) What is a rotary die encapsulation?

In a rotary die encapsulation, a gel ribbon is incorporated with a unit dose of liquid fill matrix.

These two substances combined to form a Softgel.

This is an important process that requires thorough control over three major parameters.

#1. Temperature: This is an important parameter that provides a specific heat suitable for gel formation.

#2. Timing: Timing is very critical during the incorporation of a matrix into the Softgel.

#3 Pressure: The pressure applied between the two rotary dies manages the whole shape of Softgel shape and ultimate final cutting from a gel ribbon.

6) How Softgel encapsulation machine originated?

A Softgel encapsulation machine is also known as a softgel capsule manufacturing machine specially designed to make Softgel capsules.

Since 1970, it was the first time introduced in the market that opened a horizon for further development of Softgel capsules machines in pharmaceutical industries worldwide.

In 1986, the Chinese have developed their first Softgel encapsulator. Now they are an expert manufacturer of Softgel encapsulation machines for more than 30 years. Not only this but they are also considered as a leading exporter of Softgel encapsulation machines worldwide. They produce a well-equipped modern device that ranging from laboratory to an accelerated larger size encapsulation machine.

7) What is a production line of the softgel encapsulation process?

There is a certain production line that plays a vital role in the process of softgel encapsulation.

Here is a list of softgel production line equipment.

1- Gelatin melting machine

This equipment is made up of stainless steel comprised of three layers of jacketed structure, heating accompanied by an electric and water circulation. This equipment provides a strong, fast, and sustainable environment for the smooth melting operation of gelatin and associated mixture.

2- Filling material

For filling material, a good quality mixing tank is required with heating (as per requirement) and homogenizing properties to get an even and homogenized liquid solution. Keep in mind, the mixture solution has no single gain inside because it may cause clogging during a plunger filling.

3- Softgel encapsulation

A softgel encapsulation machine is a piece of electromechanical equipment that is complemented with the filling and hermetic sealing of capsules. It allows the filling of liquid and semi-liquid or viscous material into a capsule soon after cutting from gelatin ribbon that moves opposite from each side.

4- Shaping and drying

This device is generally relying on two components: a fan and rotation of air blower for drying softgel.

The softgel when drops from an encapsulator available in a wet form which is extremely soft and fragile. So, you cannot dispense the product or package that softgel. Therefore, it is a smart decision to use an air dryer to hold softgel capsules in their shapes. The tooling system or die roller can easily allow a desirable shape of a softgel capsule.

Softgel encapsulation drying machines

5- Final drying

The final drying is achieved by an independent tumbler dryer machine which is widely used for manufacturing unit of soft gelatin capsules for food and health supplements. This machine helps in taking out water content from the softgel capsule and circulating air allows the capsule to dry.

When softgel capsules are discharged from the tumble dryer, to keep suitable humidity and drying conditions these capsules are added onto drying trays to cool down the capsules naturally within one and two days. Sometimes it may take a longer time which is depending upon the type of material used.

Softgel encapsulation final drying process

6- Printing

The printing of capsule could be achieved by using UV laser technology. A permanent code marking is done directly to avoid the risk of counterfeiting the product identification.

Printing of softgel capsule by UV laser machine

7- Inspection and Screening

By following the above-mentioned steps, you can get a final product.

But this is not the end of the show!

Because as you get softgel capsules, you need to evaluate those capsules which are not OK for final packaging. Therefore, careful examination and sorting are required to get a bestselling quality product.

If you have capsules with too much oily or sticky surface, then you can wipe off the oil with the help of cotton cloth and alcohol washing in a polishing pan.

8- Packing of the finished product

All accepted capsules with non-greasy, smooth, proper size and shapes should be allowed for the final packaging process.

Softgel capsule packing

8) What industrial sector requires a softgel encapsulation machine?

Softgel encapsulation machine incorporates a broader range of industrial scale.

1- Pharmaceutical Industry

Softgel encapsulation machines are a complete solution to manufacture a wide range of pharmaceutical dosage forms.

These capsules are suitable to dispense non-aqueous mixtures or solutions such as oils. These capsules contain the active ingredient in the form of oil or a suspended base and inactive component such as excipients.

Upon administering, these capsule starts to dissolve at their specific site, for example, intestine.

Many capsules are aimed to mask the unpleasant taste and smell of drug substances. Therefore, pharmaceutical preparations now increasingly selecting this strategy. Besides this, the Softgel capsule facilitates a high content uniformity especially for low dose drugs, reduces the probability of microbial contamination or protects the cytotoxic compounds, and improves patient compliance.

The most interesting innovation made by the pharmaceutical industry is the development of liquid and semi-liquid formulation that increases bioavailability, improves the solubility and absorption of a drug substance.

Retinol, Digoxin, Adalat, Zantac, Simethicone etc., are the examples of currently available pharmaceutical Softgel capsules preparations.

2- Cosmetic Industry

Softgel capsules are often designed in various shapes and colors to dispense cosmetic skincare substances. This Softgel encapsulation machine is extensively used in cosmetic industries to boost their product selling via attractive appearance and better function of products.

Almost every cosmetic preparation has incorporated silicone oil in its filling content. Silicon oil is very sticky more than lecithin. Therefore, they have a customized die roll with good sealing properties and creates a beautiful shape.

The cosmetic industry manufactures Softgel capsules that could be anhydrous devoid of water and preservatives improving stability. As you know, a formulation with no preservatives is ideal for skincare. The most used shapes are, twist-off, bath beads, and cut-off Softgel capsules.

Twisted-off type softgel capsules

Bath-beads type softgel capsules

Cut-off type softgel capsules

3- Nutraceuticals

The prime concern of the nutraceutical industry is to deliver herbs, vitamin supplements, extracts in an original non-oxidized form.

Therefore, softgel capsules are ideal dosage form for nutraceutical preparations.

Softgel encapsulation machines are significantly used in the nutraceutical industry due to certain benefits:

- They provide oxidation proof obstacles.

- They maintain oils in their original state devoid of interacting with environmental elements.

- They can efficiently mask the unpleasant taste and odor of oils, extracts and vitamins.

- They improve the shelf life of the product.

- Protect the substance from interacting with other incompatible ingredients.

- Easy to ingest, especially woman and children.

Nutraceutical softgel capsule

Common examples of nutraceutical softgel capsules are vitamin D, Omega-3, vitamin E, etc.

4- Veterinary Industry

The Veterinary mainly establishes licensed veterinary products that offer medical, dental, and surgical therapy to animals. Softgel capsules perfectly deliver a controlled unit dose of substances to animals. As you know, to administration to animals is a challenging task. Therefore, dose acceptance and therapeutic obstacles are perfectly operated by softgel encapsulation machines. A specifically designed formulation by softgel formulation technology ensured that the drug can easily be administered to animals. You can apply softgel capsule formulation as an oral or topical form for parasitic control.

The prime benefits of softgel encapsulation machines in the veterinary industry are:

- You can deliver insecticides and nematicides safely

- Deliver unit-dose plant food

- Highly attractive fish bait

- Supplements for animals such as omega-3 fatty acids.

9) What are the different types of capsules?

There are two basic types of capsules, a softgel capsule, and a hard gel capsule.

A) softgel capsule

General Aspects

In the 19th-century softgel capsules were introduced to mask the unpleasant taste as well as odor of medicines. Today, due to their beneficial properties, softgel capsules are extensively used on a larger platform of health, cosmetics, and food sectors.

Not only this!

Softgel capsules are also used for recreational purposes like paintballs.

Softgel capsules are the preferred choice to get a high-content uniformity, easy to swallow and a significant safety aspect as it lessens the chances of cytotoxicity to specialist/operator and environment.

The basic components of softgel capsule are as followed.

A) Gelatin

It is a basic component of softgel capsule which is obtained from animal sources.

There are various formulations available that require gelatin in the molten form.

B) Plasticizing agents

The plasticizing agents of softgel capsules ensure adequate flexibility of capsules. The commonly used plasticizer in softgel capsules is glycerol.

You can also add, mannitol, polypropylene glycol as well as sorbitol along glycerol.

C) Water

The content in softgel capsules accounts for 30-40%. It is a very important element required for manufacturing and in a finished product to assess the flexibility of capsules.

D) Colorant/ Opacifier

To make an appealing look a colorant is incorporated into the shell. Colorants can also reduce the chances of light penetration hence it prevents photosensitive substances.

E) Other Excipients

Sometimes sweeteners are used to improve the palatability of softgel capsules.

Acid-resistant polymers are used for enteric release capsules as well as for chewable softgel capsules.

EDTA, which is a chelating agent used to prevent the oxidation of sensitive drugs such as iron.

B) Hard-gel Capsule

General Aspects

Most capsules available in the market are made up of hard gelatin capsules. The shell of a hard gelatin capsule has two parts a cap and a capsule body. A cap is shorter in size which is capable to fit tightly within the body of capsule.

The basic composition of the hard gelatin capsule includes sugar, water, and gelatin. Most often they are clear and tasteless capsules.

Hard gel capsules

A) Gelatin

Gelatin is far more common material used in the manufacturing of capsules shells. It is a combination of purified protein fractions extracted from the skin collagen, bones, and connective tissues.

B) Plasticizer

Plasticizers are used to overcome the rigidity of polymers and make them more flexible.

The commonly used plasticizers are glycerin. Water has also participated as a plasticizer that is naturally available in the gelatin.

C) Colorants

Colorants are frequently used in the hard gel capsule to enhance the aesthetic and identifying properties of the product. The commonly used colorants are azo, and xanthene dyes.

D) Opacifiers

Opacifiers are used to make a gelatin opaque such as titanium dioxide.

10) What is the difference between softgel capsules and hard gel capsules?

- A soft gelatin capsule is made up of single-piece gelatin while a hard gelatin capsule is comprised of two halves a body and cap.

- The solution for softgel capsule is oil based as a water-based solution tends to dissolve the gelatin. Hard gelatin capsules commonly hold dry ingredients such as powder form.

Softgel and hard gel capsules

- Once the softgel capsule is ingested it dissolve in the body and release the drug. On the other side, the hard gelatin capsule dissolves rapidly soon after ingestion and quickly releases the drug within three minutes.

- Soft gelatin capsule is relatively more flexible than hard gelatin capsule.

- The manufacturing of softgel capsule is achieved by a single machine. Whereas the manufacturing of hard gelatin capsule requires two types of machines. In one type of machine, shells are produced while filling of hard gelatin capsules is achieved by another machine.

- Softgel capsules are available in different shapes such as round, oval, or tubular. While hard gelatin capsule has a standard cylindrical shape.

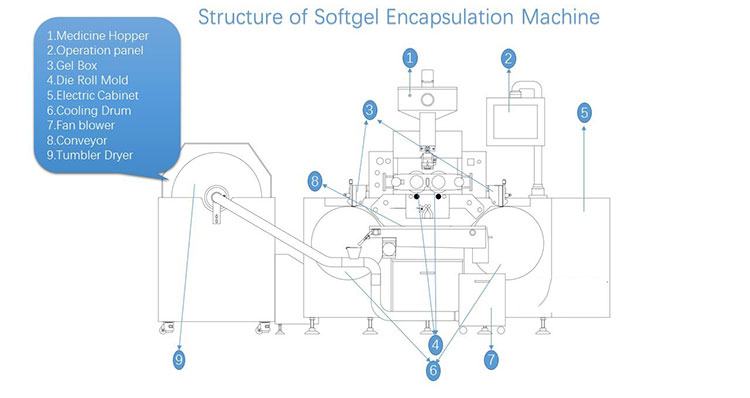

11) What are the major components of the Softgel encapsulation machine?

The major components of softgel encapsulation machines are as follow:

Structure of softgel encapsulation machine

#1- Machine Hopper

Machine hopper is used to fill the medicine or content of capsule that is intended to flow inside the softgel capsule. Normally, machine hopper is constructed in a way that carries a hot water jacket that continuously provides heat. Machine hoppers keep on stirring the content of capsule to avoid sedimentation. A presence of a circulating jacket allows to monitor liquid level.

Approximately 5 kilograms of medicinal or capsule content is allowed to load up into the hopper. A little filling cause machine to plunge blankly and large or hard particles cause blockage as it may enter the pump. Therefore, 60-80 mesh is considered as a suitable filtering size.

Softgel encapsulation machine

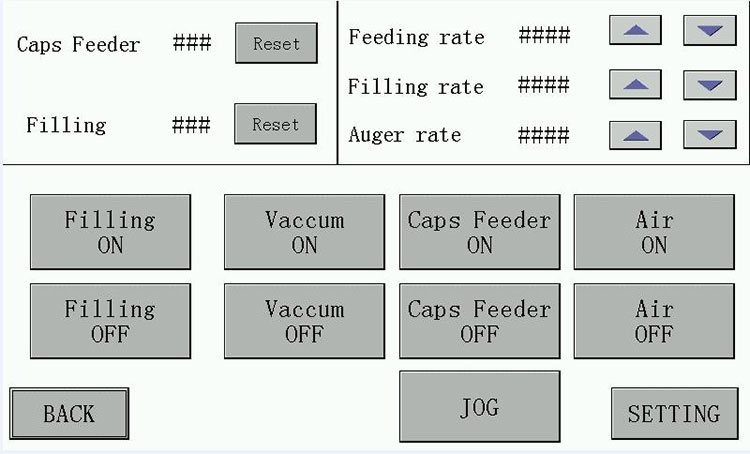

#2- Operation panel

A touch screen and PLC system is now introduced and widely used system across the globe. A PLC system combines all the required parameters added manually and stores the data to ease the operation and process control.

Operation Panel of Softgel Encapsulation Machine

So, you can manually add the required setting according to your need. For example, acceleration, vacuum, air pressure, feeding and filling rate.

A softgel encapsulation machine touch screen display

#3- Gel Box

A gel solution is stored in the gel box accompanied with continuous heating and detecting liquid levels. Thus, a gel box ensures the height and fluid levels of the gelatin solution. A thickness of gelatin ribbon is also adjusted in a gel box.

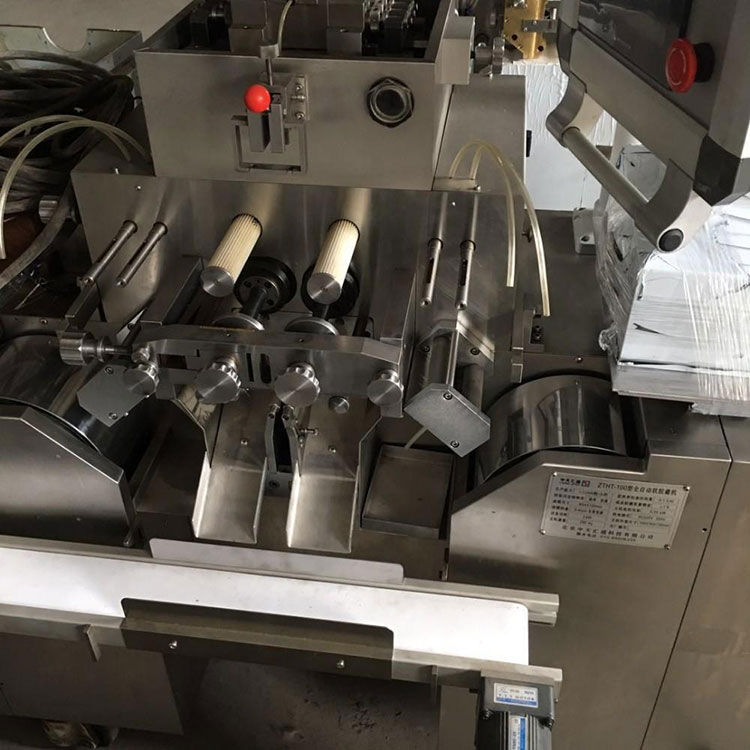

#4- Softgel Die Roll

A softgel die roll is an essential and precise component of softgel encapsulation machine that determines the shape, size, cutting as well as sealing of softgel encapsulation. This is a vital component that influences with an appearance and quality of a finished product.

Die rolls of softgel encapsulation machine

#5- Electric Cabinet

An electric cabinet is constructed with a stainless-steel assembling with all-electric components such as a breaker, terminals, fuses etc.

To operate and maintain the electric cabinet an expert electrician is allowed.

An electric cabinet of softgel encapsulation machine

#6 -Cooling Drum

A cooling drum or gelatin ribbon drum is utilized to spread a gelatin solution which is located inside the gelatin box. In this box, a gelatin liquid is quickly cool down to form a film of gelatin. The cooling system operates the encapsulation machine for cooling the drum and softgel die roll.

#7- Conveyor

A conveyor sends softgel capsules toward the discharge part, here it links to a tumbler dryer and moves back and forth as directed by a PLC system.

#8- A Fan Blower- Tumbler Dryer

From a conveyor, the soft gel capsules rolling down into a tumbler dryer for cooling. The presence of fan blower allows the blowing capsules into a cooling basket.

12) What are other integrating parts of the Softgel encapsulation machine?

#1- Machine Frame

The machine frame is a supportive component that holds various functional units installed outside of the softgel encapsulation machine.

#2- A Plunger Filling System

A plunger filling system plays a vital role in the pumping of an accurate quantitative amount of therapeutic drug or any active ingredient into each soft gel capsule.

#3- A Heating system

There are several components of softgel encapsulation machine that essentially required a constant heat during the encapsulation process.

For example

- Medicine hopper

- Gel box

- Wedge

Many industries utilize hot water bath or electric heaters for manufacturing of products. But pharmaceutical preparations most often opt for slow and steady heat that could be achieve by use of water bath which is a better option for mature and stable manufacturing.

#4- Lubrication system

A lubrication system is also integrated with softgel encapsulation machines that provide adequate and adjustable lubrication to the machine when required.

#5- Softgel polisher

A softgel polisher is required at the final stage of the softgel encapsulation process.

It ensures the polishing of dry softgel capsules facilitating a shiny, glossy outer surface.

A softgel polishes ensure that a manufactured capsule is cleaned, without any oil residue before consumer packaging.

#6- Softgel Pulverizer

This equipment is very effective in reducing the cost of production. Because it helps in the recovery of damaged softgel capsules that happened during the manufacturing process. It may also include those capsules which are misshaped or unsuccessful for the end stage production. It grinds the softgel capsules and separates the shell and filling material.

#7- Softgel Sorting Machine

Softgel sorting machine performs an integral part in the sorting capsules based on sizes and shapes. This machine plays a key role in the quality assessment process of capsules.

#8- Softgel Inspection Machine

A softgel inspection machine is significantly equipped with mirrors, rollers, and a vibratory system. This machine allows the examination of capsules from all angles and ensures the manufacturing process complies with a high-quality standard.

#9- Medicine Mixing Tank

It blends medicine/active ingredients to get a standardized solution prepared for an encapsulation process.

#10- Air Compressor

An air compressor is integrated with a main body and a gelatin melting machine that facilitates an accelerated production and uniformity of gelatin mixture.

#11- Gelatin Melting Tank

A gelatin melting tank is used for melting the gelatin mass and keep them at a desirable temperature before feeding into an encapsulation machine. You can also incorporate a different type of ingredients, blend and melt them as required. For better results, a homogenous solution should be prepared from gelatin and other incorporated ingredients.

#12- Water Chiller

A water chiller is a well-acknowledge device used to cool the temperature of a system. Most often, they utilize a refrigerant within a closed system to enables a heat exchange and pump out the excessive heat into the atmosphere.

Water chiller connected to a cooling drum which facilitates circulation of chilled water that to lowers the temperature and allows the cooling of gelati when pressed.

Hence, the above-mentioned integrated equipment is very important that you always require during softgel encapsulation process.

13) Do you know the disadvantages of a softgel encapsulation machine?

Along with numerous benefits, every piece of equipment also encompasses some disadvantages. Such as;

- The installation of a softgel encapsulation machine is an expensive process that necessitates a huge amount of cash as compared to other conventional machines.

- The initial cost of a softgel encapsulation machine is extremely high.

- Softgel encapsulation machine is a non-portable machine due to its massive size and weight.

- In the beginning, you will be required a team of a few experts to assist you with the production as well as maintenance process.

14) What is an average estimated price of a softgel encapsulation machine?

The price range of softgel encapsulation machine varies that depends upon the type of machine. For instance, a small-scale softgel encapsulation machine's price range is approximately 5000-15000$ whereas, medium speed production line machine that provides 8 hours working shift costs around 110,000 to 150,000$.

15) What are the best consideration points before buying a softgel encapsulation machine?

It is important to determine the best consideration points when selecting a softgel encapsulation machine.

- It is necessary to choose a fully automatic softgel encapsulation machine, as it is easy to operate and facilitates an excellent workflow with no worries. Furthermore, a conventional softgel encapsulation machine requires high-ranking manpower but, in this case, you do not need additional manpower.

- Always go for such a machine that provides an extensive range of tooling systems to manufacture various shapes and sizes of softgel capsules.

- Choose a machine that can easily integrate other systems to improve working efficiency and save your time and effort.

- Always opt for such machines that can produce maximum output with moderate electric consumption.

- It is mandatory to evaluate the size of a machine according to the size of your working station where you are intended to place the machine.

- Always choose those machine that produces a less significant noise and give efficient results.

- The material of the machine should be durable and resistant to the process of oxidation and other environmental condition. Therefore, stainless steel is a better choice.

- Always choose a high-quality and renowned brand before buying the machine. Because a reputable manufacturer can provide you quality services with confidence.

- The speed of machine must comply with the speed of the production line.

16) How do you make different shapes and colors of soft gel capsules?

This is well-known that softgel capsules are available in various shapes, sizes, and colors across the globe. A softgel encapsulation machine can form such shapes and sizes with the help of rotary rolling dies. But every machine has specific mold size, this mean number of cavities is specific or limited.

Different shapes and colors of softgel capsule

Bigger capsules occupy larger space hence less cavity for softgel capsules and forms lesser number of softgel capsules. But the production time for smaller or larger capsules will be same. The most common sizes of softgel capsules range from 500mg to 1000mg.

For different colors of softgel capsules, you will be required various pigments to be added to the gelatin coloring machine.

17) Does the Softgel Encapsulation machine comply with recommended quality standards?

A Good Quality Softgel encapsulation machine must conform to the following goals of quality standards:

1) C.E Quality Standard

C.E standard is considered a mandatory key for every manufacturing unit. C.E quality standard of softgel encapsulation machine determines an accurate assessment certified by a manufacturer and complies with health and environmental protection guidelines offered by European union safety.

2) cGMP- Quality Standard

A cGMP quality standard is aimed at producers and suppliers whose works are governed by assigned standards of the federal government. Such as the manufacturing unit, packaging department and QC, QA, and so on.

3) Restriction of Hazardous Substances (RoHS)-3

Softgel encapsulation machine complies with the goals of RoHS that is helpful to reduce the harmful impact of electronics on the environment and health system.

4) Federal Communications Commission (FCC)

The FCC certification of softgel encapsulation machines ensure that equipment can oscillate beyond 9kHz and manufacturer must assure that their product is safe and do not cause risk and harm public.

18) Can you explain how a softgel encapsulation machine sustains the uniformity level of soft gelatin capsules?

Maintaining the uniformity level of capsule content is very important. Softgel encapsulation machine efficiently performs this job to sustain a uniform level of soft gelatin though out the process to bring a quality product.

Certain features help soft gel encapsulation machines to achieve perfect content uniformity.

1) Filling with a small number of active substances accurately is a challenging job. However, a softgel encapsulation machine can accurately dispense the dose with the help of calibrated mini pump that ensures an accurate filling.

2) To sustain a content uniformity level, it is mandatory to assess the entire condition of the softgel encapsulation machine for any damaged plunger, or sealing system, valve, etc.

3) For a smooth running of the encapsulator, this machine features servo motors that help to provide a controlled electrical pulse of various widths by the control wire.

4) The machine setting is adjusted accurately that ensure accurate and correct manufacturing of gelatin ribbon and the network.

5) Softgel encapsulation machine associated with an accurate die roll and a wedge system.

In a nutshell, all these factors are linked with each other for running a high-quality system and making a softgel encapsulation machine the most reliable tool for the encapsulation process.

19) Do you know the production room requirement for a softgel encapsulation machine?

For efficient performance, softgel encapsulation machines require specific working conditions that should be maintained to bring a considerable outcome.

Production Room Process Requirement

- For the softgel encapsulation machine, the room temperature should be around 18 to 22℃ with a relative humidity of 35-45%.

- All integrated rooms should be cleaned according to classification standards.

- There should be adequate space assigned to place a softgel encapsulation machine.

- The softgel encapsulation machine must monitor the microbial and adulteration factors.

- There should be an aligned softgel production room for appropriate encapsulation processes such as medicine room, drying room, tray, and inspection room ultimately a packing room.

Softgel encapsulation production room

20) How can you install a softgel encapsulation machine?

The process of installation is depending upon the type and size of softgel encapsulation machine. Smaller units do not require a prolonged installation time. Because you place them at an assigned location and continue the normal procedures.

Although in the case of larger manufacturing units, you require a larger space for machine installation process. They are most often run on an industrial scale to produce bulk capsule content.

- First, assemble all the required components of the softgel encapsulation machine in such a manner that you may find each component guided by the manufacturer.

- Keep all the required tools available for installation process and contact a technician from the manufacturer to assist the installation process.

- In many cases, the assigned position should be considered as a permanent location for the installation process.

- The installation area should be ventilated adequately to avoid harmful or toxic effects of certain substances, such as the preparation of drugs.

- By the help of user guidelines, every part of the machine should be connected properly and tighten. The joints, screws and nuts should be fixed correctly.

- Always initiate the installation from machine frame that to create the strongest foundation. As a machine is prone to shake during operation therefore, a strong foundation enables the firm production devoid of shaking the entire structure.

- After installation, check the machine functions to assess the operational capabilities. If it does not work, check the system, and find out the potential issue and consult the manufacturer.

- The installation will be ended when the machine starts working properly.

21) What is the major classification of softgel encapsulation machines?

We can classify softgel encapsulation machines into three categories.

1- Small-Scale Softgel Encapsulation Machine

Machines under this category are small which is mainly used in laboratories and research institutions for the small unit production of softgel capsules. This machine occupies lesser space and easy to handle. This machine is fully automatic provide robust outcome. You can also set all the require parameters in PLC control system. This machine is integrated with tumbler dryer to get excellent drying and attain ultimate production.

Small-Scale Softgel Encapsulation Machine

2- Medium-scale Softgel Encapsulation Machines

The medium scale softgel encapsulation machines have the capacity to produce a medium size unit production of capsules. This is a perfect device to mainly used for research institution for product development and trial. It may also be used in the pharmaceutical and health sectors, food industries.

Medium-scale Softgel Encapsulation Machines

This machine is also integrated with supportive components of softgel encapsulation machines such as cooling drums, dryer, etc.

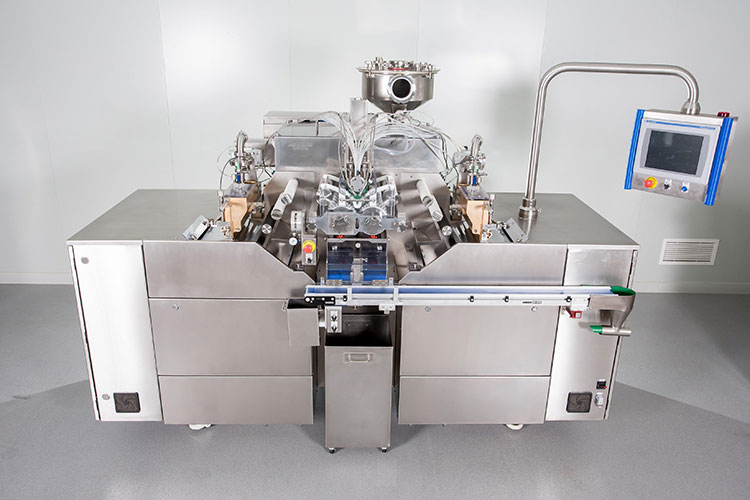

3- Large-Scale Softgel Encapsulation Machine

A large-scale softgel encapsulation machine is a suitable machine to run a large-scale production such as pharmaceutical, nutraceutical, food industries.

Large-Scale Softgel Encapsulation Machine

This machine extensively incorporates all essential components required for the high-quality large-scale production of softgel capsules. For instance, the spread boxes, rotary die rolls, capsule discharge chute, and a broader conveying system.

22) What is an average estimated price of a softgel encapsulation machine?

The price range of softgel encapsulation machine varies that depends upon the type of machine. For instance, a small-scale softgel encapsulation machine's price range is approximately 5000-15000$ whereas, medium speed production line machine that provides 8 hours working shift costs around 110,000 to 150,000$.

23) What are the best consideration points before buying a softgel encapsulation machine?

It is important to determine the best consideration points when selecting a softgel encapsulation machine.

- It is necessary to choose a fully automatic softgel encapsulation machine, as it is easy to operate and facilitates an excellent workflow with no worries. Furthermore, a conventional softgel encapsulation machine requires high-ranking manpower but, in this case, you do not need additional manpower.

- Always go for such a machine that provides an extensive range of tooling systems to manufacture various shapes and sizes of softgel capsules.

- Choose a machine that can easily integrate other systems to improve working efficiency and save your time and effort.

- Always opt for such machines that can produce maximum output with moderate electric consumption.

- It is mandatory to evaluate the size of a machine according to the size of your working station where you are intended to place the machine.

- Always choose those machine that produces a less significant noise and give efficient results.

- The material of the machine should be durable and resistant to the process of oxidation and other environmental condition. Therefore, stainless steel is a better choice.

- Always choose a high-quality and renowned brand before buying the machine. Because a reputable manufacturer can provide you quality services with confidence.

- The speed of machine must comply with the speed of the production line.

24) Do you know the disadvantages of a softgel encapsulation machine?

Along with numerous benefits, every piece of equipment also encompasses some disadvantages. Such as;

- The installation of a softgel encapsulation machine is an expensive process that necessitates a huge amount of cash as compared to other conventional machines.

- The initial cost of a softgel encapsulation machine is extremely high.

- Softgel encapsulation machine is a non-portable machine due to its massive size and weight.

- In the beginning, you will be required a team of a few experts to assist you with the production as well as maintenance process.

25) What is the required verification documentation for the softgel encapsulation machine?

After purchasing a softgel encapsulation machine you will be always required the following list of documentation that verifies the right working condition of the purchased equipment.

The manufacturers are responsible to provide the following verified documentation.

#1 FAT Documentation

After purchasing the softgel encapsulation machine, you will be received with a FAT certificate along with equipment testing conduct by manufacturer that approves that machine is in under suitable condition. Remember that you will assess the test with manufacturer before and after purchasing the machine.

#2 IQ Documentation

Every pharmaceutical or production sector always require keeping IQ documentation that ensure working of machine is perfect after installation.

Manufacturers provide this certificate soon after installing and testing the machine.

#3 OQ Documentation

Operation Qualification is a certificate that ensure a proper functioning of machine accordance to production specifications.

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine