Vial Cartoning Machine: The Complete Buying Guide In 2025

Are you a manufacturer? Are you seeking for an efficient equipment to optimize your vial packaging? This guide helps you to select an appropriate vial cartoning machine that will streamline vial packaging process and proves to be a fruitful investment for you.

Vial cartoning machine is a requisite part of production of all the sterile products that are needed to be dispensed in vials. Here you find answers to all relevant questions that come up into your mind when you decide to invest in vial cartoning machine. This topic explains you about this machine’s types, benefits, applications, working mechanism, maintenance and much more. Let’s join us to explore more about this useful machine!

1.How can you define vial cartoning machine?

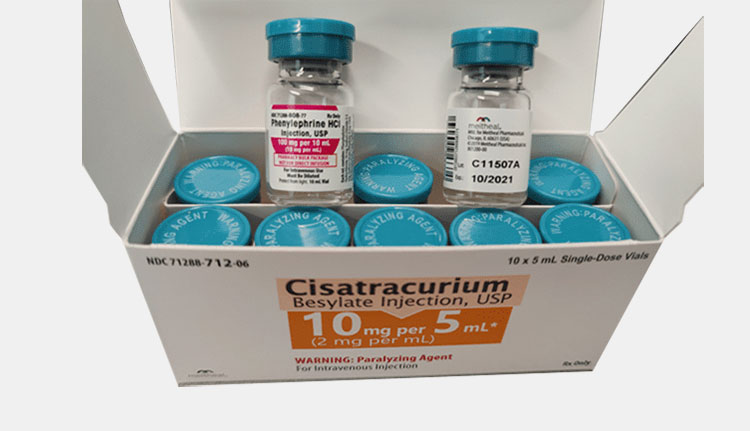

COVID Vaccine Vial Packaged Flawlessly By Vial Cartoning Machine

Vial cartoning machine is specifically designed equipment to facilitate the cartoning of vial, a small cylindrical container. Now you need to understand what does this cartoning of vial mean? Cartoning is a process of packaging the vial into a box to keep it safe from any source of harm during storage and distribution. Vial can be of different sizes (2ml, 5ml, 10ml etc.), shapes (round, oval etc.) or materials (glass or plastic).

Vial cartoning machine secures the vital place in manufacturing of several products. And you know why? You cannot market these products without packaging. Incorporation of this machine in manufacturing process makes the operation seamless that’s why you must consider it as a significant investment.

2.Can you elaborate the beneficial role of vial cartoning machine?

Vial cartoning machine offers a convenient yet efficient way for you to package vials and this packaging way is far different from conventional method of packaging. In order to witness the worth of this machine, you have to be mindful about its advantageous role.

Productive and expeditious:

Productive & Expeditious-Picture Courtesy: The Davis Enterprise

When it comes to narrate the vial cartoning machine’s benefits, first thing comes in mind is about how it runs the whole operation? This machine proves to be so productive and expeditious that after using it, you can experience vast difference in production quality and speed. Hundreds of vials can be packaged in less time and it results in the quick completion of batch, which is of course so desirable.

Minimum chances of errors:

Vial Cartoning Machine Shows Minimum Chances Of Error-Picture Courtesy: Hospital Quality Institute

Vial cartoning machine as being efficacious equipment, minimizes the chances of error during the packaging process. Fewer errors in production can be helpful to raise the quality of resulted product.

Budget-friendly:

Budget-Friendly

Vial cartoning machine proves to be a pocket-friendly machine, you need to understand how? The process of packaging is carried out by machine not labor and low wastage will be generated. This fact helps to reduce the overall cost of production.

Versatile:

Versatile

As a versatile equipment,vial cartoning machine can package different kinds of products from it and even of various sizes and materials. This machine is considered as important part of manufacturing process of pharmaceutical, veterinary, biological products, etc.

Ensures safety of product & staff:

Ensures Safety Of Product & Staff

Vial cartoning machine incorporation in production is essential to maintain safety of products and staff too. You know why? Vials are delicate containers, demands extra care at the time of packaging. Secondly staff remain save as they don’t need to engage with heavy weight products or sometimes chemically reactive materials.

Environmentally friendly:

Biodegradable Material Is Used To Make Cartons

Vial packaging machine utilizes sustainable material to form cartons, so it is not only contributing in safety of product and employee but also have part in protecting ecosystem. You experience less waste production and that waste is also biodegradable, making it an eco-friendly investment.

Ensures high quality product:

Vial Cartoning Machine Helps To Attain High Quality Product

Vial cartoning machine makes it easier for you to attain a high quality product. You learnt it well that using a machine with such prominent qualities, do increase the quality of resulted product. Several manufacturers assure to have this machine in their production line to achieve incredible quality.

3.Do you know about the applications of vial cartoning machine in pharmaceutical industry?

Who can deny this fact that vial cartoning machine is considered as an imperative part of manufacturing of many pharmaceutical products. Here you will get the understanding of all medicaments that are using this machine in their production line.

Injectable antibiotics:

Injectable antibiotics

You have seen it many times in your life that antibiotics that are administered parenterally, chose to dispensed in vials to keep them sterile and stable. These vials need to be packaged in carton to keep them safe during storage and transportation. For this purpose vial cartoning machine is used.

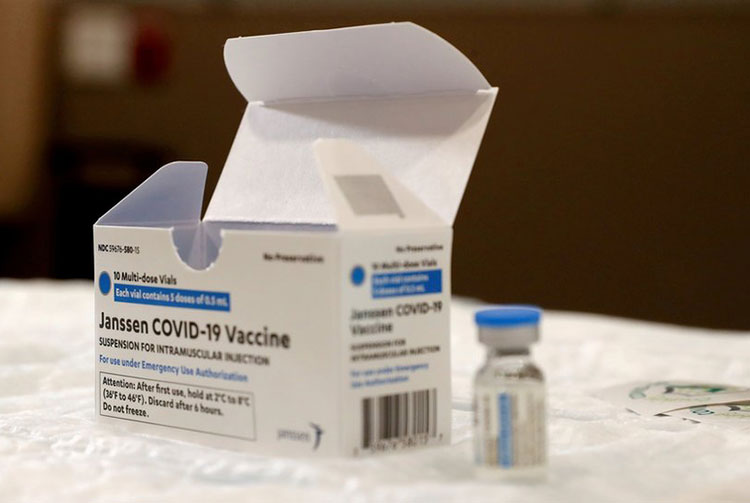

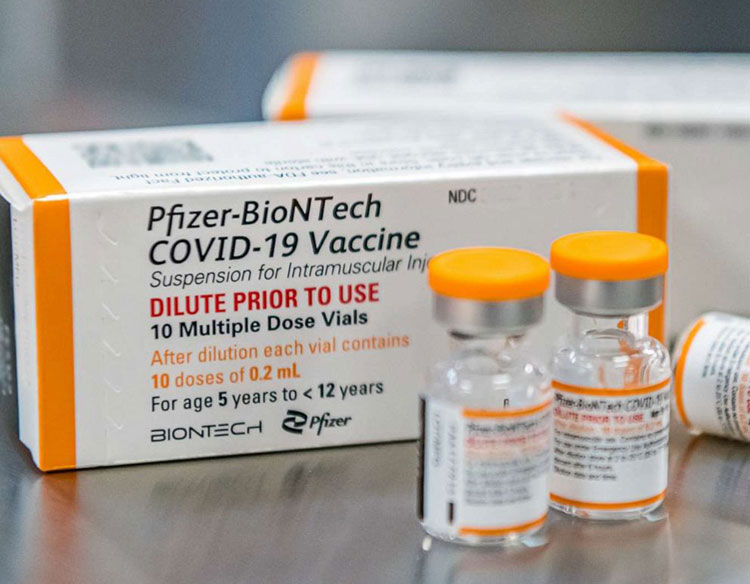

Vaccines:

Vaccines

Vaccines are given to make your immune system stronger. They are filled in vials to avoid degradation in preparation and keep the sterility intact. These vials are packed in boxes to make them secure during storage and distribution.

Nutritional supplements:

Nutritional Supplements

You may see very often that nutritional supplements like iron, vitamins, minerals etc. are available in vials. To pack them in boxes and cartons, vial cartoning machine is requisite.

Chemotherapeutics:

Chemotherapeutics

Anti-cancer drugs are important products of medicine industry and you find it mostly dispensed in vials. Vial cartoning machine is needed for secondary packaging of these anti-cancer drugs.

Other medicines:

Anti-Inflammatory Drug

Another important drugs that you use in your life time for so many reasons, required to fill in vials like anti-fungal, anti-inflammatory, anti-emetics, anti-pyretic, anesthetics, anti-neuroleptic etc. and vial cartoning machine is utilized to package these drugs in boxes.

Veterinary products:

Veterinary Products

Do you know that various medicines are given to animals through parenteral route? These medicines are filled in vials and packaged by vial cartoning machine efficiently.

4.Can you use vial cartoning machine in other industries?

Yes, of course you can use vial cartoning machine in other industries too. This valuable machine is not only contributing in pharmaceutical production efficiency but also adding its role in packaging of other industries goods.

| Other industries | Picture |

| Chemical industry:

Certain chemicals are filled in vials for different reasons like some are sensitive, hygroscopic, flammable or corrosive. These vials are then subjected to vial cartoning machine for packaging in boxes. |

|

| Cosmetics industry:

You have observed it so many times that, serums, fragmented oils and other cosmetic products are filled in vials. Afterwards, it becomes necessary to use vial cartoning machine to pack it in boxes for safety purposes. |

|

| Food industry:

You can see some food products like essence, preserve food items, sauces are filled in vials to keep them safe from moisture and light exposure. To pack these products, vial cartoning machine is utilized. |

|

5.What containers beside vial can be packaged by vial cartoning machine?

In order to highlight the value of vial cartoning machine, this topic is designed to make you understand the versatile use of this machine. There are other containers, used to package by the help of this machine. Let’s have a look!

| Containers | Picture |

| Pre-filled syringes:

Pre-filled syringes are easy way to deliver precise dose. When it comes to efficacious packaging of this container, vial cartoning machine is preferred. |

|

| Ampoules:

You often see ampoules are packed in boxes. Vial cartoning machine is utilized for secondary packaging of this container. |

|

| Blister packs:

You are well known of the fact that medications like tablets, capsules are packed in blister packaging and after that vial cartoning machine can be used to pack it in a box. |

|

| Dropper bottles:

You often observe different formulation packed in dropper bottle like eye drops, ear drops, and nose drops. These products use vial cartoning machine for their packaging in boxes. |

|

6.What can be the various kind of packaging offered by vial cartoning machine?

You are learning it from the beginning is vial cartoning machine takes part in secondary packaging of vials and other containers too. Do you want to know the types of packaging vial cartoning machine supports? This topic is specially written to make you aware from available types of packaging.

| Kinds of packaging | Image |

| Folding cartons: you have seen it in most common practice that vials are packaged in foldable cartons to get stored and distributed. It is most convenient way of packaging, made from low-weight paper and you find it easy to carry. |  |

| Boxes with different compartments: when you have demand to pack more than one vials, so this kind of packaging is preferable for you. Each vial gets fixed in a compartment, facilitating the safety of product. |  |

7.What are the types of vial cartoning machine?

Here it is very important for you to know the difference between various available types of vial cartoning machine. After acquiring such knowledge, it becomes easier for you to select the machine according to your needs or characteristics of product. Types of this machine can be distinguished on the basis of automation (semi-automated or fully-automated), position of placement of container (horizontal or vertical) and mode of operation (continuous or intermittent).

Basis of automation:

Do you know what automation refers to? When machine functions without the interference of human. On the basis of automation, vial cartoning machine can be divided into following:

Semi-automated vial cartoning machine:

Semi-Automatic Vial Cartoning Machine

In this type of vial cartoning machine, you perform few functions by yourself like loading of vials and other functions are completed by machine itself like closing of carton through different methods. It is preferably applicable in small-medium scale production.

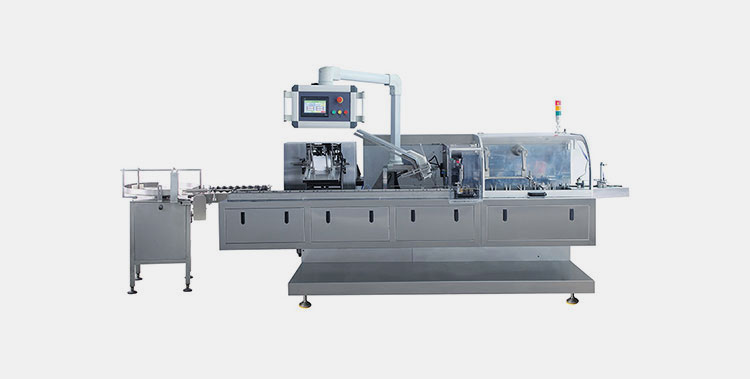

Fully-automated vial cartoning machine:

Aipak Fully-Automated Vial Cartoning Machine

Fully-automated vial cartoning machine carries out every function by itself, either its formation of cartons till sealing of these carton. You don’t need to do anything. It is considered as ideal for large scale production and preferably used widely in pharmaceutical industry.

Basis of placement of container:

On basis of placement of container, vial cartoning machine can be divided into:

Vertical vial cartoning machine:

Vertical Vial Cartoning Machine-Picture Courtesy: Citus Kalix

Such machine is required when you want to place vial in vertical position in to the box. In case, when you are packaging single vials, this machine proves to be helpful to you.

Horizontal vial cartoning machine:

Aipak Horizontal Vial Cartoning Machine

This machine is used when you have to package vials in horizontal placement into the box. If you observe that, when there is need to package several vials in one box, we put these vials in horizontal position.

Basis of mode of operation:

Machine can be chosen on the basis of method, as in which manner it is carrying the whole process. On basis of mode of operation it is classified as:

Continuous motion:

Continuous Motion Vial Cartoning Machine-Picture Courtesy: MGS Machine

In this vial cartoning machine, process is being carried out continuously, without being stopped at any station. Such way of process is facilitated by conveyors that used to move cartons from one station to another station. The privilege of using such machine is that you can get packaging at a very high speed. This kind of machine is ideal for large productions.

Intermittent motion:

Intermittent Motion Vial Cartoning Machine-Picture Courtesy: SMO

Such vial cartoning machine works by stopping the carton at every station. The whole process performs in such way. Although speed is not that high but complex products can be packaged with satisfaction.

8.What can be the important parts of vial cartoning machine?

It has positive impact when you are educated about important parts of vial cartoning machine; this thing prevents you from making inauspicious investment.

| Important parts | Function |

| Machine frame:

|

Machine frame is a requisite part of vial cartoning machine. It is made from stainless steel. You see a sturdy machine frame that protects the inner parts of equipment and provide a strong structure to whole machine. |

| Conveyors:

|

Do you know which part of machine is utilized in moving carton from here to there? These are conveyors.

Conveyor is used to align and move cartons and products |

| Carton Feeder:

|

Do you have idea about where you get different sizes cartons while processing? Here is a place in vial cartoning machine to store unfolded cartons. This place is known as carton feeder. |

| Suction cups:

|

Suction cups have important work to do and you know what? These suction cups hold the carton from carton magazine and aligned it for next process. |

| Carton folder:

|

Different sizes and shapes products are packaged in vial cartoning machine, have you thought which part is sharing this function? Its carton folder, which folds the carton in proper shape according to the product. |

| Packing system:

|

This system takes part in placing the product into the carton. |

| Carton pusher:

|

Filled carton has to be moved forward, for this you utilize carton pusher; it can have more than one heads to facilitate its function. Leaflets or bottles can be added in product carton by the aid of this pusher. |

| Carton sealer:

|

What is left after filling the carton with product? It’s the sealing process. Carton sealer is used to seal the product containing cartons. |

| Carton output & rejection system:

|

Cartons that are filled and sealed move out by the carton output. There is a sensor system to inspect about the defected cartons. This system is carton rejection system. |

| Control panel:

|

Whole process is controlled by the help of control panel. You can observe that operator uses this control panel to assist the process. Proper setting helps in efficient working of equipment. |

9.How does vial cartoning machine function?

How Vial Cartoning Machine Functions?

Vial cartoning machine functions so efficiently, do you want to know how? Let’s have a look on its whole process!

| Steps of process | Working |

| Loading cartons: | First step you perform every time is to load the cartons that are unfolded, into the machine by the help of feeding system. |

| Folding and formation of carton: | After loading, cartons are stored in carton magazine.

By using suction cups, unfolded carton are picked and by using conveyor, these unfolded carton are moved to carton folder. Carton folder has function of folding cartons in respect to the size and shape of product. |

| Placement of vial: | There is an incredible packing system installed. At first, vials are loaded by the help of conveyor system. This packing mechanism has role of placing vials into formed cartons with great accuracy. |

| Placement of leaflet: | After placing the vials, it is also necessary to put a leaflet. For this purpose, you utilize carton pusher.

This part contributes in inserting leaflet in product’s carton and also forwards the carton for sealing process. |

| Sealing of carton: | Sealing contributes in complete safety of product so it has to be done with great precision.

The most common sealing methods you have seen so far, can be: Tuck-in method Glue sealing method Hot-met sealing method |

| Inspection of carton | The last step is to inspect about the desirable packaging and sealing of box.

Vial cartoning machine has sensor system that moves out the finalized boxes and defective boxes are sent back to the machine. |

10.What things are considered while buying vial cartoning machine?

Things You Need To Consider While Buying Vial Cartoning Machine!

Are you looking for the knowledge that helps you to buy well-efficient vial cartoning machine? This topic is crafted to tell you about all the features that you need to consider before making an investment this machine.

| Things to be considered: | Why? |

| Productivity: | Do you want to complete your packaging process quickly? Then you have to look for equipment that has capability to work fast and package maximum cartons in short span of time. |

| Versatility: | You have products of different shapes, sizes and even materials. You need such machine that can support proper packaging of all products. |

| Automation: | When you have a large scale production, you have to go for fully-automated machine that can perform whole process seamlessly in less time. |

| Compatibility: | You should always look for a cartoning machine that can be easily integrated with your product’s manufacturing process.

Your selected machine must have convenient sealing methods like tuck-in or adhesive one. This helps you in carrying out the packaging smoothly. |

| Easy to use and maintain: | You must keep your eye upon this fact that you should have fine understanding of machine use and for maintenance; spare parts must be easily available. |

| Cost effective: | Cost of machine is an important factor but if this machine is helping to reduce the cost of labor and producing less waste so you must go for it. |

| Compliant to regulatory standards: | You should always look for a machine that meets mandatory standards so that the packaging process remains flawless for whole time. Guidelines that are given by good manufacturing practice (GMP) must be followed while operating vial cartoning machine. |

11.How can you maintain vial cartoning machine?

Do you know every machine requires proper care to perform proficiently? Here you are going to have awareness about maintenance of vial cartoning machine.

| Important aspects | How to maintain? |

| Proper cleaning:

|

For efficient working, it is necessary for you to clean the machine, after completion of each batch. There must be dust and leftover material that can affect the function of machine for further process. |

| Lubrication:

|

Do you observe that moving parts always demand lubrication for proper functioning? You have to lubricate the parts whenever they require. |

| Inspection of whole machine:

|

Vigorous inspection of whole machine keeps you safe from being in trouble. You have to inspect about:

Moving parts that they are working in right position and are well-lubricated. You must look for any wear or tear in machine and repair it soon to avoid downtime. |

| Checking electrical components:

|

Electrical components comprise of the wires and all the electrical system by which machine is working automatically. You must check it properly to avoid any problem during operation. |

12.Do you know the expected problems and their solutions while operating vial cartoning machine?

Expected Problems In Vial Cartoning Machine And Their Solutions

Are you worried about the troubles that you are expecting to have in future? There is no need to think about it. This topic contains information about possible problems and their solutions so that you don’t get panic at the hour of need.

| Expected problems | Their solutions |

| You may face issues in alignment of cartons, like improper alignment that leads to interruption of process. Reason could be related to feeding system or sensors don’t work properly. | You need to calibrate your machine’s sensor and feeding systems. |

| Cartons get stuck in machine and you know why? There is possibility that suction cups or conveyors have some problems. There is chance of incorrect loading of cartons in machine. | You need to inspect the machine, especially the feeding system, conveyors and suction cups |

| Improper sealing of carton has also been reported and reason is very understandable. Sealing unit is having defects like proper pressure is not applied or glue nozzle is blocked itself, temperature is not kept high while applying glue etc. | You have to check your sealing unit and maintain it accordingly. |

| Machine fails to continue the process and do you understand what can be the main reason? Any problem in electrical system or software that causes the machine to stop working. | You have to inspect your electrical system and software of machine. Calibrate it and make sure it will work smoothly. |

| Sometimes vials are also got damaged and cause is very simple. Excessive pressure is applied for holding it. | You need to inspect the packing system to avoid damage of vials. |

13.What quality compliance must be followed by vial cartoning machine?

What Quality Compliance Should Be Followed By Vial Cartoning Machine?-Picture Courtesy: Medical Device And Diagnostic Industry

Vial cartoning machine has a purpose of packaging important sterile products and sometimes non-sterile products too. Don’t you think it must follow some quality compliance? Yes you are thinking right. This quality compliance is integral for dominant quality of packaging and exceptional performance of machine. Let’s have a look on quality compliance!

| Quality compliance: | Purpose |

| Good manufacturing practices (GMP) | The guidelines of GMP must always be followed by vial cartoning machine, do you know why?

This system guides you about maintaining high quality, stability and uniformity during manufacturing of products. This systems makes sure the production is carried out in aseptic environment or having different means to maintain sterility and controlled environment during production. |

| ISO 13485: | Have you ever heard about ISO1385? This is special standards that ensures about the performance of machine either it is working according to specified quality or not. It is necessary to follow it to get excellent functioning of machine. |

| Food safety standards: | When you have products that are used as food, then vial cartoning machine needs to follow food safety standards like FDA. |

Conclusion:

Vial cartoning machine offers a great facility of flawless packaging of vials and other products. Production is considered incomplete without incorporation of this well- capable machine. For buying vial cartoning machine, you need to be well-informed about important parts, process, maintaining tips and issues of this machine. For further knowledge you can contact AIPAK at any time!

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine