Food Cartoning Machine: The Complete Buying Guide In 2025

Are you wondering how food is packed in cartons? There is a machine known as a food cartoning machine that efficiently packs your food products in a carton. This food cartoning machine securely pack not only one kind of food but can packs a wide variety of food from frozen meals, cereals to ready-to-use food.

Various innovations in cartoning machines will come across you in 2025 such as automation level, production speed, material handling and many more. This machine smoothly handles cartoning forming, product insertion and sealing. With advancements in cartoning machine, you can pack your product in various carton sizes and designs.

If you own a small-scale or large-scale food production and looking for a machine to upgrade your production, this buying guide will help you to know about food cartoning machines. Let’s explore the world of food cartoning machine.

1.What is a food cartoning machine?

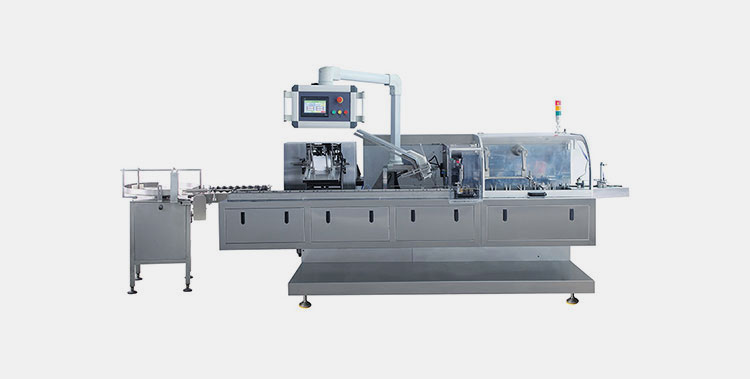

AIPAK food cartoning machine

Food cartoning machine is an automated packaging machine that is designed to pack a food product in a carton. This machine carries multiple tasks in one continuous and smooth process such as molding the carton sheet in a desired shape, inserting the food product, sealed and even label it. Food cartoning machine is an advanced machine that packages a variety of food products such as snacks, ready-made meals, and other foods. It can improve production speed, consistency, reduce the manual labor and maintain the hygiene of food.

2.Do you know the advantages you can get from a food cartoning machine?

Behind the neat, clean and precise packaging of food products, there is a technology and this technology is food cartoning machine. It showers manufacturers with benefits that it becomes a high demand. Let’s unwrap the benefits of this machine.

Improve hygiene

Improve hygiene-Picture courtesy: conveniencestore.com

Maintaining hygiene of the food is important to satisfy the consumer and improves the brand image. The machine parts are made of stainless steel and there is less intervention of humans so this reduces the contamination.

Provides product safety

Provides product safety-Picture courtesy: Virasmart.com

Another advantage you can get is that it protects the food from moisture, temperature and other environmental factors as food products are sensitive to these. Many manufacturers worry about their safety but this prevents spillage and other defects, and ensures food is fresh and safe.

Increase production speed

Increase production Speed-Picture courtesy: summitpackaging.com

Food cartoning machine packs food products in a carton at high speed. It can handle hundreds of cartons. Hence, this increases the production speed. By an automated design of this machine, large market demand can be met.

Versatility

Versatility-Picture courtesy: cyymc.com

This machine can handle food products to be packed in various cartons sizes and styles. Does it carton one kind of food? Not. You can carton different kind of food in a single machine and you don’t have to buy separate machines for food products.

Customization

Customization -Picture courtesy: chowhound

Brands can customize cartons for their brand promotion. Logos, product details and other information are printed on cartons. Thus, all this can be done in one go-process. You can easily grab the brand products by this differentiation.

Reduce labor cost

This machine works automatically, reducing the involvement of humans in cartoning food products. This results in less wastage. It eventually reduces the waste of packaging material.

3.What are the applications of a food cartoning machine?

Food cartoning machine offers wide variety of its application in different industries. Products are packed in a carton to provide protection while shifting from one place to another. Cartoning machine handles all this. Following industries are pinned below that uses this machine.

Food industry

Food industry-Picture courtesy: cartonservice.com

In food industry, cartoning machine is used to pack different food products such as cereals, tea bags, frozen meals, beverage powders etc. It packed food accurately and maintains the hygienic standard that needs for food to retain freshness and safety.

Food is packed in an attractive carton that appeals the consumer.

This machine provides protection by sealing and packaging.

Here below you will know what are the food industries where food cartoning machine is used. So here you go.

| Food industry | Explanation | |

|

Dairy industry |

Dairy products such as cheese, milk, yogurt etc. are all packed by using food cartoning machine. This machine ensures best hygiene so they are packed in clean and attractive cartons. |

Diary industry-Picture courtesy: packaginggateway.com |

|

Bakery industry |

In bakery industry, a food cartoning machine is used to package the bakery goods such as cookies, cakes, cupcakes, breads etc. These goods need protection from environmental factors; these cartons provide protection from damaging and

crushing. What else a customer needs than a fresh bake goods, that is all by blessings of food cartoning machine. |

Bakery industry-Picture courtesy: ecopakonline |

| Beverage industry | Variety of products such as soup, coffee, sauces, tea etc. are packaged in cartons, sometimes bulk quantity of any product is packed in one carton for retail. This improves the packaging presentation. |

Beverage industry-Picture courtesy: graphicpkg.com |

| Snack food industry | Have you ever seen nuts, chips, popcorns etc. in a safe and eye-catchy cartons? These products are packed in such amazing cartons that attract customers to their shelves. |

Snack industry-Picture courtesy: thimm.com |

Nutraceutical industry

Nutraceutical industry-Picture courtesy: emenacpackaging.com

Nutraceutical industry uses this machine for its efficiency. Protein powder, vitamins, dietary supplements etc. are cartooned. It can pack it kits or in daily-dose packs. This machine not only place your product in cartons but also an important information such as instructions, or certifications such as gluten-free and organic.

Pet food industry

Pet food industry-Picture courtesy: ibexpackaging.com

In market, pet foods have separate shelves. You might have seen their food packed in neat cartons. Do you think what machine will be behind this packaging? Well, food cartoning machine is used to carton and seal them consistently and efficiently. Nutritional information, production and expiration date and barcodes are labeled on cartons by cartoning machine.

Pet foods are packed in various cartoning styles and then placed them solely or in group in a carton.

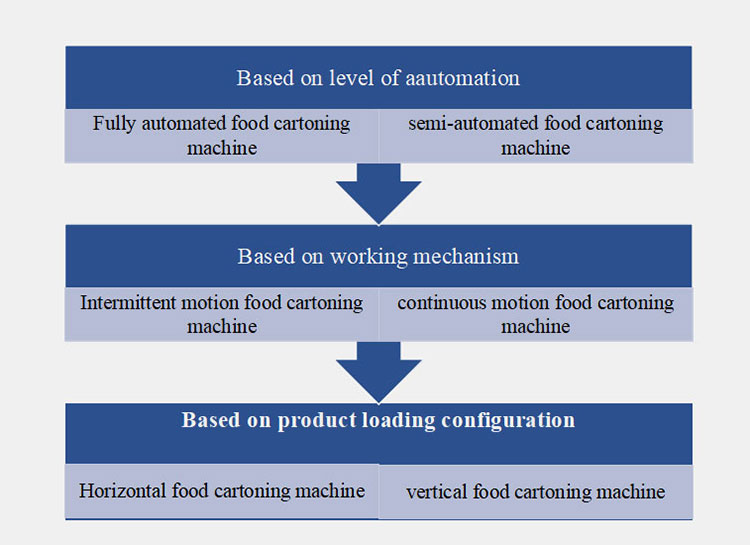

4.Enlist the types of a food cartoning machine?

There are different types of food cartoning machine, each categorize on the basis of automation, product loading and on design. Let’s explore the world of types of food cartoning machine.

Based on level of automation

Food cartoning machine is classified on the basis of automation. Here these are:

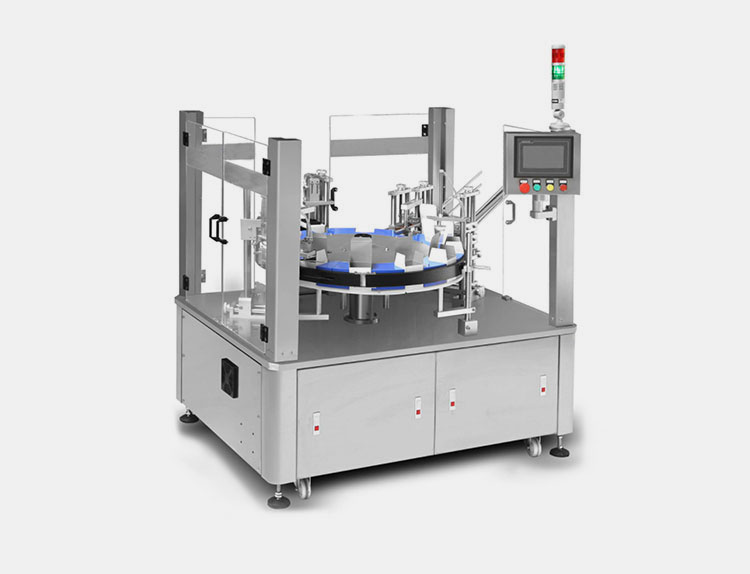

Fully-automated food cartoning machine

AIPAK fully automated food cartoning machine

This type of machine is designed in such way that it operates all the functions automatically. There is no human intervention so there are fewer chances of mistakes. The carton formation, erection and product insertion are automatically done.

It works by erecting the flat carton. Food product is fed into the machine by a conveyor that is put in a carton by robotic arms and sealed.

This is ideal for large-scale production.

Semi-automated food cartoning machine

Semi-automated food cartoning machine-Picture courtesy: jochamp.com

As from the name of this machine, some of its operations are manually done and some automatically. This is ideal for small and medium-scale production.

In this machine, cartons and products are manually fed into the machine. Then, the machine automatically forms and erects the carton. Food products are automatically inserted in cartons which are sealed by an automated feature.

Based on working mechanism

Intermittent motion food cartoning machine

Intermittent motion food cartoning machine-Picture courtesy: serpapackaging.com

This type of machine works in step-by-step manner. It stops after each step to ensure precise and accurate operation. A fragile food product such as cookies, tea bags etc. is handled by an intermittent motion food cartoning machine.

From carton erection to sealing, this machine flows the stop-go pattern.

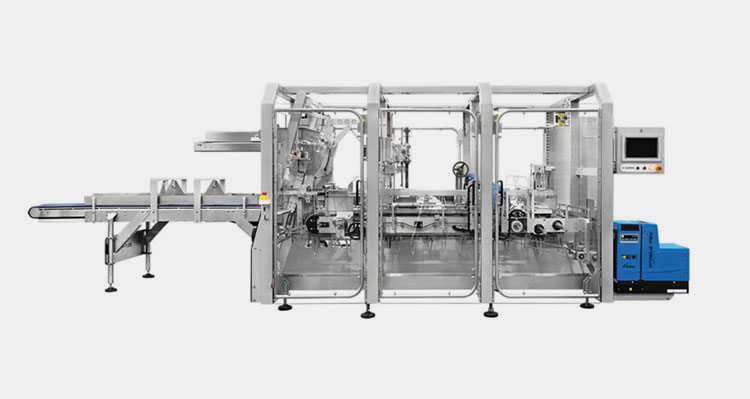

Continuous motion food cartoning machine

Continuous motion food cartoning machine-Picture courtesy: directindustry.com

You can guess its function from the word ‘continuous’ that it operates continuously. It is ideal for large production where speed and efficiency matter as it operates at high speed. It works by loading cartons and food products continuously. Products are inserted in cartons and sealed quickly.

Based on product loading configuration

On the basis of product loading, food cartoning machine is classified in following types.

Horizontal food cartoning machine

AIPAK horizontal food cartoning machine

In this type of machine, every process, means product feeding or cartons shaping, all done horizontally. The food products are inserted into cartons from side. The product is pushed in cartons horizontally and seal the flaps. It is best for flow-wrapped snacks or trays.

Vertical food cartoning machine

Vertical food cartoning machine-Picture courtesy: endflex.com

Vertical food cartoning machine is designed to vertically insert the food product in cartons. Dry pasta, tea bags, snacks are mostly cartooned by this machine. Cartons are hold upright and food products are inserted from top using robotic loader.

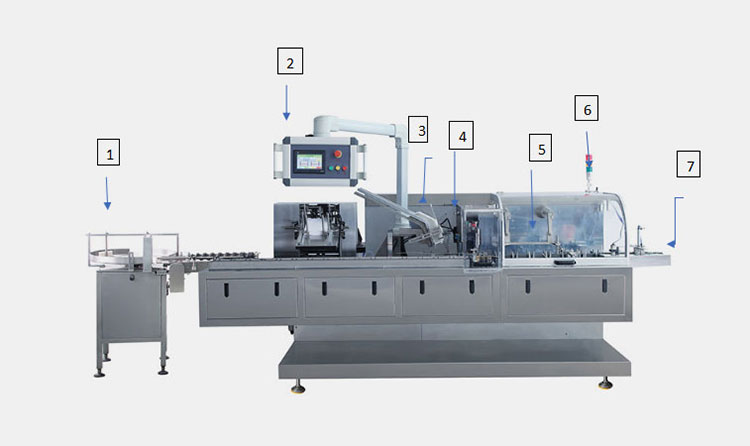

5.Do you know the components of a food cartoning machine?

AIPAK food cartoning machine

These components work together to efficiently and accurately do the cartoning. Components work in cooperation enhance smoothness and increase the production, whether you are cartoning snacks, beverages or bakery products. let’s learn these.

| Components | Explaination |

| Infeed unit | The process starts from here where the food products are entering the machine. The food products in trays, pouches, bottles or in sachets are feed in machine. There is guide rails and conveyor belt that ensures that each product is deliver timely and accurately. High speed and error free packaging are all depend on the smooth function of infeed unit. |

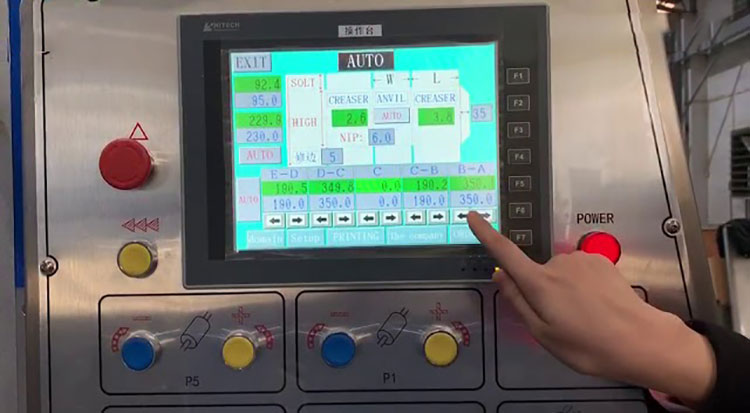

| Control panel | It is the head of cartooning machine that controls the whole process. Through a user-friendly control monitor, it manages the machine operation. Through this digital panel, the production speed, manage different products and their sizes are managed by operator from here. |

| Box holder | The flat carton blanks are picked here and then postponed them for forming. Then, they are erected before products are inserted. Here, it is made sure that no cartons are misaligned, properly shapes, no missing or jamming that can improve the production and machine speed. |

| Pushing unit | How food products are inserted in cartons? They are inserted by using a pusher arm that gently out the products in erected cartons. There is synchronization unit that checks whether the cartons are opened for products or not. The guide rail also works with them to ensure no product is damages or fall out. |

| Carton sealing unit | After food product is inserted in cartons, they are moved to sealing unit to seal the cartons. Here, glue or tucking method is used to seal the carton flaps. The sealing arms press the flaps to tightly seal them and make the cartons suitable for transport. |

| Warning light | Warning lights are used to indicate the safety or show a warning if there is an error. As you can see there are three lights such as red for faulted, green for running and yellow for paused; indicated different machine condition. |

| Output | It is the final section. Once the carton is shaped, food products are inserted and sealed they are passed to

this section. The cartons are collected and make them ready for shipping and ready-to-use. |

6.What is the working principle of a food cartoning machine?

A food cartoning machine works by following a systematic sequence. The packed food in cartons is not simply inserted. There are various steps behind this attractive, safe and precise packaging. Here below, you will know the step-by-step working of a food cartoning machine.

Carton loading

Carton loading

For making cartons, flat carton blanks are needed. Without cartons, the process does not proceed forward. In hopper, flat pre-cut pieces of cardboards are loaded. During loading, it is cautiously placed to avoid damage to carton blanks. These are moved to the erection station through conveyor.

Carton erecting

Carton erecting-Picture courtesy: rochain-cupmachine.com

Open or flat cartons are changed in the proper box shaped. This is all done by using mechanical arms or vacuum suction cups. These arms or cups pick up the blanks and fold them in designed styles.

All you have to do is carefully carton erection; even a slight defect can result in crap loading and sealing.

Product loading

Product loading-Picture courtesy: ketegroup.com

The food products are load in machine. The speed is managed to prevent the bottleneck. Here, there are features like product counting, grouping and proper orientation. What’s next? Funnels, automated pushers or arms that does the function of product insertion in cartons.

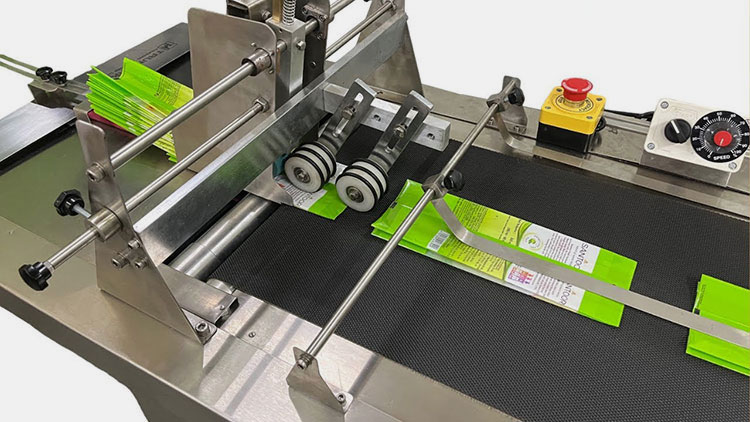

Carton’s flap closing and sealing

Cartons flap closing and sealing -Picture courtesy: rmlmachinery.com

After product is loaded in cartons, the next important step is flap closing and sealing. With help of flat plats, flaps are folded to ensure a clean fold. After flaps folding, sealing is done by tuck-in, hot glue or cold glue methods. Any of these methods are used depends on the product size, weight, and packaging material.

Carton discharge

Once the product is fed and sealed, cartons are moved out of machine through outfeed conveyor. In some of machines, there is a rejection system that remove the incomplete and unsealed cartons.

7.What type of cartons are handled by a food cartoning machine?

Food cartoning machine is used in many industries. So, one type of carton style does not use in all industries. It can handle various cartons style. Excited to know? Well, following below are the carton styles this machine can be processed.

Top-load cartons

Top-load cartons-Picture courtesy: grocers.com

In top load cartons, food products are inserted from the top. You have seen that you open the powder soups, spices, tea sachets cartons from top. Products are neatly packed and are good packaging for pourable stuffs.

Wrap-around cartons

Wrap-around cartons-Picture courtesy: graphicpkg.com

As you can assume from its name, its flap is wrap around food products and then sealed. This type of packaging is mostly used to carton beverages bottles, cans and jars.

This kind of cartons are ideal for multipacks and group of can or jars.

End-load cartons

End-load cartons-Picture courtesy: ibexpacakaging.com

Have you ever seen a frozen meal pulling out from side of cartons? This type of carton is end-load carton. Food products are inserted from either left or right side of carton, sealed using a tuck-flap.

Pasta, read-to-eat meals etc. are packed in this carton format.

Sleeve cartons

Sleeve cartons-Picture courtesy: almujahidprinting.com

Bakery items, desserts, ready-meals etc. are packed in sleeve cartons. A question may pop in mind that isn’t this carton if wrap fully can spoil the food products? This carton does not fully enclose the products but partially wrap.

Customers can see the food product from the clear film and this also enhances the brand image.

Gable-top cartons

Gable-top cartons

These cartons have pointed top. All you have to do is to pull the spout out to open it. Milk, juices etc. are often packed in these cartons. It is resealable.

8.What are the factors that influence the performance of a food cartoning machine?

There are several factors that affect the speed, accuracy and overall product quality. So, to reduce the downtime of food cartoning machine, knowing the following factors are necessary.

Product consistency

A food products have different characteristics, some are small or large in shape, variant density etc. These may not properly be packaged in a carton. Sticky and irregular shaped products also causing handling trouble.

Speed

Speed

Production speed is good when it comes to the fast-cartoning process. But there is limit of everything. Over-fast speed can create hurdles for machine and results in error and damaging of food products.

Carton quality

Carton quality- Picture courtesy: pakfactory.com

Cartons plays an important role in quality of food products. If cartons are of poor quality, it results in jamming, misalignment and poor sealing.

Automation

Automation-Picture courtesy: tmrobot.com

The automation features in machine can enhance the output. All the parts in automation readily work together, but poor integration causes the machine to stop.

Cleanliness

Another factor that influences the performance of food cartoning machine is negligence in cleaning. Sticking of dust particles and remaining of glues-buildup hinder the performance of cartoning machine by hinder the sensors and moving particles.

9.How to maintain a food cartoning machine?

For long-life and better performance of food cartoning machine, maintaining is necessary. You have to consider the following points to maintain the machine.

Lubrication

One of the important things is to do lubrication of moving parts. This reduces the friction and machine works smoothly. Over-lubrication causes problems. So, use the lubrication oil or grease according the manufacturer guideline.

Monitor glue temperature

Monitor glue temperature-Picture courtesy: gluemachinerycorrporation.com

For sealing glue is used. But this glue is melted for better sealing. If temperature of glue is to low, weak sealing of cartons will be done. If too high temperature can degrade the glue and also nozzle will be damage.

Software updated

Software update

Manual system of cartoning machine does not improve the performance and slow down the production speed. Thus, update your machine software. This makes the machine performance better and efficient, along with this bug would be fixed.

Maintain cleaning

Cleaning is important to maintain hygiene of the food. Dust particles and debris build up overtime, its cleaning is necessary otherwise it can affect the machine efficiency. Use a cleaner to clean them to prevent any microbe’s accumulation.

Maintain records

Maintain records of machine cleaning, lubrication, and other maintenance activities. By looking at this, you can analyze and follow the preventive maintenance.

10.What are the factors to consider when buying a food cartoning machine?

A cartoning machine has an impact on your production speed, quality and other related to products. Investing on a food cartoning machine is a big decision. Hence, the following below factors should be considered when buying a food cartoning machine.

Speed

You better know how many cartons you want to be packed. According to your production demand, choose a machine. Some food cartoning machine have slow speed that is compatible with small scale production. While some have high speed that meets high production demand. So, choose a machine that suits you.

Changeover

Changeover

If you are planning to handle different food products, quick change over is necessary. Buy a machine that has quick changeover features. This reduces the downtime.

Handling method

Different products require different handling methods as some products are fragile and some are hard. Foreample cookies and other baked products require gentle handling, choose a machine with gentle loading system.

Level of automation

Level of automation-Picture courtesy: jrautomation.com

A food cartoning machine comes in different level of automation, some in manual, semi-automated and fully automated. Each has different features. If you want a high-speed machine, choose an automated machine. If your budget is low, go for manual and semi-automated machine.

Conclusion

To conclude this buying guide, it must be noted that while buying food cartoning machine, choose a machine that is compatible with your product carton style and shape or size. In 2025, cartoning machine comes in various advancement, so choose a machine that is smarter and faster. If you are looking for an efficient food cartoning machine, AIPAK provides you with these machines. Visit our website and boost your production capacity.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine