Why Should We Choose the Automatic Cartoning Machine?

The importance of packaging in the manufacturing process cannot be overstated. Many industries rely on efficient and effective packing solutions to ensure quality and speed.

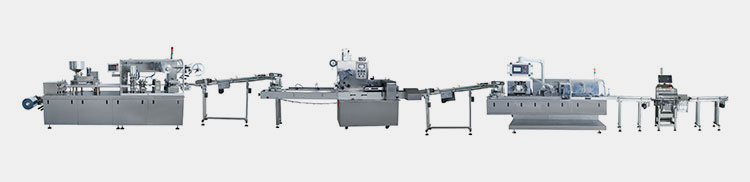

Choosing an automatic cartoning machine can greatly enhance production efficiency, improve packaging quality, and reduce labor costs. This equipment is vital for modern manufacturing.

In a world where speed matters, relying solely on manual labor can slow you down. An automatic cartoning machine can complete tasks like box assembly, product filling, and sealing much faster than any human can. This reduced time spent on manual processes helps prevent production line bottlenecks and ultimately increases overall capacity.

1.How Does An Automatic Cartoning Machine Ensure Packaging Quality and Consistency?

One of the significant aspects of an automatic cartoning machine is its ability to maintain quality and consistency. With precise alignment and control systems, every product fits perfectly within its box. This precision prevents issues such as misaligned boxes, product damage, or missing items. Ensuring that each package meets the same standards strengthens the overall brand quality.

Quality Assurance in Cartoning

When I first started exploring packaging solutions for my business, I was surprised by how much impact packaging quality could have on customer satisfaction. Products that arrive in perfect condition evoke a sense of professionalism and care. An automatic cartoning machine reduces the risk of human errors, which can lead to inconsistent packaging. This machine ensures that every box looks and feels the same, enhancing product quality and customer trust.

2.Why Choose an Automatic Cartoning Machine?

A.Superior Efficiency and Cost Savings: The ROI of Automation

The most compelling reason to invest in an ACM is its direct impact on your bottom line. By replacing tedious manual labor with precision engineering, an ACM simultaneously cuts costs and boosts output.

Significant Labor Savings:One of the most immediate benefits is the drastic reduction in labor dependency. Manual packaging requires a large, often rotating team, leading to high training costs, potential human errors, and high wage expenditures. An ACM handles the entire process—from carton forming to product insertion and closing—requiring only a handful of operators for oversight and material replenishment.

Maximized Productivity & Throughput:Unlike human workers, who are subject to fatigue, breaks, and varying speeds, an ACM operates at a consistent, high speed (e.g., capable of running at 60-120 boxes per minute, depending on the model). This constant, reliable speed dramatically increases your daily and monthly production capacity , ensuring you meet demanding production schedules and capitalize on market opportunities.

We recently worked with a leading pharmaceutical company struggling to keep up with peak season demand. Their manual cartoning line was capped at 30 boxes per minute with 5 operators. By installing our high-speed horizontal cartoner, they achieved a sustained output of 80 boxes per minute with just 2 operators. This move led to an estimated 35% reduction in annual labor costs and a 166% increase in efficiency , allowing them to fulfill a major contract that was previously unattainable.

B.Uncompromising Quality and Accuracy Control

Beyond speed, the consistency and precision of an automatic machine are critical for maintaining product quality and protecting your brand's reputation.

Precision Material Handling: ACMs utilize sophisticated features to ensure the correct contents are placed in every box:

Automatic Counting: Ensures the precise number of items (e.g., blisters, bottles, or sachets) are inserted.

Photoelectric Sensor Detection : Verifies the presence of all required components, including the product, leaflet, or instructions.

Automatic Rejection System : Cartons missing any required component are automatically kicked off the line before sealing, guaranteeing that only complete, accurate packages reach the consumer.

Reduced Product Loss: By minimizing human error in counting and insertion, the ACM significantly reduces waste and product rework, further enhancing operational savings.

C.Superior Package Presentation and Brand Image

The final appearance of your product package is the consumer's first impression of your brand.

Flawless Consistency: ACMs use precision-engineered mechanisms for carton forming, tucking, and sealing. This ensures that every single box is folded, inserted, and closed with perfect uniformity .

Enhanced Aesthetics : Automated sealing results in crisp edges, perfectly square boxes, and neat tucks or glue seals—a level of aesthetic quality that is nearly impossible to replicate reliably with manual labor. A professional, high-quality package presentation instills consumer trust and reinforces premium brand positioning.

C. Additional Advantages from Advanced Cartoning Solutions

Based on the capabilities and specifications often found in detailed quotes, modern ACMs offer several other key advantages:

| Feature/Component | Benefit to the Customer |

| High-Grade Stainless Steel Construction (e.g., 304/316) | Durability & Longevity: Ensures compliance with strict GMP (Good Manufacturing Practice) standards, especially crucial for Pharma/Food industries, and guarantees a long machine lifespan. |

| User-Friendly HMI (Human-Machine Interface) / PLC Control | Ease of Operation & Maintenance: Simple recipe changes, quick troubleshooting, and minimal training required. Maximizes uptime. |

| Flexible Adjustment & Quick Changeover | Versatility: The ability to quickly adjust the machine to handle multiple carton sizes and product formats (e.g., within 15-30 minutes) makes it ideal for companies with a diverse product portfolio. |

| Integrated Safety Features (e.g., Safety Doors, E-stops) | Operator Safety & Compliance: Protects personnel and adheres to international industrial safety regulations. |

| Energy Efficiency / Optimized Power Consumption | Sustainability & Lower Utility Bills: Modern servomotor technology often reduces energy usage compared to older, pneumatic-heavy machines. |

3.Why is Reducing Labor Costs Essential for Manufacturers?

One significant advantage of automating the cartoning process is the reduction of labor costs. With an automatic cartoning machine, you no longer need to rely heavily on manual labor. This not only decreases the amount you spend on salaries but also minimizes the risk of errors caused by human oversight.

Cost-Effectiveness in Packaging

During my career, I’ve seen firsthand how labor costs can spiral out of control, especially when companies depend heavily on manual tasks. By transitioning to automation, businesses can save money and allocate those resources elsewhere. An automatic cartoning machine also creates a more stable production environment, minimizing disruption caused by human errors.

Labor Cost Reduction

Investing in automation, especially with tools like cartoning machines, can make a huge difference. These machines work quickly and accurately. They can handle many tasks that would otherwise require multiple workers. This means fewer people are needed on the floor, which can significantly lower payroll expenses.

4.How Versatile is An Automatic Cartoning Machine?

The versatility of automatic cartoning machines cannot be underestimated. They can quickly adapt to different product sizes and shapes, making them suitable for various industries, including pharmaceuticals, nutraceuticals, cosmetics, and food.

Versatility in Cartoning Machines

From my experience, the ability to switch between products efficiently can be a game changer for businesses. I once worked with a client who needed to package various products of different sizes. The automatic cartoning machine accommodated all their requirements seamlessly, allowing them to maintain high production levels without compromising quality.

5.How Does An Automatic Cartoning Machine Enhance Brand Image?

Packaging is often the first impression a customer has of a product. An automatic cartoning machine provides neat and aesthetically pleasing packaging that elevates the perceived value of the product. When products are packaged consistently and professionally, it enhances the market's perception of the brand.

I remember a project where we rebranded a product line. The switch to an automatic cartoning machine transformed the packaging from average to top-notch. The enhanced packaging not only attracted more customers but also fostered trust and loyalty.

6.What About Compliance With Industry Standards?

For industries like pharmaceuticals and nutraceuticals, compliance with regulations like GMP and ISO is crucial. An automatic cartoning machine ensures that your packaging meets all necessary standards, providing peace of mind to manufacturers and consumers alike.

In one case, I worked with a client who was struggling to meet regulatory requirements with their manual packaging process. The transition to an automatic cartoning machine streamlined their operations and ensured compliance, making it easier for them to navigate the complex landscape of industry regulations.

A Real-World Case Study

I recently assisted a client who was involved in OEM packaging. They had a bagging machine for powder products but relied on manual labor to package those products into boxes. This led to significant delays and human error, as their speed during manual cartoning couldn’t match that of the current bagging machine. After assessing their needs, it became clear that an automatic cartoning machine would solve their challenges.

First, we needed to understand how their existing bagging machine operated. They provided a video showcasing the output, allowing us to design an appropriate connection plan for the new system.

Next, we learned that their boxes and bags came in various sizes. It was essential to determine the correct packing style for optimal performance. We compiled a table with all necessary information, including dimensions, images, and required speeds. This meticulous planning ensured everything would work together effectively.

The assessment revealed that one box was too tall for the existing system, requiring a specification change. We suggested that some of the products be placed manually due to compatibility issues. However, five other product configurations could share a single feeding mechanism. Although other feeding methods can be used interchangeably, this type of feeder is more expensive and slower, so it is not recommended. The customer accepted the suggestion.

After providing a quote, I requested additional details about the bagging machine's output height and the facility dimensions. This information allowed us to draft a layout diagram for optimal connectivity. The client designed a sketch of the available space and specified height restrictions, even suggesting adding a check-weighing machine after the cartoning machine.

After revising the layout based on the client's feedback, we ensured the new cartoning machine had enough space for materials and equipment. Additionally, we took into account the need for extra space to accommodate the machine's operations compared to manual packing.

To help the client further, we offered to create a mock box design during testing to eliminate the need for them to produce new cartons. This move saved them both time and costs.

Ultimately, we thoroughly evaluated the packaging materials and provided additional solutions, such as pressure devices, to ensure smooth operation.

Conclusion

In summary, choosing an automatic cartoning machine can lead to better efficiency, improved quality, reduced costs, and greater compliance — essential factors for any manufacturing business.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours