Wet Granulation Machine:The Complete Buying Guide in 2024

Wet granulation machine is a most widely used machine of agglomeration in pharmaceutical industry. The wet granulation measure basically includes wet massing of the powder mix with a crushing fluid, wet estimating, and drying.

There are a number of granulation technologies available to pharmaceutical manufacturers. Given the importance of granulation in the production of oral dosage forms Wet granulation machine’s role is great.

However this article will guide you through all the way from knowing about wet granulation process including Types of Wet Granulation, comparison of different related methods with all the pros and cons of the machine.

1.What is wet granulation?

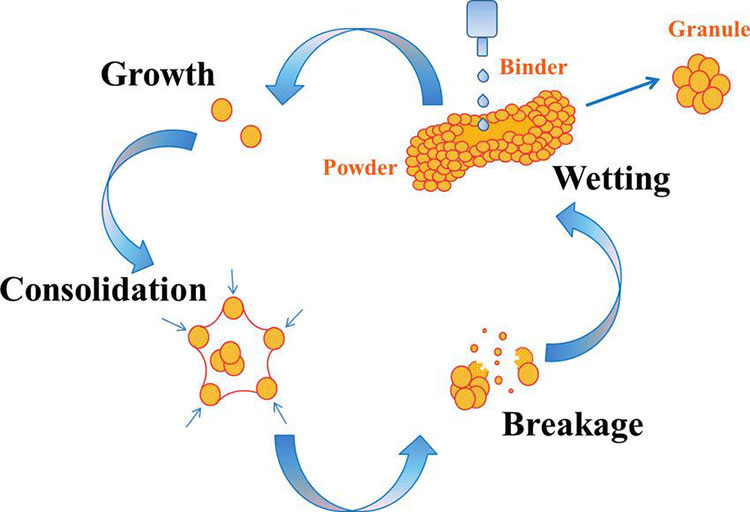

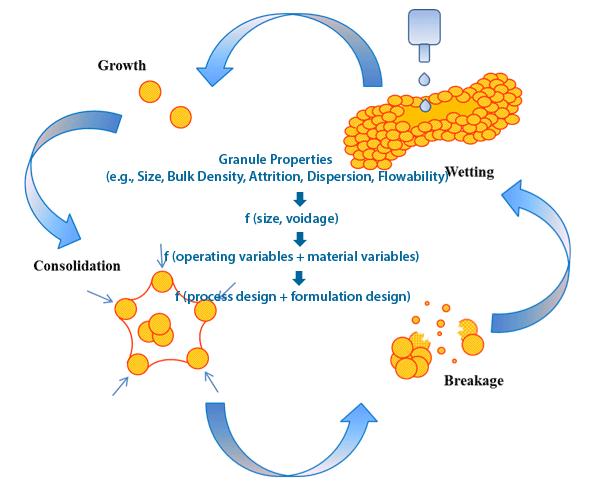

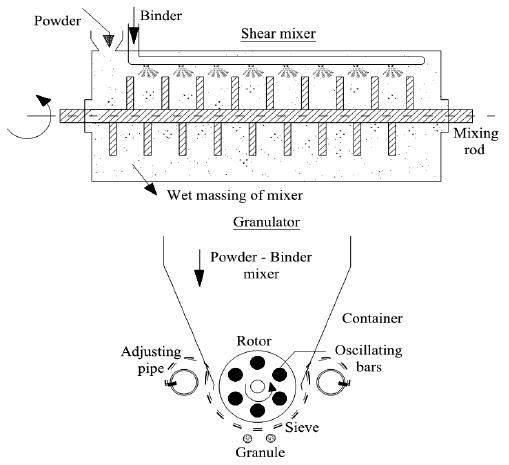

Wet Granulation- Image source: ResearchGate

Wet granulation is a process in which there is formation of granules by the application or introduction of a fluid (called granulating fluid) into the powdered medications.

In the process of wet granulation, the particles of the powdered substance are mixed along with the application of granulating liquid.

A granulating fluid is a liquid that has a carrier substance (can be solvent) in it. An important requirement for the carrier substance is that it must be evaporative.

The reason behind the requirement of volatility of carrier is that the granulating fluid can easily be removed.

Also, the granulating fluid must be non-toxic so that it may not harm the medication they are used to prepare.

Examples of the fluids that are commonly used as granulating fluids are: isopropanol, water and ethanol (primary alcohol).

Wet granulation is a process used mostly in the pharmaceutical industries for making different dosage forms.

2.What is wet granulation machine?

AIPAK Wet granulation machine

A wet granulation machine is special kind of machine that is designed to perform the process of wet granulation.

This machine is electrically run and assist you in making the granules of your powdered substance (medicinal powders). This helps to increase the size of particles.

A wet granulation machine can be a great addition to your industry if you require efficient, accurate and rapid wet granulation.

3.What are the Advantages of wet granulation process?

Wet granulation is a very important process with a lot of advantages in different kind of industries, especially the pharmaceutical industries.

Some of the advantages of wet granulation are listed below.

1.Helps in Making the Homogenous Mixtures Easily

The homogenous mixture of your powdered products can be made very easily during the process of wet granulation.

The reason for this lies in two things. Firstly, the application of the granulating fluid into the powdered product and secondly, the special design of the wet granulation machine.

The granulating fluid provides a suitable medium for the mixing of powders while the rotatory impeller of the wet granulation machine helps mix the particles thoroughly.

In this way, the wet granulation machine makes it very easy to attain a homogenous mixture.

2.Enhances the Flowability (Flow Properties) of the Particles

As s already mentioned, in the process of wet granulation, the moisture content of the powdrerd material is increased by the introduction of granulating fluid into the material.

This increases the flow of the particles by reducing the friction. The friction is reduced by the lubrication that is provided by the granulating fluid.

The whole process of enhanced flow and reduced friction helps in making the granules of the powdered substance easily.

3.Efficiency

When compared to the dry granulation, the process of wet granulation is way more efficient. This makes it a preferred method over the dry granulation.

4.Ease of Production of Dense Granules

The process of wet granulation involves the addition of a granulating fluid to the powdered substance. This addition is crucial and plays an important role in making the production of dense granules easy.

5.Cost Effectiveness

The wet granulation process is very cost efficient when compared to the dry granulation process.

5.Environmental Factors

The environmental factors are always taken into consideration when talking about the efficacy of any process.

Nowadays, governments around the world are emphasizing on protecting the environment by reducing the pollution and so those processes are preferred which produce lesser pollution.

The wet granulation process plays an important role in protecting the air from getting polluted. It does not allow the dust particles to just escape into the air and cause air pollution. The addition of the granulation liquid also halts the particles of the powdered substances to escape.

6.High Compression of the Particles

The wet granulation process allows you to attain a very high compression of the particles of the powdered substances.

7.Formation of Compacted Tablets

Compacted tablets are the type of tablets that are made by compressing the powdered substances by a high pressure.

This kind of tablets are made easily by the wet granulation process.

8.Uniformity of Content

The wet granulation process makes sure the uniformity of your content.

9.Enhanced Rate of Dissolution

The wet granulation process is seen to have enhanced the rate of dissolution of the substances that were otherwise poorly soluble.

10. Require the Use of Regular Excipients

The wet granulation process requires the use of only regular excipients and so you do not have to worry about finding some special or uncommon type of excipients.

These were some of the most significant advantages of the wet granulation process.

4.What are the Disadvantages of wet granulation process?

Despite its far spread advantages, the wet granulation process has some drawbacks too. Some of these drawbacks or disadvantages are described below.

1.Unsuitable for Sensitive Substances

The wet granulation process is not suitable for sensitive substances. The process of wet granulation usually includes high heat and so it is not suitable for the heat sensitive substances or products.

Also, the wet granulation process involves moisturization due to the addition of the granulating fluid and so we cannot apply this process to those substances that are sensitive to the moisture.

2.Migration of the Dyes

The wet granulation process involves a drying process in which the granules of the powdered substances are dried. During this process of the wet granulation process, the soluble dyes sometimes tend to migrate.

5.What are the vital application of wet granulation in industries?

The process of wet granulation has proved to be very beneficial at many levels and stages in many industries. It has far spread applications in different industries. Some of these are discussed below.

1.Pharmaceutical Industries

In the pharmaceutical industries, the process of wet granulation has many applications. The most important one being its contribution in making the tablets.

Wet granulation has widely been used in making tablets and capsules and ither solid dosage forms.

This is because of the high and compact compressibility that wet granulation provides. This feature of wet granulation process helps in making the compressed tablets.

Wet granulation process also improves the flow rate of the substances which helps not only in pharmaceutical industries but also in all the other industries using this technique.

2.Food Industry

Wet granulation process helps in making different kinds of food such as cereals etc. This because of the property of wet granulation to provide a high-quality agglomeration of the smaller particles and after that, the prevention of segregation of those particles back to the separated particles.

Wet granulation also provides another interesting feature that is very important for the food industry. It increases the attractiveness of the food product. The more attractive is your food, the more is the demand and the more you can sell it and ultimately, the more profit you can earn.

So, it will help you in gaining financial profits.

3.Agriculture Industries

The wet granulation process is very widely used in agricultural industry for making fertilizers and agricultural chemicals.

The fertilizers made by this method are better in quality and effectiveness.

Fertilizer- Image Source: SGS Pakistan

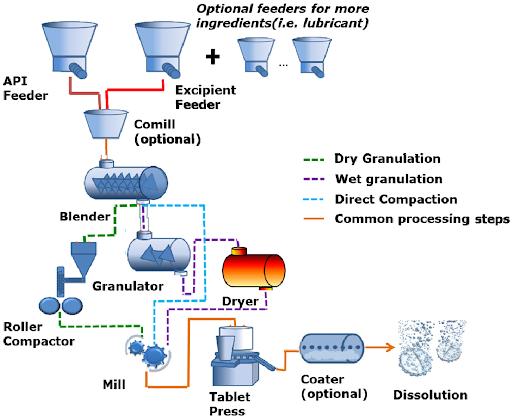

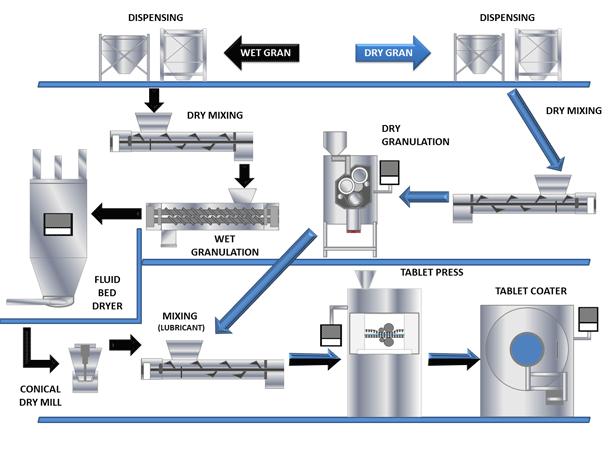

6.What are the types of Granulation Processes & Techniques?

Granulation is a technique which is used for the agglomeration of the particles of the powdered substances into larger particles with better flow properties.

This process is divided into two major types

1.Wet Granulation

2.Dry Granulation

The details of these processes along with methods are described below.

1.Wet Granulation

Wet granulation is a type of granulation in which agglomerates of the powdered substance are made by the introduction of granulating fluid.

The granulating fluid can be water, ethanol or isopropanol.

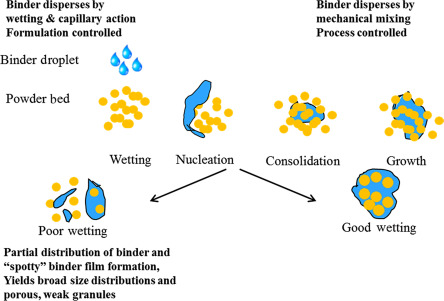

Different steps involved in wet granulation method are;

- Mixing of Drugs with Excipients

In the first step, the drug particles are mixed with the excipients. The mixing should be thoroughly and finely done. The particles of drugs and excipients must be mingled finely.

- Mingling of the Mixture with the Binder Solution

The mixture of drug particles and excipients are then mixed with the binder solution.

Binders in Wet Granulation- Image Source : Science Direct

- Sieving of The Mixture (Wet Mixture)

The wet mixture obtained by mixing of the drug and excipient mixture is then sieved through granular sieving.

- Drying of Wet Granules

The wet granules are then dried and the moisture of the granules is removed.

- Sifting of the Dried Granules

The dried granules are then sifted through a mesh.

In this way, granules of the powdered substance are made by wet granulation method.

Tablet Manufacturing by Wet Granulation- Image Source: Pharmapproach

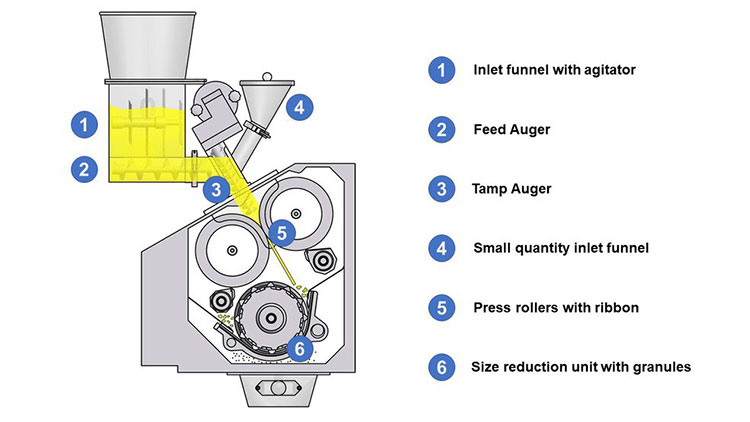

2.Dry Granulation

Dry granulation is a process of granulation which involves the formulation of granules without the involvement of any granulation fluid.

There are two methods of dry granulation that are often used in the pharmaceutical industreis.

- Slugging Method

- Roll Compaction Method

- The Slugging Method

This is a relatively older method. In this method, the powdered material is first agglomerated into larger granules called “Slugs”. This is done by special kind of machine made specifically for this process.

The slugging method of dry granulation has some drawbacks. These are discussed below.

- Control on the process is very poor

- It is not healthy for the environment as it causes a lot of sound as well as air pollution.

- It requires a greater number of storage tanks.

- The production output of the slugging method is very low.

- Energy requirements are greater as compared to other methods.

Dry Granulation Method- Image Source Pharma Tips

- Roll Compaction Method

The roller compaction method is an advanced method with better results and efficiency. In this method, the particles are made to pass between the two high pressure rollers. In this way, they are densified and then the densified substance is divided into the granules of almost equal sizes.

This method is very efficient and can handle very large number of materials in a much smaller duration.

Dry Granulation Method- Image Source

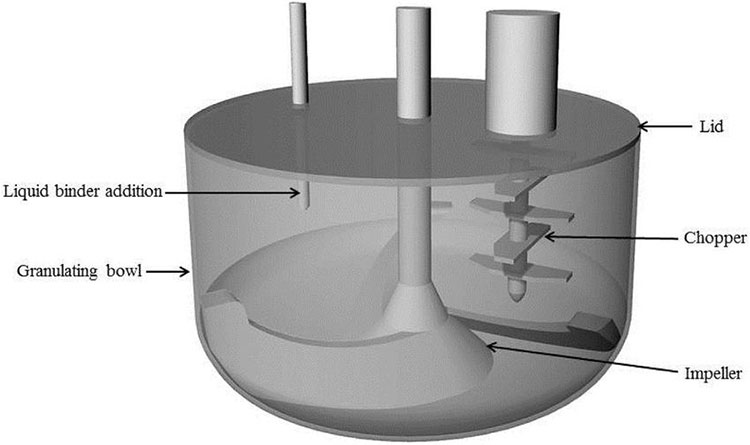

7.What are the components of the wet granulation machine?

Wet granulation machine is a specialized machine that is made for carrying out the process of wet granulation.

Some of the most important parts of the machine are discussed below.

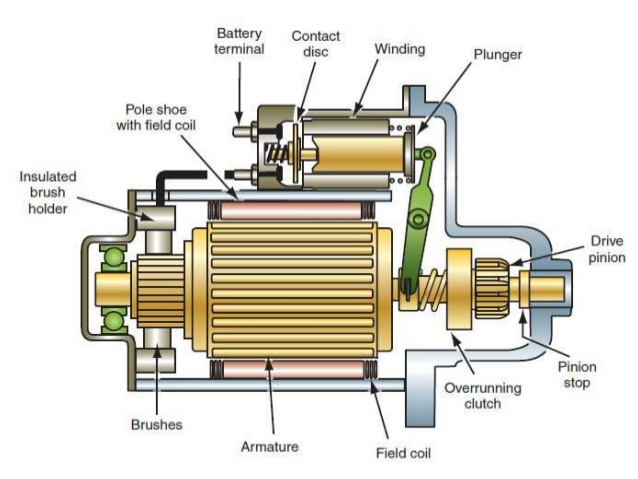

- Motor Drive Mechanism

This part of the machine rotate chopper and impeller.

This system thus controls the whole process of granulation. It also helps in the regulation of the motor drive.

Motor Drive Mechanism-Photo Credit: slideshare

The motor drive mechanism also provides you an access to adjust the speed of rotation. By doing this, you try to maintain the high level of the efficiency.

- The System of Granule Discharge

This part of the wet granulation machine that plays its role in guiding and allowing the granules once they are manufactured.

The granule discharge system comes in a variety of sizes and shapes and you can choose the one that best suits your business.

This part guides the granules for further processing through the discharge ports.

- The Spraying Nozzle

You should be careful while choosing the spraying nozzle that it must have the features that support your business by fulfilling your requirements in the best possible way.

Spraying of the binder solution in the form of droplets onto the mixture of drugs and excipients during the wet granulation process is the most important function of the spraying nozzles.

An interesting fact about the spraying nozzles is that it distributes the binder solution on the mixture particles evenly.

The spraying nozzles also come in variety of variants depending upon size, mode of action (peristaltic or mechanical) and the pressure with which it sprays.

- The Granulation Container

It is one the biggest part process of wet granulation. It has small parts like blades and so forth things.

The most important function of the granulation container is that it helps in separating the blending chamber of the wet granulation machine from the external environment.

The material used for this part must be corrosion resistant for the overall safety of the wet granulation machine.

- The Safety Mechanism of The Wet Granulation Machine

In the wet granulation machine, there is a special system for the safety of its users. The safety system is present for protecting you from any injury during the working of the wet granulation machine.

- The Impeller

The impeller is one of the most important parts of the machine as it performs one of the most crucial steps of the wet granulation process. It assists in mixing the mixing materials with the granulation fluid.

For doing so, it rotates both of these components at variable speeds.

- The Granulator Chopper

As the name indicates, this part of the wet granulation machine is involved in the chopping of the granules (the granules are wet due to mixing of granulation fluid). In this way, the granulator chopper is involved in making the granules.

Granulator Chopper-Photo Credit: senieer

The speed of rotation of the granulator chopper is somewhere between one thousand rotations per minute to around three thousand rotations per minute.

- The Frame of Wet Granulation Machine

The frame of the wet granulation machine is that part of the machine which holds or keeps all the other parts of the wet granulation machine.

The frame is the biggest and the external most part of the machine. Therefore, it has to be strong enough to support the whole wet granulation machine. It must be able to withstand the vibration produced during the wet granulation process.

The material used for manufacturing the frame of this machine needs to be strong and corrosion resistant for the overall safety features of this machine.

Parts of Wet Granulation Machine- Image Source : Research Gate

- The Sealing Mechanism

For solving this problem, a sealing mechanism is introduced into the wet granulation machine. This sealing mechanism has seals that are often made up of good material used for the sealing.

This prevents the loss of fluid during the wet granulation process. The sealing mechanism is mostly present on the granulator chamber and the impellers.

- The Electrical Control Panel

Talking about the display of the electrical control panel of the machine, the display is touchscreen which makes it very easy for its operators to operate it. You can control many possible functions using it.

These were some of the most important parts of the wet granulation machine. All these parts play important roles and thus contribute in success of wet granulation process.

8.What is the working principal of the wet granulation machine?

There are two types of machine and both of the types have different working principles. The types of the wet granulation machine are and these are high shear wet granulation machine and fluid bed wet granulation machine.

The working principles of both of these wet granulation machines are described below.

High Shear Wet Granulation Machine

The working principles of the high shear wet granulation machine is described as under.

Process No. 1. The Material is Filled in the Granulation Container

It mostly comes with an automatic system for filling the materials to be granulated into the granulation container.

A button is provided on the interface of the electrical control unit of the high shear wet granulation machine which causes the automatic filling of the material into the granulation containers when pressed.

Some of the variants of this machine come without this automatic system and thus you have to manually fill the granulation containers with the mixing materials.

Processing of the Wet Granulation Machine - Image Source: Research Gate

Process No. 2. The Actual Process of Mixing

During the second step, the actual mingling of the powdered materials and granulation liquid occurs in the high shear wet granulation machine.

The chopper and Impellers rotate in opposite directions for optimizing the process of mixing. This actually ensures the homogeneous mixing.

Process No. 3. The Addition of Granulation Fluid

After the homogeneous mingling of the materials is done, there is an automatic turning on of the spraying nozzles which start spraying the granulation fluid on to the material to be granulated as soon as it gets turned on.

The spraying nozzles are present to ensure that the granulation fluid gets distributed evenly and the choppers reduce the granules into suitable and nearly equal sizes so the granules formed at the end are almost equal in size.

After the granules are given their final form, they are ready to get discharged from the granulation discharge unit of the high shear wet granulation machine.

The Spraying Nozzle- Image Source : ISPE

Process No. 4. The Discharging of the Prepared Granules

After the first three steps the granules are prepared and are ready to get discharged.

During this fourth and the last step of the wet granulation process in the high shear wet granulation machine, the speed of the impeller rotation and the granulation choppers slows down and the spraying nozzle gets turned off on its own.

The discharge doors for discharging the granules open automatically and the granules get discharged and are then moved to the miller of the high shear wet granulation machine.

The function of the miller is to further reduce the previously formed granules to the suitable sizes.

This was all about the working principle of the high shear wet granulation machine.

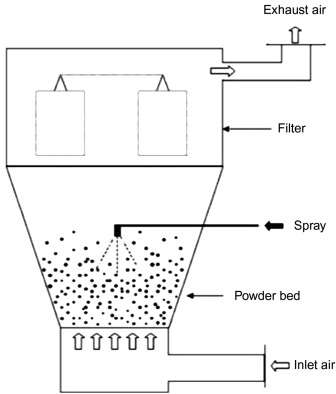

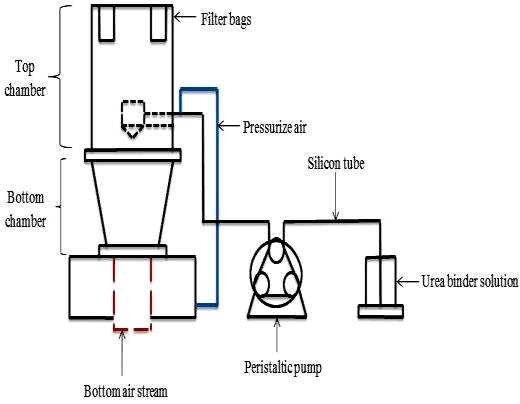

Fluid Bed Wet Granulation Machine

The working principle of the fluid bed wet granulation machine is described below.

Actually, the working principle is somewhat different as compared to that of the high shear wet granulation machine and is dependent on the process of fluidization.

The process of fluidization involves liquification of different materials by the introduction of the gas that flows in the upward direction.

Following are the important steps involved in the working of the fluid bed wet granulation machine.

Fluid Bed Wet Granulation- Image Source: Science Direct

Step 1. Fluidization of the Wet Granulation Bed

During this step, heated and filtered air is blown to the materials in order to fluidize them. The method of blowing heat varies and is different in different variants of the fluid bed wet granulation machine.

You can adjust the amount and pressure of air being blown to the mixing materials. The air blown until the point comes when the particles of the powdered material that is to be granulated starts behaving like fluids.

At this point the blowing air is stopped. An important point regarding this process is that it is suitable not only for heat insensitive particles but also for the heat sensitive particles.

It must be noted that some particles of the material to be granulated get blown away due to the heated air blown on them. In order to catch these particles and to stop them from escaping the fluid bed wet granulation machine, the exhaust filters are present.

The exhaust filters of the fluid bed wet granulation machine catch all the particles and prevent them from escaping.

Step 2. The Addition of Granulation Fluid

Unlike the high shear wet granulation machine, the spraying nozzles of the fluid bed wet granulation machine are present on the upper side of the machine (most commonly on the top side).

The granulation fluid is evenly sprayed on the particles and these particles continue to agglomerate, leading to the formulation of bigger particles.

Granules of the right size are made in this step which are then ready to get dried in the next step.

Step 3. The Process of Drying of the Granules

During the formation of right size granules is done in the second step and the next step is their drying. The granules are dried by getting exposed to hot air that takes away any moisture present in the granules.

These were the principles of working of the two types of the wet granulation machines i.e. the high shear wet granulation machine and the fluid bed wet granulation machine.

Fluid Bed Wet Granulation- Image Source: Research Gate

9.Compare different granulation method: Single pot, Fluid bed granulation, Integrated high shear granulation and Continuous granulation process.

Different granulation methods are briefly discussed below.

Single Pot Granulation Method

It is named as single pot granulation method because in this process, all the processes involved in wet granulation process even mixing itself and mingling processes of drugs and excipients, addition of the granulation fluid, formation of granules, drying of the formed granules and eventually, the formulation of right sized granules are completed in one single machine.

Fluid Bed Granulation Method

In this type of wet granulation method, heated and filtered air is blown to the particles for the fluidization of the solid particles.

After that, the granulation fluid is evenly sprayed via the spraying nozzles and equally sized granules are made.

The prepared granules are then dried by exposure to the hot air.

Integrated High Shear Granulation

This is one of the normal method of the Integrated High shear process of the granulation.

The machine used in the process of integrated high shear granulation i.e. the high shear wet granulation machine has impellers and choppers that rotate at high speed in the directions opposite to one other. The opposite rotation of choppers and impellers helps in thorough mixing of the particles and making of the equal sized granules.

The prepared granules are then discharged by the discharge unit.

Continuous Granulation Process

The continuous granulation process involves the uninterrupted flow of process. In the pharmaceutical industry, the continuous granulation begins with the formation of the API and continues all the way till the final packing of the dosage form (can either be tablet or capsule).

Continuous Granulation Process – Image Source: Weebly

10.What factors affect the efficiency of wet granulation?

Some of these factors are discussed below related to the efficiency of the granulation method.

- The Solubility in the Granulation Fluid

The solubility of the solid particles of the substance to be granulated greatly effects the efficiency of the wet granulation process. The higher the solubility of the particles into the granulation fluid, greater is the binding and higher is the efficiency of the wet granulation process.

- Morphology of its Surface and Shape of the particular

Particle substance to be granulated has a huge impact on the efficiency of the wet granulation process. If the particles have suitable shape, the efficiency of the wet granulation process automatically increases.

- The Angle of Contact of the Granulation Fluid to the Particles

The angle at which the granulation fluid comes into contact with the solid particles also has an influence on the efficiency of the wet granulation process.

If the contact angle is right, the binding of the granulation fluid and the solid particles is better leading to a greater efficiency of the wet granulation process.

- The Packing Properties of Particles

The packing properties of solid particles also play a deciding role in determining the efficiency of the wet granulation process. The better the packing properties, the greater is the efficiency of the wet granulation process.

- Average Particle Size of the Solid

The ideal size of particle also plays a role in determining the efficiency of the wet granulation process. Small size particle the more is the granulation fluid required and lesser is the efficiency of the wet granulation process.

- Duration of Granulation

If the process of granulation takes too long, the resulting granules are hard which decreases the efficiency of the wet granulation process.

11.Why do companies prefer to use dry granulation over wet granulation?

Most of the companies prefer dry granulation over the wet granulation because of the following reasons.

1.Suitable for Wider Variety of Substances

The dry granulation method is suitable for a greater number of substances compared to the wet granulation method because the former does not involve any heating or moisturizing steps.

Therefore, the dry granulation method can be used for both heat and moisture sensitive substances which would otherwise get damaged in the wet granulation process.

That is why the dry granulation method is preferred over the wet granulation method.

2.No Requirement of Special Excipients

Unlike the wet granulation method, the dry granulation method does not require any special excipients and can be done with the excipients that are easily available at cheaper prices.

3.Improved Blending

The dry granulation method offers improved binding because there is no process of migration and thus there is no loss of material as occurs during the migration process in the wet granulation method.

4.Cost Effective

The dry granulation method is much better when it comes to cost effectiveness as compared to the wet granulation method because the former requires lesser number of equipment.

Cost Effective- Image Source: HiTeches Enviro Solutions

5.Easy Handling of the Substances

The handling of the substances in the dry granulation method is way easier as compared to the wet granulation method.

6.Improved Rate of Dissolution of Tablets

The dissolution rate of the tablets formed by the dry granulation method as compared to the tablets manufactured the wet granulation method.

7.Easier Method

Unlike the wet granulation method, the dry granulation method is much easier as it does not have multiple steps.

12.What’s your advice for choosing the right granulation system?

Whenever you are buying a granulation system, you should be very cautious and vigilant because the granulation machines are mostly expensive and you surely do not want to waste your money.

Some of the key factors that must be taken into the consideration before buying a granulation system are discussed below.

1.Consider the Speed of Operation of the Machine

You should choose the granulation system which have has enough speed to fulfill your production requirements.

2.Choose the Best Suited Variant of the Granulation

The granulation machines come in a variety of models, each having specific qualifications. You should choose the granulation machine that best suits your business and production requirements.

3.Consider the Dimensions of the Granulation Machine

Dimensions of the machine refer to the size and shapes of the machine as a whole and of the individual parts of the machines. The dimensions must be taken into consideration while choosing the granulation machine.

4.The Automation Level of the Granulation Machine

The granulation machines come in different levels of automation ranging from manual

granulation machine to the fully automated granulation machine.

You should go for the granulation machine that best suits your industry.

5.Quality Compliance of the Granulation Machine

You should make sure that the machine you are going to buy complies with all the required quality standards.

6.The Capacity of the Granulation Machine

The capacity of the granulation machine is arguably the most important factor that needs to be considered when buying the granulation machine because this is the factor that is going to decide that how much raw material can be utilized in a specific interval of time.

13.What needs to Consider when Choosing Granulating Liquids?

Choosing the granulating liquid is a very crucial step in the wet granulation process because almost the whole process gets affected by the nature of the granulating liquid.

There are three main factors that must be considered while choosing the granulating liquid. These are described below.

1.The Granulating Liquid Must be Non-Toxic

liquid Before choosing the granulating liquid, you should make sure that it must be non-toxic. If you choose a toxic liquid, it will not only damage your product (maybe drugs or any other food or agricultural products) but also will be harmful for the consumer of your product. Therefore, care should be taken while choosing the granulating.

2.The Granulating Liquid Must be Volatile

You should always choose a volatile substance as granulating liquid so that it becomes easy for you to evaporate it during the drying process. If the granulating liquid is volatile, it evaporates at much lower heat as compared to the non-volatile granulating liquid which does not get evaporated easily, complicating the drying process.

3.Compatibilty with the Solid Particles

The compatibility of the granulating liquid with the particles to be granulated is very important as choosing an incompatible granulating liquid will reduce the efficiency of the granulation liquid drastically.

14.What is your advice in terms of care and maintenance of granulation machine?

Care and maintenance of granulation machine is very important for proper functioning of the granulation machine for an extended duration of time.

For the proper care and maintenance of the granulation machine, you have to follow two simple steps.

1.Regular Cleaning and Lubrication of the Granulating Machine

Regular cleaning of the machine makes sure that the dust particles do not get permanently stuck on your granulation machine which can lead to corrosion and rusting of the parts of the granulation machine. Therefore. Regular cleaning is necessary for saving your machine from rusting and corrosion.

Lubrication involves regular oiling of the moving parts of the granulation machine. This reduces friction and thus saves your machine from the damage caused by heat and friction.

2.Timely Replacement of Damaged Parts

If any part of your granulation machine gets damaged, you should replace it as soon as possible so that your granulation machine does not get damaged any further.

Following these two simple steps will greatly increase the life of your granulation machine

Granulator Machine Related Products

Granulator Machine Related Posts

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine