Automatic Pharmaceutical Cartoning Machines: High-Speed & cGAMP Compliant Solutions

In high-volume pharmaceutical production, the cartoning process is the critical bridge between primary packaging and logistics. AIPAK’s cartoning systems are engineered to handle complex dosing forms—from blister packs and bottles to tubes—ensuring hermetic carton integrity and full traceability at speeds up to 120-150 BPM.

Cartoning Machine Applications

Pharmaceuticals

Ideal for packing tablets, capsules, and blister packs into cartons, ensuring compliance with GMP standards.

Food & Confectionery

Suitable for packaging pouches, sachets, and stick packs, maintaining product integrity and hygiene.

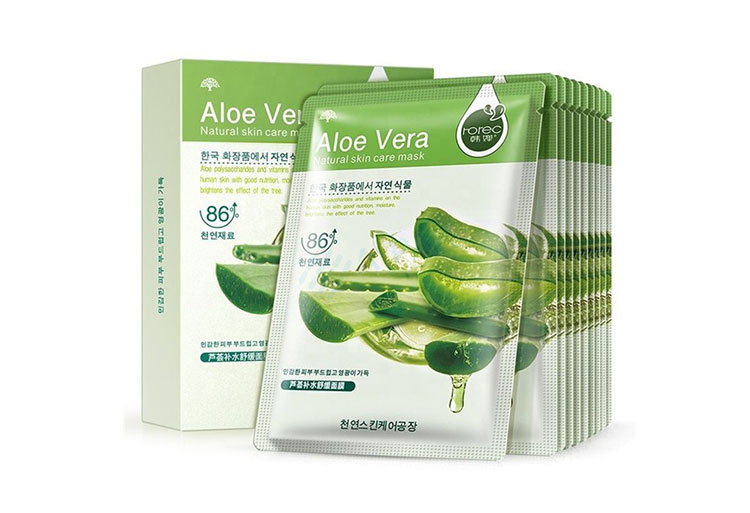

Cosmetics

Perfect for cartonizing skincare products, ensuring secure and attractive packaging.

Consumer Electronics

Efficiently packs small electronic

items, protecting them during

transit.

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

Cartoning Machine FAQ

1.What types of products can the cartoning machine handle?

It can pack tablets, capsules, blister packs, pouches, stick packs, cosmetics, and small electronics.

2.Can the cartoning machine handle different carton sizes and shapes?

Yes, the cartoning machine is adjustable to accommodate a wide range of carton dimensions and product types.

3.What is the maximum output speed?

The cartoning machine can achieve up to 100 cartons per minute, depending on product type and carton size.

4.Is the cartoning machine fully automatic or semi-automatic?

Models are available in both fully automatic and semi-automatic configurations to suit different production needs.

5.How easy is it to change over for a new product?

The cartoning machine features quick-change tooling and pre-set parameters, allowing fast and efficient product changeovers.

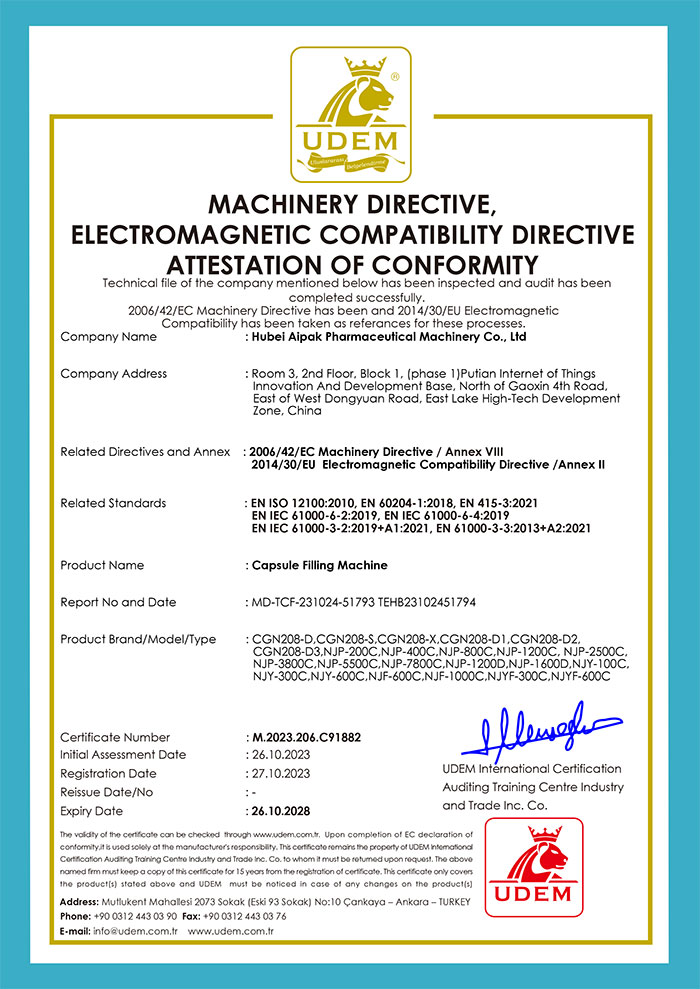

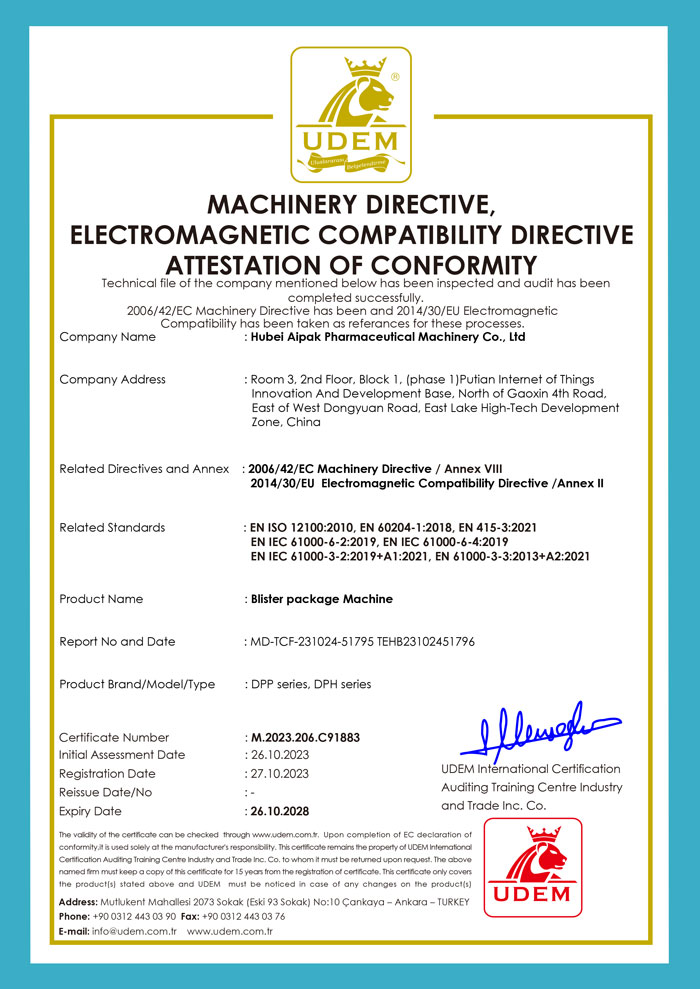

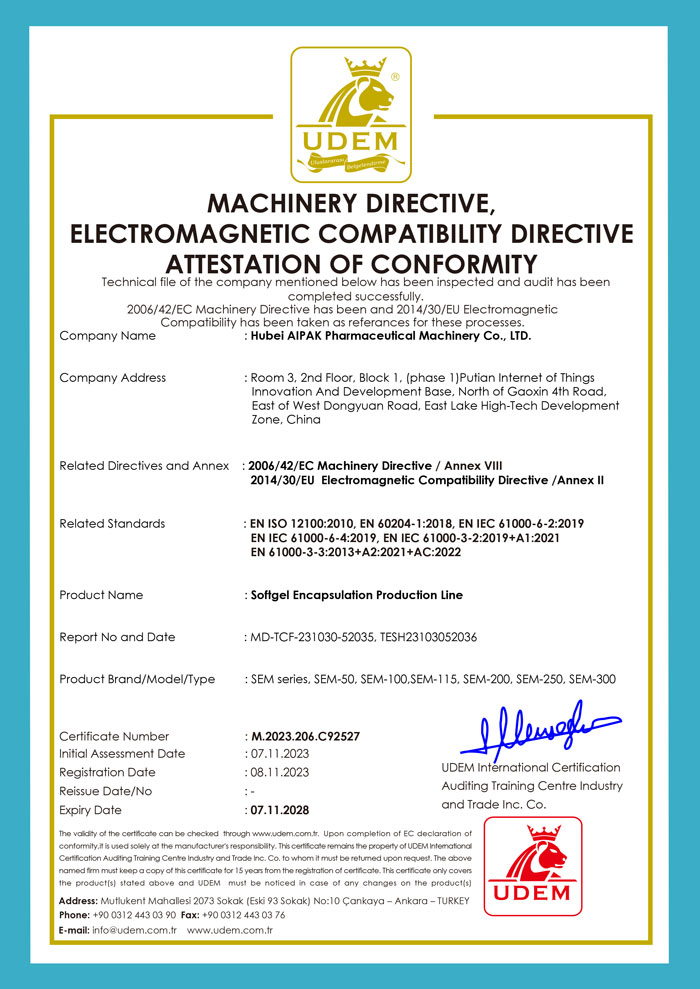

6.Does the cartoning machine comply with GMP, CE, or ISO standards?

Yes, all the cartoning machines are designed and manufactured according to GMP, CE, and ISO 9001 standards.

7.Is the cartoning machine easy to operate?

Yes, it comes with a user-friendly PLC control system and touch-screen interface, making operation simple and intuitive.

8.How often does the cartoning machine require maintenance?

Routine maintenance is minimal; daily cleaning and periodic inspection are recommended to ensure optimal performance.

9.Are spare parts readily available?

Yes, AIPAK provides global spare parts availability along with technical support.

10.Can the cartoning machine integrate with other packaging equipment?

Yes, it can seamlessly integrate with blister machines, labeling machines, bottle fillers, and conveyors to form a fully automated line.

11.Does the cartoning machine handle fragile or delicate products?

Yes, it uses gentle feeding and handling mechanisms to prevent damage to sensitive products.

12.What are the electrical and space requirements?

Electrical requirements vary by model (220V/50Hz or 380V/50Hz), and space requirements are optimized for efficient factory layout.

13.Is training provided for operators?

Yes, AIPAK provides on-site installation, operator training, and detailed manuals.

14.What is the warranty period and after-sales support?

Standard warranty is 2 years, with remote support, on-site service, and spare parts supply.

15.Is the cartoning machine suitable for high-speed mass production or small batches?

Yes, different models support both high-speed continuous production and smaller batch runs, offering flexibility for various business needs.

The Buyer's Guide

Cartoning Machine:the Ultimate Buying Guide in 2024

The Ultimate Buying Guide to Automatic Cartoning Machines: Maximizing OEE & Compliance. Lead Paragraph: In the modern pharmaceutical and food industries, an automatic cartoning machine is no longer just a luxury—it is a critical asset for scaling production. This comprehensive encyclopedia provides technical insights into classifications, working principles, and ROI analysis to help you select the most efficient secondary packaging solution.

Let’s go to the main topic of this guide directly:

1.What is a Cartoning Machine?

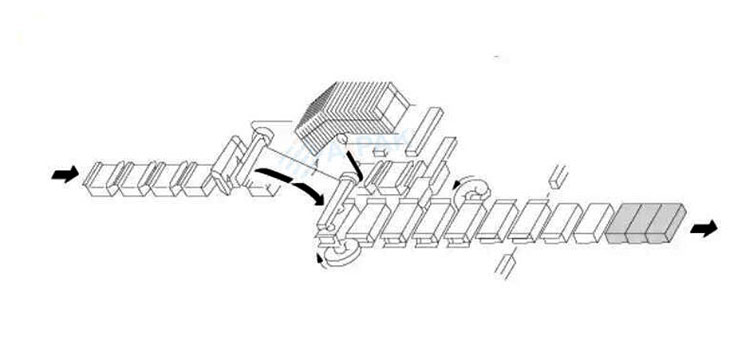

A cartoning machine is a high-tech packaging equipment integrating mechanical, electricity, air and light.

It can automatically complete the work of pharmacopeia-compliant leaflets folding, carton opening, product cartoning, batch number printing and carton sealing .

A cartoning machine can be used alone or connected with other equipment to form a complete production line.

From above definition,you may be still confused what is a cartoning machine ,why it is called cartoning machine ,but not other packaging machine.

Yes,the above definition is too technical for you to understand.You may get the other explanation from the following:

It is called cartoning machine as its sole purpose is to form cartons.

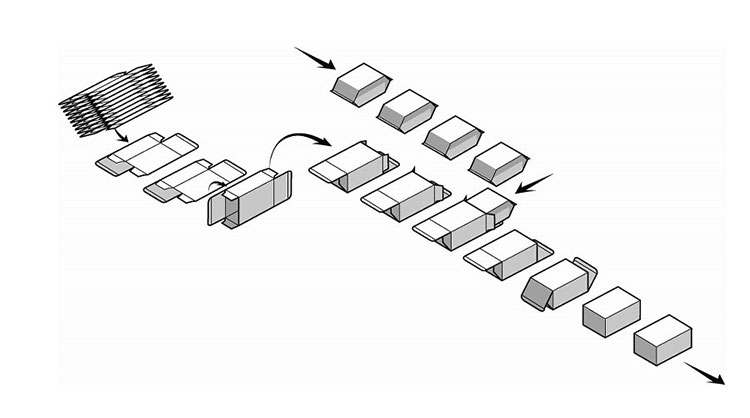

1.Pre-glued Flat Cartons stand up straight

2.Cartons side close

3.Product filling

4.Cartons fold

5.Cartons side seam and sealing

And from this cartoning process,you can also easily image that the cartons are originally blank stacked ,then filled to the cartoning machine for the afterwards packaging.

2.Where is the practical application of Cartoning Machine?

The application of cartoning machine has greatly reduced labor dependency and saved whatever time and labor costs for you .

Now I would like to highlight its various applications in different areas and make recommendations for you to choose the right cartoning machine in different industry.

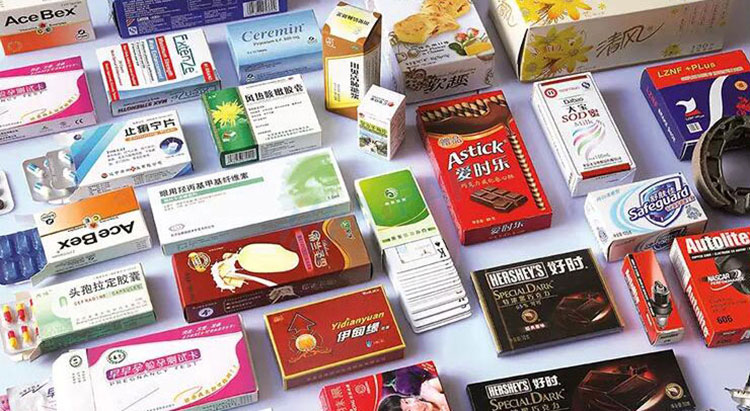

Products by cartoning machine

1.Application of cartoning machine in pharmaceutical industry

In pharmaceutical industry,you can use the cartoning machine to package your products including:bottles,blisters,medicine board, capsules,oral liquid, ampoule, vials, granules in bags, pastes, ointments, aerosols, etc.

In addition to the high efficiency and highly automatic intelligence,you need to know the cartoning machine in the pharmaceutical industry also solved the anti-counterfeiting problems faced by most industries. As anti-counterfeiting of drugs is very important.

At present, the anti-counterfeiting function of the cartoning machine is mainly embodied in the packaging itself.

Since the drug packaging in the past was mostly tongue inserting mode, that is, the product can be obtained by opening the top of the carton. But now, the cartoning machine mostly uses the mode of gluing carton, which makes it possible to take out the medicine only by tearing the whole package. This is to play a good role in the anti-counterfeiting of drugs.

2.Application of cartoning machine in food industry

From the production, sale and consumption of food, the purpose of food packaging is to prevent corruption and ensure quality.

And as the physical, chemical and microbiological properties of food may deteriorate in the process of preservation, circulation and sale. Only by preventing these deterioration can the inherent quality of food be guaranteed.

The second is to prevent microbial and dust pollution. In the process of food production and consumption, there are more opportunities to contact with people, various tools and air, and it is easy to be polluted by microorganisms and dust.

If consumers eat seriously polluted food, it will cause food poisoning. Therefore, it is necessary to use necessary packaging to prevent the secondary pollution of food.

Moreover, it is conducive to transportation and circulation. After reasonable packaging, the transportation conditions can be simplified and the storage period can be extended.

Then you will find below food are packaged by different cartoning machines.

Strip food

Strip coffee

As part of the food industry products, strip milk powder, or strip coffee, strip tea powder, as it is easy to carry, do not occupy area, more and more popular with consumers.

Therefore, the large-scale mass production of strip packaging products has already become a sharp tool for the market competition of major food brand enterprises.

In this competitive sea, whoever has mastered more advanced technology or equipment will be able to better occupy the market commanding height.

However,it is the food cartoning machine provides better advanced supporting equipment for food production enterprises.

Biscuits and cookies

Cartoning machine helps biscuits and cookies so much in keeping away from dampness inside.Here,it is advised to choose a horizontal cartoning machine for packaging such kinds of food as it is more safe and reliable in the packaging mechanism.

Dessert and chocolate

The cartoning dessert and chocolate will look more prestige and their appearance look more luxury than other common food,it also make them more expensive than normal.

The other aspect embodys here is the cartoning machine has prevent them from deformation as chocolate implies special meaning.

Prepared meals

You will be beneficial from a vertical cartoning machine to packaging your fast foods,prepared meals as you can insert your food to the multiple units of the carton box at the same time and automatically .

Besides,you can also create various compartments if there are trays include,that is you will have the cardboard sleeve fill first then have your food insert at the trays.

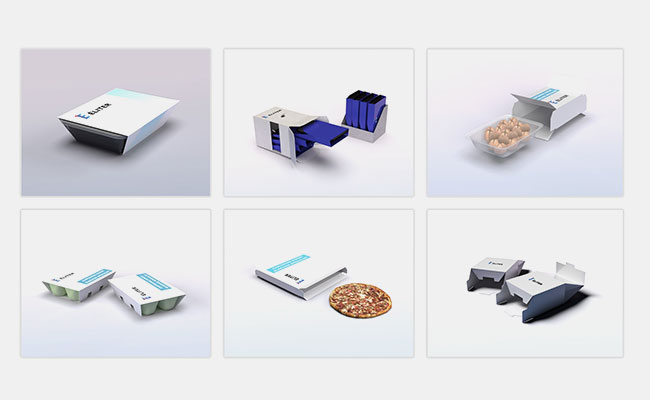

3.Application of cartoning machine in commodity and cosmetic

Both horizontal and vertical cartoning machine can be used to package commodity and cosmetic.

Such as toothpaste, soap, facial mask, face cream, lipstick, mosquito repellent incense, paper towels, sanitary napkins, pads, cosmetic cotton ,etc.

As an automatic cartoning machine for daily necessities adopts PLC to control the photoelectric monitoring of the action of each part.

During the operation, it can automatically remove the unqualified articles. In case of any abnormality, it can automatically stop the machine and display the cause, so as to eliminate the fault in time.

The machine can be used alone, and it can also be used in conjunction with the blister packaging machine and its hot-melt glue installation or other equipment to form a complete set of production line.

4.Application of cartoning machine in hardware and electrical appliances

You are recommended to purchase a vertical automatic cartoning to package your hardware and electrical appliances like bearing, bulb, switch, socket, relay, charger, etc.

5.Application of cartoning machine in entertainment industry

In the entertainment industry ,you can use the cartoning machine to package oil painting stick, stapler, printing mud, glue, modifier, playing card, jigsaw, toy, handicraft and pencil, marker / whiteboard pen, neutral pen, stapler / nail, printing mud, glue, modifier, playing card, puzzle, toy,etc.

Here,it is advisable for you to choose the vertical high-speed automatic cartoning machine.

6.Application of cartoning machine in plastic industry

In fact,it should be included in the daily commodity industry,you will make a vertical automatic cartoning machine to package your fresh film or plastic products.

7.Application of cartoning machine in auto parts industry

The products such as spark plug, filter, piston ring, automobile light bulb, automobile electric appliance, etc. need to be cartoning packaged.

3.Why you need a cartoning machine?

From the above cartons forming process,you can easily image that all cartoning machines share the same ultimate goal of increasing efficiency and eliminating the taxing and time-consuming labor associated with forming cartons and filling product into them by hand.

But in fact,apart from that labor saving reason,you will also need a cartoning machine for your mass production for the following aspects:

Wide range of packaging

If you have a various kinds of products,a cartoning machine with muti-sukers will help you realize your muti-packaging at the same time,that not only get the twice result with half the effort ,but also improve the efficiency.

Compact structure

For some equipment that may take up quite a bit of floor space,which in some cases is inconvenient ,but an automatic cartoning machine is compact in structure ,that is only need a few squares to complete whole packaging line.

In other words,an automatic cartoning machine doesn’t have too much requirement on the floor space ,it is the best choice whatever enterprise you are.

AIPAK Full automatic bottle cartoning line

Smart PLC Integration & IoT Ready

The automatic cartoning machine adopts PLC control panel with intelligent display, you can clear see the cartoning process and cumulate your product quantity.

While also abides the principle of no products,no sucking cartons,no cartons,no blacking,no pharmacopeia-compliant leaflets,no blacking,that’s the product and carton waste is eliminated .

Besides,your operator will be easy to get started as it smart shows the issues if any problems occur,

and stop working automatically to let the problem solved,that doesn’t lead to more machine damage.

Protect product for easy transportion

A carton will provide a more firm protection to your product especially for the liquid in bottle,bulbs that is easily broken.

While also make it safe for long-distance transport,such as truck,container and other bulk vessel export.

Bottles need packed in carton

4.How many types of Cartoning Machine are there?

As there are various products in the world ,the packaging form they need is different,thus,for different shapes packaging purpose,there are various types of cartoning machine on the market now.

And you need to get familiar with them first,then determine the suitable cartoning machine according to your products requirement.

Normally,the most commonly used cartoning machine are automatic cartoning machine and medical cartoning machine,but in fact ,cartoning machine can be classified according to:

- Degree of automation

- Product into carton

- Carton sealing form

- Shapes of packaging

- Specification of packaging

Let's find the detailed classification as below:

1.Degree of automation

According to the degree of automation ,cartoning machine can be classified into:

Semi-automatic cartoning machine

Fully-automatic cartoning machine

What they are suitable for,let’s find out.

Semi-automatic cartoning machine

Semi-automatic cartoning machine

A semi-automatic cartoning machine can open and seal the box automatically and add materials to the box manually.

It needs manual assistance to complete all processes so it is called semi-automatic cartoning machine.

A semi-automatic cartoning machine is most suitable for packaging products in food, daily necessities, chemical industry, medical hardware and other industries .

While,semi-automatic cartoning machine can also be horizontal or vertical cartoning machine.

And Some semi-automatic cartoning machines also have additional functions such as sealing labels or heat shrinkable wrapping.

Fully-automatic cartoning machine

A fully-automatic cartoning is a more intelligent invention compared with a semi-automatic cartoning machine.

AIPAK full automatic cartoning machine

The state-of-art machine has made the packaging quality much higher than that of manual packaging.

Nonetheless,apart from supplying cartons at its entrance,it also completes other tasks including:

Carton erection

Caron ear folding

Product insertion

Pharmacopeia-compliant leaflets inserting

Carton sealing

Hot spraying

Date stamping

Ink-jet printing

Besides,the full-automatic can also check on the completeness of the carton after the process to charge if it is damaged or good.

Automatic feeding

As the structure various,there are two types of full-automatic cartoning machine you can find ,namely:

Intermittent automatic cartoning machine

Continuous automatic cartoning machine

Intermittent automatic cartoning machine

Intermittent automatic cartoning machine,just as its name implies,it will stop to make the carton have a packaging cycle.

It is slower than the continuous automatic cartoning machine,as its cartoning speed is 50-100 cartons/min while the continuous is 180 cartons/min.

Intermittent automatic cartoning machine-Photo credits:Radpak

Continuous automatic cartoning machine

The continuous automatic cartoning machine is refer to the high-speed cartoning machine,and mostly used for mass manufacturing high-speed production line.

The continuous automatic cartoning machine adopts circular rotation,and its product feeding,carton conveyor chain and push rod are synchronized, and one-to-one correspondence.

While the intermittent mode adopts linear reciprocating motion,and its carton conveyor is reciprocating,only one push rod ,the product feeding system is not correspondent to them.

2.Product into carton

The most commonly used cartoning machine applied in most industries are based on how the products insert into the carton.

In fact,there are two types of cartoning machine according to its way of entering the carton,they are:

Horizontal cartoning machine

Vertical cartoning machine

And here you also need to know that either the full-automatic or the semi-automatic cartoning machine can be horizontal or vertical.

Then let’s explain what they are?

Horizontal cartoning machine

Basically,the product is pushed into the carton horizontally is called horizontal cartoning machine.

AIPAK horizontal cartoning machine

It completes the tasks of automatic feeding bottle(round, square bottle)into carton (either for blister or bottle),online bottle unscramble and feeding, leaflet fold( 1-4 folds) and feeding, leaflet detecting, canton opening and forming, products and leaflet pushing into carton, printing batch number, sealing carton with hot melt glue device, automatically reject lacking of leaflet or product until finished product out.

Horizontal cartoning machine is an ideal equipment for packaging various solid regular objects, such as biscuits, bread, instant noodle, ice cream, moon cake, candy, blister medicine etc.

Vertical cartoning machine

Vertical cartoning machine-Photo credits:Richpacking

Definitely,the product is pushed into the carton vertically from the feeding system is called vertical cartoning machine.

It is most suitable for packaging bottles, jars and vials into cartons,so it is most preferred in cosmetics,food and pharmaceutical industry.

It is vertical that you will not hard to understand its compact and flexibility features,thus,meet most products high packaging requirements.

Besides,so much experience and statics have told us vertical products inserting will have lower risk of product damage.

Products by vertical cartoning machine

And you will also get other benefits from a vertical cartoning machine if you choose to buy one:

The cartoning machine includes an automatic station to form the cartons. The carton boxes are held by vacuum

No suction carton if missing blister

No suction carton ifmissing leaflet

Automatically displaying device for trouble, speed and finished products counting

Machine stop running if no products or incorrect position of products. And stop automatically if incorrect position of product into carton after returning or no cartons or out of leaflets continuous.

Adopt human-machine operation system.

International famous brand of electric components such for PLC touch screen, frequency inverters, etc

Stable performance, operation is easy Controls

3.Carton sealing form

According to the sealing form of the final carton, the cartoning machine can be divided into types of tongue, adhesive, mixed, labeling, unfolding, self-locking, etc.

4.Shapes of packaging

As to the shape of the packaging, the cartoning machine can be divided into plate shape (such as blister packaging), bottle shape, hose shape, special shape, etc.

4.Specification of packaging

According to the specifications of the packaging, the cartoning machine can be divided into single piece, double piece, multiple pieces, and combination pieces (such as 1 antibiotic bottle powder needle + 1 ampoule water needle), etc.

As the later three cartoning machine are just different forms,we will have not too much explanations about them.

5.What are the main parts of a Cartoning Machine?

An automatic cartoning machine is drived by combination of mechanical,electricity, gas and light which work together in such a method so as to produce, transform and effectively use the mechanical energy generated by the system.

Getting to know the various parts of the automatic cartoning machine is crucial for you to choose the most suitable machine for your mass production.

You will find the main components of a cartoning machine as the following:

PLC control panel

This is one of the most important parts of a cartoning machine with the human-machine interface (HMI),which plays the role of “brain”.

You will configure the whole process and make it a high automation control model.

It is designed easily for your operation, you will have it to control and monitor :

Number of cartons

Number of products per carton

Printing

Indicator of the electrical and gas

Product placement

Besides,stop the machine immediately if any deemed necessary or faults occur.

Apart from these,the HMI will also enable you to set all the parameters and requirements for the whole process so as to realize an ideal point with definite duration.

Last but not the least,the PLC control panel will also alert you if any breakdown happens for the other parts of the machine,that’s in other word,you can check the specific situation on the PLC.

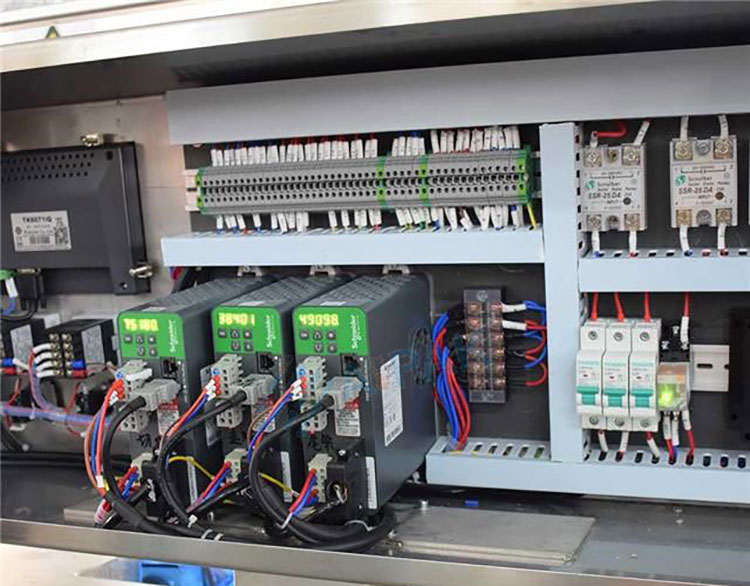

Electric system

From the above image,you can see the main power of a cartoning machine comes from here,and also include power up the pneumatic system to get normal operation, as it takes all the connections to the whole machine.

It plays the role of “heart”of the machine as all the electric circuits are allocated here.

In fact,the electric system is the combination of the electric motor and electric panel ,can be also called gearing system.

Then you may ask what is the electric motor?

Actually,the electric motor is a device that transform electricity into mechanical energy to get an ideal movement.

You may have noted that all the package cartoning process movement and motivation is solely owe to the contribution of the motors.

Just like many other machines,the electric motor in a cartoning machine is well enclosed and configured at the bottom of the machine.The conveyor,bearing ,belt,gear and shafts are combined as the supporting axis to motive the product to be transmit to the cartoning place.

Moreover,you must know that the electric motor has different specification,such as different revolution per minute,power supply and capacity,you must consider as that’s related with your product and factory state when purchasing a cartoning machine.

And it is also cruical when deal with any machine breakdown.

Automatic Lubrication System

You must have known if you want to keep the life-long-span of your machine,you must make it lubricated regularly.Especially for the cartoning machine,who is an electromechanical device,its moving section must be appropriately lubricated to take the most advantage of its performance.

Besides,both the service life of bearing,conveyor and gears has the risk of contamination,by the air humidity,moisture or temperature.And it may increase your maintenance cost and reduce the machine performance if you don’t use lubrication.

While the cartoning machine has the automatic lubrication system that make the well working of the processing operation.

It automatically provide enough amount of oil lubricant to all the moving parts,and you will need to add suitable lubricant to the system when you are maintaining or clean the machine.

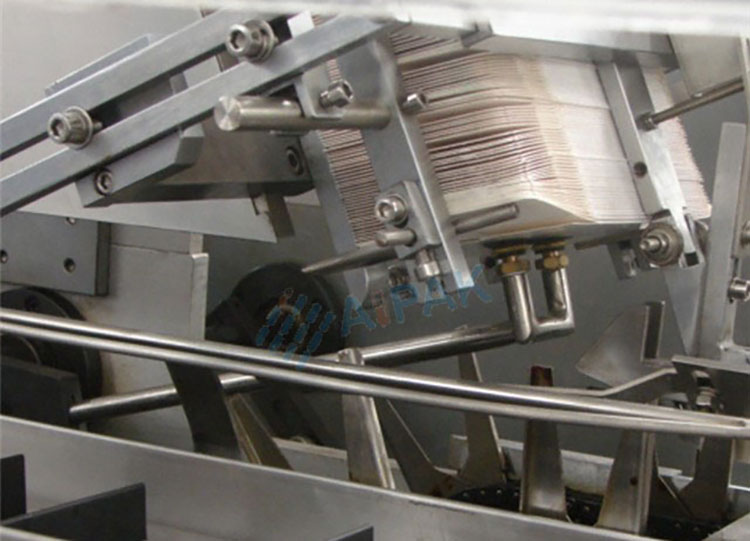

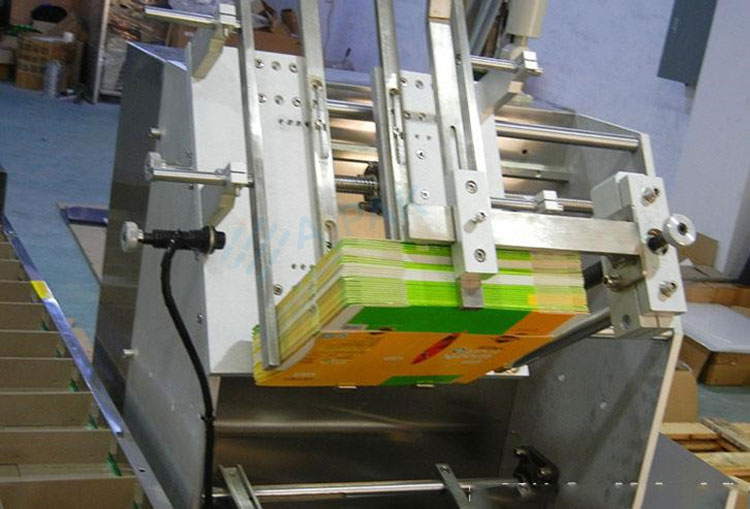

Carton feeding system

This is the parts that actually responsible for the cartoning process.

When the machine is running,the pneumatic system will suck the vacuum to draw the pre-glued flat cartons to start the cartoning process.

The carton storage room is where the cartons are put. It consists of front and back parts with front and middle plate. The intermediate plate is movable and can be adjusted according to the length of the carton.

Carton feeding

And in front of the storeroom you will find there is a press device,which is to send out signal to stop the machine immediately if the carton is blocked,damaged or deformed during the sucking process.

Leaflet feeding

Behind the press device ,you will find the leaflet feeding,that’s the leaflet will be placed in the middle of the pins for automatically feeding into the carton.

Then the products will go through the conveyor belt to be insert into the cartons.

Product conveyor belt

And there is vertical screw for you to adjust the thickness of the carton box,it is convenient and simple for your operation.

Injet spraying system

For the last labelling requirement ,you will find there is a inkjet printer equipped with the cartoning machine.

It is smart to be input with the product information such as manufacturing date,expiry date and other disclaimer rules you want to display to your customers.

The words printed are the real information that is very intuitive to your customers.

Conveyors, Guide Rail and Carton Chute

From the above parts,you may have known that the conveyor is motivated by the electric motor to carry the carton to move from one point to another,and you can also see the conveyor is connected with the rollers.

This section is very crucial to the operation of the cartons as you can once the product is packaged,all this parts will drive the cartons move to the next section, and simultaneously the guide rail will make it form the runway.

The carton chute is designed for the full packaged inventory to drop down for further packaging into more bigger box for storage or transport.

6.What is the working principle of Cartoning Machine?

The efficiency of a cartoning machine is determined by the synchronization of its mechanical, pneumatic, and electronic components. AIPAK’s systems are designed with a four-stage precision cycle to ensure zero-damage product handling.

Stage 1: Dynamic Carton Extraction & Opening

The process begins at the Flat Carton Magazine. A rotary vacuum pickup system draws a single pre-glued flat carton from the stack.

-

Pre-breaking Technology: To prevent carton jams, the machine active-opens the carton at a 90-degree angle using a specialized push-plate and dual-suction mechanism. This ensures even stiff or high-GSM paperboard opens reliably every time.

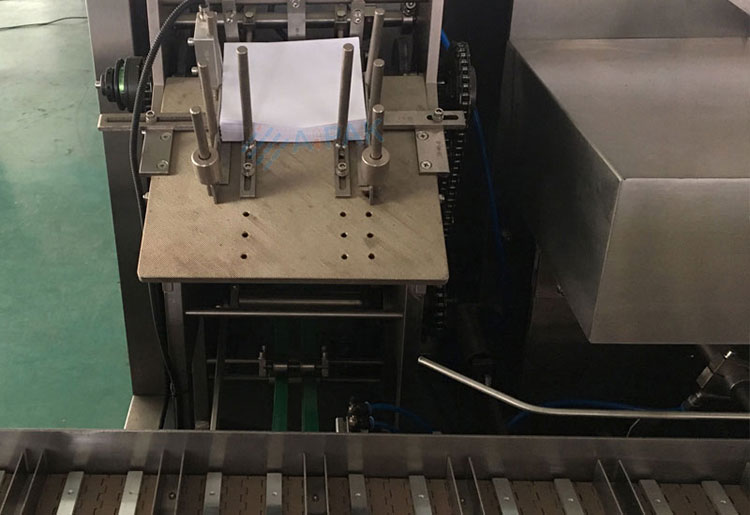

Stage 2: Synchronized Leaflet & Product Insertion

This is the most critical stage where the Leaflet Folder (GUK-style) and the Product Feeder meet.

-

Parallel Feeding: The instruction manual is folded (1-4 folds) and positioned simultaneously with the medicine bottle or blister pack.

-

Gentle Pusher Mechanism: A servo-driven pusher gently slides the product and the leaflet into the open carton. The system monitors resistance; if an obstruction is detected, the machine triggers an Emergency Stop to prevent product damage.

Stage 3: Multi-Stage Carton Closure

Once the product is loaded, the chain conveyor moves the carton to the folding section.

-

Mechanical Tuck-in: Mechanical fingers fold the "ears" (side flaps) into the guide rails.

-

Sealing Options: Depending on your anti-counterfeiting requirements, the machine completes the seal via a Tuck-in tongue or an optional Hot-melt glue application. The latter provides a tamper-evident seal essential for modern pharmaceutical standards.

Stage 4: Verification & Discharge

Before the carton reaches the exit, it undergoes a final audit.

-

Vision & Sensor Check: The machine verifies the presence of the leaflet, product, and batch code.

-

Automated Rejection: Any non-compliant carton—missing a leaflet or having an illegible batch code—is automatically diverted to a Rejection Chute, ensuring that only 100% qualified products reach your logistics chain.

7.What are the main features of Cartoning Machine?

In order to greatly improve the production efficiency, you will use the cartoning machine when packing boxes. However,the automatic cartoning machine is an intelligent operation machine, and the operation method is relatively simple.

So as to master the operation skills, before this, you must understand the use characteristics of the cartoning machine:

Multifunctional

The cartoning machine has mut-functions of packaging operation,all kinds of complicated packaging work can be completed at the same time.

However,when you are using,remember to set the corresponding functions according to the actual application requirements, so that the machine can successfully complete the packaging process.

Harmony operation

The machine will have continuous mechanical feeding of materials and carton, and working of each function part are in harmony, stable and reliable.

And the constantly moving of carton-opening mechanism and pulling carton-opening mechanism are also more stable and reliable.

Safety guarantee

When your products do not reach the correct position, the pusher will have an alarm and half facility for that, so as to ensure good quality of carton packaging and safety in operation effectively.

And there is facility for air pressure and vacuum protection,that is,when the caster is opened,the facility will automatically check for the safety operation of the machine.

Convenient operation

It is easy, convenient and quick for you to change and adjust the product size by the hand wheel on instrument panel.

And there is variable frequency speed regulation, PLC automatic control, Operating on the touch screen, words and numeric display,that is,have stable coefficients in operation, which is easy for your operation.

Automatic diagnosis

It will save your maintenance cost as any machines will have faults sometimes,however,with the overload protection for the principal driving,the cartoning machine will have indication of failure diagnosis automatically and stop working immediately.

8.How do you use a Cartoning Machine correctly?

Have gotten the various advantages of the cartoning machine,you may get to know how to use the cartoning machine correctly.

Below you will find the step by step procedures:

1.Preparation before startup

1)You shall check the equipment status, and replace the equipment status mark as "in operation" after confirming that there is no abnormality.

2)You will check the equipment item by item according to the equipment point inspection form and make records. In case of any abnormality, report for repair in time.

After confirming that there is no abnormal condition, proceed to the next step.

3)You should lubricate the equipment according to the equipment lubrication table and make records.

2.Startup operation

1) After confirming that the equipment is normal, turn on the power of the cartoning machine in the distribution box and turn the power knob of the control cabinet,when the equipment is powered on, and the alarm light on the control cabinet starts to flash.

2)You need to turn on the air inlet switch that is the pneumatic system.

3) You shall press the reset button,if there is any abnormality, "alarm information" will be displayed on the touchscreen; if there is no abnormality, the device can be started.

4) Then you can set the parameters such as packaging speed, feeding angle and photoelectric detection angle on the touchscreen according to your product needs.

5) You should put the instruction mannul and the cartons in place according to the production requirements.

7) Press the green "run" key on the control panel, the device will run automatically and put the cartons into the conveyor belt,then you will get the automatic cartoning.

8) In the process of adjustment, you need to press the "single cycle" button, the machine will perform a complete packaging process. If the packaging switch is touched, the machine also performs a complete packaging action. If film feeding is not required, the film feeding switch can be closed, and the equipment will not operate under the no film blanking.

9) if there is a fault in the operation of the equipment for maintenance, the tools must be counted, and before starting the equipment, the tools must be counted

10) After production, press the "stop" button on the equipment control panel to stop the equipment.

3.Shutdown operation

1) After the equipment stops running, turn off the "paper unloading on" and "vacuum pump" buttons on the touch screen.

2)Turn off the air intake switch and the power switch on the side of the equipment distribution box. 3)Turn off the power switch in the wall distribution box to control the transparent film packaging machine.

9.What should be paid attention to when using the full-automatic Cartoning Machine?

After correct and reasonable selection of the type,correct and reasonable use, operation and maintenance can extend the service life of the machine.

When using the full-automatic cartoning machine, it is recommended to pay more attention to the following aspects:

1) The carton supplier shall be required to provide substrate specification compliance in strict accordance with industry standards and user requirements, and ensure that these qualified cartons do not go out of shape during the temporary storage and transportation, so as to ensure the cartoning qualified rate.

2) Before using the equipment, you shall carefully read the operation manual and operation procedures of the cartoner, and be familiar with its performance and operation methods of the control part.

3) Before the start-up of the cartoning machine, the position of the mold shall be adjusted correctly. The equipment shall be idled first to confirm that the sound is normal and the lubrication is good before normal operation.

4) You shall check the cartons to be used to avoid adhesion. If such situation is found, handle it in time. Otherwise, it will affect the operation rate and produce too many waste products.

5) The speed of full-automatic cartoning machine has influence on product quality and equipment life. Generally, when the size of the carton box is large, you shall choose slower speed, while the appropriate size of the carton box can select fast speed.

6) You are not allowed to dismantle the machine parts on the equipment at will. In case of large vibration or abnormal noise of the machine during its operation, you shall stop the machine immediately for inspection and continue to use after troubleshooting.

7) Regularly check and maintain the easily worn parts to prevent the damage of individual parts from affecting the performance of the whole machine.

8) Before shutdown, reduce the operation speed of the cartoner as much as possible, and then stop the machine.

9) According to the requirements of the operation manual, the cartoning machine shall be maintained regularly to ensure the normal daily use of the equipment and extend the service life of the equipment.

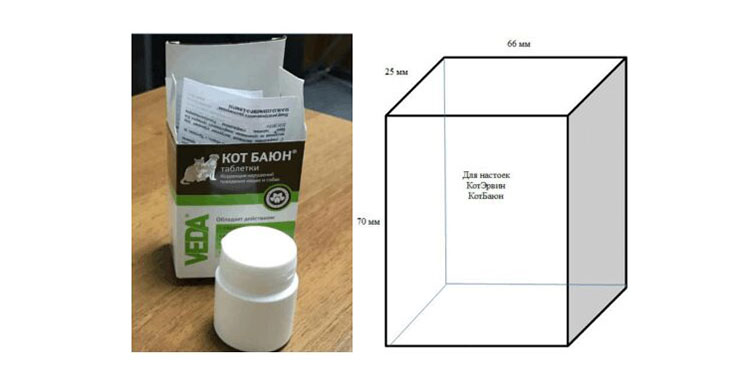

10.Is there any requirements to the carton shape and size?

Of course ,there is requirements to the carton shape and size just like every product have its unique taste.But before promoting detailed explanation,you need to know what is the carton first.

Cartons are light box or container and typically made of waxed cardboard or paper with some extent thickness and in which goods especially food or liquids are packaged for easy transiting.

We commonly known cartons are six-side rectangular or square shaped cartons,but as different packaging needs the shapes and size of carton can be various,such as octagonal,polygonal,folding,triangular, tapered trays and wave-shaped.

Then let's get to know what is requirement for the carton shape and size.

Generally speaking, the carton size should be considered from the perspective of cost saving, that is, the smaller the size, the compact and better it will be.

As in the process of manual packaging, people's dexterous hands can put almost any product into the carton box, and the size of the box is smaller. However, when using the cartoning machine, the tolerance between cartons and products should be considered.

In order to make the inner package into the box smoothly, the inner dimension of the box and the inner package should have a large interference fit, especially when multiple inner packages (blister plate with instructions, oral liquid with straw, etc.) are put into the carton box at the same time.

The pharmacopeia-compliant leaflets is usually "pushed" into the carton together with the inner package, and forming “U” shape in the carton,so the two ends of the carton may not be the same length, then you will need to consider the length of the carton.

For the same reason, the thickness of the pharmacopeia-compliant leaflets takes up space, you should also have a judgement to height of the carton to leave some space.

11.How to solve the contradiction between the cost of packaging materials and the requirements of Cartoning Machine to the cartons?

In recent years, with the price reduction of drugs and the fierce competition in the drug market, pharmaceutical manufacturers pay more attention to the production cost.

In the process of reducing the cost of finished drugs, you will find people pay more attention to the cost of cartons as medium packaging.

Even if a cartons can save 0.5 points, it is also a considerable cost for mass production. If manual cartoning operation is adopted, the quality requirements of cartons are low, and their dimensions are compact, which will save at least 0.01-0.02 for a carton.

However, once the cartoning machine is used, it will put forward higher requirements to the cartons and the pharmacopeia-compliant leaflets, that is the size of cartons is larger than that of manual cartons.

Then as I conclude and calculate from much experience and statics ,you will follow the below rules to design your carton box dimension.

| Carton deimensions | Empirical formula |

| Outer width | Product width+2 x paper thickness+>3/mm |

| Outer height | Product height+2 x paper thickness+>4~5/mm |

| Outer length | Product length+>5/mm |

In other words,to solve the contradiction between the cost reduction of cartons and the production cost reduction after using the cartoning machine depends on the coordination and consideration of both the manufacturer and its users.

That is to say,first of all, you can’t only see the increase of cost of each carton in front of them, and do not comprehensively consider the cost reduction caused by the reduction of labor force after the use of the cartoning machine.

Secondly, there are special requirements for the quality and size of the cartons, you need to consider how to improve the utilization of the carton.

12.How to modify the carton specification of a Cartoning Machine?

From the above ,you may have known that a suitable carton shape and size will save your material cost using a cartoning machine,then have calculated the carton size as the above formula,you need to how to modify the carton specification on the machine.

Actually,you can begin to adjust from the carton conveyor chain.

That is,first you need to nip the up-cover and place the carton to the middle of the chain,then move the adjust knob and adjust the middle plate to a point so that the output strip can clip the carton more accurately.

However,during your adjust proceed,you need also not touch the inner crease-slice.

Then you will need to loosen the nuts on the carton-sending chain to adjust the chain plate to get the correct carton width.

While,the left and right shafts of the block need also be adjust to the appropriate place to match with the length of the black carton.

And you will also need to adjust the carton vacuum suction device and the height of the carton press device to make them aligned .

In fact,you need also adjust the carton sealing and batch number printing according to the carton height and width.Simultaneously the batch number printing should be adjust according to the paper carton height.

And make sure the front plate track of the carton should be the same as the carton height.

Of course ,you can also refer to the pharmacopeia-compliant leaflets to get the correct procedure to adjust the carton specification.

13.Why you need to powder the pneumatic system before turning on the Cartoning Machine?

From the working principle of the cartoning machine,you may have known that the pneumatic system is to suck the pre-glued flat cartons from the stacks.

Therefore,it is important to power the pneumatic system before powering the machine as if there is no air,there will be no carton forming process.

14.How to choose the most suitable Automatic Cartoning Machine?

Selecting a cartoning system is a long-term capital investment. Beyond basic speed, professional pharmaceutical buyers evaluate equipment based on Total Cost of Ownership (TCO) and Operational Excellence. Use the following expert criteria to guide your decision:

1. Mechanical Stability & "Heavy-Duty" Engineering

-

Vibration Control: Ensure the machine frame is constructed from high-grade SUS304/316L stainless steel with a reinforced base to minimize harmonic vibration during high-speed runs.

-

Component Provenance: Request a Critical Component List (CCL). Premium systems should utilize world-class motion control parts (e.g., Schneider, Rockwell, or Siemens) to ensure global spare parts availability.

2. Versatility & Rapid Changeover (The 30-Minute Rule)

-

Tool-less Adjustment: In a multi-product facility, changeover time is a hidden profit killer. Prioritize machines featuring digital position indicators and tool-less adjustment for different carton sizes.

-

Format Flexibility: Verify if the machine can handle the full range of your current and future secondary packaging needs—from single blisters to multi-unit bottle packs.

3. Seamless Integration (Upstream & Downstream)

-

Handshaking Protocols: A cartoning machine must act as a "smart bridge" in your production line. Ensure it supports standardized PLC communication protocols (like EtherNet/IP or Modbus) to synchronize with upstream Blister Machines and downstream Case Packers.

4. Compliance & "Zero-Defect" Assurance

-

Validation Support: For pharmaceutical clients, the machine is only as good as its documentation. The supplier must provide comprehensive IQ/OQ/PQ protocols and support for FDA/GMP audits.

-

Rejection Logic: The system must feature active verification for product presence, leaflet insertion, and batch code legibility. A fail-safe automatic rejection chute is non-negotiable for 100% compliant output.

5. Digital Readiness & Industrial 4.0

-

Data Integrity: Look for HMI systems that offer multi-level password protection and audit trail capabilities, compliant with 21 CFR Part 11.

-

Remote Diagnostics: Modern machines should support remote VPN access, allowing engineers to perform real-time troubleshooting and reduce on-site service costs.

15.How to troubleshoot common problems of Automatic Cartoning Machine?

Follow the below steps,you will get the common problems solved soon when using an automatic cartoning machine:

Belt interval stop or fully stop

- You shall check whether there is material shortage or restart the machine.

- You may stop the machine and check whether the power supply, motor or control panel are normal.

Cartons cannot be drawn down

- You need to check whether the cartons are placed in order.

- Whether the cartons are pasted together.

- Whether the air pressure of suction head is normal.

After the carton is sucked down, it does not form or pop up at the entrance of the box feeding

- You will check if the carton is too hard.

- Check whether the position of the guide rod of the carton box and the box feeding is not in place.

- Check whether the small hook spring at the back of the box feeding is deformed.

- Check whether the height of suction head and carton delivery track is aligned.

Pharmacopeia-compliant Leaflets does not suck down

- You need to check whether the pharmacopeia-compliant leaflets is deformed, making the suction head can’t suck.

- Whether the suction head gas is parallel to the pharmacopeia-compliant leaflets.

- If there is varities on the width of the pharmacopeia-compliant leaflets, it must be within 1mm.

- The stacking position of the pharmacopeia-compliant leaflets should be adjusted to the difference of 0.5mm between the inner side when the suction head rises to the highest position.

- The movement time of the paper separating hook above the suction head of the origami machine is too early.

Generally, the small hook should be inserted into the space between the paper and the paper before the suction head is about to drop. The height of the small hook is adjusted by 0.5mm when the suction head is at the highest position.

The pharmacopeia-compliant leaflets rebounds after being sucked down

- This is maybe the action of the driving foot to the pharmacopeia-compliant leaflets is too early, even it has not been pulled down it is taken away.

- In other words, the position of the driving foot is suitable to return to the highest position when it does not touch the sucked instructions manual and return to the highest point when the paper is not pulled by the paper grabbing notch wheel.

- You shall check whether the speed of the suction head and the paper grabbing notch wheel is matched. The suction head shall be lowered first, and then the front part of the paper grabbing notch wheel shall be pressed onto the paper.

The Pharmacopeia-compliant leaflets is not folded well

- You should check whether the paper is deformed and bent, and whether there is burr.

- Whether there is any foreign matter in the fence board, blocking the paper.

- The gap between the opening of the fence board and the folding rod is too large, which makes the paper jump out.

- Whether the gap between the folding sticks is too large to nip the paper.

- Then you shall adjust the adjusting screws at both ends of the folding rod to reduce the gap. If the folding rod is worn due to long service life, it must be replaced.

Uneven folding of instructions manual

You will check and adjust the front and back position of the barrier strip in the fence board to meet the required folding size.

After folding the Pharmacopeia-compliant leaflets, there are rolls and creases

- Check whether the gap between baffle and folding rod is too large. And then adjust the middle position between the baffle plate and the folding rod.

- If the middle position of the baffle plate and the folding rod has been adjusted and there is a large gap, remove the locating pin on the baffle plate and re-adjust it until there is no paper blocked into the gap.

The Pharmacopeia-compliant leaflets in the fence board is stuck

- You will find whether the gap between folding sticks and paper feeding is too large, and the paper feeding is weak. The adjustment method is the same as before.

- The installation position of the lower half of the fence board is longer than that of the guide board with arc on it, so that the paper can not enter the lower folding stick.

Then you should loosen all the fixing screws on the fence plate, adjust the panel back, but not shorter than the guide plate above, and 1-3 mm longer than the guide plate.

If it is shorter than the guide plate, the pharmacopeia-compliant leaflets may enter directly into the below folding stick without folding.

16.How to maintain the Cartoning Machine?

The use of cartoning machine has brought the rapid development of packaging industry. In today's fast-paced society, all kinds of automation equipment gradually replaced manual operation in major production industries.

In many packaging industries, the use of cartoning machine not only achieves the improvement of production efficiency, but also saves a large part of human and material resources for the enterprises.

At the same time, the cartoning machine in some production environment has also done a lot of works that cannot be completed manually.

In daily production, the cartoner needs some maintenance to play a better role.

Now, let's have a specific understanding of the maintenance operation.

First of all, when the cartoning machine is not in production and work, it should be cleaned and scrubbed in time. To keep the cartoner clean and tidy, and cut off the power supply when cleaning.

Then, for some parts that are easy to wear or have worn, you should repair and replace them in time. If a part of the cartoning machine is found to be loose, it shall be tightened in time.

Secondly, add lubricating oil in time after the long work of the cartoner.

Finally, in addition to daily inspection and cleaning. In order to make the service life of the cartoning machine longer, a large overhaul should be carried out regularly.

17.What are the specialities of medical Cartoning Machine compared with other Cartoning Machines?

But the above practical applications,you have know that cartoning machine has a wide range of utilizations and application areas.But there are some difference between the cartoning machines in pharmaceutical industry and other industry.

They are listed below:

- Compared with cartoning machine used in food ,it needs to be inserted with the drug Pharmacopeia-compliant leaflets into the cartons when the drugs are loaded.

- After completing packaging the cartons, the production date, product batch number and expiration date must be printed, which are all carried out during the packing process.

- The medical cartoning machine also needs to check the quality of the drugs in the inner packaging to ensure the quality of the drugs is qualified.

18.Is there any new technology in Cartoning Machine?

The research of the new technology to the cartoning machine is mainly concentrated on the following two directions:

Pay attention to excavate and develop the structure details of the cartoning machine.

As the quality of the structure detailed development of cartoning machine will determine the fate of your products, and it unlikes other equipment, the structure detailed development of a superior cartoning machine will improve the overall product quality.

That is, from the perspective of quality control, to detail the design of cartoning machine,but the basic principle is to ensure that the change of materials in detail does not affect the production quality of the cartoning machine.

Develop the cartoning machine in combination with a complete set of back packaging production line.

That is,as the cartoning machine is not only a machine to reduce labor intensity and production cost, but also a sign of modern pharmaceutical production, and combine it with other back packaging equipment, make it become a branch of the back packaging production line.

And in the future, what the pharmaceutical factory will buy is not a single cartoning machine, but a complete set of packaging production line, which is the trend and the most effective method to popularize the application of cartoning machine.

Make the inner packages have multiple adaptability to develop the cartoning machine.

That is,different inner packages will have different packaging conditions, and the cartoning machine can adapt to different inner packages, which is the future development direction of the new technology of the cartoning machine.

A new trend of digital development in cartoning machine.

Digital packaging machinery can not only provide greater output and more flexible equipment, but also add many new features, such as remote maintenance, integration with ERP system, evaluation of production data, etc.

With the increasing speed of the electronic process, there was a need to increase the distribution box.

However, when the number of cables required for the bus system can be greatly reduced, coupled with the emergence of distributed computers, it will mean that the size of the distribution box does not need to be increased.

Nowadays, the independent distribution box is no longer necessary in the packaging industry, and the digital packaging machine occupies less space than the previous mechanical or electromechanical packaging machine.

That is the digital development in the cartoning machine will bring more benefits to you .

Cartoning Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586