Tube Cartoning Machine: The Complete Buying Guide In 2025

In today’s competitive packaging, everyone wants to package products in different cartons with high precision, efficiency and automation. Either you are in the pharmaceutical, food, chemical or food industry, you’ll definitely package the materials like tube in well-sealed and customized cartons. But is it possible to get good quality packages in a less time?

Well, the tube cartoning machine is available in the market that can boost your business. But in 2025, there are many types of cartoning machines are available, how would you choose the best matched tube cartoning machine for your products?

In this AIPAK buying guide, the types of cartoning machine, materials it handle and what should you consider while buying the machine? Everything will be explain so, keep reading!

1.What is tube cartoning machine?

AIPAK tube cartoning machine

A tube cartoning machine is a type of machine in which the tubes like toothpastes, ointments, gels, lotions and creams are inserted into the cartons (cardboard boxes) and then automatically sealed and printed the essential information on the cartons.

The purpose of cartoning of products are to provide support, protect, organize and easily support and protect the tubes during transportation.

2.How can you get advantages by using tube cartoning machine?

Have you ever wondered how beautifully packed tubes are positioned in an aesthetic cartons with high accuracy? How is it possible to store the tubes in a strong packages that satisfy you? Well, this is due to the blessings of tube cartoning machine. You can achieve many of the goals by using this machine. These are as follows:

Increased packaging speed:

Are you worrying about the packages of thousands of tubes with high precision and accuracy? Don’t worry, you have a sleek machine that package thousands of your tubes in a minute by ensuring the tubes quality and its cartons. In this way, the labor costs is reduced and the risk of human error is also reduced.

Enhanced products protection:

Enhanced products protection

If you wants to reduce the customer complaints and wants to keep the integrity of your products then you can get advantages by using this machine. It can place and pack the tubes into sturdy cardboard boxes, you can called it cartons, which protect your products from environmental damage, contamination and environmental exposure.

Improved packaging consistency:

Improved packaging consistency-Picture courtesy: pinkit.nl

You want to look your products same and maintain your brand image professional? This machine can place, seal, and insert leaflets in every carton with high precision and accuracy. This machine can fold and hold the cartons for tube insertion so, reduce the error of missing tubes and open cartons.

Reduced errors and waste:

This machine can automatically eliminate the open cartons or damage products and reduce the material waste for packaging mistakes. The leaflets inserted into the cartons can also be eliminated if found damaged. The machine also stops automatically if error occurs.

Traceability of the products:

Traceability of the product-Picture courtesy: vitl.com

This machine can imprint the barcode, batch number, and other essential information of the cartons. In this way, it helps you to meet the government and industry regulation. The barcodes etc. can help the customers to trace the products and ensure the safety of the products and its authenticity.

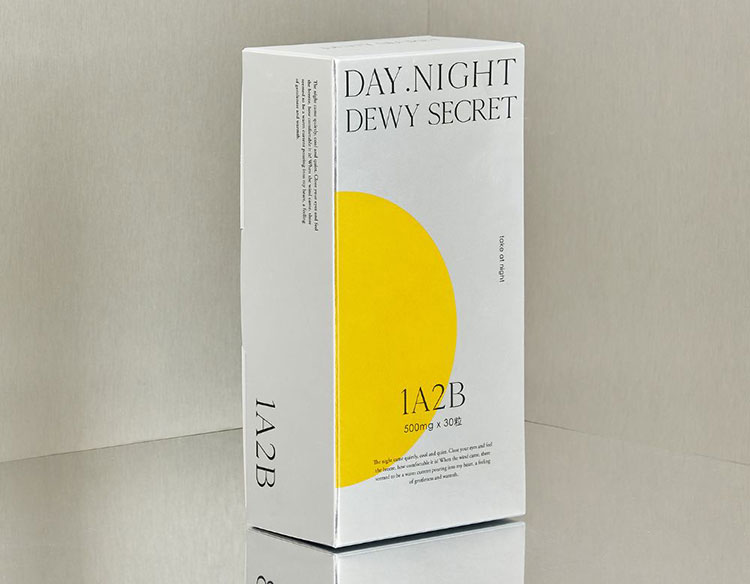

Better brand presentation:

Better brand presentation

This machine have customized functions. You can adjust the style and size of the cartons. The machine packs the tubes in cleaner, tighter and more appealing way. In this way, your products in the market can catch the customer’s concentration because your products may seem eye-catchy and trustworthy for them.

3.Which industries get benefit by using tube cartoning machine?

There are several industries that can take advantages by using tube cartoning machine. Every industry wants to package their products in a strong, flexible cartons that ensure the product safety, accuracy, consistency and efficiency. Due to these reasons, the versatility of tube cartoning machine is huge but some of the main industries that can take advantage of using this machine are as follows:

Pharmaceutical industry:

Pharmaceutical industry

The pharmaceutical industry wants to pack various tubes like ointment, creams, antibacterial and antifungal creams with high precision and with high speed. This machine can packages these tubes by accurate leaflet insertion, temper proof packaging and printing batch coding and serialization.

These factors can ensure the customers safety and traceability.

Cosmetic and personal care industry:

Cosmetic and personal care industry

The cosmetic and personal care products in the tubes are necessary to packed in a various carton styles and customization because these factors can seem eye-catchy to the customers. This machine is widely used in this industry because it can pack lotions, creams, toothpastes etc. tubes in a professional way.

Food industry:

Food industry –Picture courtesy: suma.coop

The food industry packs tomato pastes, energy gels and food supplements tubes in a cartons to ensure the safety, protect flavors and increase the shelf life of the products. It can also help in maintaining the hygienic environment for the products. The high production can meets the demand of the markets.

Chemical industry:

Chemical industry

The products safety and preventing leakage is the major concern of chemical industry. This machine can pack the adhesives, cleaners, and industrial pastes and gels in a sturdy cartons and ensure leak-proof packages for various tubes. This machine can handle various tube sizes and materials so, chemical industry can get benefit from this machine.

Veterinary and animal care industry:

Veterinary and animal care industry

The animal care products like gels, creams, pet medications and nutritional supplements for animals are packed in cartons for the safe, hygienic animal treatments. This machine ensure the safety of products from oxidation, and make convenience for the customers.

Household products industry:

Household products industry

The various household products like wall repair pastes and craft adhesives are packed in various cartons. This ensures the safety from oxidation and protect them from light, heat to prevent the hardening of the products. The machine can support large scale and medium scale products production.

4.What are the types of tube cartoning machine?

The various types of tube cartoning machine is ruling the world as many of the industries take advantages by using them. Each type of machine has its own advantages and purposes. Let explore the types and the industries that get most benefited by using them.

Based on products insertion:

On the basis of the products insertion into the cartons, these machines are divided into two types:

Horizontal tube cartoning machine:

AIPAK horizontal tube cartoning machine

In this machine the cartons are formed, opened, placed the tubes, closed tem, seal, and print and finally discharge them. The opened cartons are hold by the mechanical arms in place and the tubes are inserted horizontally into them. Then, the cartons are closed, insert leaflets and then seal it.

It produces thousands of tube cartons per minutes and ideal for uniform tube sizes.

The pharmaceutical, food, and cosmetics products industries get most benefited by using this machine by packing toothpastes, creams and sauces.

Vertical tube cartoning machine:

Vertical tube cartoning machine

In this machine, the mechanical arms hold the opened cartons vertically and place the tubes in these cartons vertically. Then the cartons are sealed and discharge. This machine can be used for light weighted and short tubes packaging.

The pharmaceutical and cosmetic and personal care products like ointments and sample sized skincare tubes are packed in these cartons.

Based on automation level:

On the basis of automation, they are divided into two types.

Semi-automatic tube cartoning machine:

Semi-automatic tube cartoning machine

This machine needs the assistance of operator for cartons loading on to the machine, folding the cartons flap. This machine is less expensive as compared to fully automatic machine. This machine offers flexibility for different sized cartons.

This machine is suitable for low volume production and small businesses.

Fully automatic tube cartoning machine:

Fully-automatic tube cartoning machine

This machine does not need the assistance of the operator. It can complete automation from carton forming, tubes feeding, placing, leaflet insertion, sealing and to the discharge of the cartons. It has sensors and programmable factors that can eliminate the waste and detect the error.

Pharmaceutical, food, chemical, cosmetic and veterinary industries can get benefits by using this full automatic cartoning machine.

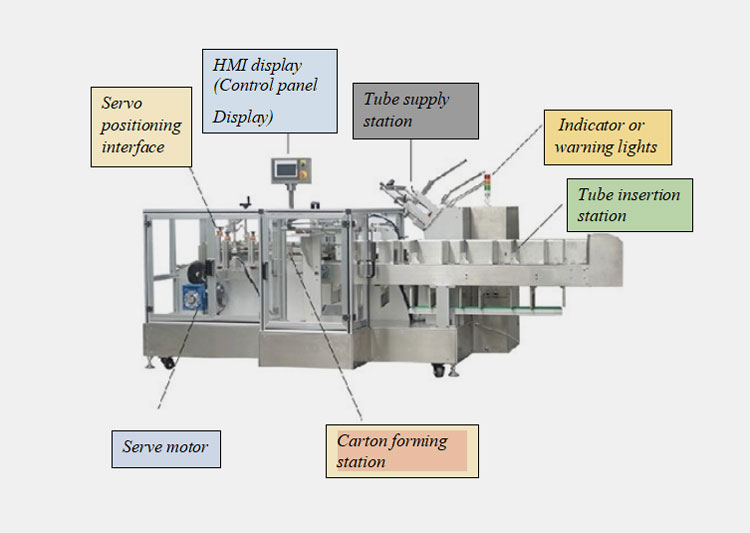

5.What are the components of tube cartoning machine?

AIPAK tube cartoning machine

If you want to smoothly operate the process of tube cartoning, then you must make sure to know the components of the tube cartoning machine. These are as follows:

| Components | Function |

| HMI display ( control panel display) | It is the central control panel of the machine where operator interact with the machine. The operator adjust the tube size, carton size, and positioning of tube in the cartons. The touch screen shows the machine setting, status and faulty messages. |

| Tube supply station | The key components of the tube supply or holder station are tube magazine, grippers, sensors and transfer mechanism. This station holds the tubes in a queue, grippers function during movement by securing the tubes, and sensors detect the misalignment of the tubes and then moves the tubes for the cartoning. |

| Indicators or warning lights | The warning lights are used to detect any fault in the machine. There are three lights red, yellow and green. The red light shows the fault in the machine and you have to stop the machine via emergency button. The green color indicates machine running normally and yellow light shows warning or your attention is needed in this case. |

| Tube insertion station | This station consists of pusher arm, alignment guides, servo driver and safety guard. These components are used to mechanically drive the tubes into the cartons. The tubes are aligned with carton inlet to ensure every tube is perfectly placed in the carton. It also controls the force or speed of pushing the tubes into the formed or open cartons. |

| Carton forming station | The key components of this station are carton magazine, carton holding arms, and glue and carton flap folders. In this portion, the open cartons are ready for the tubes insertion and also ensure one carton is pick up at a time for the tube insertion. After tube placing, the flaps are folded from front and bottom side and then apply glue for sealing procedure. |

| Serve motor | The key components here are high precision servo motor units, servo drives and synchronization units. It control different mechanical parts of the machine, power the motion of servo motors and control the machine parts motion and movements. |

| Servo positioning interface | The key components are positioning control interface, encoder feedback system, and recipe storage. In this, the operator is allow to set the exact position of cartons, tube and speed of insertion. It can also control the multiple motor drives for smooth functioning of the cartoning and the machine. It can saves the specific settings for tube sizes and their cartons formation for the future production. |

6.Elaborate the working steps of tube cartoning machine?

The working steps of tube cartoning machine integrates mechanical precision, sensors feedback and synchronized process which ensures the high production tube cartoning. These are as follows:

Carton feeder:

Carton feeding into the machine

The flat cards are loaded into the machine where the smooth separation and feeding of each cardboard or paperboard occurs. There are sensors that detected if the machine is out of flat blank cards. This step ensures the smooth cards are fed into the machine. The flat cards are then moved to the cards erection station where cards are picked up and formed into the opened cartons.

Carton picking and forming:

Carton forming-Picture courtesy:gte-engineering.nl

In this step, the flat cards are picked up from the hopper and convert it into the rectangular shaped opened boxes or cartons. The opened cartons are then hold by the carton holders which is then processed to the next station. The one end remains open for the insertion of the tube.

Tube holding:

Tube holding

The tube holders align and prepare the tubes for the insertion into the opened cartons. The tubes are hold one by one in place. Sensors are integrated which shows that tubes are correctly aligned and oriented for pushing into the cartons.

Leaflet insertion:

The leaflet having information regarding the products are folded by means of folding unit and placed it into the carton. The leaflet is inserted before or alongside of the tube which makes your customer safety and satisfaction.

Tube insertion:

Tube insertion

A pusher arm push the tube from the holder into the cartons. It is inserted in the same direction in which the leaflet has inserted. The pushing of tubes into the cartons are set at controlled speed to prevent damage.

Cartons closing and sealing:

Cartons closing and sealing

After the tube insertion, the flaps of the cartons are folded over. Then the carton is sealed by tuck-in method which is sealing method without applying glue or by hot-melt glue method. The flap press station apply pressure on the flaps for strong sealing.

Inspection and rejection system:

In this section, the quality of products and cartons are reviewed. It is necessary to verify here that if the cartons are properly sealed, leaflet is present or not and clarity of codes are there or not. If some defaults are there, then the cartons are automatically rejected and collected separately for review.

Carton discharge:

Carton discharge

After the completion of cartoning of the tubes, the cartons are discharged onto the exit conveyor. From there, you can manually collect the finished tube cartons.

7.What types of products can a tube cartoning machine handle efficiently?

The diversity of handling a tubular products by the tube cartoning machine is vast. This machine is widely used in different industries because it has the capability of hold and handle different products in the cartons. The types of products it can handle are as follows:

Pharmaceutical products:

Pharmaceutical products –Picture courtesy: healwell-homeo.com

The tube cartoning machine is used to pack the ointments, creams, antiseptics, and medicinal pastes tubes in the cartons. The leaflets are inserted into the cartons for the detailed information regarding the products. In this way, the products safety, accuracy, safety from contamination are ensured and oxidation of the products are prevented.

Food products:

Food products –Picture courtesy: souschef.co.uk

This machine is used for the packaging of condensed milk, pastes, cooking pastes and chocolate spreads in tube format in the cartons. The materials used for cartons are sustainable and eco-friendly and ensure contamination-free packages and ensure hygienic packaging.

Cosmetic and personal care products:

Cosmetic and personal care products-Picture courtesy: pixpine.com

The cosmetic and personal care products like face creams, hand and body lotions, hair care products etc. especially their tube formats are placed in cartons to ensure the high quality packaging and eye-catchy styles of the cartons.

Industrial products:

Industrial products –Picture courtesy: whateverwheels

If you are running your industry in which different adhesives, lubricants, silicon pastes and cleaning agents are used then you can safely pack them in a cartons to support safe storage. It can also ideal for chemical based substances which may affect by the environmental factors but the cartons support them by storing them.

Animal care products:

Animal care products

The ointments for animal and pets, the creams and deworming tubes are packed in cartons by securing the products information in the form of leaflets. The products are also protected from external contamination and safely deliver the products to the owner of the pets and animals.

Dental and oral care products:

Dental and oral care products

The toothpastes, tooth polishers and dental gels tubes are packaged in the cartons. The products integrity remains safe and secure in these cartons from foreign agents and high efficiency of the products. The batch code print ensures the tractability of the products.

8.Can a tube cartoning machine handle multiple tube sizes and carton formats?

Are you curious about different sizes and carton formats? Yes, tube cartoning machine is capable of carrying and handling various varieties of tube sizes and carton formats but it depends upon the machine design and the automation level of the machine.

Handling multiple tube sizes:

Handling multiple tube sizes

Tube cartoning machine can handle multiple tube sizes according to the dimensions of the tubes and their dosage.

Adjustable tube holder station:

Some machines have holder station or grippers in which the tubes are securely adjusted according to their length and diameters or they have a system that automatically adjust the size of the tube.

Flexible tube feeding system:

Tube type

The tube feeding system also have system that suit according to short or long tubes. The servo controlled system allows the machine to adjust the alignment and positioning the tubes into their cartons.

Tube pushing station adaptability:

The tube pushers are often height adjustable that insert tubes of different heights into the depth without damaging the tubes and cartons.

The sensors detect the sizes and placing of tubes into the cartons. If wrongly placing of tubes in cartons occur, then it will give you signal to stop the machine.

Handling multiple carton formats:

Handling multiple carton formats –Picture courtesy: packagingcircus.com

The tube cartoning machine is suitable for handling different carton styles and sizes, customized according to the products. This can elevate your branding at the market.

Adjustable cards magazine and carton feeder:

You can adjust the magazine manually or automatically according to the width and length of the cards. The feeder pulls the blank cards from the magazine and your desired carton styled are achieved in the next station. This system has interchangeable feeder heads that can handle various formats of the cards.

Flexible carton forming station:

Carton style

The carton forming station has a suction cup that can adjust according to the carton sizes like small, medium and large cartons formation. The servo system helps in readjusting the suction cups depending upon the carton size and style.

Adjustable closing and sealing system:

The alignment of various carton height and style can be adjusted by folding guides. The glue is applied according to the carton styles.

Software support: HMI and servo interface

The operator is used to adjust the carton style, its size and format according to the tubes through the HMI screen. The system allows the repeatability of the process with high precision and accuracy without the misalignment.

9.How to maintain the tube cartoning machine?

The tube cartoning machine require maintenance to ensure the longevity of the machine. A well-maintained machine will ensure you the high productivity, precision packaging and good quality cartons production. So, here are some of the points you must be follow for the efficient working of the machine.

Cleaning and lubrication:

Cleaning and lubrication –Picture courtesy: leadrp.net

You must wipe down the machine parts to remove any dust particles, glue and wastes of the cartons. The tube and carton magazine should be clean down to remove the debris in these parts.

Also, apply good quality and light lubricants to the moving parts like chains, bearing and guide rails for proper functioning and to avoid the unwanted noise.

Inspection and maintenance:

Inspect the belts, pulleys, pushers, nuts etc. and also inspect and check the wiring and other systems. If nuts are founded loose, tight them right away. Check the valves for the correct operation of the machine.

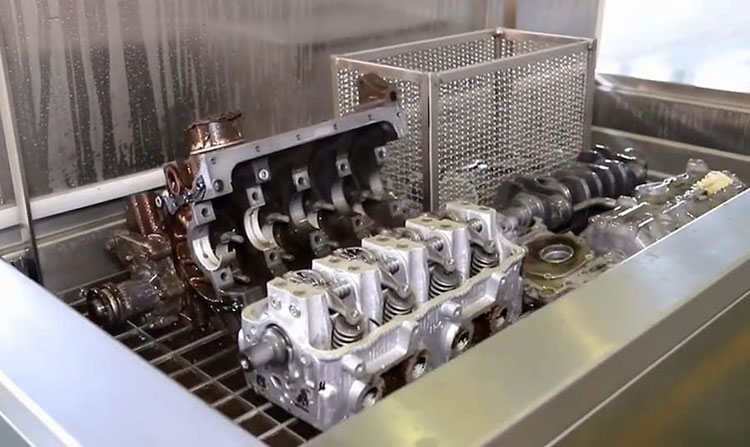

Deep cleaning and software update:

Deep cleaning and software update-Picture courtesy: enginebuildermag.com

Once in a month, you have to clean the machine parts by completely shut down the machine system. Check the sensors, and check the alignment system for proper functioning.

You can also backup the system and recipes from the HMI.

Components replacement:

Replace the worn out parts of those parts that are not functioning well. If the parts are not been replaced, then the normal functioning of the machine can effect.

10.What should you consider while buying a tube cartoning machine?

There are various machine types are available in the market but buying a correct machine for your business is very important. Some of the considerations are as follows:

Level of automation:

If you wants to invest on the semi-automatic machine then also invest on manual feeding. But if you are running your own business on industrial scale, then invest on automatic cartoning machine. This will reduce the cost of labor and will produce high production of tube cartons.

Material compatibility:

Material compatibility

Is the machine you are investing in, can handle different tube materials like aluminum, plastic or tin etc. and can it handle various carton types and carton materials like corrugated cardboard, paperboard, Kraft paper and folded carton board.

The coated cartons are fragile and can be customized into different styles for elevating your brand so, the machine also should be compatible with coated cartons also.

Cleanability and hygiene design:

A Cleanability machine is essential for the faster cleaning of the machine parts, product safety and customers’ health concerns. As the hygiene is most important factor in pharmaceutical, food and skincare industries so must look for the Cleanability features of the machine.

You must look for machine that have smooth surfaces and no sharp edges should be present in the machine.

After sale support and spare parts:

After sale support and spare parts

Always make sure the machine has the warranty. Also, if the machine is not working properly or machine parts replacement is needed then, you should easily accessible to the spare parts of the machine. Also the local service is also important for the service of the machine.

Conclusion:

A tube cartoning machine is widely used in different industries due to its versatility in handling different sized tubes. This machine is expert in handling various format of cartons for your products and pack them in an aesthetic boxes without compromising the quality of the products. You can get many advantages by using this machine. Also in 2025, different types of cartoning machines are available in the market. Hopefully, after reading this guide, you’ll be cleared about all the queries. Are you still confused about which machine is worth buying for your business? Contact AIPAK! We’ll guide you in choosing the best tube cartoning machine for your business.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine