How to Choose the Right Tablet & Capsule Counting Line for Pharmaceutical Production?

Have you ever been amazed by the accurate number of tablets or capsules in every medicine pack you buy? Do you know who is behind this perfection? It’s wonderful piece of equipment, known as tablets & capsules counting line.

This article will help you understand how to choose the right tablet & capsule counting line for pharmaceutical production. It covers all the key aspects that can assist you in selecting the most suitable machine. You are going to learn much more about this equipment including its functions, applications, types, sizes, products it could handle, counting methods, integration options and compliance requirements. Let’s dive in!

1.What is a tablet and capsule counting line?

AIPAK Tablet & Capsule Counting Line

Tablet and capsule counting line is a combination of different equipment used to count and pack tablets and capsules in to containers. All the machines in this line are automated and mainly used in pharmaceutical industry to dispense an accurate number of tablets or capsules.

2.Why is accurate counting crucial in pharmaceutical production?

Accurate Counting Is Crucial In Pharmaceutical Production

As per EU GMP (European Good Manufacturing Practices), the reconciliation of number of units is mandatory, so accurate counting is crucial in pharmaceutical production. It ensures that each package holds the exact number of tablets or capsules mentioned on the label. Moreover, it helps prevent more or less filling and reduce product wastage. In this way it supports dose precision, patient safety, and compliance with regulatory standard.

Real case study: FDA recall of Apotex Drospirenone-Ethinyl Estradiol tablets due to inaccurate tablet arrangement.

Source: U.S. Food & Drug Administration (FDA) recall notice, Apotex Corp., Weston, Florida (U.S.)

Background:

Drospirenone and ethinyl estradiol are a combined oral contraceptive, available in 28 count blister packaging. It includes 21 active yellow tablets and 7 placebo white tablets. Accurate order and count is necessary to achieve therapeutic effects. Absence of even a single unit can cause contraceptive failure, jeopardizing regulatory approval and patient wellbeing.

Problem identified:

As per FDA recall report, four batches of this contraceptive tablet were found to have faulty blisters, empty blister pockets and inaccurate tablet arrangement

The issue created due to:

- Inaccurate counting verification

- Inspection error

- Incompetence to GMP requirements for final packaging

Regulatory solution:

Apotex commenced a voluntary class II recall with FDA awareness and oversight. The measures included:

- Direct and immediate notification to distributors and wholesalers.

- Isolation of all affected product batches.

- Providing patients with directions to use a non-hormonal supplemental contraceptive method.

- Recovery of defective units.

3.How many tablets or capsules do you produce per hour?

Number Of Tablets Or Capsules Per Hour

The number of tablets or capsules that can be produced per hour is totally depends entirely on the capability of equipment. Regulatory bodies like GMP (Good manufacturing practices) only demands for authentic processes and documented control at whatever speed you run.

| Speed of counting line | Tablets or capsules per hour |

| Low speed counting line | 3000-1000 tablets or capsules per hour |

| Moderate speed counting line | 20,000-120,000 tablets or capsules per hour |

| High speed counting line | More than 300,000 tablets or capsules per hour |

4.What types and sizes of tablets or capsules are you handling?

Types & Sizes Of Tablets Or Capsules

As per recommendation of FDA (Food and drug administration) guidance, the dimension of tablet should not be more than 22mm and capsule should not exceed the standard size 00. As far as shape of tablet and capsule is concerned, it must be easier to swallow for patient to optimize the patient compliance.

Generally tablet and capsule counting line is designed to handle various types of tablets or capsules. It can process coated and non-coated tablets of different shapes such as round, oval or oblong, and can also handle hard and soft gel capsules. In terms of size, it can accommodate tablets ranging from 5mm to 25mm in diameter, while capsules sizes usually vary from 000 (largest) to 5 (smallest). The stable and efficient performance of machine shows its flexibility and versatility in handling different dosage forms.

5.Are there special requirements like coated, fragile, or high-value products?

Special Requirements For Coated, Fragile & High-Value Products

Yes, there are special requirements related to coated, fragile or high-value products and such products require risk control as per regulatory guidelines.

Coated tablets:

Do you have an idea about risks related to coated tablets? Coating could get damaged by many factors like humidity, excess mechanical pressure while feeding, counting or packaging. This affects the dose precision and efficacy of drug. As per PIC/S (Pharmaceutical inspection convention scheme) guidance, the equipment must be designed prevent any damage and contamination to product. It must have features that support proper handling like

- Vibration free feeding mechanism

- Desirable environmental conditions in terms of humidity and temperature

- Chemically compatible contact surfaces

- Automated inspection

Fragile products:

Fragile products have the risk of chipping, cracking or breaking during feeding, counting and packaging. This leads to product rejection and patient safety problems. According to EMA (European medicines agency) the processes and equipment both must be capable enough to handle sensitive products to maintain the product quality. Counting line needs to be equipped with

- Low impact feeding system

- Proper inspection system

High value products:

Commonly high value products are at possible risk of being stolen, counterfeit, lost or tampered during production. FDA CGMP guides to provide suitable control, protection and documentation for manufacturing and distribution. For this purpose, following measures need to be taken:

- Strict inspection during production process by using camera system and closed setups.

- Keeping such products in limited access zone.

- Tamper evident packaging to maintain traceability during supply chain.

- Documentation and physical inventory checks.

6.What counting methods are available?

Available Counting Methods

Here you can get an idea about the counting methods that are available in tablet and capsule counting line. Basically the machine can count products either by weight or by using sensors. Let’s take a closer look on these on these two methods to understand how each one works.

Weight-based counting method:

A literature Dispensing techniques tells about the weight-based method in which a weighing balance can be used and weight of sample unit is used to determine. After that, the entire batch is weighed to compute the approximate number of units.

However, this method is only reliable when tablets or capsules have a uniform weight.

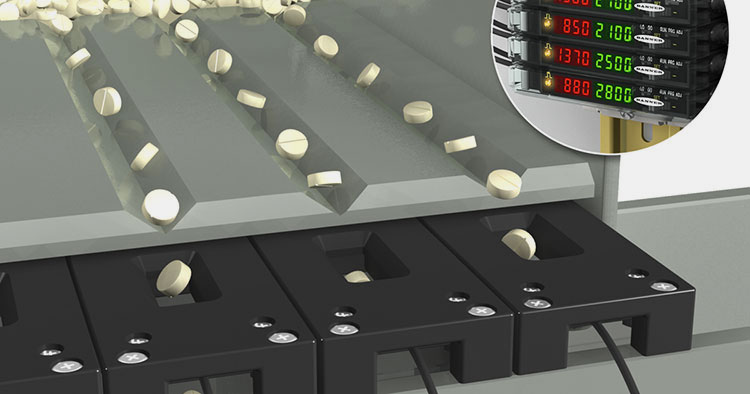

Sensor-based counting method:

A well-known equipment manufacturer AIPAK claims this method as most reliable and GMP-compliant counting method used in tablet and capsule counting line. In this process, tablets or capsules pass through a photoelectric sensor, infrared beam or camera system and each unit is detected and counted by the system. It is highly precise method that can handle tablets and capsules of different types, shapes and sizes.

7.How important is speed and accuracy for your production volume?

Importance Of Speed & Accuracy For Production Volume

The speed and accuracy is very important for your production volume, as GMP (Good manufacturing practices) demands consistency, precision and validated processes. The quality of product depends on the right balance of both. Let’s suppose you have a vast production volume, speed helps complete the entire production on time, while accuracy ensures that each container receives the exact number of tablets or capsules. In addition, accuracy helps the product stay compliant with regulations and ensures it is reliable and customer-friendly.

Real case study: How speed and accuracy contributes in seamless production.

Source: Pharma GMP

Background:

A medium scale production facility was unable to fulfill market demands while maintaining the GMP-compliant quality requirements. They had experienced fluctuated results, slow production, and manual documentation bottlenecks. It costed them least production volume and delayed product supply.

Problem identified:

The manufacturer was using manual equipment and it was causing him serious issues related to entire production.

- Manual feeding, counting and packaging slowed production speed.

- High deviation rates were seen.

- Human dependent processes were causing errors.

- Inappropriate documentation increased audit time.

- Inaccuracy was causing low production capacity.

Solution:

The company made below changes to improve speed and accuracy:

- They upgraded the manual handwritten log by digital systemsknown as automated environmental monitoring and CAPA.

- They used advanced technology automated equipment for counting and packaging.

- They replaced the paper batch records with electronic batch records (EBR).

Outcome:

Deviation rates decreased by 35%.

Batch completion time reduced by 20%

Audit findings dropped by 40%

8.Does the machine support automatic rejection of defective units?

Machine Supports Automatic Rejection Of Defective Units

Yes, a literature by Pharma packaging systems discussed about the capabilities of tablet and capsule counting line which claims that the machine supports automatic rejection of defective units. You can experience different defects like chipped, broken, misshaped or poorly coated tablets or capsules. The machine is equipped with sensors and cameras that detect the defective products as they pass through it. This allows the machine to remove the defective units before they are packed into containers; guaranteeing only fine quality products reach the end stage packaging.

9.Can it handle multiple formats or batch sizes efficiently?

This Machine Can Handle Multiple Formats & Batch Sizes

According to AIPAK, this machine can handle multiple formats and batch sizes efficiently. You know it well that pharmaceutical industries often deal with tablets or capsules of various types, shapes and sizes. Moreover, production may involve small, medium or large batch sizes. The machine’s flexible feeding system, sensor technology and automation ensure smooth operation and high performance across all formats and batch volumes.

10.How easily can the counting line integrate with your existing bottling or blister packaging lines?

Integration Of Counting Line With Bottle Packaging Line

The counting line can integrate easily with your existing bottling or blistering packaging lines but you need to consider some important aspects. Let’s discuss them!

Modular units:

According to NJM packaging, counting lines with modular units can easily integrate with other packaging lines due to having capability of reducing or excessing their capacity coherent to production needs.

Flexible batch processing:

Urban pack line explains that the counting line must be flexible enough to handle different batch sizes like small, medium or large and also packaging formats like blisters, bottles or cartons. This flexibility allows it to integrate conveniently with other equipment, as it can adjust to match with speed and capacity of existing bottle or blister packaging line.

Adaptable conveyor system:

NJM packaging discussed the importance of standardize bottle-conveyor interfacing, which allows easy integration with bottle or blister packaging line by ensuring the smooth and uninterrupted product flow. As this machine comprises of conveyors, bottle feeding system and sensors for bottle position that enable the integration.

Efficient sensor and control system:

Dnc automation stated that counting line can integrate easily with bottle or blister packaging line when it is equipped with an efficient sensor and control system. In addition, sensor system ensures streamlined product flow, while control system coordinates the operations of all machines, resulting in smooth and continuous operation.

11.What role does automation play in reducing labor and human error?

Automation Helps To Reduce Labor & Human Errors

According to Pharma GMP, automation plays a significant role in reducing labor and human error, but how? You will get to know it by reading this topic!

Handling repetitive tasks:

Tablet and capsule counting line performs many important tasks repeatedly as part of the production process and automation helps handle these tasks like feeding, counting, and packaging seamlessly. It lowers up the need for multiple operators resulting in reduced labor and human errors.

Detecting and rejecting products:

Automation helps the counting line detect defective products by using advanced sensor systems like photoelectric or infrared beam etc. Moreover, it also ensures that poor quality products are automatically rejected before final packaging. This feature enhances the accuracy and overall performance of the equipment.

Synchronizing counting line with integrating equipment:

Automation is crucial in aligning all the machines in counting line and also plays role in synchronizing it with other integrating equipment. It promotes a consistent product flow and minimizing manual intervention, which helps reduce errors.

Minimizing human intervention:

An automated counting line requires little to no human intervention for most of the tasks. By minimizing the manual involvement, it reduces labor requirement and human errors, ensuring that production remains compliant with regulatory standards.

12.How does the counting line ensure compliance with FDA, GMP, or other regional standards?

Tablet And Capsule Counting Line Ensures Regulatory Standards

After learning about tablet and capsule counting line, a question arises as to how this advanced equipment ensures compliance with FDA, GMP or other regional standards? As per Pharma GMP recommendations, counting line needs to incorporate certain key features that enable it meet these regulatory requirements, as described below.

Machine material:

When tablet and capsule counting line are constructed from high quality materials like stainless steel, they easily comply with regulatory requirements. Stainless steel is corrosion resistant and non-reactive, ensuring that product quality remains unaffected.

Machine design:

Tablet and capsule counting line must have design that allows easy cleaning and timely maintenance of its parts. Moreover, it should be capable of preventing cross contamination between batches by incorporating proper physical barriers.

Use of advanced technology:

By employing advanced technology at every stage of process, the counting line ensures compliance with regulatory standards. The use of modern counting methods enhances accuracy and adherence to these requirements. In addition, the detection and rejection of poor quality units further contribute to keeping the equipment compliant with regulatory guidelines.

Data recording:

The feature of automatically recording every action throughout the production process ensures full transparency and traceability. This capability not only facilitates monitoring and quality control but also helps the equipment comply with regulatory requirements.

13.Does it provide traceability and audit-ready documentation?

Tablet & Capsule Counting Line Provides Audit-Ready Documentation

As we discussed earlier that tablet and capsule counting line is regulatory compliant equipment, so inherently it provides traceability and audit-ready documentation. Usually a document is prepared containing all relevant production data such as batch history, machines used, process steps, and material details. In addition, integrating the counting line with a manufacturing execution system (MES) enhances the traceability and simplifies the auditing process.

14.How to summarize the factors for selecting the right tablet and capsule counting line?

Key Factors For Selecting Right Tablet & Capsule Counting Line

You must look for below key factors while selecting right tablet & capsule counting line.

Offers precise and accurate outcome:

Your counting line must deliver precise and accurate results to ensure product quality and maintain the authenticity of the production process.

Shows versatility:

Tablets and capsules are available in various shapes, types and sizes. Your counting line must be versatile enough to handle all product formats efficiently and accurately.

Fulfills production needs:

Production needs can vary according to batch size, market demand or product type. Your counting line must be adaptable to these requirements and capable of meeting variations in production demands efficiently.

Possesses automation:

Automation offers numerous advantages making the entire production process more robust, precise and accurate. You must check that counting line possesses complete automation in order to achieve the high performance.

Supports integration:

A continuous product flow requires proper integration of counting line with other equipment such as packaging lines. Your counting line must support such integration to enhance the smooth product processing and optimize operational speed.

Provides convenience in cleaning and maintenance:

As per GMP journal, your counting line must be designed to allow easy cleaning and maintenance. This not only reduces the downtime and prevents cross contamination but also contributes to optimal performance.

Ensures adherence to regulatory guidelines:

Your counting line must be equipped with all features necessary to comply with regulatory guidelines. It should be capable of generating documentation that supports audit ready traceability.

Conclusion:

This topic provides guidance on how to choose the right tablet and capsule counting line for pharmaceutical production. Opting an appropriate machine is crucial for maintaining product quality and ensuring an optimal production process. So it is necessary to carefully evaluate the equipment before making a selection for your business. For more information, you can visit AIPAK at any time!

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine