Medicine Cartoning Machine: The Complete Buying Guide In 2025

It’s a common understanding that when a new product is made, extensive trials and studies are performed before making it commercialized. But, what you must not have wondered is whenever a new formulation or scale up of a pharmaceutical product is being done, another procedure is also underway to choose a suitable packaging and cartoning of the product which depends upon the type of product, client and market needs.

To make this cartoning procedure efficient and precise there are cartoning machines being used, not only in pharmaceutical industries but wherever cartoning is required. They are very advance machines, speeding and automating the process of carton forming, loading and sealing. All this while making sure of the regulatory compliance, quality and speed of the process.

In the pharmaceutical industry, the accuracy and hygiene are the most critical parameters and these cartoning machines ensure the integrity and traceability of the product. Let’s unfold this article to learn about the fine details and complexity of the medicine cartoning machine, where every seal and fold matters.

1.What is a medicine cartoning machine?

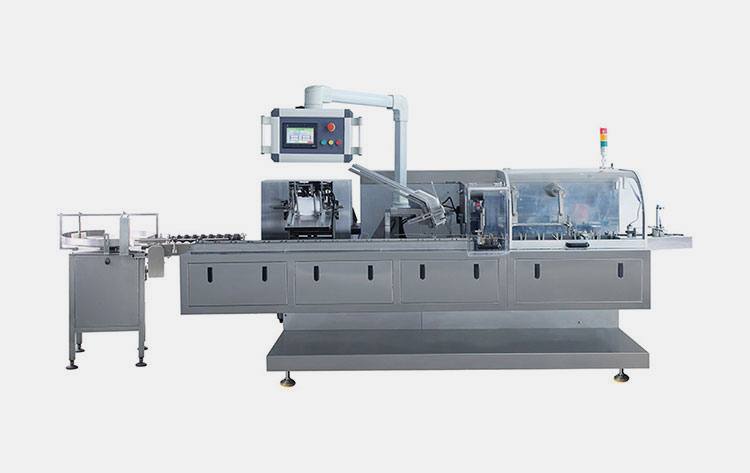

AIPAK medicine cartoning machine

A medicine cartoning machine also known as a pharmaceutical cartoner, it is specialized equipment used for packaging in the pharmaceutical industry for efficient and high speed packaging of the medicinal cartons. They are usually automatic but they can also be semi-automatic machines.

The medicinal cartons containing medicines in various forms like blister packs, glass bottles, plastic bottles, vials, ampoules, sachets and tubes are formed, filled, closed and sealed automatically through these medicine cartoning machines. They could be horizontal or vertical medicine cartoning machines.

The sealing, closing and sometimes even labeling of the carton is also carried out in the medicine cartoning machine.

2.What type of pharmaceutical products can be packed by a medicine cartoning machine?

Different types of medicine cartons –picture courtesy: pharmaceutical packaging

The medicine cartoning machine is very versatile in nature and can handle the cartoning of all the different forms of pharmaceutical products, including:

Solid dosage form:

This is the most commonly packed type of dosage form in the pharmaceutical environment.

| Solid dosage form | Example |

| Tablet blisters

The blister packs require precise placement to avoid any damage to tablet or blister. Machines are often directed for automatic insertion of blister with leaflet. |

Pack of tablet blister-picture courtesy: Freepik |

| Loose tablet or capsule bottles

The medicine cartoning machines ensure the counting of tablets during cartoning of tablet bottles. |

Loose tablets in a glass bottle |

| Powder sachets

The sachets are handled very gently during the packaging using pick and place feeder to avoid any kind of tearing or damage. A carton could be packed with a single sachet or multiple sachets. |

A carton packed with powder filled sachet-picture courtesy:halcon |

Parenteral products:

The parenteral product is usually not directly packed in cartons they require a primary packaging after that packed in cartons.

| Parenteral products | Example |

| Ampoules

They are very delicate so they are handled with cushioning method during cartoning to avoid breakage. They are usually packed in upright position; with cartons having inner sleeves or trays for protection. |

A well packed carton of ampoules |

| Vials

The vials cartons always have trays in them with unique spacing to avoid breakage. They usually have tempered evident sealing. |

Vials packed in carton-picture courtesy; loud.kr |

| Pre filled syringes

Their cartoning is done horizontally usually. They go through safety cap verification before cartoning. |

Pre filled syringes cartoning-picture courtesy: key stone folding |

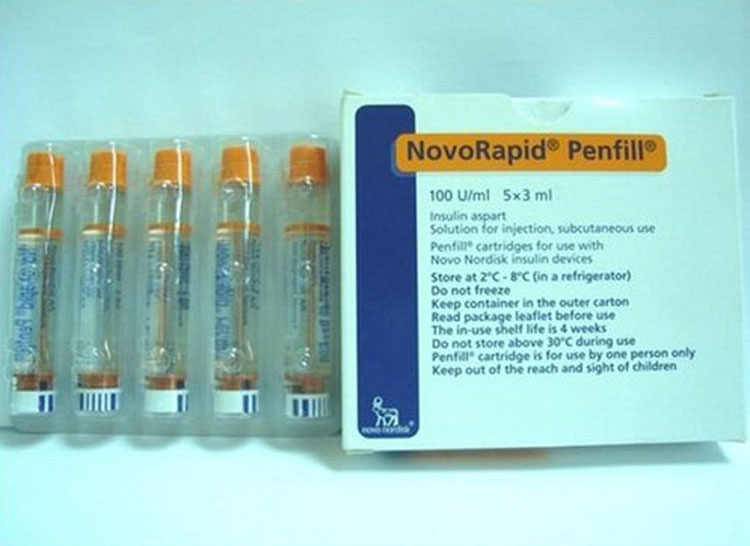

| Cartridges for insulin pens

They are stacked in blisters before cartoning. They could have custom inserts in the carton to keep the cartridges stable. |

Insulin pen refill-picture courtesy: novorapid |

Liquid and semi-solid forms:

The primary container of the liquid or semi-solid dosage form is further packed into cartons to provide protection and stability to the product.

| Liquid and semi-solid dosage form | Example |

| Syrups and suspension bottles

They usually have droppers, measuring spoons or cups to be packed along the bottle. They also have inserts or molds in the carton for stability. |

A liquid suspension bottle along with dropper to be packed into the carton |

| Ointments and creams tubes

They are loaded flat and upright with the use of tube feeders. |

Carton packaging for tubes form-picture courtesy:shinerayad |

| Gel pouches

The gel pouches are flexible and slippery in nature which requires care during packaging. The carton usually has divider in it to maintain shape. |

Gels pouches in carton packaging |

| ENT drops or sprays

They are packed in upright position to avoid any leakage or damage of nozzle. Cartons usually have protective caps for protection. |

Cartons for mini mouth sprays –picture courtesy: card weibo |

Combinations kits:

Medicine cartoning machines are efficient enough to handle even more complex products and their packs, like:

| Combination kits | Example |

| Combination therapy kit including cream and tables

The cartons are packed with different forms of medicine, i.e. capsules, syrups and ointment all in one carton. The cartons are very organized. They have inserts or trays to make compartment for each product type and make the secure and stable. |

Carton for combination kit including capsule bottle, syrup and ointment tube |

| Medical device kit packs

They usually have medical devices, like inhalers, applicators, needles packs without the medicine itself. They are comparatively larger cartons with instruction leaflets in multiple languages. |

Carton packaging containing medical device-picture courtesy:burgopak |

| Drugs kits with syringes and vials

These kits are packed with syringes and pre measured vials. They are proper compartmentalized cartons for the stability of products inside. They are packed with temper evident labeling and sealing to maintain integrity. |

Carton packaging containing needles and vials-picture courtesy:burgopak |

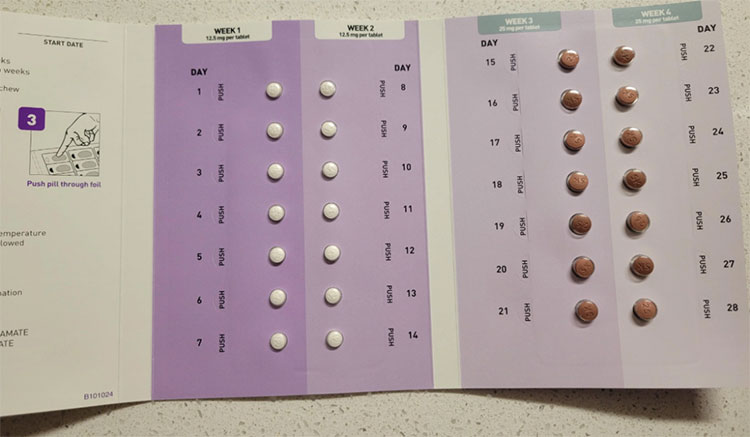

| Mixed dosage starter packs for titration therapy

These cartons contain different doses of a medicine in a single carton. They are packed as per their step wise administration. The correct sequencing and dosage tracking is essential for this cartoning. |

A titration medicine carton pack |

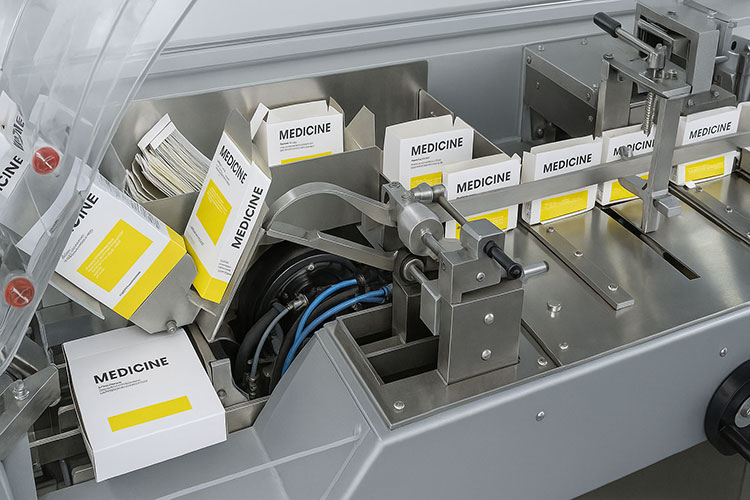

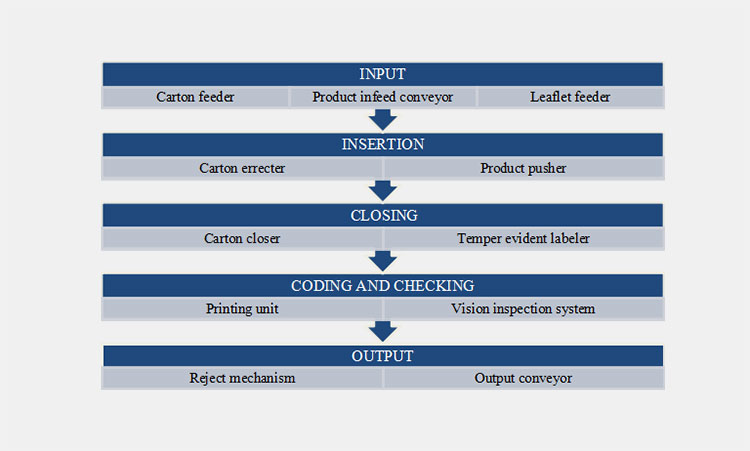

3.What is the working mechanism of medicine cartoning machine?

The chart below shows a very basic and common working mechanism of the medicine cartoning machine:

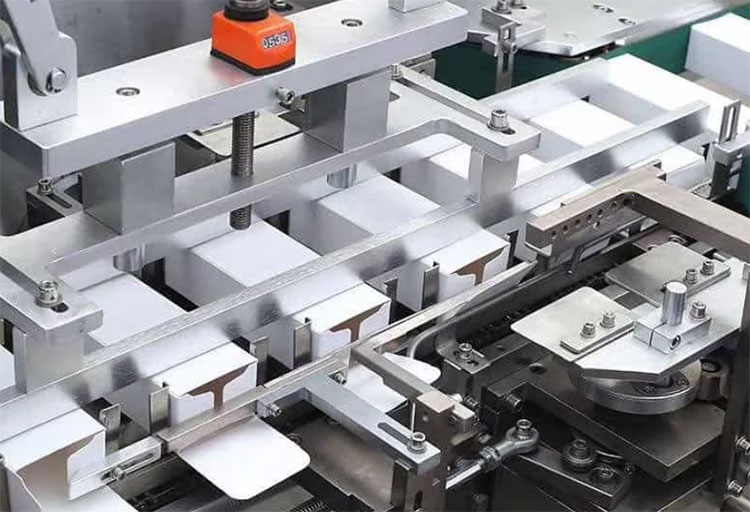

Carton feeding system:

Flat cartons being fed into the machine –Picture courtesy: paxon

This is where the whole process begins; flat precut cartons are stacked in a carton holder, often referred to as carton magazine.

The machine fed the pre folded carton from the tray into the machine automatically.

There are suction cups to detach a flat carton from the stack and feed it into the machine.

Carton opening system:

Cartons after fed into machine given proper shape

- This process is also termed as the erection process of cartons, as the flat cartons after being fed into machine are erected and given the required shape.

- The machine has mechanical arms for the opening of cartons, can also be done through air pressure or suction cups.

- This step ensures that the carton is in the right place and shape to avoid any kind of line collapsing or jamming.

Product and leaflet insertion:

Successful addition of product in properly shaped cartons-picture courtesy: sustainable packaging

- After the successful operation of carton opening, the cartons move through the belt to the next stage where the product is added in them.

- The product could be blister packs, bottles, tubes, syringes, vials, ampoules or any medical device.

- This is done through pushers or robotic arms, depending upon the type and advancement of the machine.

- There are special sensors which control the orientation of the product with high accuracy.

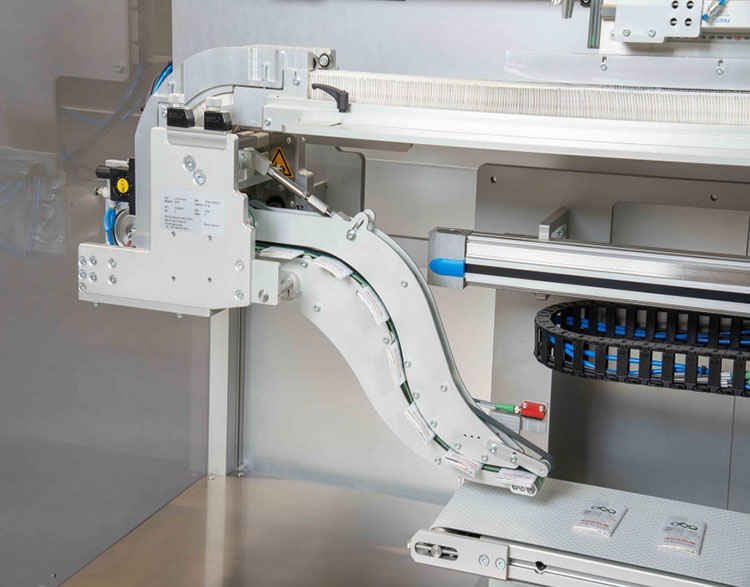

Leaflet insertion:

Leaflet adjustment along with the product-picture courtesy: contract pharma

This is an optional step, if the packaging requires the patient information leaflet (PIL) than it is folded and inserted along with the product in the carton.

The modern medicine cartoning machines have even the leaflet forming units to avoid any hustle of manual input.

Carton closing and sealing:

Closing of the medicine cartons –picture courtesy: infinity solutions

After the successful placement of the product and leaflet into the carton, the machine carries on the procedure to the closing and sealing of carton.

The closing and sealing are usually the same steps.

It can either be done through tucked in flaps of the carton or by hot melt glue, sometimes a temper evident sealing is also done of the high importance medicine cartons.

Tuck in flaps: the flaps of the carton are folded into one another, closing the carton completely, without any further need of taping or hot glue.

Hot melt glue method: In some cases after the tucked in flaps, the carton is completely closed by using hot glue for sealing of the carton.

Temper evident sealing: It is a type of one time seal, that once it is opened up it cannot get back to the original form again. It is done to avoid any kind of miss handling of the product.

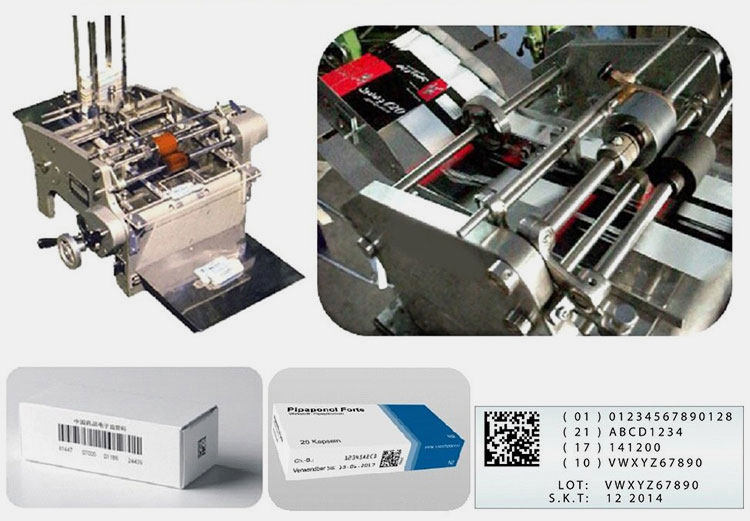

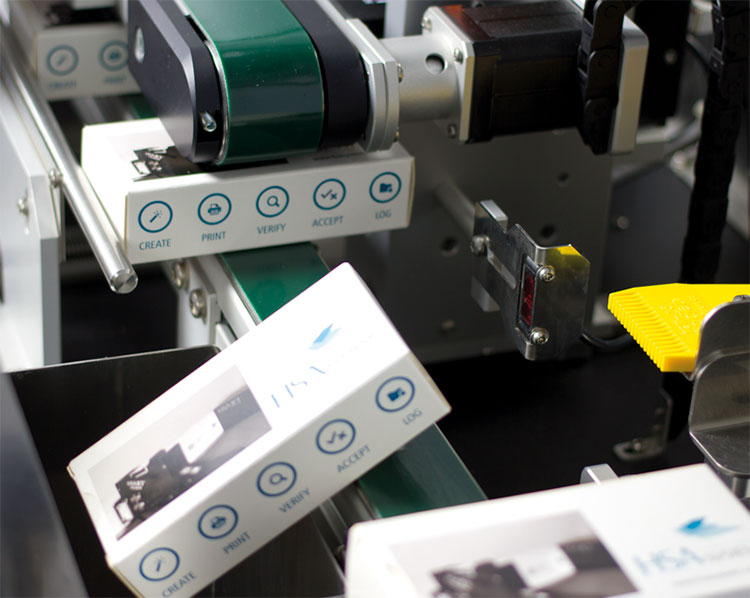

Coding and printing:

A packed carton coded through the printing unit

- The cartons after successful sealing and closure are moved toward the printing or labeling unit.

- Sometime the medicine cartoning machines are integrated with inject printers to add the batch number information, manufacturing or expiry date of the product and sterilization codes.

- They also add the bar code or the QR code to meet the regulatory requirement of the pharmaceuticals.

Quality inspection:

Control panel to provide all the required input to machine-Picture courtesy: jornen

- The medicine cartoning machines have integrated quality check system, which comprises of camera and sensors.

- The photoelectric sensors make sure the product and leaflet inside the carton.

- The codes and printed information of the medicine cartons is verified through the vision system.

- All this information is fed to the machine through a control panel at the beginning of the procedure, which is controlling and monitoring the required protocols of the medicine cartoning machine.

Final carton discharge:

Finally packed and labeled carton moving out through conveyor belt-picture courtesy: baumer

- The final good quality cartons are discharged from the machine through a conveyor or they are collected in trays.

- The cartons which are not correctly labeled, incompletely or faulty for any reason are rejected automatically to a separate rejected items bin.

- This procedure of cartoning in the medicine cartoning machine is entirely automated which decrease the chances of human error and maintain the integrity of the product.

4.What are the essential parts of medicine cartoning machine?

The medicine cartoning machine comprises of a group of essential parts, with each part playing an important role in the efficient packaging of the medicine carton, the process starts from the feeding of flat precut cartons in to the machine to the final product packed in labeled and sealed carton.

The following chart shows the group of essential parts of the medicine cartoning machine:

Let go through the working details of each part of the medicine cartoning machine in the following table:

| Components | Functions |

| Conveyor belt system

AIPAK conveyor belt of medicine cartoning machine |

It is driven by a chain drive mechanism to move the products throughout the cartoning machine.

It aligns the cartons as well to move them efficiently to the next stage. It can accommodate cartons of various size and shapes. |

| Suction cup assembly

Suction cup assembly-picture courtesy:zonesun |

The suction cups are essential part of the medicine cartoning machine.

It’s safe to say they act as hands of the machine. They are supplied with vacuum to pick the carton accurately and move it further for processing. This process of picking and positioning the carton triggers the machine sensors for monitoring. |

| Carton feeder

Carton storage unit-picture courtesy: Korber |

The carton feeder is drive by a synchronized motor system to ensure the continuous supply of cartons into the machine.

It usually have suction pumps that detach the flat precut carton from the carton stack and move it to the machine belt for further action. |

| Carton erecter

Opened up cartons-picture courtesy: dreamstime |

The flat carton when fed into the machine is opened up and given the proper shape.

The machine uses air jets or mechanical arms to open up the cartons. The bottom of the carton is tucked in already to make the carton ready and erected for the insertion of product. |

| Product loading unit

Loading of vials in cartons-picture courtesy: GMP packaging |

The product loading unit transfers the product into the carton precisely.

The product is added in the carton in a much synchronized manner through mechanical or robotic pusher. The timing is critical to avoid any kind of damage to the product or carton. |

| Leaflet inserting unit

Folded leaflets to be added in the cartons-picture courtesy: Kraus inc |

The leaflets are fed into the machine in same way as the cartons.

The machine adds the leaflets along with the product in the carton. The leaflet and product are brought together on the insertion track. |

| Carton sealing unit

Cartons closed through tuck in flaps-picture courtesy: grand pack machine |

The closing and sealing of the carton is carried out by the sealing unit of the machine, consisting of a small tongue folding mechanism and a large tongue sealing mechanism.

This unit has mechanical spindles to carry out the procedure. It is either tuck in flaps closure or by using hot glue. |

| PLC

The PLC control system-picture courtesy: standard Knapp |

Programmable logic controller is a user friendly control panel.

All the input output functions of the modern medicine cartoning machine are carried out through it. The right instructions to the PLC ensure the maximum efficiency and minimum waste. |

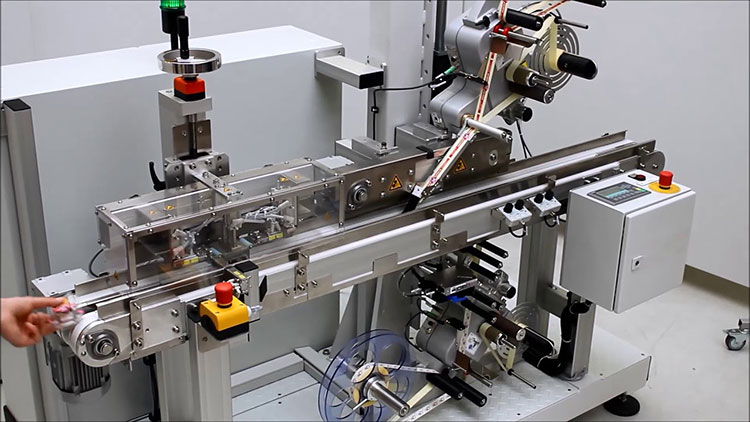

| Printing unit

Printed carton being ejected-picture courtesy:HSA |

There are integrated inject or thermal printer for the labeling of the cartons.

There are sensors at the printing unit, which after detecting the cartons activates the printing process. It also applies the temper evident or security labels at the opening side of the flap, which mainly include holograms, QR codes or VOID text layers. |

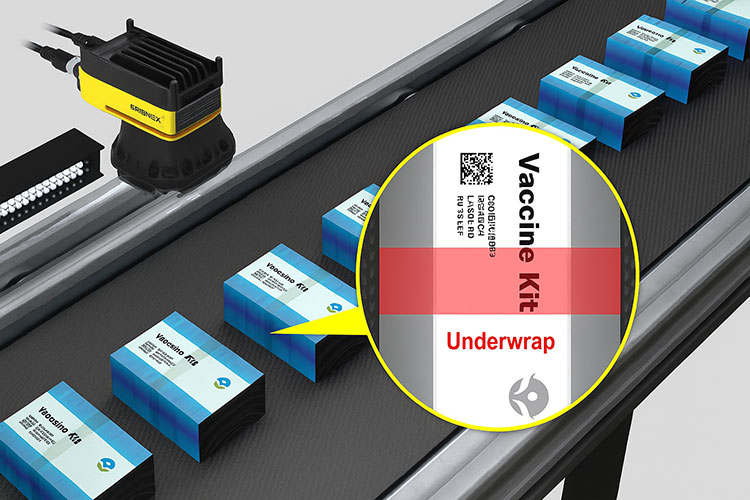

5.What is the vision inspection system in medicine cartoning machine?

Vision inspection cameras-picture courtesy: vision bot

Vision inspection system is a quality control system by the use of cameras. They are integrated into modern medicine cartoning machines to ensure the integrity and optimum packaging of the cartons. It ensures the pharmaceutical regulatory standards of the medicinal carton.

They have image processing soft wares and high speed cameras to monitor the carton as it moves on the conveyor belt throughout the cartoning machine. They hold a great importance in medicine cartoning machines to meet the requirements of international regulatory compliance.

- They make sure the right orientation and presence of the carton on the belt.

- They use 2D/3D imaging to verify the correct amount of blisters, bottles or any type of specified product in the cartons.

- The clarity and accuracy of the batch number, expiry dates, manufacturing and other information is ensuring through this vision system.

- They can scan bar codes and QR codes to offer track and trace compliance of the product.

- They verify the label is placed in the right direction and also check for any kind of duplication.

In a nutshell, the carton integrity and quality is maintained through the continuous inspection of the vision inspection system.

6.How does medicine cartoning machines can handle inline rejection of faulty cartons?

Under wrapped medicine carton detected through vision system-picture courtesy: cognex

Inline rejection of the faulty cartons is a very crucial step of the medicine cartoning machine as it is essential to ensure the quality and compliance of the final product in pharmaceutical packaging.

The modern medicine cartoning machines are equipped with sensors, quality check modules and vision system which detect any fault in the carton at any stage of the process. The fault could be a missing leaflet, a damaged carton, wrong alignment of the carton, empty carton or a missing bar code or labeling of the carton.

The sensors detect the fault and signal a series of process, to make sure the faulty carton is rejected, the process is:

- The vision system through cameras and sensors make sure that the pre-determined parameters are being followed.

- If a fault is detected during automatic inspection, the machine immediately sends a signal to the rejection unit.

- The automatic machines have pneumatic arms system or air jet drives to divert the faulty carton to the rejection bin.

- All this procedure is logged into the control system of the medicine cartoning machine to for future tracking and auditing.

Benefits of inline rejection system:

- It enables the achievement of 100% quality assurance of the cartons.

- The GMP standards are maintained.

- The burden and cost of manual inspection is reduced to a great extent.

- The non-compliant and incorrect products are prevented from reaching the market.

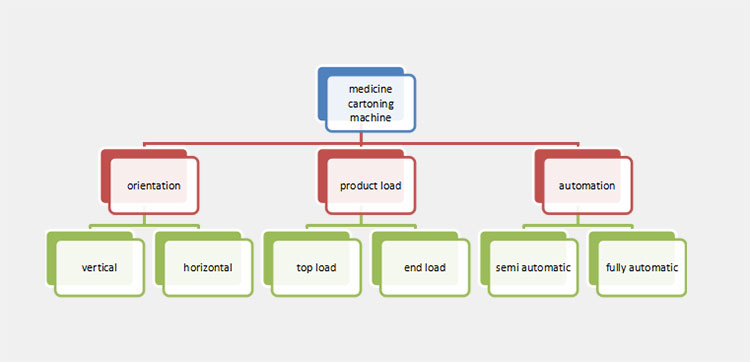

7.What are the types of medicine cartoning machines which are most reliable in pharmaceutical industry?

In the pharmaceutical environment, the medicine cartoning machine can be differentiated on the basis of the type of the product or level or automation and also their own orientation as per the requirement of the user.

Given below is the classification of the types of medicine cartoning machine:

Vertical cartoning machines:

A vertical cartoning machine-picture courtesy: nuspark

- The cartons feeding direction is from the top in vertical machines.

- They are usually used when manual loading of product is being carried out.

- They are best suited for bottles or vials when the product is intended to be fed under the act of gravity.

Horizontal cartoning machines:

AIPAK horizontal medicine cartoning machine

- The cartons are erected and fed sideways into the machine.

- They are the high speed highly automatic cartoning machines.

- They are best suited for the high speed automatic production limes.

- They are best choice for blisters, tubes and sachet cartoning.

Top load cartoning machines:

Product insertion from the top of carton-picture courtesy: Schubert pharma

- The product is added from the top of the carton.

- They are best suited for heavy or stacked products.

- They are more suitable for irregular shaped or fragile items.

End load cartoning machines:

Side way insertion of product into the carton-picture courtesy: sirosilo

- The product is added into the carton from sideways.

- They are best suited in horizontal high speed production lines.

- They are best paired with the automatic leaflet insertion and the addition of temper evident sealing.

Semi-automatic cartoning machines:

Semi-automatic vertical cartoning machine-picture courtesy: parth.PNG

- It offers a combination of automatic and manual operations.

- It has a manual feeding system of the product into the carton.

- The sealing and closing of the carton is automatic.

- They are suitable for a medium capacity budget friendly production.

- They require manual inspection of the product.

Fully automatic cartoning machines:

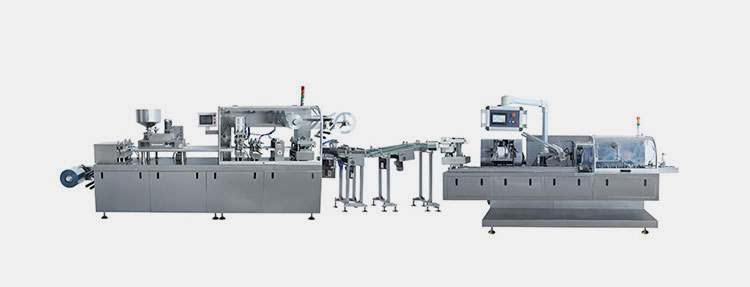

AIPAK fully automatic medicine cartoning production line

- They are most advanced and modern cartoning machines.

- They are best suited for large scale production.

- They are completely automatic from the carton feeding into the machine to the last ejection of the completely filled, closed, labeled and sealed carton.

- It has integrated vision, sensors and printer to make the whole process completely automatic while maintaining the integrity and compliance of the carton.

8.What are the different types of sealing and closing mechanism for medicine cartons?

Finally packed cartons stack-picture courtesy: felins

The pharmaceutical packaging requires a very critical and efficient cartoning mechanism to ensure the safety of the product while maintaining the tempering resistance and regulatory compliance. The choice depends upon the type of the product and market requirements.

A few common examples are given below:

Tuck in flap closure:

Tuck in flap cartons for blisters and bottles-picture courtesy: carepac

- It is the most common, cost effective and simple form of carton closing.

- This closure requires flap of the cartons to be tucked in without any need of glue.

They are of two types further:

Straight tuck in:

The flaps on both the side of cartons are tucked in the same direction.

Reverse tuck in:

The flaps on both the side of cartons are tucked in opposite directions.

They are best used for blisters pack and sachets.

Glue sealing:

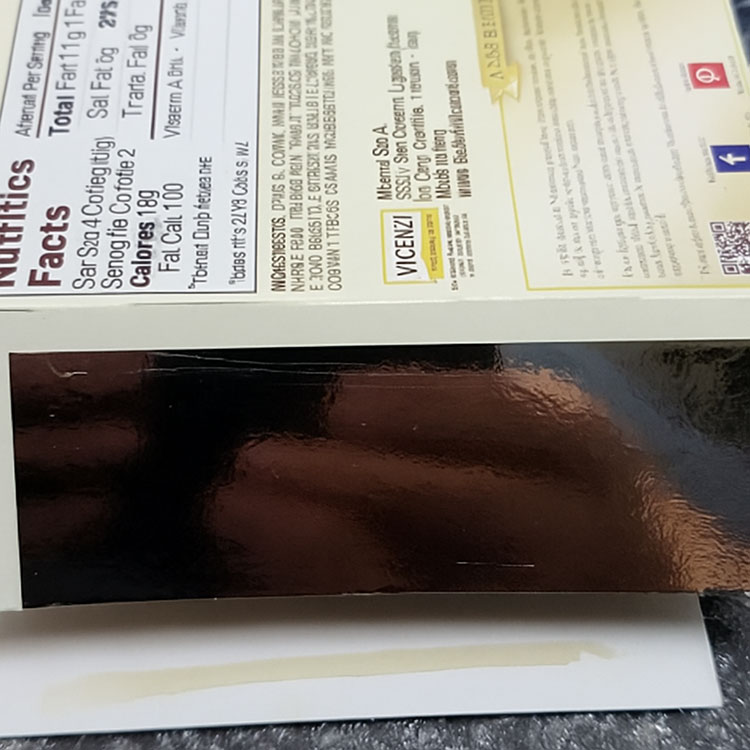

Sealed end carton with glue -picture courtesy: vicenzi packaging

- The carton flaps are completely sealed by using adhesives.

- The medicine cartoning machines have precise glue applicators to apply hot glue for sealing.

- The heavier items or combination kit cartons are sealed using glue sealing method.

- The glue sealed cartons are comparatively strong, temper resistant and best suited with high speed cartoning machines.

Locking tabs:

Locking tab carton

- The cartons have specifically die cut tabs that lock into the slits of the carton for sealing.

- The tabs and slits are aligned to each other for proper locking of the carton.

- These cartons also don’t require any use of glue.

- These cartons are secure and reclosable without the use of glue making them eco-friendly.

- They are mostly used for medical kits, vials or ampoules.

Temper evident seals:

One time opening tear strip lock carton -picture courtesy: element cosmetics

- The cartons are sealed in such a way that once the seal is opened up, it can’t go back to original form.

- The sealed stickers or labels are placed on the top of the carton, to show if they have been tempered.

- The other way is carton has built in tear strip, which has to be torn off to open up the carton, making it temper evident.

- They are used for high safety medicines as well as OTC medicines to maintain the integrity of the product.

9.What is the role of medicine cartoning machine in sustainable packaging?

Sustainability is not just a trend but a responsibility in today’s world. The medicine cartoning machines play their part in supporting sustainable packaging by reduction in material waste, optimization of the carton size and above all the use of recyclable cartoning material. Some important points are explained below:

Supporting eco-friendly and recyclable material:

Recyclable packaging –picture courtesy: codefine

- The medicine cartoning machines are well compatible with the bio degradable and environmental friendly cartoning material which is usually recyclable as well.

- They work well with the environment friendly inks and coating which are eco-certified.

- They avoid using plastic tray as much as possible.

Reduction in packaging waste:

Medical plastic waste –Picture courtesy: CAS

- The medicine cartoning machines are efficient enough to fold and cut the cartons with so much precision which result in reduced or no scrap at all.

- They use just the right amount of material to avoid any over packaging, due to their precise nature.

- This machine enables the folding of leaflet and product grouping n such a schematic way that helps in reducing the size of the medicine carton.

Use of QR code:

Scanning QR code for the information-picture courtesy: QR code tiger

- The quick response (QR) codes can be added on the packaging cartons through the printing and labeling feature of the medicine cartoning machine.

- The QR code addition on the carton is also known as e-labeling, it reduce the need to add leaflets or other medication guidelines pamphlets in the carton, which adds a great deal to sustainable pharmaceutical packaging.

- QR codes are in fact, a requirement of the EU regulation of 2021/2226 for the pharmaceutical packaging.

Enable the right size packaging:

Glass vials adjusted in suitable carton-Picture courtesy: CCL healthcare

- The adjustment of the carton according to the various size and shapes of products is essential, so that no excess storage space or material is used.

- The compact carton which reduces the space during storage and transport can be made through the cartoning machines.

- All this help reduction of carbon foot print, through the efficient logistics methods.

Ensure lean production:

picture courtesy: IPM

- The ability of the machine to produce on demand cartons and integration of digital printing promotes the lean production by eliminating the requirement of large stock of preprinted cartons.

- This leads to cutting the use of energy and supply chain waste.

- The batch wise production in the cartoning machines minimizes the wastage.

In short, the medicine cartoning machines offer safer and smarter packaging of the medicine cartons, which leads to a lean and green supply chain for the company.

10.How does a medicine cartoning machine helps in telling the story about your company?

Carton packaging of different medicine bottles-picture courtesy: Stella pharmaceutical

We are well aware about the protection and stability carton packaging provide to the medicine. But the fact cannot be denied that cartoning of a product plays a subtle but very strong role in telling about the company and increase its market value to a great extent. The manufacturer should know about its consumer demands when looking for a product.

Here are a few things that show how the brand is perceived through packaging:

Brand identity and consistency:

Beautifully packed ampoules carton-picture courtesy: dermastir

The medicine cartoning machines are highly versatile and they make sure the uniform carton packaging of medicine which are professional and offers high quality throughout the whole batch. The modern medicine cartoning machines offer customization in printing and modern packaging styles, this innovation, sustainability and reliability in the cartons communicate your brand values.

Customer trust and credibility:

Temper proof seal

These automated machines provide perfectly sealed and temper proof packaging which makes the product attractive as well as it reinforces the idea of high maintenance and safety and quality control of the company. The accuracy in labeling and coding of the cartons tells a lot about the regulatory compliance which is integral part of pharmaceutical environment.

Product experience:

Nicely packed vials carton-picture courtesy: Kooding

The neatly packed cartons with unique packaging and proper leaflets and labels show the user friendly policies of the company, making them a preference for the customer. It’s a common understanding that customers are always looking for the best and innovative options, so such cartoning of the medicine reflect user centric thinking of the company.

Message of sustainability:

Sustainable carton of medical device-picture courtesy: shore group

These advance medicine cartoning machines offers minimum waste policy and use of eco-friendly materials align with the go green values and becomes a perfect choice for the environmental safety.

Hence, every single carton packed by your medicine cartoning machine becomes a silent brand ambassador highlighting the quality and integrity of the company.

11.What are the common challenges in operating medicine cartoning machine?

Well maintained labeling unit of cartoning machine-picture courtesy: weber packaging

The following are common challenges in the operation of medicine cartoning machine, especially in the pharmaceutical industry where precision and compliance are integral part of manufacturing unit:

Carton feeding issue:

The misaligned cartons from the carton feed can jam the conveyor belt. The misalignment of the cartons can result in reduced carton quality and improper loading, which can result in interruption of the packaging cycle.

Product insertion error:

The inconsistency of time between the carton feed and product conveyor leads to rejected cartons as well as product damage. This is one of the main reasons we come across the cartons where product is not properly inserted in the carton.

Printing and coding error:

The malfunctioning and poor maintenance of the inject printers causes missing or unclear batch numbers, expiry or bar codes. This causes a major impact of non-compliance with the regulatory standards.

Changeover downtime:

The manual adjustments and lacking of modular component can reduce the overall equipment efficiency, which is a major cause of long down time when switching in between the different product types and product sizes.

Cleanliness and cross contamination:

The improper and inadequate cleaning process during the changeovers produces a big threat of contamination to the medicines, especially where sterilization is essential. This is a severe regulatory and quality control issue.

Conclusion:

If you have come this far of this questionnaire, you must have understood that behind every well packed medicine carton, there is a back story of care precision and technology. These machines make the patient experience better while streamlining the industrial process. We live in a world where first impression holds a great power; packaging is the main component which can leave a mark on the consumer. The decision of right medicine cartoning machine is not only a technical but a strategic decision that highlights your brands worth and values impacting the future building of the company. For more details, head over to our website for our AIPAK team.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine