VFFS Machine: The Complete FAQ Guide in 2024

VFFS machines for packaging are always fascinating! If you’re looking about purchasing one for your business, then there are various things to consider before making a final decision.

If you just go online and select a random piece of equipment, so you might end up with the wrong product. You must educate yourself about VFFS machines. This article will introduce you to various aspects of VFFS machines currently available worldwide perfect for your business.

1.VFFS Machine: What is it?

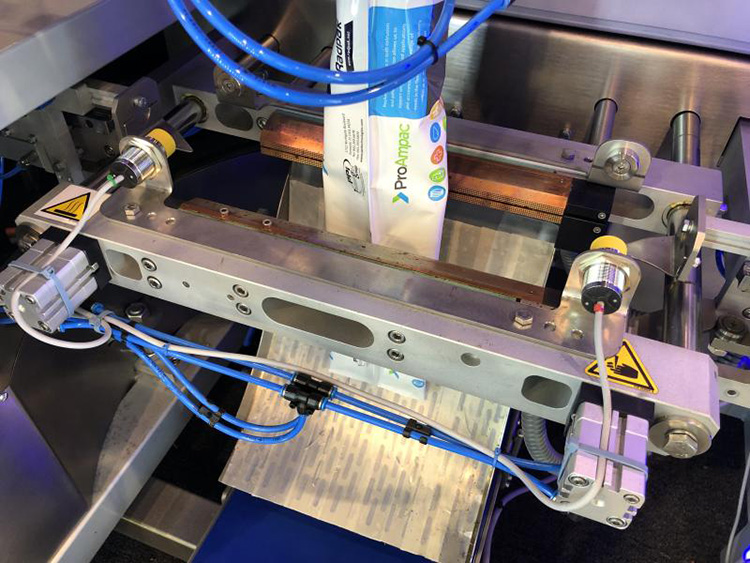

It is the type of bagging machine which fill, package and seal the products in the bag or the pouch. This instrument forms bag from the roll.

VFFS machine also called vertical form fill sealing machine is a kind of packaging equipment was first introduced in 1936. These automations can be configured in number of ways. There are many makes and models of such machines available in market.

VFFS machines are employed for packaging solid and liquid variety of products.

2.VFFS Machine: What is it best for?

These machines are best for filling and sealing loose and granular materials. The substances as liquids or mushy products are filled using gravitational force. These items are also known as free-flowing products.

VFFS machines employ volumetric filling for packaging sugars, salts, pastes, creams, sauces, etc.

These instruments cannot process fragile and delicate items because they can break while moving for top to bottom.

3.What are the Industrial Applications of VFFS Machines?

These equipment are need of packaging industries. With innovation in VFFS machines, they are able to fulfil instant packaging demands for industries. Some useful applications of these machines are detailed below:

| Pharmaceutical Industry

VFFS machines are increasingly used in pharmaceutical and nutraceutical industry for packaging of powders. The loose granular probiotics, supplements and fibres are hermetically sealed in pouches using these equipment. |

|

| Food Industry

Food packaging lines are incomplete without VFFS machines. They are used for filling and packing of every kind of foodstuff for instance, sugars, spices, salts, chips, ketchups, grains, tea, snacks, etc. |

|

| Agriculture Industry

Granular products such as feedstuff and fertilizers are packaged in pillow pouches using VFFS machines in agriculture industry. These equipment boost the shelf life of horticulture and gardening feeds. |

|

| Cosmetic Industry

Various kinds of oil, pastes, lotions, hair masks, body syrups, and creams are packaged into elegant and striking packages by VFFS machines in the cosmetic industry. |

|

| Personal Care Industry

In the personal care industry, VFFS machines are routinely employed for packing shampoos, hand sanitizers, liquid soaps, etc. |

|

4.What Size and Shape of The Bag Can Be Produced?

Shapes of Bags

VFFS machines are generally utilized for forming square or rectangular shaped bags or pouches. Sometimes, they produce triangular shaped bags.

Size of Bags

The size of bag is usually around 2.5” x 3” to 8” x 14”.

The width options for VFFS machine packaged bags are around 65mm to 140 mm while the length of bags is up to 150 mm.

Bags Style

Some bag styles produced by VFFS machines are:

Stand-up Pouch

These are also called doypack pouch. This is flexible packaging kind that is displayed at upright position in retail shelves. Stand-up Pouch is used for packaging variety of consumer goods such as grains, teas, milk powders, spices, etc.

Flat Bags

These bags are without folding or gussets. These flat bags are most economical packaging as they are simple to produce. They are sealed at bottom or at sides.

Wide-top Bags

These bags are most evolved packaging style. These pouches are opened easily for taking out contents. These packages have self-standing feature which give them elegant appearance.

Pillow Pouch

They are pillow shaped having bottom, top, and back sealing. They are called back or T seal bags. Pillow pouches have full wraps with attractive graphics.

Zipper Bags

This packaging form has a slider or mechanical sealing mechanism usually formed by pinching together two edges. These bags are easily resealed by pressing together hence are called press-to-close bags.

Three-Sided Seal Bags

They are commonly employed for packaging single use of granular products powders. In these bags, front and back panels are sealed from 3 sides while have folding at one side.

Block Bottom Bags

Packaging bags that have extra laminated or plastic film material below top seal but above bottom seal is called block bottom bags. These bags are squared at the bottom. These are bulkier and are used to pack more quantity of products.

Punch-Hole Bags

A hole is punched in the top seal of punch hole bags usually assists in hanging of bag. These are versatile type of pouch bags used for packaging coffee beans, tea, powders, etc.

5.How Portions Are Controlled Using VFFS?

The answer is quite simple by using weight control options on HMI touch screen installed in VFFS machine. Usually, a desired weight is programmed on machine interface which in turn controls the filling volume.

This helps to achieve constituency and uniformity in packaging batches and also decreases the chances of underfilling and overfilling of bags.

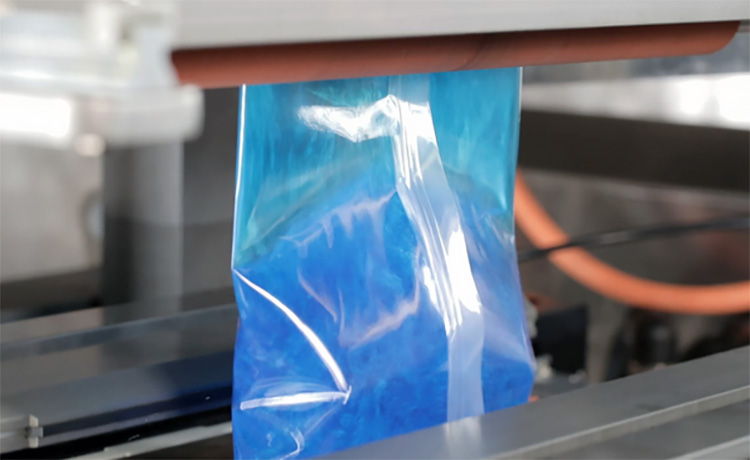

6.How VFFS Machines Seals the Bag?

VFFS machines seals the bags using pressure and heat resulting in crimp or hermetic sealing and is employed for protection of packaged products. Variation in sealing type is decided by their flatness and texture.

Sealing is useful since it reduces the length of bags and cuts down the usage of film materials. Reduction in length of bags also saves the space and makes transportation of pouches easier.

7.VFFS Machine: What Packaging Material Can Be Made Of?

Like other packaging machines, VFFS machines also uses plastics and paper materials for forming pouches and bag. Plastic materials generally include Polyethylene terephthalate (PET) or polyethylene (PE) film.

These two are the most robust and durable materials that offer best barrier against moisture, high temperature, oxygen, and light. They increase the expiry date of products.

Additionally laminate material is also used between plastic layers for protecting goods and preserving their aroma and flavor. This keeps product fresh and prevent its spoilage by chemicals present in environment.

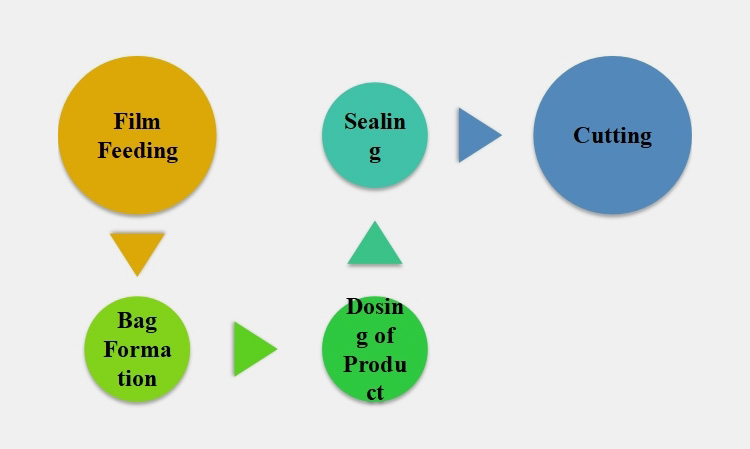

8.STEP-BY-STEP PROCEDURE: How VFFS Machines Works?

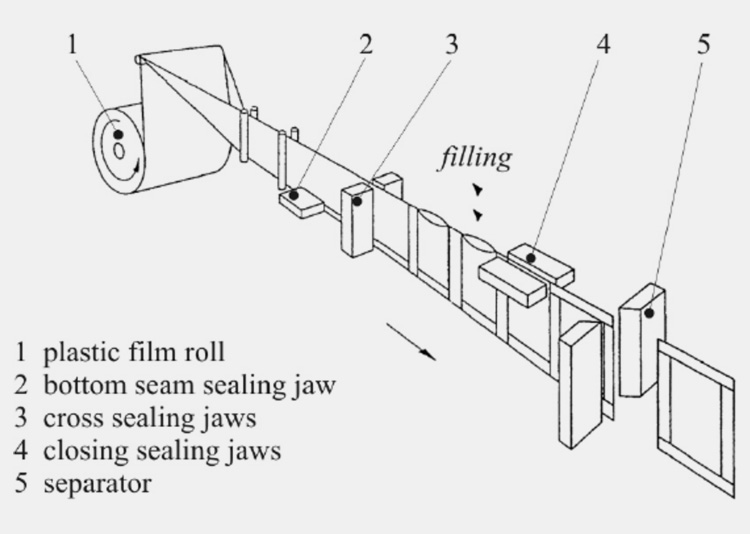

Learning about function and working of each component present in VFFS machine facilitates in its maintenance and repair. Some basic steps involved in working of VFFS machine are:

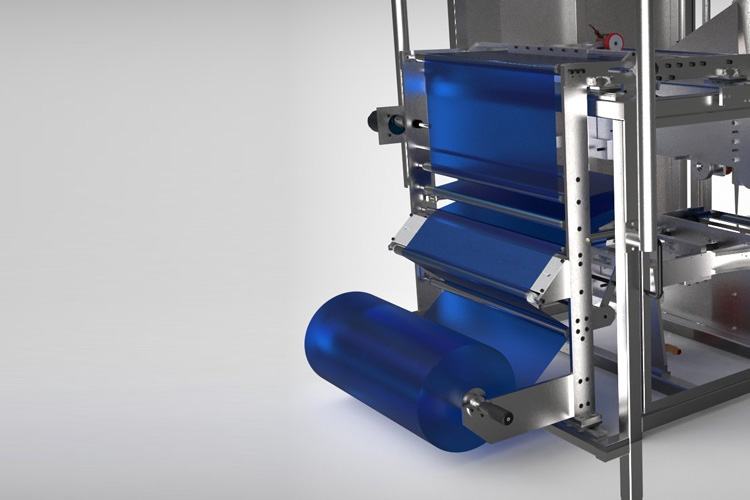

FILM FEEDING

First film is unwounded by film rollers and passed over unwind rollers. The dancer arms move to and fro for maintaining film under proper tension and for providing accuracy in unwinding.

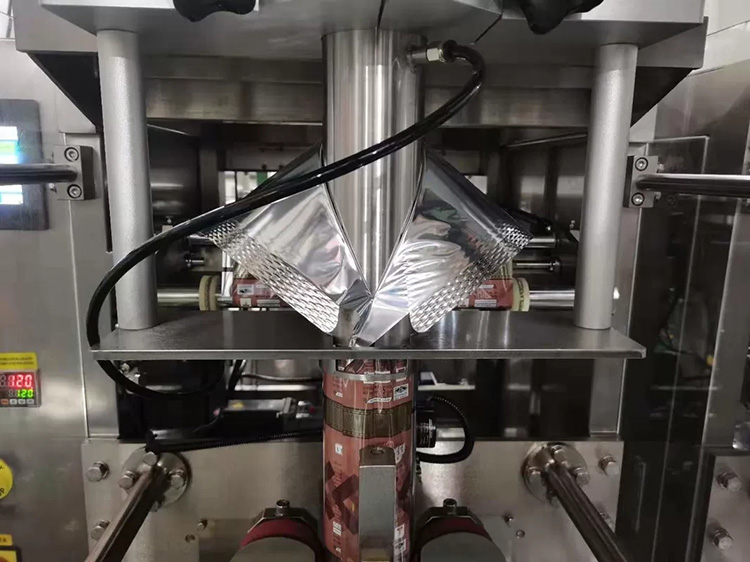

BAG FORMATION

Film is then passed to forming tube which resembles human collar. The film takes the shape of tube. The forming tube supports the film during this process and keeps the latter under necessary tension. Afterwards, the vertical sides (where two layers of film meet) and bottom portion is sealing via sealing jaws.

DOSING OF PRODUCT

The filling of product is carried out by equipping VFFS machine with augar fillers, volumetric dosing units, or by piston fillers.

When bag is formed the product is loaded inside the bag via feeders. Sometimes the gas such as nitrogen is flushed inside the bag for keeping products fresh throughout their retail life.

SEALING

After filling of products, the top side of filled bag and bottom portion of next bag is sealed using sealing jaws. These sealing jaws are heated using electric energy.

CUTTING

Cutting knife or blade located inside the sealing jaws is employed for cutting the edge of bag after sealing. This cutting knife separates the two subsequent bags from each other.

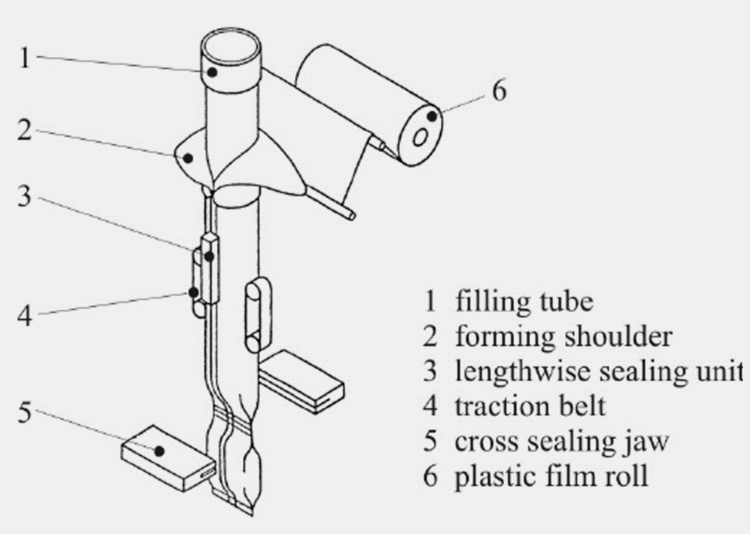

9.How VFFS Machines Are Designed?

VFFS machines have vertical configurations. Some major parts and their placing is detailed down.

Rollers and Forming Tube

The roll is usually located at the bottom of equipment. The film then passes series of rollers present uphill. The forming tube or collar is found at the top of the machines.

Servo Belts

Servo belts are essential in holding the film under tension. These drive belts pull the film across the series of rollers and then move down the formed bags from forming tubes.

Feeders

This automation is equipped with volumetric fillers, and auger filler and a multi-head weigher is installed at the top of the VFFS machine for accurate filling and dosing of numerous granular and liquid products.

The products are loaded in these fillers or weighers. These items then move with the means of gravity to the bottom where they are dropped into a formed bag.

Sealing Jaws

Sealing jaws are situated at the lower end of equipment and heat seal the bags. Cutting blades present in the centre of sealing bars cut the edges of two successive bags.

Finally formed pouches are discharged from the bottom side of VFFS machines.

10.VFFS Machine: What Are Its Types?

Presence of various models of VFFS machines in market creates confusion when you go for purchase new machine or upgrade your existing equipment. For your understanding, some basic types of VFFS machines are discussed below:

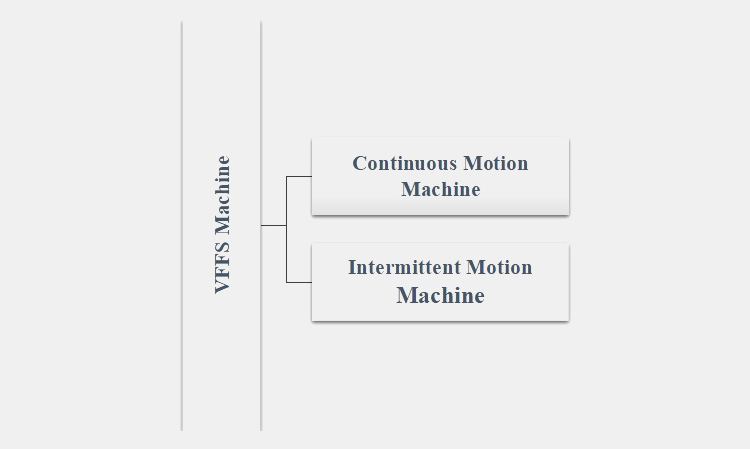

CLASSIFICATION ON THE BASIS OF WORKING MECHANISM

VFFS machines are broadly classified into two kinds on the basis of working principle.

Continuous Motion Machine

These machines run without stopping. An unwinding of film and sealing of pouches take place continuously in continuous motion machines. The motion of feed rollers, sealing jaws, and cutting blades are complete synchronization with each other.

In this equipment, the end sealing jaws go up and down while following the film to seal the pouches. This movement inhibits the product damage that might occur if product falls down.

The running speed of these equipment is very high and thus can produce numerous products within one minute about 180 packs per minute. These are best of packaging delicate and breakable items.

Intermittent Motion Machine

As the name indicates, the equipment operates periodically. During the stop cycle, top and bottom seals are made via cross-sealing jaws. These sealing jaws are fixed in place. The control over cross-sealing jaws aids the formation of multiple varieties of bags.

The speed of packaging is slow, and 60 to 80 bags are produced per minute. These machines are used for packing items that do not damage easily if fell down.

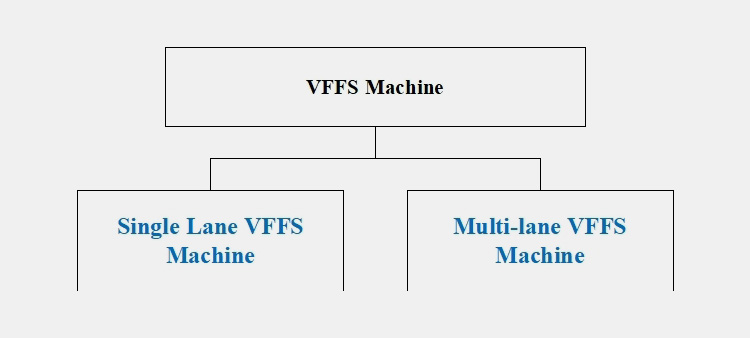

CLASSIFICATION ON THE BASIS OF DESIGN

There are two types of VFFS machines based on the design.

Single Lane VFFS Machine

It has one lane for forming pouches, filling, and sealing them. This machine has one forming tube to fashion bags at each cycle. Single Lane VFFS Machines can process a variety of products. It is the routinely employed configuration of VFFS machines in industries.

Multi-lane VFFS Machine

These machines have more than one forming tube and sealing jaws. Multi-lane VFFS machines can package multiple products at a given time. They have 4, 6, and 8 lanes for forming pouches. These are used for packing sugars and salts in small bags.

11.VFFS vs HFFS Machine: How Should You Choose?

Indeed, there is a huge difference between vertical form fill seal machine (VFFS) and horizontal form fills seal machine (HFFS) as it sounds! Some of them are:

Type of Machine

VFFS machine forms a bag for vertically packed products whereas HFFS produces fills, and packed horizontally.

Working

The working of VFFS involves a vertical plane for product sealing i.e product from upward is going down and ends up with final cutting. Whereas, HFFS involves sealing products sliding on a plane horizontal conveyor that ends up with side to side cut of the pouch.

Type of Packaging

VFFS is ideal and well-suited if you want packaging in a pillow or gusseted bag. In contrast, if you require packaging like a stand-up pouch bag or doypack then you should opt for HFFS bags.

VFFS VS HFFS Machine: The Packaging Films

A rollstock formation process is flexible and allows faster runs with less downtime. The HFFS machine procedure is a bit more complex than VFFS in terms of forming rollstock.

To choose what is best for you you must align with your current packaging requirement and business expectation and consumer demand. The final decision of the machine relies on the type of bagging you required. (Most often, the HFFS machine can pack the product in a vertical manner such as a flow wrapper).

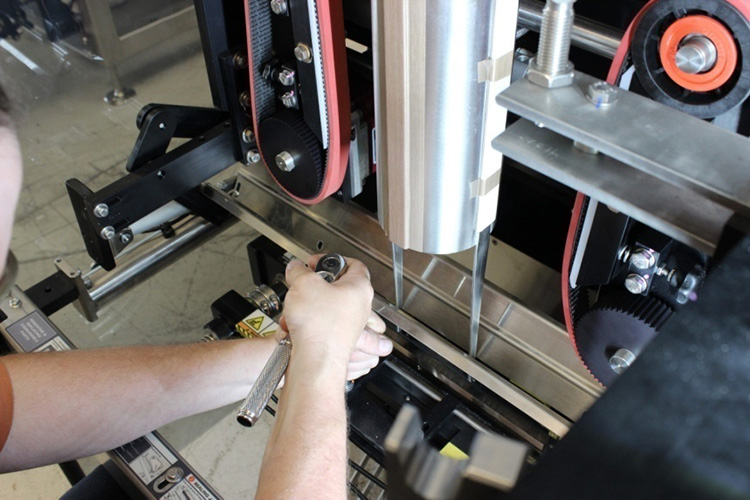

12.How to Install, Clean, and Maintain VFFS machines?

Some tips for installing, cleaning, and maintaining VFFS machines are discussed for your information.

INSTALLATION

- Disassemble the package and place the machine in the right spot according to your requirement.

- Tighten the screws and connect the machine to the ground to properly leveling the machine. Ensure that there is no leaning and bumpiness in the position of the instrument.

- Next, inspect bolts and cables for damage.

- Connect the cables to their respective linkages as recommended in the equipment manual. Attach the air pipe and vacuum system of the machine.

- Link the main switch to a power supply and then switch on the buttons for starting the VFFS machine.

CLEANING

- First use air nozzle with low setting to remove dust or debris accumulated on the exterior of machine.

- Remove the forming tube and then wipe the interior of the equipment.

- Inspect if sealing jaws are unclean. If they are then disassemble the cutting knife from the jaws and thoroughly clean both sides of the jaws with a clean cloth.

- Clean the stainless-steel guards, film rollers, air cylinders, and guiding bars using detergent water and then wipe the surface with a clean cloth

- Reassemble the forming tube and cutting blade.

MAINTENANCE

| Daily | Inspect the screws and bolts regularly and tighten them if they are loose.

Pour oil in oil injection roles in sealing camshafts for proper movement. Clean sealing jaws and cutting blades for getting rid of excess debris. |

| Weekly | Lubricate and clean all the moving parts.

Scrub the vacuum system and compress the air pipes. Check the alignment of rollers. Examine worn-out steel strips underneath jaws. |

| Monthly | Inspect and lubricate the film unwind drives.

Check the gauge and regulator of air pipes for maintaining proper pressure Lubricate the pumps once a month. Inspect safety circuit buttons for proper working. |

13.What are the Technical Problems and Troubleshooting of the VFFS machine?

Running VFFS machines is not without technical problems but here are some tips for troubleshooting this equipment.

| Technical Problems | Causes | Remedies |

| Loose horizontal sealing | A low temperature of heating element.

Little sealing time frame. Material gets struck between sealing jaws. Failure of heating or compress air system. |

Increase the temperature of a heating element.

Increase the sealing time. Replace the film with the new one. Inspect heating element or compress air system for damage. |

| Pouch do not cut | Erroneous cutting values.

A cutting blade is damaged. Malfunction in the compress air system. |

Reset cutting values.

Repair or replace a cutting knife Fix or replace the compressed air system |

| Incorrect cutting position | The alignment of photo sensor is not accurate.

The position of the color marker is wrong. The location of the cutting knife is incorrect. Sensing of registration sensors inaccurate. |

Adjust the positioning of the photo sensor.

Examine the color marker of the film. Calibrate the position of cutting knife. Correct the alignment of the registration sensor. |

| Improper film feed | Photo-sensor cannot locate color mark of film.

Spillage of drive belts. No film in a roll. The film is spliced. Splicing clamps are down. |

Adjust the location of the photo sensor.

Secure the drive belts. Place new film roll on roll. Fix the position of the splicing clamps. |

| Film does not unwind | The coefficient of friction of plastic film is very high.

Little or no film on roll. Alignment of dancer arms is inaccurate. Faulty wires or sensor. Film is broken or uneven. Improper setting of film unwinds brakes. |

Replace the film.

Check and correct the positioning of the dancer’s arms. Examine wires or cables for damage. Check and replace the film. Correct the setting of unwind brakes. |

| Inconsistency in bag length | Incorrect webbing of film.

Tension of film unwind belts is incorrect. Unclean or dusty film belts. |

Adjust positioning of the film and unwind rollers.

Fix the tension of the film belts. Wipe out the belts with a clean cloth. |

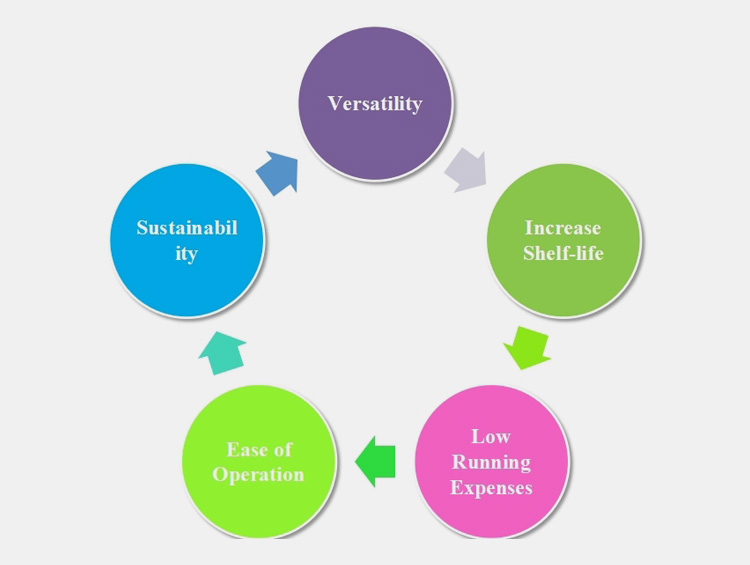

14.How VFFS machines are Beneficial for your Business?

This equipment has wide-ranging applications and are extremely beneficial for every kind of product.

Some advantages of these machines are penned below:

VERSATILITY

VFFS machines can process and handle variety of film material. Single layer or laminated materials are used for filling and sealing bags that preserve freshness and crispiness of salty foods and snacks.

INCREASE SHELF-LIFE

By using these instruments, products are packaged in secure airtight pouches or bags which boosts the expiry period of items. The gases are passed inside the bag that eliminate oxygen and prevent the rancidity of items.

LOW RUNNING EXPENSES

These machines operate at high speed and offer high throughput per hour consequently reducing operational expenses. Furthermore, they need minimum maintenance and human supervision to save additional expenses as well.

EASE OF OPERATION

VFFS machines are furbished with HMI and are simple to program and command. These touch screens report the operational progress of equipment that decreases the constant need for human intervention. Additionally, this reduces the work burden on human operators.

SUSTAINABILITY

One of the major advantages of having this automation in a production line is its sustainability. They have lower carbon print thus decreasing carbon emissions. Moreover, they consume less energy and generate less material waste which attributes to their environmentally friendly feature.

15.Top 5 Best VFFS Machine Manufacturers

VFFS machine shows broad applications in various production companies. We have chosen the top 5 VVFS machine manufacturers who have shown the strongest sale and market growth in the last few years. In addition, you can rely on them for their incredible machinery and import services. Some of the prominent players are:

BARRY- WHEMILLER

BW offers a flexible solution including bag fillers, palletization VFFS, and horizontal flow wrapping machine. A US-based company with tremendous success history since 1885 till now. This is an absolute choice for those who want to make their business among the top list of company’s value.

WINPAK

A Canadian and US-based company offering comprehensive production services by providing sophisticated packaging solution that meets challenges for specific applications absolutely boosts your product.

GEA GROUP

A profound name in the packaging world and supplier of food, beverage, and pharmaceutical machinery since 1881. GEA has widespread services in 62 countries worldwide; offers industrial-linked equipment that is specially designed to give every final product as you expect.

TOKYO AUTOMATIC MACHINERY WORKS LTD.

In terms of innovation, Japanese machinery is always fascinating! VFFS offered by TAM is the result of 50 years experienced and expertise. Broad applications and bagging styles can help in achieving everything that you want. The continued efforts, integrating sales, incredible designs, and services make them among the top manufacturers and providers globally.

AIPAK PHARMACEUTICALS

A true maker of the pharmaceutical packaging line, running their business for the past ten years with affordable and sustainable packaging contributions suitable for food, beverage, nutraceutical, chemical, and pharmaceuticals. Aipak provides a complete packaging solution with a critically coordinated range of high-grade materials in order to meet consumers' requirements.

16.VFFS Machine: Global Market Value

These machines are need of every industry for instance pharmaceutical, food, beverage, herbal, cosmetic, and personal care industries.

- Since their invention, they have come a long. It has been estimated that market size of VFFS machines was US$ 17428 million in 2021 and with the CAGR of 6.44% during the forecast period 2022-2029, it will accumulate US$24265.13 million in 2029.

- VFFS machines are high in demand because of their flexibility and rapid changeover from one bag format to another. Customer preference of ready-to-eat products and growing e-commerce are enhancing the market growth of this equipment.

- Currently, manufacturers are using paper films instead of plastic ones in VFFS machines. Moreover, they are improving their automation to process a wide variety of liquids.

17.VFFS Machines: What Are Things to Consider Before Buying It?

VFFS machines are essential in enhancing your production capabilities. It is imperative to buy equipment that fit your packaging demands.

Some tips are penned below for aiding you in your selection.

PACKAGING PRODUCT

Manufacturers claim that their VFFS machines can package products of any size, but the reality is far from the truth. So it is always best to check and test whether these automation package products are of your particular size or not. Make sure that this machine is tailored fit for packaging your highest volume products.

SIMPLE OPERATION

If you have growing business and production needs, then it is best to select VFFS machines that require little maintenance and are capable of performing self-diagnosis.

ERGONOMICS

It is essential to keep in mind the space of your manufacturing plant when going to purchase a VFFS machine. This equipment should be compatible with a footprint of your production line.

DESIGN

VFFS machines come in all shapes and sizes varying in their level of automation. So it is imperative that you keep in mind your production volume and manpower while selecting VFFS machine.

CUSTOMER SUPPORT

This instrument requires a lot of investment hence you should choose your vendor with great care. It will be beneficial for your business in long run to go for a machine manufacturer who understands your needs and problems.

Conclusion

VFFS machines are an integral components of packaging lines. Every industry from pharmaceutical to food, cosmetic use these machines to significantly boost their packaging capability. If you have additional queries in your mind regarding this handy equipment you are always welcome to contact our customer care service.

Don't forget to share this post!

Stick Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine