Soap Cartoning Machine: The Complete Buying Guide In 2025

A soap that is beautifully packed not only cleans but it seals the deal too. There is nothing new about first impression is the last impression. The fragrance or that soft lather of soap will reach the audience later; first of all it’s the carton and packaging that catches the audience eye. Now it’s a world of aesthetics and ambiance, we live in.

A basic humble soap with a fancy packaging will make more space for itself than an ordinary or not well packed soap. The warrior behind all these pristine looking soap is a soap cartoning machine that is making it possible for the manufacturers to produce best cartoning of the soap to complement its formulation.

Soaps come in various size and shapes these days

These soap cartoning machines are high speed and intelligent. They have not only made the production steady but the uniformity and elegance of the soap cartoning is maintained through these machines. The automation of these machines decreases the possibilities of human error to a great extent. Let’s find out more about the factors that makes soap cartoning machines a smart investment in your manufacturing in the following FAQ!

1.What is a soap cartoning machine?

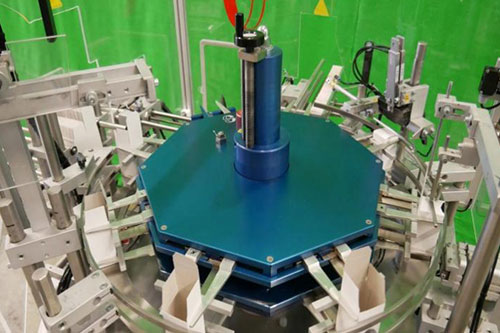

AIPAK automatic soap cartoning machine

Soap cartoning is a process that is related to the packaging of soap bars into cartons for retailing or distribution purpose. This process could be manual or automatic. The machines which are involved in this process of cartoning are known as soap cartoning machines.

The process may include cartoning of one or multiple soap bars into the cartons which further go through the process of sealing and labeling. The soap cartoning machines stream line the overall procedure and steps involved in uniform and efficient cartoning of the soap bars.

2.What are the benefits of soap cartoning machine?

Soap cartoning machines can be a game changer for the manufacturers. Soap cartoning machines provide such efficient packaging and reduce the labor cost increasing the output rate of soap packaging. These machines make sure that the soap is cartoned in such a way that it looks flawless and ready to for the shelf. Let’s have a detailed view on the benefits of the soap cartoning machine:

Consistent & precise packaging:

Consistency in packaging-picture courtesy: dreamore

The soap cartoning machines produce precise soap cartons by correcting all the misalignments and make sure that each soap bar is placed accurately in the carton.

The uniformity in carton sealing and flap folding is maintained which gives a fine look to the packaging.

Regardless of whoever operating the machine, soap cartoning machines give similar results across different shift because unlike manual cartoning, these machines are independent of skills and attention of the person doing the job.

Enhance branding and shelf appeal:

Soap cartons making the market shelf attractive-picture courtesy: the soap opera company

The packaging of a product needs to be very attractive to turn heads in a packed and busy market shelf which is made possible through soap cartoning machines.

These cartoning machines support the die cut windows which shows the product inside.

The cartoning machines make the use of premium cartoning materials which give attractive finish to the soap cartons.

The perception of the product is increased by looking at a fine and well packed cartoning which ultimately increases the consumer confidence of in the brand.

Enhanced product quality:

Customized luxury soap carton-picture courtesy: serene

The soaps produces are sometimes very fragile, these machines have gentle and adjustable pressure features to handles fragile soap bars.

The machines are advanced and automatic which ensure there is no contamination due to manual handling.

The integrity and finishing of embossed and luxury soaps are maintained through fine soap cartoning machines.

Reduce labor coast:

Less labor more profit-picture courtesy: milestone

The automatic cartoning machines cut down the requirement of man power to a great extent which is a positive outcome for the manufacturer by reduction of labor cost.

The reduction in training and supervision cost due to the automatic procedures make soap cartoning machines a great investment.

The labor previously involved in manual cartoning can be shifted to other quality control tasks to keep up with production efficiency along with the quality.

Improve hygiene & safety:

Picture courtesy: getty images

The soap cartoning machine implies stainless steel or sanitary materials in its manufacturing to maintain all the hygiene standards.

These machines are made compatible with GMP and ISO guidelines in case of pharmaceutical and cosmetic grade soap.

These machines have an enclosed and sterilized design which reduces the exposure of dust, moisture and human contamination to the soap.

Greater packaging flexibility:

Multiple soap bars in one carton-picture courtesy: Fragonard

These days you won’t find regular or basic soap cartons in the market. There is a great innovation and variety in the packaging of carton which is made possible due to the flexibility of the soap cartoning machines.

This customization is made easy and possible through these soap cartoning machines.

These cartoning machines give you the choice to pack a single soap bar or multiple soap bars in a single carton.

These cartoning machines support all multiple shapes of soap, oval, square, oval, octagon etc.

Reduced waste and cost effective:

Picture courtesy: aim to flourish

The precise and control cartoning reduce the packaging waste reducing the expense of the material.

The repacking cost is also reduced due to decreased or almost no errors in packaging.

The advance automatic cartoning machines are energy efficient, hence low operational cost.

All these factors contribute towards cost saving over time.

3.What are the applications of soap cartoning machine?

The following table highlights a range of industries that require various cartoning styles and innovations in the cartoning of their products:

| Applications | Examples |

| Retail soap packaging

Most commonly seen type of soap cartons available in the market. Soaps from different brands and manufacturers are packed in soap cartoning machines to be made available in the market. They have customized printing, window cutouts and everything required by the manufacturer. |

Most commonly available retail soap-picture courtesy: design vibes |

| Gift soap combine sets

There are promotional or gift sets, it could be a combo pack with assorted fragrances or multiple soap bars. These cartons usually have decorative dividers or sleeves for luxurious presentation. The cartoning done for these is seasonal, according to the occasion. This customization is done through soap cartoning machines. |

Soap bar gift pack carton-picture courtesy: mylittlespace |

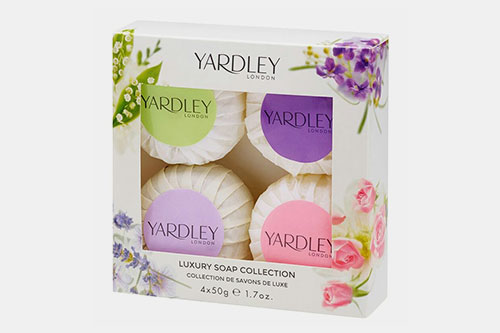

| Hotel and hospitality soap bars

This is usually done with small or mini soap bars for hospitality purpose in the hotels, spas, resorts or airplane. These cartoning machines easily handle the cartoning of small bars. The machines are also compatible with cartoning of the pillow pack soap bars. The soap bars for sample purpose are also smaller in size, they are also packed in soap cartoning machine. |

A multipack carton of mini soap bars for hotels-picture courtesy: Yardley |

| Artisan soaps

Artisan’s soaps are usually handcrafted. They are herbal soap, made from natural ingredients like clay, oil, butter or essential oils. They are usually packed through the semi-automatic cartoning machine. They are made at a relatively small scale. The cartoning machines help the small scale manufacturer to achieve consistent and elegant packaging to make the product compete with other brands in the market. |

Artisan soap-picture courtesy: sharme |

| Pharmaceutical soap bars

The pharmaceutical companies are producing medicated soaps, which require all the pharmaceutical GMP standards for packaging. The soap cartoning machines enables the cartoning of medicated soap with batch coding, expiry date printing and sealing. They follow all the GMP guidelines. |

Antifungal soap carton |

| Cosmetic and luxury

There are many cosmetic and skin care brands, which produce soap that require high end flawless packaging. The soap cartoning machines make sure to carton the soap in such way that maintains the integrity of the brand and the sophistication of carton is equivalent to the brand image. |

Cosmetic soap for skin problems-picture courtesy: Himalaya |

4.What are the main parts of soap cartoning machine?

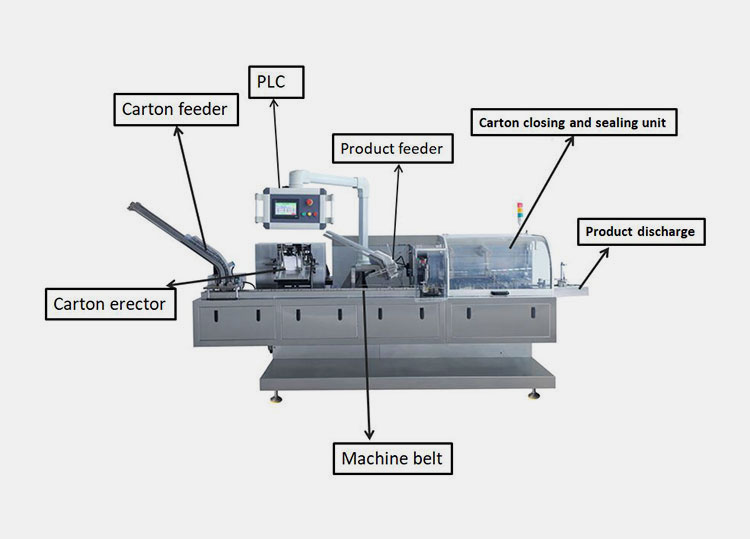

AIPAK horizontal cartoning machine parts labeled

The parts of soap cartoning machine can vary depending upon the model and type of machine, but there are some essential parts common to all the soap cartoning machines.

The main basic parts of the soap cartoning machines are explained below:

Product in feed conveyor belt:

- It is the primary system for the conveying of product and carton through the cartoning machine.

- It transports the soap bar from wrapping to the cartoning unit.

- It is well synchronized with the parts of machine for effective and precise transfer of the product.

- It could be a chain, belt or push type conveyor.

- It is integrated with metal detectors, weight checkers or vision inspection system through out to ensure the optimized cartoning of soap.

Control panel:

- Control panel comprises of HMI (Human machine interface) and PLC (programmable logic controller).

- It is the central commanding unit for all the operations of soap cartoning machine.

- The precise instructions ensure precise working and packaging of the product.

Carton feeder:

- It is the main starting point of the machine that holds the unfolded carton stacks.

- It feeds the unfolded carton from the stack into the machine.

- It is provided with suction cups to detach the carton from stack and feed into the machine.

- It has synchronized motor system which ensures the effective feeding of carton into machine.

Carton erector:

- The flat cartons are opened up here and given a proper 3D structure.

- The carton erector has mechanical arms or air jets which give the carton proper shape and open it up.

- It also ensures the proper alignment and corner creasing of the carton.

Product feeder:

- It inserts the soap product into the carton.

- It is integrated with guides and pusher system to handle soap bars of different shapes sizes and their effective insertion into the carton.

- It could be a mechanical pusher which is more common in horizontal machines.

- The other types include robotic arm or vacuum suction cups for delicate soap bars.

Carton closing unit:

- The closing and sealing of carton takes place at carton closing unit.

- The carton is closed through folding the top and bottom flaps of the carton.

- The sealing of carton includes tuck in flaps method or lock tab method which is a non-glue method.

- In high speed lines, hot glue sealing method is also implied for complete sealing of the carton.

Printing unit:

- In the high speed production lines, cartoning machines are integrated with printing and labeling unit.

- It could use thermal, inject or laser printer.

- The batch number, bar code and other required information is printed here on the closed packed carton.

Product discharge unit:

- The perfectly packed, sealed and labeled carton reaches the discharge unit.

- No faulty carton reach the discharge unit because it is already rejected through the inspection of rejection system

- The discharge unit of the soap cartoning machine can be further integrated with the wrapping or case packaging line in high speed production lines.

5.What is the principle and working mechanism of soap cartoning machine?

Soaps manufactured in different colors-picture courtesy: olivos Istanbul soaps

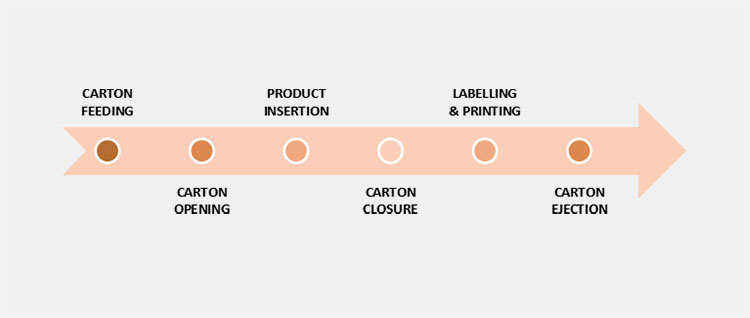

The following figure shows the sequence of events taking place in the working of soap cartoning machine:

The soap cartoning machine works on the principle of synchronized motion and mechanical automation, leading to formation of cartons from flat cardboards and automatic insertion of soap bars following closing, sealing and labeling and ejection of the carton in a coordinated sequence of events.

The following table explains the working mechanism of soap cartoning machine:

| Mechanism | Features |

| Carton feeding and erecting | The flat cardboards are detached from the stack and fed into the machine through this carton feeding system.

It is provided with suction cups and mechanical arms for feeding an opening of the carton respectively. The blanks are opened and erected into a 3D structure through folding mechanism. There are clamps which keep the carton open and ready for product insertion. |

| Soap feeding via conveyor | The conveyor belt brining in the soap bars, are aligned and spaced evenly using the guides and sensors.

The insertion of product into the carton could be horizontal or vertical depending upon the type of machine. |

| Soap insertion unit | This unit has robotic arms or mechanical pushers which ensure the proper insertion of product into the carton.

The robotic arms work like pick and place arm for inserting the soap bar into the carton. The machine has servo motor system which make the product insertion precise by making all the movements across the machine timely, avoiding any kind of collision or misalignment. |

| Carton closing and sealing | The closing and sealing of the carton is done through different mechanism.

Tuck in flaps in which the flaps are folded in a specific sequence. Some machines have lock tab or snap lock system. After the flaps are tucked in and carton is closed, it may under goes sealing through hot glue method, if required by the manufacturer. |

| Coding and printing | This step is sometimes optional.

The high speed automatic machines are integrated with coding and printing units. They have injected printer or thermal as required. The batch code, expiry and other required information is printed over packed and sealed label. |

| Inspection and ejection | There are sensors and vision inspection systems in the advance soap cartoning machines.

The vision system visually inspect for the faulty cartons. The sensors check and sense the incomplete or empty carton and send signal for rejections of the faulty cartons. |

| Carton ejection | The well packed and sealed carton reaches the ejection unit to move out of the machine.

The procedure can be finished here or the machine is integrated further for the downstream process like shrink wrapping or case packaging. |

Automation and Control:

This whole working mechanism is carried out automatically by giving instructions to the control panel of the machine. Control panel is a programmed logic controller provided with a human machine interface.

The operator conveniently adjusts the speed, carton customization, and modes of machines are changed as per requirements via the touch screen panel. The servo motors in the high speed and advances cartoning machines supports the instantly format changing maintaining high precision.

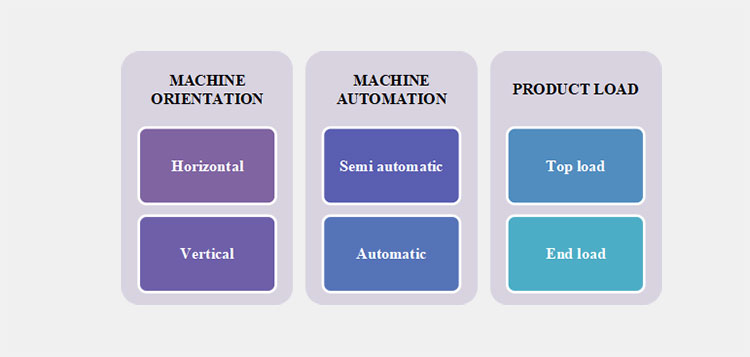

6.What are the types of soap cartoning machine?

The soap cartoning machines can be classified depending upon their automation level, direction of cartoning and orientation of the mach.

| AUTOMATION LEVEL | ||

| Semi-automatic soap cartoning machine

Semi-automatic soap cartoning machine-picture courtesy: packaging and labeling Usage: They are better suited for small scale productions. The brands with short production runs can rely on it. The handmade or artisan soaps are cartoned. |

It has combination of manual and automatic characteristics.

There is automatic forming of carton. The feeding of the product into carton is a manual process. The further process of closing and sealing of carton is done automatically by the machine. |

|

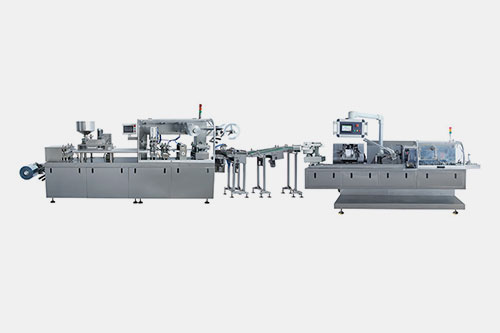

| Automatic soap cartoning machine

AIPAK fully automatic soap cartoning production line Usage: They are best suited for large scale manufacturers. These machines make the right choice for industries requiring low labor and high speed with precision. Ideal for large number of batches. |

These are the most advanced and intelligent machines system.

The whole process of carton feeding, filling, closing, sealing and labeling is automatic. The automatic machines have advanced PLC system and provided with sensors and motors for effective packaging of the soap bars into cartons. |

|

| MACHINE ORIENTATION | ||

| Horizontal soap cartoning machine

AIPAK horizontal cartoning machine Usage: They are used for high speed and continuous operations. The rectangular or any irregular shaped soap is suited in these machines. They are used in FMGC and large scale production. |

As the name suggest, the whole system of the machine operates horizontally.

The soap is inserted into the machine from side of the carton. They are compact and continuous machines, integrated in high speed operations. |

|

| Vertical soap cartoning machine

Vertical cartoning machine-picture courtesy: Rauapack Usage: They can be used for grouped or stacked soap bars. These are compatible with irregular shaped soaps. |

The carton feeding direction is vertical.

The carton is erected and opened vertically. The soap is added vertically into the carton. They have a low to medium speed. They are better implied in manual or semi-automatic feeding. |

|

| DIRECTION OF PRODUCT LOAD | ||

| Top load cartoner

Top load cartoner-picture courtesy: MLTC Europe Usage: They are used for tray and lid cartons. They support packaging of multiple soap bars in single carton. They could use manual or semi-automatic systems. |

The soap is added from the top of the carton.

The premium and fragile soaps are better suited of top load cartoning. |

|

| End load cartoner

End load cartoner-picture courtesy: propack Usage: The very commonly used soap of retail packaging is packed through end load cartoner usually. The big and heavy size soap bars are preferred in end load cartoner. |

The soap is inserted from the side of the carton.

The carton closing is done through tuck in flaps methods, often accompanied by hot glue seal method. |

|

7.What types of cartons can be used with a soap cartoning machine?

The soap cartoning machine is versatile enough to support different kind of cartons structures depending upon the market trends and consumer demands. The machine can be configured for the required structure and dimensions. The commonly available types are given below:

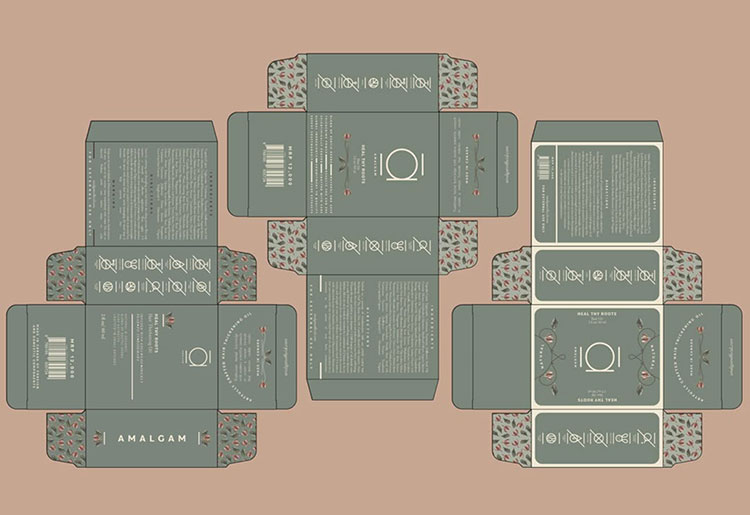

Straight tuck in:

Straight tuck in carton structure from different angles-picture courtesy: amalgam

The straight tuck in cartons have the top and bottom flaps tucked in on the same side.

They are used for light to medium weight soap bars.

They are ideal for the regular retails soap bar packaging.

Reverse tuck in:

Reverse tuck in soap carton

As the name suggests, the flaps are tucked in opposite directions in a reverse manner relative to each other.

The top flap is tucked in forward direction the bottom is tucked in reverse direction.

They are widely used in automatic cartoning lines due to convenient closure and sealing,

Window carton:

Soap carton with central window

These cartons have a transparent plastic film window or cut out to show the soap inside.

They are used for hand made or luxury decorative soaps.

The machine is configured carefully to avoid any damage to the cut our portion.

Sleeve-type carton:

The sleeve carton

The carton is open ended paper board sleeve structure that wrap around the soap bar directly.

The other way is the sleeve carton if wrapped up like a sleeve over a open mouth carton containing the soap.

They are used in premium soap packaging.

They are sustainable hence environmental friendly.

Crash lock bottom carton:

Crash lock soap cartons

These cartons have a locked base structure that gives additional support to the soap.

They are preferred for heavy soap bars due to their firm base.

They are convenient with the high speed packaging due to their firm base.

8.Can you integrate the soap cartoning machine into existing soap production line?

AIPAK soap cartoning machine integrated with high speed production line

Yes, absolutely! The soap cartoning machines are made to be integrated with the manual and automatic production lines for efficient packaging and quality products. The soap cartoning machine is placed post soap wrapping unit in the production line. The conveyor system brings the soap bars from previous unit into the cartoning machine, where the automatic process for cartoning is initiated as soon as the soap bar arrives.

Following are the essential key factors to ensure smooth integration:

Synchronization:

The speed of the soap cartoning machine should be in accordance to the speed of machines involved in upstream process that take place before cartoning.

Product orientation:

The feeding system is required to be aligned with guiders and pushers so that the soap bars are positioned correctly with proper spacing and alignment to make the cartoning efficient.

Control system interface:

The PLCs (programmable logic controller) of the machines linked together in production line, are required to be linked together to make the synchronization effective.

Foot print and lay out:

Whenever you are adding any equipment or machine to the existing production line, it is recommended to make sure there is enough physical space because these machines usually require a large space for their operations.

There should be proper space for inlet conveyor belt, outlet conveyor belt and machine body for its effective working and avoid any kind of incident. The layout of the machines is the order plan according to which the machines are arranged. The wrong lay out could cause damage to the soap.

9.How sustainable carton material does affect the working of soap cartoning machine?

Sustainable and environmental friendly packaging

The sustainable and eco-friendly material reduces the carbon footprint.

They put a positive image of the manufacturer, reflecting the nature and eco-friendly image of the company.

The sustainable packaging is also usually lighter in weight due to its simple formation, which reduce the shipping cost and reduced fuel usage.

The erection and effective closing of the sustainable cartons could be difficult because they are less stiff and sturdy.

There could be alignment or feeding issues in the machines due to friction caused by sustainable carton material.

The krafted and recycled cartons boards can wear off the cutting and folding tools faster than the regular cartons.

Speed adjustments with fine tuning are regularly required while dealing with such material.

10.What are the common faults or trouble shooting in soap cartoning machine?

Picture courtesy: red hat partner

The most commonly reported trouble shoot and faulty issues in the soap cartoning machines are as follows:

- The suction cups are sometimes worn out or the vacuum pressure is very low which causes the inability of feeder to pick up the carton from the carton feed.

- The solution requires replacing of suction cups and adjustment of vacuum pressure.

- The cartons failed to open up properly stiff or wrapped cartons due to the use of poor carton material.

- The irregular shape of soap and mismatched timing can cause jamming in the machine.

- The clogged glue nozzle or empty glue tanks cause improper sealing of the carton.

- The wiring issues or dust on the sensors could cause the failure of sensors by not detecting the product or other faults in the carton could go unnoticed.

- The overloading, opening of safety doors or any sudden system error can result in sudden or frequent machine stops.

Conclusion:

You must have understood by now, the versatility and importance of the soap cartoning machine. Because it’s not only about boxing of soap in a carton, it is the story of delivering a unique and pleasant experience from the company to the consumer. Soap cartoning machine is a key player to maintain the efficient and smooth packaging while maintaining the consistency and quality. Apart from the efficient working of the soap cartoning machine, it is the flexibility of the soap cartoning machine with the existing production line that make it user friendly and help in growth for the business. For more information and questions refer to our AIPAK website.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine