How To Optimize Granulation Process Parameters?

Granulation is a necessary step in tablet production, and there is a saying circulating in the industry: granulation is the leader, tablet pressing is the core, and packaging is the tail. It can be seen that the granulation process plays a crucial role in the entire tablet production. Whether it is dry granulation or wet granulation, the granulation parameters determine the success or failure of the granulation process.

So, do you know how the granulation process parameters affect the entire granulation production? How to optimize the granulation process parameters to improve the overall granulation effect?

Next, let’s take a look at how to optimize the granulation process parameters together.

1.What Is the Definition of Granulation Process Parameter?

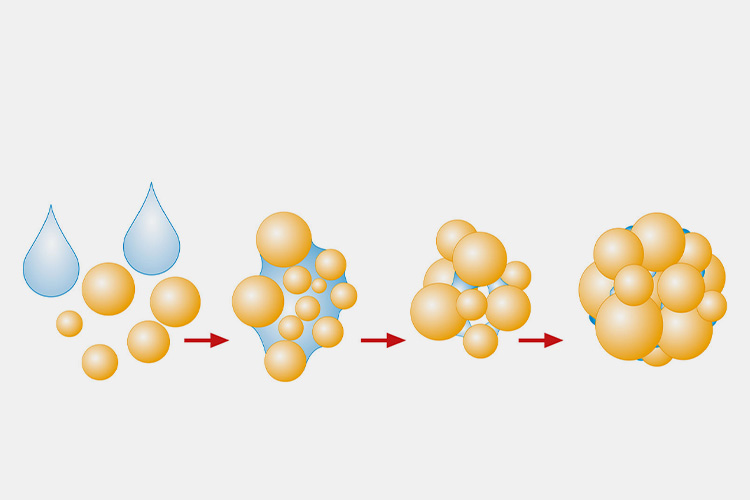

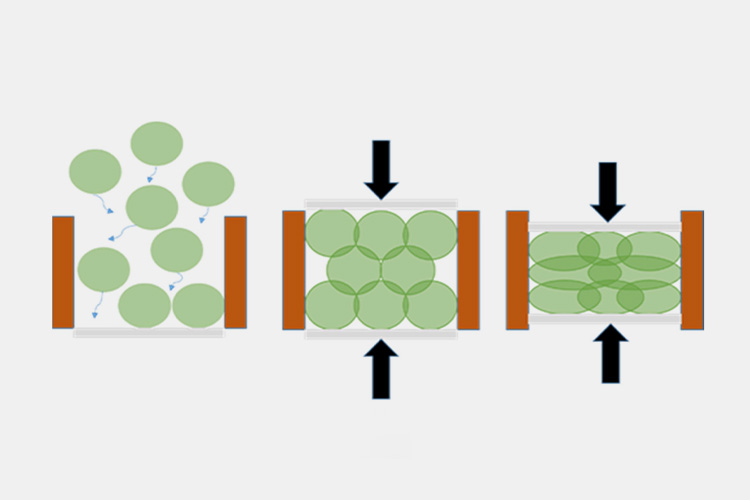

Granulation Process - Sourced: Glatt

The granulation process parameters refer to the parameters that need to be controlled during the granulation process, including speed, pressure, particle shape and other elements. To be honest, granulation is an essential step in tablet production.

The design of these parameters affects subsequent processing and also affects the quality of the final product. Therefore, it is necessary to strictly control the granulation process parameters in order to ensure the quality of tablets and other products.

2.What Granulation Process Parameters Will Affect the Quality of Granulation?

The quality of granulation is related to the quality of the final tablet product. Do you know which parameters will affect its quality?

Hardness and pressure

Generally, the greater the pressure, the closer the distance between particles, which will generate stronger binding force. Raw materials in the pharmaceutical industry are more or less elastic.

When the plastic deformation stress exceeds the elastic limit, the contact area between particles increases, and the binding force also increases. Therefore, in general, the greater the binding force, the greater the hardness of the tablet. In experiments, the hardness varies with different product process parameters, and increases with increasing pressure.

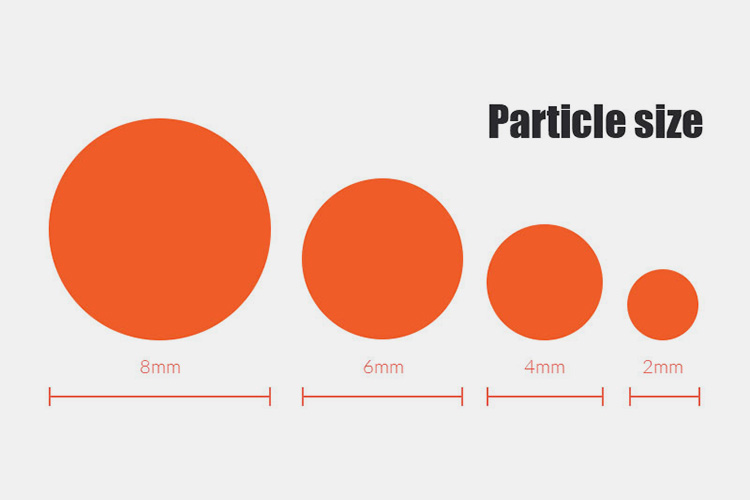

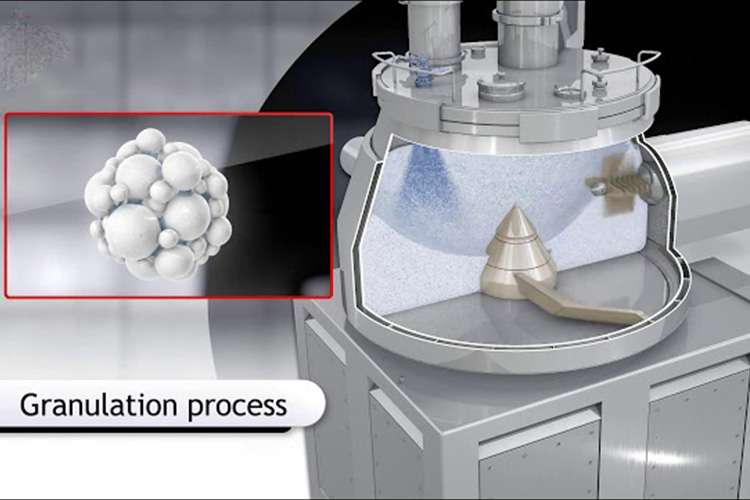

Particle shape and size

Particle Shape and Size - Sourced: Fote Machinery

The shape and size of particles serve as an important factors affecting the quality of tablets. If the particle size difference is too large, top cracking may occur during the production process. If the particles of the song are too fine, there will be sticking and flushing during the compression process.

The sizeof sieve aperture

The diameter of the sieve aperture of the granulator can determine the particle size of the finished product. The particles produced by a sieve that is too large are irregular, while those produced by a sieve that is too small may have more fine powder.

For materials with poor fluidity, it is not advisable to choose smaller sieves. A sieve aperture that is too large or too small can have a negative impact on the final particle properties.

3.What Are the Suitable Humidity Parameter During the Granulation Process?

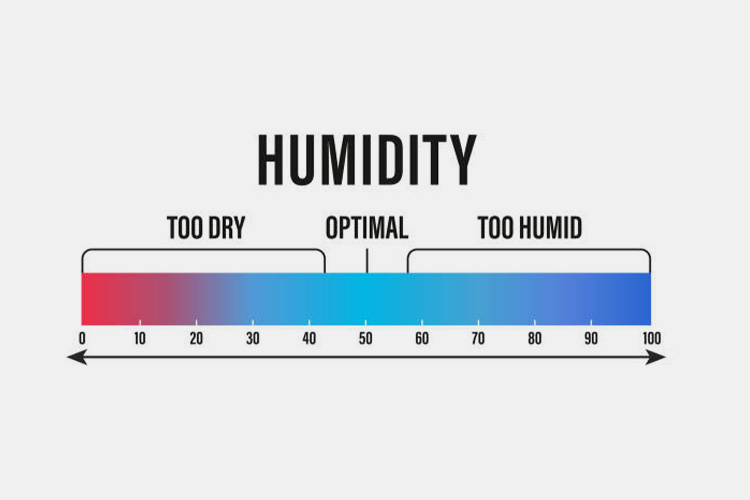

Temperature are one of the factors that affect the quality of granulation, therefore, it is necessary to optimize humidity during the granulation process.

Choosingmaterials with appropriate humidity

Choosing Materials With Appropriate Humidity - Sourced: iStock

The humidity of the material itself can also affect the particle strength. If the humidity is too high, the material is prone to clumping, which can cause excessive bonding of the particles and increase their strength during the granulation process. Before granulation, the material can be dried to control its humidity within an appropriate range.

For example, for some traditional Chinese medicine extracts, they can be dried to a moisture content of around 5%-8% before granulation. This can ensure the flowability and formability of the material, while avoiding excessive particle strength caused by high material humidity.

Maintainingan appropriate drying temperature

Maintaining an Appropriate Drying Temperature - Sourced: Freds Appliance

If the drying temperature is too high or the time is too long, the moisture inside the particles will evaporate rapidly, causing the particles to shrink, the internal structure to become dense, and the strength to increase.

Appropriate drying temperature and time should be used, such as reducing the drying temperature to 60-70 ℃, extending the drying time, allowing the moisture inside the particles to slowly and evenly dissipate, maintaining the pore structure of the particles, and reducing particle strength.

At the same time, during the drying process, the ventilation volume can be appropriately increased to promote the discharge of moisture and avoid the formation of hard shells on the surface of particles due to rapid evaporation of moisture, which can prevent internal moisture from escaping and cause excessive particle strength.

4.How Are the Flowability And Compaction of Particles Affected By Granulation Process Parameters?

The granulation process parameters will have a certain impact on subsequent processing, affecting the flowability and compressibility of the particles.

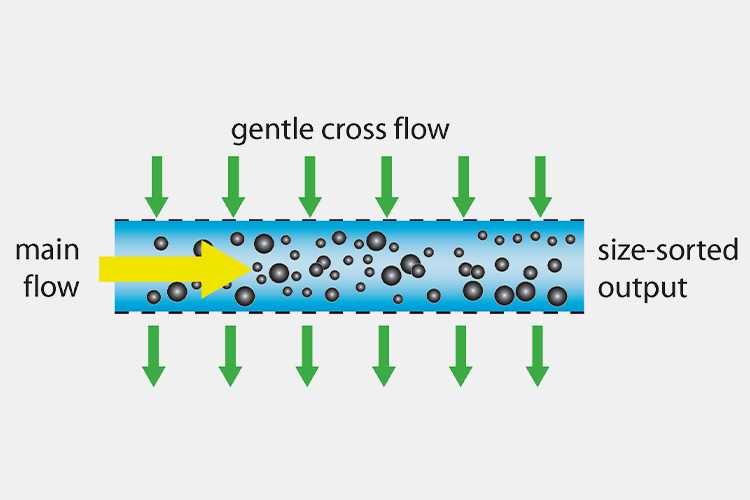

Affectingthe flowability of particles

Affecting the Flowability of Particles - Sourced: Spectradyne

Generally speaking, particles with higher density and strength have better flowability and are less prone to layering, clumping, and other phenomena during subsequent packaging, transportation, and storage processes. This is because high-density and high-strength particles have regular shapes, smooth surfaces, and low friction between each other, allowing them to flow smoothly in containers or pipelines.

On the contrary, particles with low density and strength are prone to breakage or deformation, and may adhere to each other during the flow process, affecting fluidity.

Affectingthe compaction of particles

Affecting the Compaction of Particles - Sourced: MDPI

For particles that require further compression, their density and strength have a significant impact on the compression process. Particles with moderate density and strength can withstand a certain amount of pressure during compression, and are not easily broken or deformed, thereby ensuring the hardness and appearance quality of the tablets.

If the particle density is too low, it may be excessively compressed during the tablet pressing process, resulting in problems such as fragmentation and looseness of the tablet; However, if the particle density is too high, it may cause excessive compression pressure, damage the tablet press mold, and also affect the disintegration performance of the tablets.

5.How Are the Stability And Uniformity of the Product Affected By Granulation Process Parameters?

The granulation process parameters will have a certain impact on the granulation of the final product, which will affect the stability and uniformity of the product.

Affectingthe stability of the product

Stability of the Product - Sourced: News-Medical.net

In industries such as pharmaceuticals and food, the density and strength of particles directly affect the stability of products. For example, the appropriate density and strength of drug particles can ensure that they are not easily affected by external factors (such as humidity, temperature, pressure, etc.) during storage, prevent the degradation and deterioration of drug components, and thus extend the shelf life of the product.

For food particles, higher density and strength can maintain their shape integrity during processing and storage, avoid breakage and chip shedding, and improve the appearance quality and taste of the product.

Affectingthe uniformity of the product

Affecting the Uniformity of The Product - Sourced: Alencure Biotech

Particles with uniform density and strength can ensure the uniformity of product quality, efficacy, taste, and other aspects. In the production process, if there are significant differences in the density and strength of particles, it may lead to inconsistent properties of the product in different parts.

Taking drugs as an example, uneven particle density and strength may result in different release rates of drugs in the body, affecting the efficacy of the drug; For food, differences in particle density and strength may lead to inconsistent taste and affect the quality of the product.

6.How To Choose the Appropriate Granulator To Meet Process Requirements?

A granulator is an equipment that cannot be obtained for producing tablets and other products. How to choose a suitable granulator?

According to different particle strengths

AIPAK Granulator

The impact of different types of granulators on particle strength varies. For example, the dry granulation machine shapes materials through mechanical extrusion, resulting in relatively high particle strength; The wet granulation machine aggregates materials by adding adhesive, and the particle strength can be controlled by adjusting parameters such as the amount of adhesive used.

For products with lower requirements for particle strength, wet granulation machines can be preferred. If dry granulation is necessary, a dry granulation machine with multi-stage extrusion or precise pressure control can be selected to better control particle strength.

Choosingthe appropriate sieve aperture

Choosing the Appropriate Sieve Aperture - Sourced: IndiaMART

During the granulation process, the aperture of the sieve will affect the particle size distribution and strength of the particles. A sieve with a smaller aperture will result in smaller particle size and greater squeezing force when passing through the sieve, leading to an increase in particle strength.

The aperture of the sieve can be appropriately increased to reduce the resistance that particles experience when passing through the sieve, increase the porosity inside the particles, and thus reduce the particle strength.

7.How To Adjust Granulation Process Parameters To Avoid Excessive Particle Strength?

If the particle strength is too strong, it will affect the solubility of the final tablet, which is not conducive to drug administration. How to control the particle strength to be too strong?

Choosing the appropriate adhesive

The viscosity of different adhesives varies, and their impact on particle strength is also different. For example, in pharmaceutical granulation, the viscosity of starch slurry is relatively moderate, while the viscosity of cellulose adhesives is strong. To avoid excessive particle strength, it is recommended to choose adhesives with weaker viscosity and better hydrophilicity, so that the particles will not become too hard due to the excessive action of the adhesive while ensuring molding.

Reducing the amount of adhesive used

Minimize the amount of adhesive used while meeting the requirements for particle molding. Excessive adhesive will form a thick film on the surface of the particles, tightly bonding them together and resulting in high particle strength.

The minimum amount of adhesive can be determined through pre experiments, for example, by first determining a rough range of dosage, then gradually reducing the amount of adhesive within this range, observing the formation and strength changes of the particles, and finding the amount of adhesive that can ensure both particle formation and meet the required particle strength.

Reducing the stirring speed

Reducing the Stirring Speed - Sourced: Fluid Air

Excessive mixing speed can cause significant shear and friction forces on the material, leading to over compaction of particles and increased strength. Appropriately reducing the stirring speed can make the material mix and agglomerate more warmly and thoroughly during the granulation process, resulting in a relatively high porosity inside the particles and a decrease in particle strength. For example, reduce the stirring speed from the original 500r/min to 300-400r/min and adjust it according to the actual situation of the particles.

Shortening granulation time

Shortening Granulation Time - Sourced: Glatt

If the granulation time is too long, the particles will be continuously compacted and agglomerated, and the strength will gradually increase. Shortening the granulation time can stop the agglomeration process of particles in a timely manner after reaching a certain degree of molding, avoiding excessive particle strength.

Generally, the appropriate granulation time can be determined through experiments, such as shortening it from 15 minutes to 10-12 minutes, and observing whether the strength and other quality indicators of the particles meet the requirements.

8.How to Optimize Granulation Process Parameters to Improve the Uniformity of Wet Granulation?

Uneven granulation is one of the most common problems in the granulation process, which is influenced by many factors. How to adjust the granulation process parameters to improve the uniformity of wet granulation?

Adjustingthe stirring blade speed

Adjusting the Stirring Blade Speed - Sourced: LinkedIn

The speed of the stirring blade is a key factor affecting the compactness, particle size distribution, and bulk density of particles. Different stirring blade speeds will result in significant differences in particle flowability, compressibility, and formulation dissolution performance.

If the speed of the stirring blade is too fast, the material will be mixed unevenly. If the speed is too high, the particle size will be too small, resulting in uneven distribution.

Ensuringsufficient mixing time

Ensuring Sufficient Mixing Time

Adequate mixing time is the key for granulation. Generally, it is necessary to determine the appropriate mixing time based on the properties of the material and the mixing efficiency of the equipment to achieve the best mixing effect.

Choosingauxiliary materials with better compressibility and fluidity

If the compressibility of the material is poor, it will result in a higher amount of fine powder after granulation. For example, poor material flowability may be due to the selection of lactose and microcrystalline cellulose models. It is recommended to use other straight pressed lactose or microcrystalline cellulose with better flowability.

Ensuringuniformity of drying temperature

Temperature - Sourced: Adobe Stock

It is very important to ensure that the drying temperature is evenly distributed throughout the entire drying area. If the drying temperature is uneven and the drying speed of particles varies at different positions, it will cause some particles to dry excessively, while others still contain a lot of moisture, thereby affecting the uniformity of the particles.

Adopting appropriate liquid addition method

The method of adding liquid, including pumping and spraying, is crucial for the granulation effect. Materials with a high concentration of water-soluble components may have their granulation effect affected by local over wetting when pumped in, while the spraying method is gentler and can effectively avoid such problems. In addition, different liquid addition methods can have a significant impact on the particle size and size distribution of the particles.

Conclusion

Granulation is an unattainable step in tablet production, and granulation parameters affect the quality of granulation. Therefore, it is necessary to understand granulation parameters and optimize them. After reading this article, have you gained a deeper understanding of granulation parameters? If you have any further information about granulation, please feel free to contact AIPAK at any time.

Granulator Machine Related Products

Granulator Machine Related Posts

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box? Sign up for AIPAK’s monthly newsletter, we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine