Cosmetic Cartoning Machine: The Complete Buying Guide In 2025

Do you know how cosmetic products are packed in a carton? A cosmetic cartoning machine is used to form cartons, insert the product, and seal them efficiently. This automated cartoning machine does not just handle one kind of cosmetic product but can handle all cosmetic and cosmeceutical products, versatile for various packaging.

You can enhance your brand by packaging cosmetic products in different carton styles, whether it is single bottle of foundation or an entire beauty kit. This machine is a game changer because this machine smoothly does the process relating to cartoning and ensures that your products are packed with care.

There are different machine types and features available in 2025. But, choosing them is difficult without guidance. Don’t worry- this buying guide will walk you through everything you need to know. Let’s dive into the world of cosmetic cartoning machine.

1.What is cosmetic cartoning machine?

ALLPACK cosmetic cartoning machine

Cosmetic cartoning machine is a packaging machine. It is designed to package cosmetic products from a single piece of lipstick to a whole kit of other products in a carton. It takes a flat carton, give it a shape, then, put the products in a carton and seal them. By its automation features; human errors, increase the production speed and provide a safe, efficient and consistent packaging. This machine comes with a characteristic of shifting to different carton sizes.

2.What benefits do you get from cosmetic cartoning machine?

Cosmetic cartoning machine is demandable because it provides great benefits. In packaging, a neat, clean and an appealing appearance matters a lot. All thanks to cosmetic cartoning machine that enables the manufacturer to do this. Don’t wait more. Let’s dive into this.

Versatility

Versatility-Picture courtesy: forestpackage.com

One of the benefits you can get from this machine is that you can pack different products shape and sizes in a carton. It is not limited to one type of beauty product, from jars, tubes to multi-kits. You don’t need to buy machines for these various products as this machine is designed in such way that it handles different products to be cartoned in various packaging styles.

Reduce risk of damage

Reduce risk of damage-Picture courtesy: noissue.com

Are you conscious about the cosmetic safety? Yes, every manufacturer is worried about their products safety. These products are sensitive and fragile that needs efficient cartons for packaging that protects them from breaking down.

This machine uniformly and properly packs products in cartons that minimize the damage’s risk and safe for shipping.

Accuracy

Another benefit of cosmetic cartoning machine is accuracy. Accuracy is the key to success. This machine ensures that each carton is packed accurately, with no extra or less products in a carton. Is this enhancing customer satisfaction? Well, in manual packaging, there are chances of human errors of either too many items or less. This creates bad impact of the brand and leads complaints.

By using this machine, it ensures brand reliability.

Customization

Customization-Picture courtesy: RAFESA

By cosmetic cartoning machine, businesses can make a customize cartons for their brand. As this machine beautifully packs the cosmetic products that attracts the customers because they customize the cartons which the customers eyes looking for.

Brands can create unique packaging style of cartons to improve their image.

Cost-effective

Cost-effective-Picture courtesy: completepackaginggroup.com

As the machine is automated, so it operates at high speed and meet the demands in a less time. This reduce the labor costs; only fewer employees are needed. It reduces the packaging materials by packing cosmetic products efficiently and with precision.

You don’t need to buy multiple machines as it is all-in-one go machine; do multiple tasks such as folding, filling and sealing.

3.Enlist industries that use the cosmetic cartoning machine?

Today’s competitive world, many manufacturers try their best to have a safe packaging. A product that are packed in cartons are moved to different places. So, their safety is mandatory. Cosmetic cartoning machine does all this work. Here are the industries that use this efficient machine.

Cosmetic industry

Cosmetic industry

If you ever scroll or go to the beauty shop, you will different products with eye catchy packaging. You might end up with buy the one that looks pretty to you and this, just because of the packaging. All credit goes to the cosmetic cartoning machine.

This machine protects your product by providing good quality packaging and sealing.

This machine is automated, so the labor cost, material cost in respect of wasting is minimum and human errors are less; where there is human involvement, there are chances of less profit.

No one can imagine their broken cosmetic products that are just received by online order. The famous brands such as Maybelline, Fenty beauty etc. not only enhance products perfectness but on packaging though. A cartoning machine ensures safe packaging.

Here are some of the different sectors of cosmetic industry where cosmetic cartoning machine is used.

|

Cosmetic industry

|

|

|

Skincare industry

|

Skincare products are sensitive in nature as they are use for external use. From serum to facemask all are packed in a clean and attractive carton. Any skincare product that are paced in a carton has a leaflet of that product, is all done by cosmetic cartoning machine. |

|

Fragrance industry

|

You may have seen perfumes packed in a glossy and vibrant carton. You might not feel its fragrance but feel its beauty by packaging. What is behind its attractive appearance? Of course, the cosmetic cartoning machine. This delicately handle these glass bottles to ensure enough protection. |

| Haircare industry | Haircare products are standing tall in your shower-room, in salons and in other places, and when buying them, they are in cartons that are neatly packed by cosmetic cartoning machine. They create kits in combination of different haircare products. |

Cosmeceutical industry

Cosmeceutical industry-Picture courtesy: chiltanpure.com

Cosmeceutical products include Botox, anti-aging serum etc. These are often come in pump bottles, droppers, and glass vials. Expensive yet fragile, protection is needed. Behind the fine and tamper proof packaging of the cosmeceutical products, this is cosmetic cartoning machine.

Have you ever seen in pharmacy the kits of the medicated creams? The kit in combo is a treatment set that make it easy for a customer to get the creams in one its, don’t have to look for another combo cream.

These products are pharmaceutical related so, active ingredients, side effects, dosage and other related information are necessary for customers knowledge. Therefore, only eye soothing appearance is not enough; it needs protection and precise cartoning.

Organic beauty industry

Organic beauty industry

Some people are allergic to chemicals and they fold their fingers on the organic made cosmetic products. a question may pop in your mind that how these organic made beauty products are packed? A cosmetic cartoning machine is also used to put these products in cartons and sealed them by maintaining the cleanliness and protection.

These are carton in various packaging style cartons. Some products are solely carton while others in a group. Moreover, the packaging beauty, consistency and protection go side-by-side.

4.Do you know the components of a cosmetic cartoning machine?

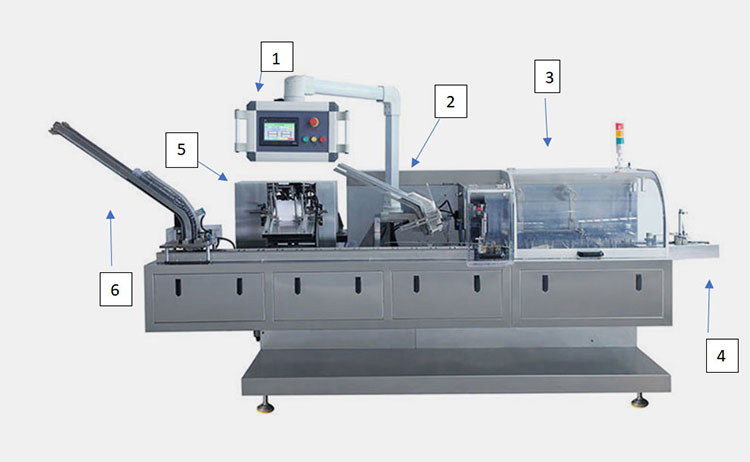

ALLPACK cosmetic cartoning machine

Followings are the components of cosmetic cartoning machine.

1.Touch screen

2.Cartoner picker

3.Carton closure unit

4.Discharge belt

5.Carton feeder

6.Conveyor belt

Touch screen

It is digital screen. To maintain a machine, its performance and parameters are controlled by touch screen.

Cartoner picker

Cartoner picker picks the carton from the stack of cartons from hopper. These are, then, transfer to the erection station. Here, robotic arms are used.

Carton closure unit

Cartons are closed here by either of tuck in or glue shut sealing method. The open flaps are closed to protect the inside products.

Carton feeder

This is designed to hold the cartons before moved to the machine, the carton picker.

Conveyor belt

Conveyor belt is designed to convey the products or cartons to the machine. There are sensors that detect that whether the products are present or not.

5.What is the working principle of a cosmetic cartoning machine?

By using cosmetic cartoning machine, a lot of stuffs are boxed. They are not manually or simply placed in carton. It involves several steps to provide you products paced in boxes(cartons). Here are the following steps.

Carton loading

Carton loading-Picture courtesy: imagroup.com

The first thing a cosmetic cartoning machine needs is the carton which is the basic player in whole process. You can just assume it like you need a cover to pack your gift. Bundle of carton are stored in hopper in flat way. A picker such as suction cups pic the carton gently to ensure that no carton gets damage. The carton is, the, moved to the erection station.

Carton erecting

Carton erecting-Picture courtesy: cphi.online.com

To transform the flat carton in proper box is done here. Here, mechanically arms and suction cups are used. Suction cups and mechanical arms is used to open up the flat carton in a proper shape. The, clamps are used to hold the box tightly which to prevent the box from looking crooked.

Product feeding

Product feeding

The cosmetic products are fed into the machine via conveyor. Products are aligned and positioned correctly. This is mandatory for the proper, consistent, clean and error free packaging.

What’s next? Then, products are inserted by pushing in a carton. Here, sensors detect whether the products are present or missing.

Flap folding and sealing

Flap folding and sealing-Picture courtesy: shinebenmachinery.com

When product is inserted in a carton, the next step is flap folding and sealing. Flaps are folded and sealed by using any of two methods depends on type of carton; tuck-in and glue shut. Tuck-in method is used for light weighted products and glue is not used, while the glue shut is used for sealing a medium to heavy products by using a hot glue.

Discharge

The fully packed and sealed cartons are ready to discharge from the machine via conveyor. It is ready for further processing and shipping.

6.Describe the types of cosmetic cartoning machine?

Cosmetic cartoning machine has numerous types available in market. Knowing them is important. Therefore, following below are the types of cosmetic cartoning machine.

Based on product loading direction

Horizontal cartoning machine

ALLPACK horizontal cartoning machine

In this type of machine, a product is horizontally means from side way is inserted in a carton. It is very efficient and don’t require a large space to operate. Here, the product such as lip balms, cream tubes, and other manageable products are loaded horizontally while the cartons are picked from hopper and open horizontally. Then, products are pushed in from side and inserted in cartons.

Vertical cartoning machine

Vertical cartoning machine

As the name indicates, it is designed in such way that the cartons are standing vertically. The principle working of this machine is that the carton is taken from the hopper and open in vertical. Beauty products are inserted from the top to the vertically laid box. The flaps are folded and sealed.

It is ideal for heavy and giant products.

Based on automation level

Cosmetic cartoning machine is also classified on the basis of automation level.

Let’s explore them.

Fully automatic cartoning machine

ALLPACK fully automatic cartoning machine

This machine is designed to do all the process itself. There is less intervention of human. So, the labor cost and material wasting will be minimum. It functions by automatically load the products in conveyor. Similarly, cartons are picked and erected. Products are dropped in a box y robotic arm and sealed.

All the process is done in no-time where in manual handling, it takes great time.

Semi-automatic cartoning machine

Semi-automatic cartoning machine-Picture courtesy: jochamp.com

In this type of machine, both manual and automatic features work side-by-side. This is efficient for small to medium scale industries. It works by manually loading of beauty products and cartons. After this, automatic features start working by erecting cartons and inserting products inside the box.

If you have a medium budget, this hybrid model is cost-effective.

Based on operation mode

Followings are the types on the basis of operation mode.

Intermittent motion cartoning machine

Intermittent motion cartoning machine-Picture courtesy: utmostusa.com

This machine works in a stop- start manners; means that after each step, it pauses to ensure an efficient and precise process. From carton erection to sealing, all follows the same manner.

This type of machine is beneficial for the delicate products. even though, the whole process is slow but precise enough to prevent the products from damaging.

Continuous motion cartoning machine

Continuous motion cartoning machine-Picture courtesy: directindustry.com

Continuous motion cartoning machine operates at high speed. The continuous movement allows high speed carton packaging. Cartons and products are loaded in non-stop manner. The erection step, product insertion and sealing follow the same. The sturdy products can withstand with this high or non-stop speed.

7.What types of cosmetic product materials are handled by cosmetic cartoning machine?

Does the question ever click in your mind that what kind of beauty products material are cartoned by this machine? It can handle different products materials from tubes to perfumes bottle. What are you waiting for?Let’s get started.

Jars

Jars-Picture courtesy: flushpackaging.com

Jars can be made of either plastic or glass. They are heavier by weight. So, a sturdy cosmetic cartoning machine handles the beauty jars. How to carton them? Well, the jars are placed in tray, first. Then, they are robotically inserted in a carton. These protect the stability and structure of jars during shipping and storage.

Sachets

Sachets-Picture courtesy: bloombeauty.com

Another cosmetic product material that it can handle is sachets. These are often in small size. Sometimes, they are pre-stacked or stacked by machine here. Sachets are counted and arranged according to the industry rules. The, they are packed in a carton of specific design.

Bottles

Bottles

Lotion, toner or other beauty product bottles are standing boldly in a cosmetic shop. There is a technology that is behind their amazing and clean packaging. Bottles are of different shapes and sizes that are all cartoned by cosmetic cartoning machine.

These bottles can enhance beauty section of your using-room.

Tubes

Tubes-Picture courtesy: ipackdesign.com

This machine is also use for tubes to be cartoned neatly in glossy and vibrant cartons. Their sealing is also checked to ensure air tight and tamper proof sealing. One can fall in love with their packaging.

Some of the slim tubes such as lip balms and lipsticks are also cartoned by this machine. There are sensors to detect their upright position. Afterwards, they are cartoned in a shiny box with leaflet insertion, if needed.

Glance of these glossy packed lipsticks will not leave you from the shop without making you convince to buy.

Perfume vials

Perfume vials

To handle gentle glass, a careful packaging and handling is also necessary. Perfume vials are delicate and comes in various sizes. These vials are picked by suction tool that place in special holder. This holder put the perfume vials in a carton along with tester and leaflet.

These cartons are of such beauty that the buyer can feel the radiant cartons before feels the fragrance of the perfume. What else can be more amazing than this? Absolutely nothing!

Blister packs

Blister packs

You might have seen that skincare capsules are efficiently packed in bubbles of blister packs made of plastic and foil. The number of capsules varies depending on how many days the skincare treatment is for.

Blister packs, along with instruction card, are slide into the cartons and sealed them with a tuck-in flap. This not only protects the capsules from contamination and environmental factors but provides a good look to the shelf.

8.What are the packaging styles a cosmetic cartoning machine handles?

This efficient machine can handle different cosmetic products material as you have read above. Therefore, there are different packaging styles in which they are packed. Below are the packaging styles a cosmetic cartoning machine handle.

Window carton

Window carton

Some of the cartons have window means a hole with transparent plastic or just a cut out. These windows give a beauty to product by showing their color and appearance. A customer can easily see what they are buying without opening them.

Sleeve carton

Sleeve carton-Picture courtesy: Custompackagingpro.com

This carton is simple and without end flap box. The machine can form this type of cartons. Are these cartons attractive? Without any doubt, modern designs enhance the attraction of the products.

Straight tuck end

Straight tuck end-Picture courtesy: sopak.com

Have you opened the serum bottle from the top with cleanly paced from the bottom? This is boxed in a straight tuck end packaging. Straight tuck end is characterized by clean tuck of flaps on the top and bottom of product.

Auto lock bottom

Auto lock bottom

There are products with auto lock bottom box. As you can get its style by its name that it is locked without need of glue for its sealing. A cosmetic cartoning machine works on this type of packaging.

Reverse tuck end

Reverse tuck end-Picture courtesy: Halcon packaging

Another packaging style it can support is reverse tuck end. It secures the products effectively because both flaps run in opposite ways, top flap tucks in one way and bottom in other. Your mascaras have this box that can be easily open and close.

Flip-top boxes

Flip top boxes

Cosmetic cartoning machine meets your demand of flip-top boxes. Makeup kits and other high standard beauty stuffs come in flip top boxes. These have a magnet in base. While open or close the box, it automatically attached to magnet and lead the box closed. Give vibes of treasure chest.

9.What are the factors that influence the performance of cosmetic cartoning machine?

There are factors that affect the function of cosmetic cartoning machine either mess with packaging or slow down its production capacity. Followings are the factors that influence its performance.

Automation

Automation-Picture courtesy: ascend.io.com

Automation features enhance the machine capabilities. Modern cosmetic cartoning machine has sensors that detect the misaligned and faulty cartons. But if the outdated features can not manage the errors.

Product consistency

Beauty products are of different shapes and sizes, some are delicate while others are hard. Irregular and unstable products cant be fit in a carton.

Carton quality

Carton quality-Picture courtesy: Vietnampaperbags.com

The basic thing about cosmetic cartoning machine is cartons. If cartons are not good with poor quality, jamming in machine may occur which slow down machine and tear the machine parts.

Environmental condition

The factor that influences the performance of this machine is environmental conditions. How they affect it? High humidity softens the cartons and low humidity harden them. By this, they get stuck in machine.

Speed

Speed-Picture courtesy: bekoireland.com

Speed is good when it comes to production. But speed beyond limit creates hurdles both for machine and products. As you know that cosmetic products are delicate, and high speed can result in their damage while feeding and cartoning.

10.What are the factors to be considered when buying a cosmetic cartoning machine?

Before buying something, there are some points in your mind that on basis of which you select machine. Same here, the following factors should be considered when buying a cosmetic cartoning machine.

Different machines can handle different products with various shapes and sizes. When buying a machine, first look at the machine handling type as different machines are designed to handle specific products.

Sealing method

Sealing method-Picture courtesy: flexpak.com

Sealing is done according to the product. a heavier product requires a glue shut sealing while light products need a tuck in sealing method. Choose a machine that is compatible with your product type sealing method.

Speed

The speed of one's machine plays a necessary role in production. Choose a cosmetic cartoning machine that matches your production demand. Machines differ in speed; some operate at high speed that are ideal for large industries while some with low speed suitable for medium or small-scale production sectors. On the basis of your production demand, look for a machine compatible with this.

Automation

In other words, automation means less intervention of human. As human are the err of mistakes. So, where there is human intervention, there are more chances of errors. Look for a machine with automated features because cosmetic products cartons are very sensitive so handling them automatically will be proved fruitful. Moreover, the automation machine offers you high speed to carton products in less time with accuracy and precision. So, choose a machine that offers the right level of automation.

Conclusion

To conclude this detailed buying guide, you may come on the point that before selecting a cosmetic cartoning machine, it must be noted that the machine could handle different size and shapes of cosmetic products with different packaging style. Therefore, if you are looking for good quality and advanced technology machines, go and check our AIPAK website.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine