High-Precision Automatic Capsule Filling Machine | GMP Compliant Solutions

Reliable capsule filling solutions for pharmaceutical, nutraceutical, and herbal products.

Ensure accuracy, efficiency, and consistent quality

GMP & CE Certified, 99.9% Filling Accuracy, 12-Month Warranty, Global On-site Support

High-Precision Capsule Filling Machines: GMP-Compliant Solutions for Pharma & Nutra

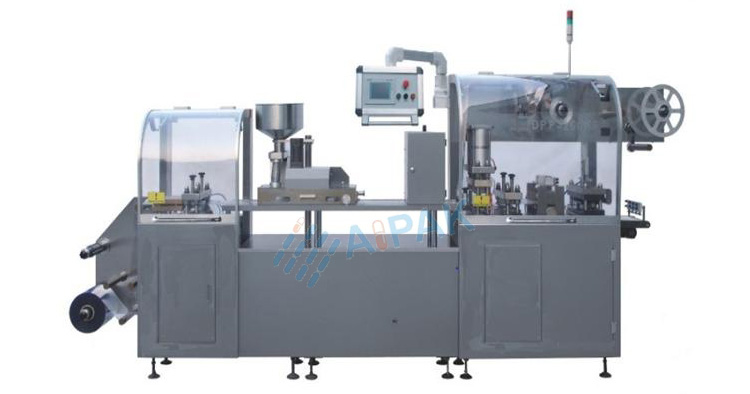

AIPAK capsule filling machine can fill empty capsules with various substances including medicine or nutrients.The capsule filler can fill different size of capsules-#00-#5 or all safety capsules with filling accuracy up to 99.99%. AIPAK’s selling products including fully automatic capsule filling machine and semi-automatic capsule filling machine.Both AIPAK capsule filling machines can be used for large, medium, small scale manufacturing as the encapsulating machines have good adaptability to drugs and empty capsules, stable performance, high degree of automation.

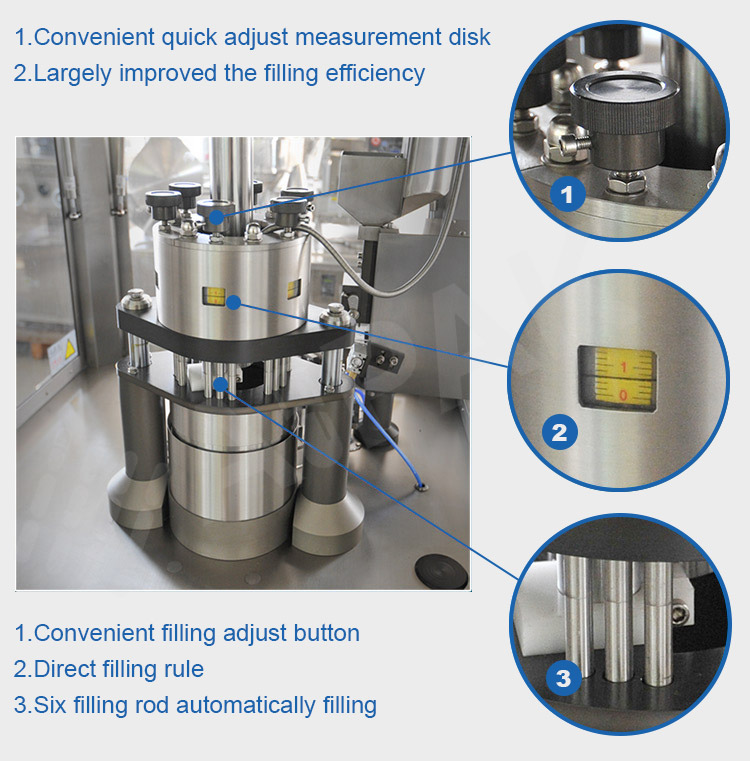

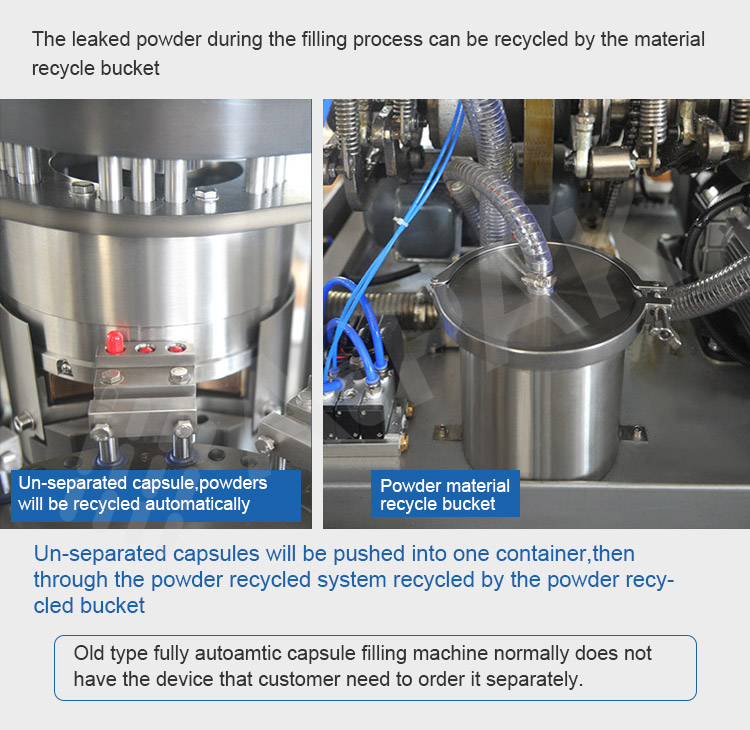

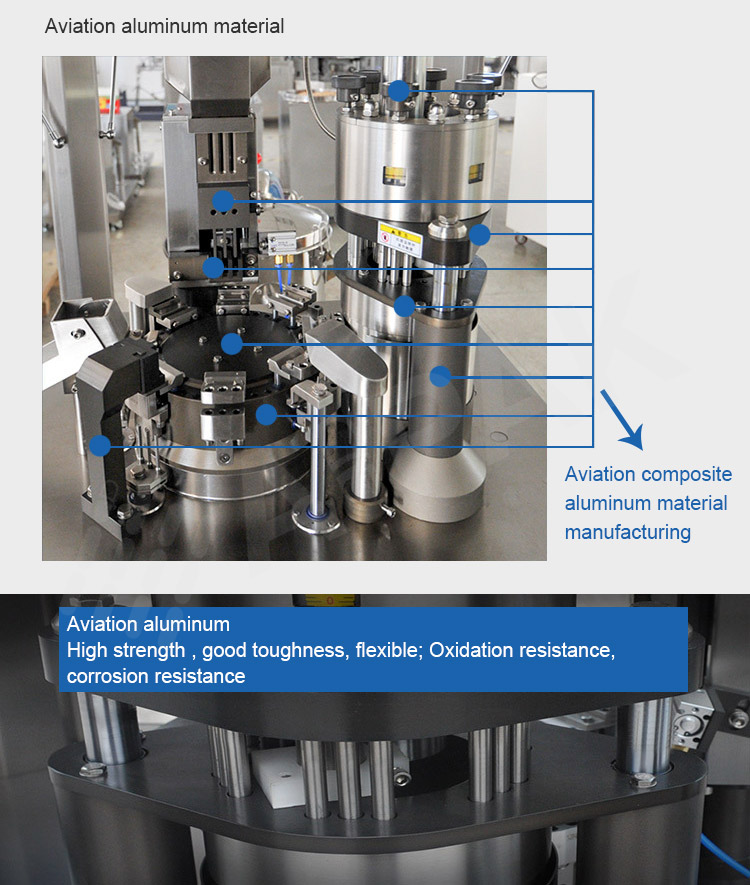

AIPAK Fully Automatic Capsule Filling Machine Details Introduction

Why Choose AIPAK?

Applications of Capsule Filling Machines

Pharmaceutical Manufacturing

Accurately fills hard gelatin or HPMC capsules with active pharmaceutical ingredients (APIs).

Ensures consistent dosing, hygiene, and compliance with GMP standards.

Nutraceutical & Dietary Supplements

Ideal for vitamins, probiotics, minerals, and other supplement capsules.

Supports both high-volume production and small-batch runs.

Research & Development Laboratories

Suitable for pilot studies, formulation testing, and small-scale production.

Provides precise control over capsule size, filling volume, and powder consistency.

Contract Manufacturing

Flexible equipment for companies offering outsourced capsule manufacturing.

Handles a variety of capsule sizes and powder types efficiently.

Small Batch / Pilot Production

Traditional Medicine

Ensures clean, polished herbal capsules free of dust or residue.

Meets both domestic and international quality standards for herbal and plant-based products.

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

Capsule Filling Machine FAQ

Q1: What types of capsules can this capsule filling machine fill?

Supports hard gelatin, HPMC, herbal, and other capsule types in various sizes.

Q2: What is the production capacity?

Depending on capsule size and filling volume, the capsule filling machine can produce 50,000–100,000 capsules per hour.

Q3: Is the capsule filling machine GMP compliant?

Yes, it is built with 304 stainless steel and fully meets GMP international standards.

Q4: How easy is it to clean and maintain?

All parts that contact capsules or powder are detachable, making cleaning and routine maintenance fast and convenient.

Q5: Can the capsule filling machine handle herbal or fine powders?

Yes, it can accurately fill powders, granules, and herbal extracts without leakage or cross-contamination.

Q6: Can the filling volume and speed be adjusted?

Yes, both are fully adjustable to meet different production requirements.

Q7: Is the capsule filling machine suitable for small-batch or pilot production?

Yes, it works efficiently for both small and large-scale production lines.

Q8: How accurate is the filling?

The capsule filling machine provides high precision, with minimal deviation, ensuring dosage consistency.

Q9: What are the power and air requirements?

Typically requires 220V/380V power supply and standard compressed air supply for pneumatic components.

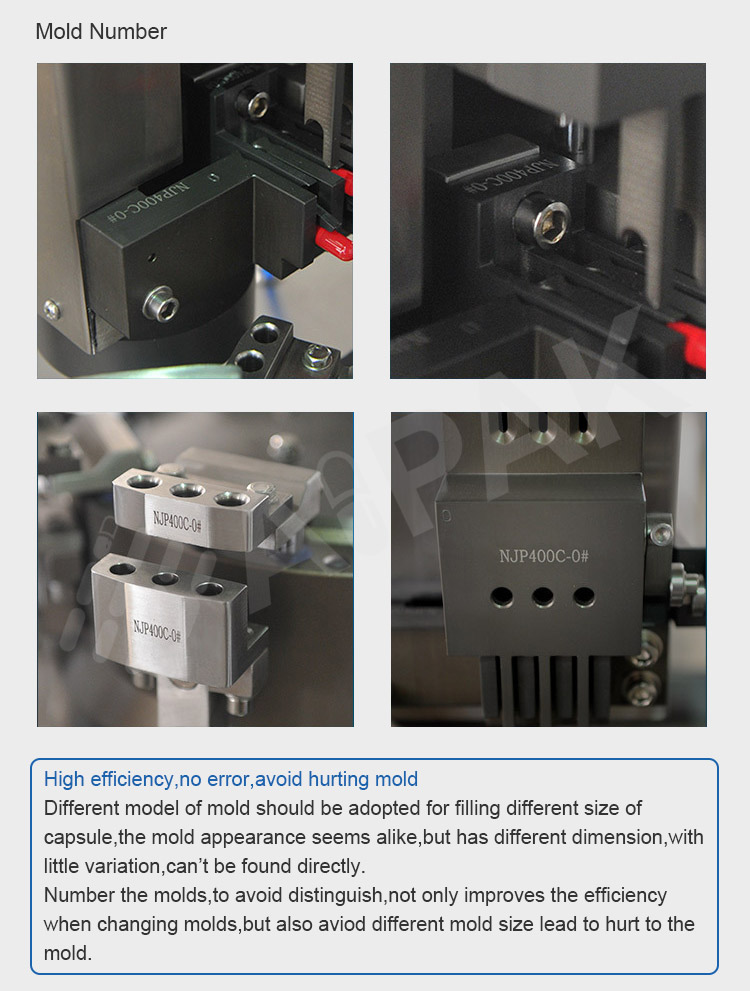

Q10: How can you replace molds or capsule size settings?

The machine is designed for quick mold change with simple adjustments to accommodate different capsule sizes.

Q11: Does the capsule filling machine support automatic capsule counting?

Yes, optional modules are available for automatic capsule counting and quality inspection.

Q12: What is the warranty and after-sales support?

The machine comes with a one-year warranty and technical support for installation, operation, and troubleshooting.

Q13: Can the capsule filling machine be integrated with other packaging equipment?

Yes, it can connect with capsule polishing, blister packing, labeling, and cartoning machines to form a complete automated production line.

Q14: Is training provided for operators?

Yes, AIPAK provides on-site or remote training to ensure safe and efficient operation.

Q15: How reliable is the machine for continuous operation?

Designed for 24/7 industrial production, with durable components and minimal downtime.

The Buyer's Guide

Capsule Filling Machine: The Complete Buying Guide in 2025

In the pharmaceutical and nutraceutical industries, the efficiency of your encapsulation process determines your bottom line.

Whether you are scaling a laboratory formulation or managing high-volume industrial production, choosing the right capsule filling machine is critical.

This guide provides a technical deep-dive into machinery classification, GMP-compliant working principles, and maintenance protocols to help you optimize your production yield.

Chapter 1: What is a Capsule?

A capsule is a protective shell of drugs and nutrients.

New developed capsules-Photo Credits: Spectator Life

You will choose to use a capsule to administer medicine but not compress to tablets due to :

- The drug may irritate the esophagus and gastric mucosa

- The medicine may have bad taste, easy to volatilize, easy to be decomposed by saliva in the mouth or easy to inhale into the trachea

Drugs packed in capsules, not only protect its properties from damage, but also protect the digestive organs and respiratory tract.

Besides, removing the capsule shell may cause dug loss, waste, and efficacy reduction.

Last, some drugs need to be dissolved and absorbed in the intestine, and the capsule can protect the drugs from being damaged by gastric acid.

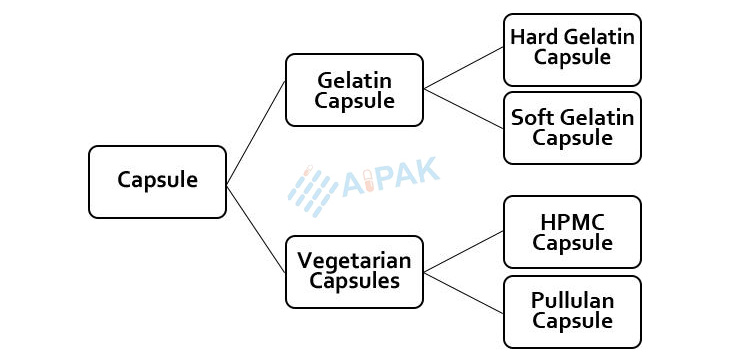

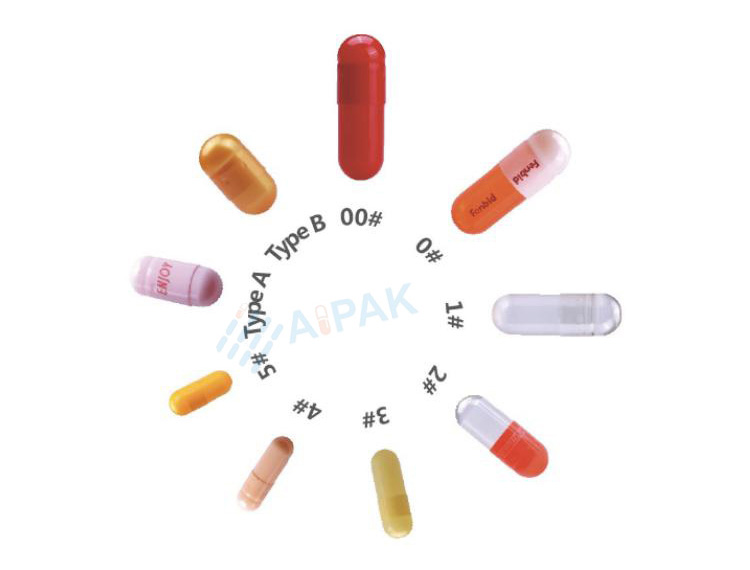

Chapter 2: How many types of Capsules are there?

Generally, there are two types of capsules: hard capsule and soft capsule.

Hard capsule, also known as empty capsule, consists of two parts of the cap body.

Soft capsule is made of film-forming material and content at the same time.

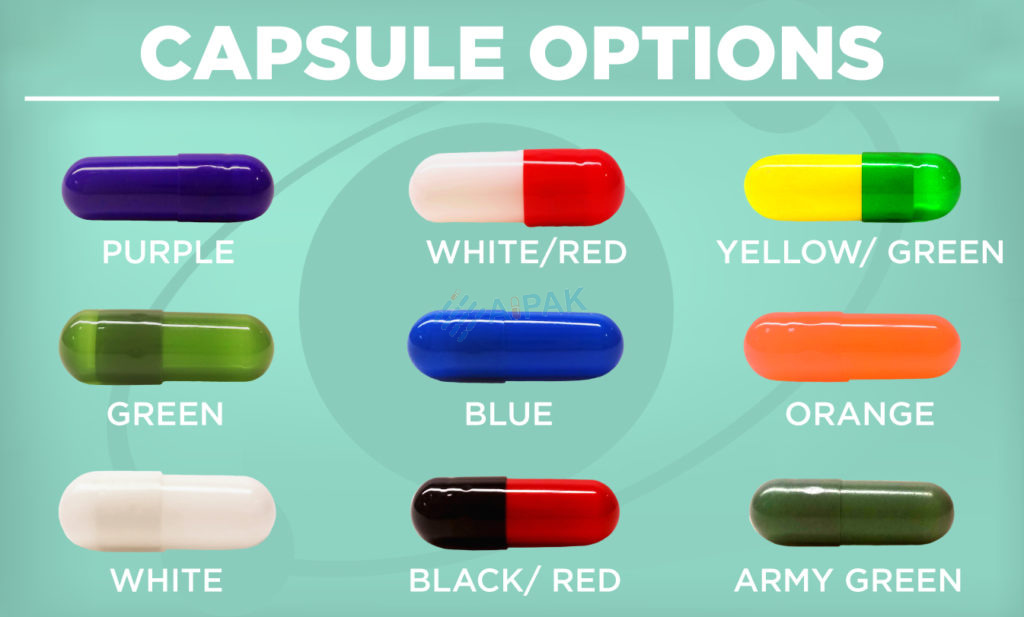

As the variety of the raw materials that you can also choose the capsule including:

Gelation Capsule

Gelatin capsule is the most popular two-section capsule in the world which includes the cap body and the cap of the capsule.

The capsule consists of gelatin manufactured from the collagen of animal skin or bone.

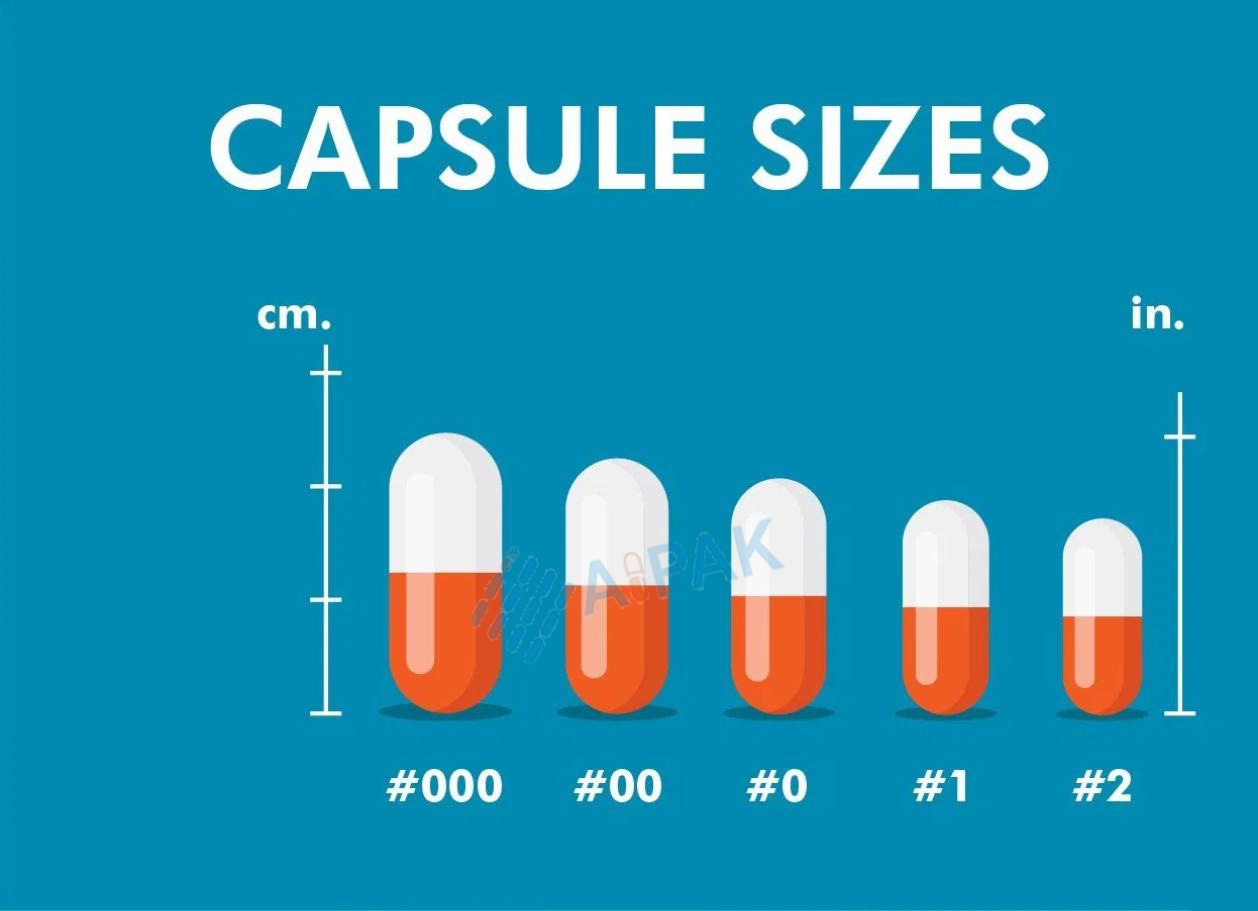

And there are various sizes of gelation capsules available including 000#, 00#,0#-5#.

You can also make the capsule colored or print your logo on it and its appearance can be uniquely customized.

Vegetarian Capsule

You can manufacture a vegetarian capsule from plant cellulose or water-soluble polysaccharide.

VEGETABLE CAPSULES (HPMC)-Photo Credits:Healsee

From these kinds of materials you can imagine that the vegetarian capsule has retained all the advantages of an empty capsule, it is convenient to take, the contents are transparent and you can clearly see what they are.

And you will also not be horrible to take the vegetarian capsules then.

Chapter 3: How is the capsule made?

You will use a capsule filling machine to make your large capsule production.

First you need to split the capsule to fill ingredients or supplements. The long end cap body is responsible for carrying these drugs and the short cap is to cover that cap body.

You will see many tiny holes in the capsule board and the machine will vacuum the capsule cap and leave it on the upper capsule board. Last, the capsule body is pulled to the lower capsule board, which then the cap and body are separated.

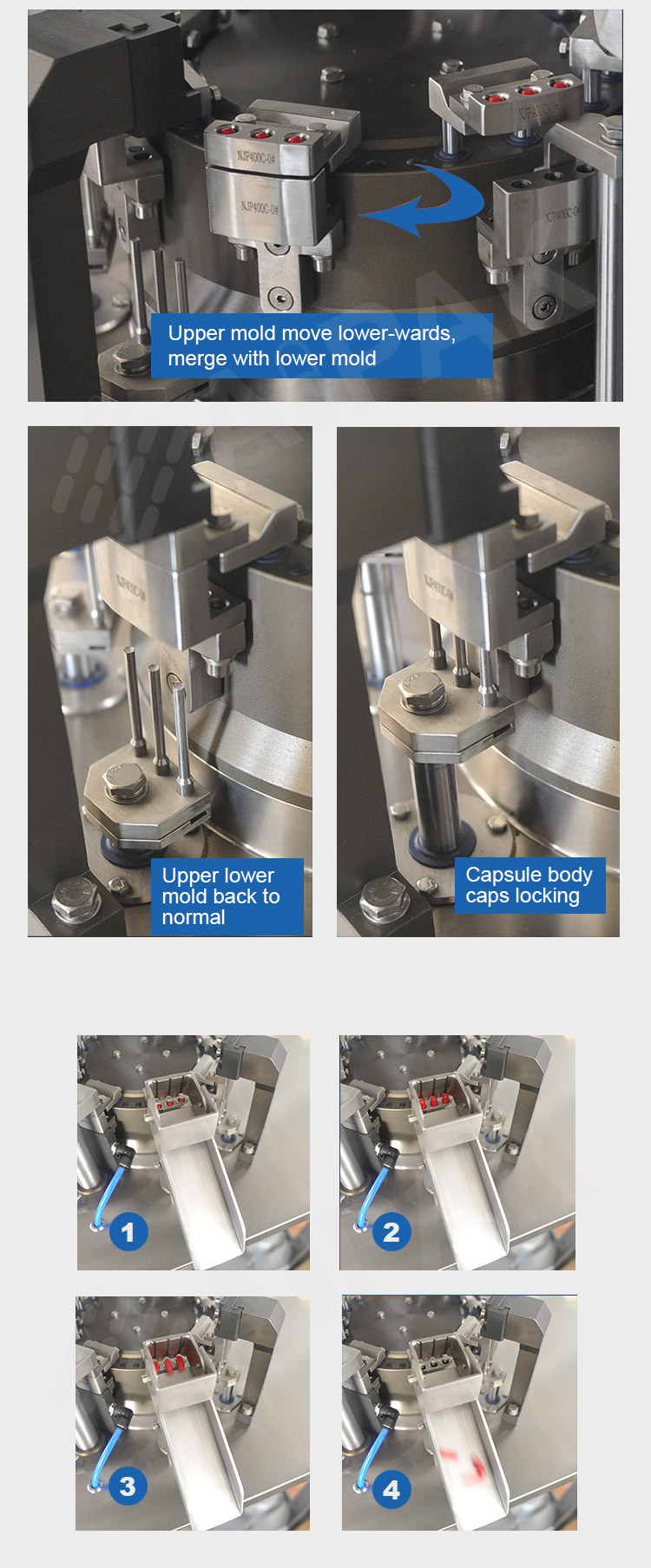

Then you will see after the cap body is filled with drugs, there will be a row of ejector pins to push the capsule body in the lower capsule plate into the capsule cap of the upper capsule plate, which closes the capsule.

Last if you continue with this, you will pop out the filled capsule.

Chapter 4:What is a capsule filling machine?

Capsule filling machine is a kind of equipment that can fill empty capsules with various substances, which including medicine or nutrients.

Have you ever thought why should we fill the empty capsules with powders, or if we can open the capsule and take the powder? The answer is these powder are packed in capsules, which not only protect the drug properties from damage, but also protect the digestive organs and respiratory tract.

Medication presented in capsule form is designed to be swallowed. Do not chew, break, crush, or open a capsule to pour out the medication, unless a healthcare professional has advised you to. Some pills may be harmful if crushed or opened.

Chapter 5: What is the purpose of the capsule filling machine?

Capsule filling machine can be used by home or produce capsules by large- scale.

You can also use different types of capsule filling machines for different applications, especially for:

- Pharmaceutical companies

- Local pharmacy

- Users of nutritional supplements and natural herbs

Besides, the machines can also be used to fill different types of internal filler materials to make different types of capsules.

In China, you can use the capsule filling machine to pack your own capsules.

Commercially, you will capsule filling machines to produce different types of capsules on a large scale.

Chapter 6:Where can capsule filling machine be used?

You can use the capsule filling machine in different domestic and commercial applications.

Here are the main applications you can use with the capsule filler.

1) Drug use

In this case, you can use the capsule filler to fill different types of medical products into empty capsules.

In addition, the capsule filling machine can also fill nutrients and other body supplements into empty capsules in the correct amount.

Various Drug Uses-Photo Credits: University of Bristol

2) Application of nutrition

In the nutrition industry, you will use a capsule filling machine to fill different nutrients into empty capsules. It can accurately and effectively inject nutrients into empty capsules, thus avoiding the waste of ingredients.

3) Food industry

You need to use capsules to supplement certain foods. Therefore, you will use different types of capsule filling machines to fill food supplements into capsules.

4) Domestic application

You can use the capsule filling machine to fill your own capsules within the comfort range of your home, which is a cheaper way to fill capsules, and you will have the right knowledge of the internal filling materials you are consuming.

Chapter 7:What should be considered during the capsule filling process?

Specific factors must be taken into account during the filling of the capsule.

The following are the main factors to be considered in the filling process of capsules.

I.Capsule type

The type of capsule you plan to fill will determine the type of machine you are using.

You can use the fully automatic capsule filling device to fill different types of empty capsules, including hard or soft capsules.

II.Type of inner filler

You will also select the type of capsule filling machine based on the type of internal filling material.

For example, a semi-automatic or manual capsule filling machine cannot be used to fill liquids.

III. Type of machine

The capsule filling machine you choose will determine many factors.

It will determine speed, efficiency, type of capsule, and infill material and production scale.

Chapter 8: What are the Benefits of a capsule filling machine?

There is a lot of benefits you will find when using a capsule filling machine:

Cost-Effective Solutions-Photo Credits:Telappliant

Cost-effective

Using the capsule filling machine can save a lot of money that you can use it in other boring capsule filling practice.

If you use the capsule filling machine domestically, it will save your money from the expensive capsules you buy on the counter.

In business, if you use a fully automatic capsule filling machine, you can also save money and high labor costs.

Easy to use and maintain

The process of using the automatic capsule filling machine is simple and straightforward because you only need to follow the instructions.

It becomes easier, especially when you use a fully automatic capsule filling machine because it performs most of the functions. It is equipped with a PLC control panel to facilitate the configuration, control, and monitoring of the machine.

Maintenance costs are also low, because most machines have self-diagnostic systems that alert you to proper maintenance.

Make unique capsules

You can easily make unique capsules with different ingredients and shapes that will meet your requirements.

Unique Capsules-Photo Credits: All-IN-One-Wallpapers

You are free to choose the type of internal filler material and the shape of the capsule.

You will also have the right knowledge that you are consuming ingredients as you are controlling the system.

Achieve mass production

With all the production factors in hand, you can easily produce large-scale capsules.

Using the automatic capsule filling machine can save a lot of time and money to produce capsules.

This is because you will eliminate the need to hire many workers, and the machine can fill many capsules at a time.

Upgradeable machinery

Depending on the existing technology, you can easily upgrade the capsule filling machine.

Most of the automatic capsule filling machines have the upgrading ability to improve production speed and efficiency.

Economic mode of production

Using the capsule filling machine will eliminate the waste of materials because it is an accurate and accurate filling process.

Other advantages of the automatic capsule filling machine include:

- It uses different capping technologies, allowing different formulations to be produced.

- It produces different capsule forms, which is beneficial to healthy and nutritious users.

- Improve the precision, accuracy, and consistency of products

- It will also ensure the proper uniformity of the component mixture.

Chapter 9:Does a capsule filling machine has any drawbacks?

AIPAK NJP-800C Capsule Filling Machine

Yes, just like other machines, the automatic capsule filling machines have their disadvantages.

Here are some of the disadvantages you may encounter when using the capsule filler.

Capital expenditure (CAPEX)

You will have to dig deep into your pockets, especially when you buy a fully automatic capsule filling machine.

It is expensive to buy and install the automatic capsule filling machine.

You need to prepare a large amount of warehouse space to install the machine, thus increasing the cost.

In addition, you may need to train your workers or higher professionals to help operate the machine.

Limited portability

This factor depends on the type of capsule filling device you use.

The larger the machine, the higher the degree of automation, the less portable it is.

This means that compared with the automatic capsule filling machine, the manual capsule filling machine is lighter.

The fully automatic capsule filling machine is larger and heavier, thus limiting the movement from one place to another.

However, though the initial cost is higher, the total cost of ownership (TCO) is lower due to labor reduction and higher precision.

Chapter 10:How many types of Capsule Filling Machines available?

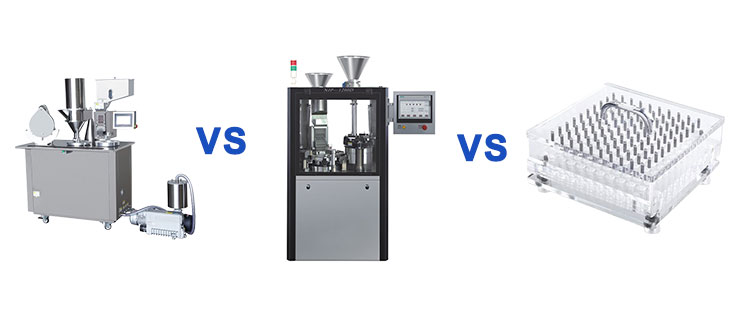

We have fully automatic capsule filling machine and semi-auto capsule filling machine for your choice.

You will find the fully automatic capsule filling machine is an electromechanical packaging system for the application of high-speed empty capsule filling.

AIPAK CGN-208D Semi-automatic Capsule Filling Machine

The semi-automatic capsule filling machine relies on automatic and manual parts to fill capsules.

You will employ some professionals to help operate the manual parts of the machine.

Chapter 11:What are the advantages of using a fully & semi-automatic capsule filling machine?

11.1 Advantage of using a Fully Automatic Capsule Filling Machine

Using a fully automatic capsule filling machine you will find its large output, accurate filling dose, good adaptability to drugs and empty capsules, stable, high degree of automation, etc such characteristics.

Below let's take NJP-1200 as an example to describe the main features of a fully automatic capsule filling machine:

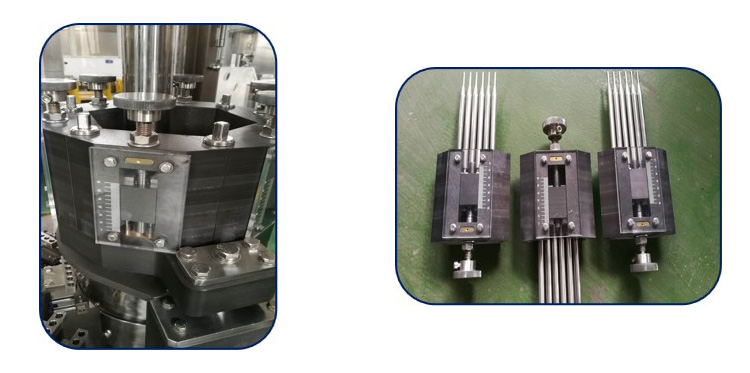

I. Closed station turntable

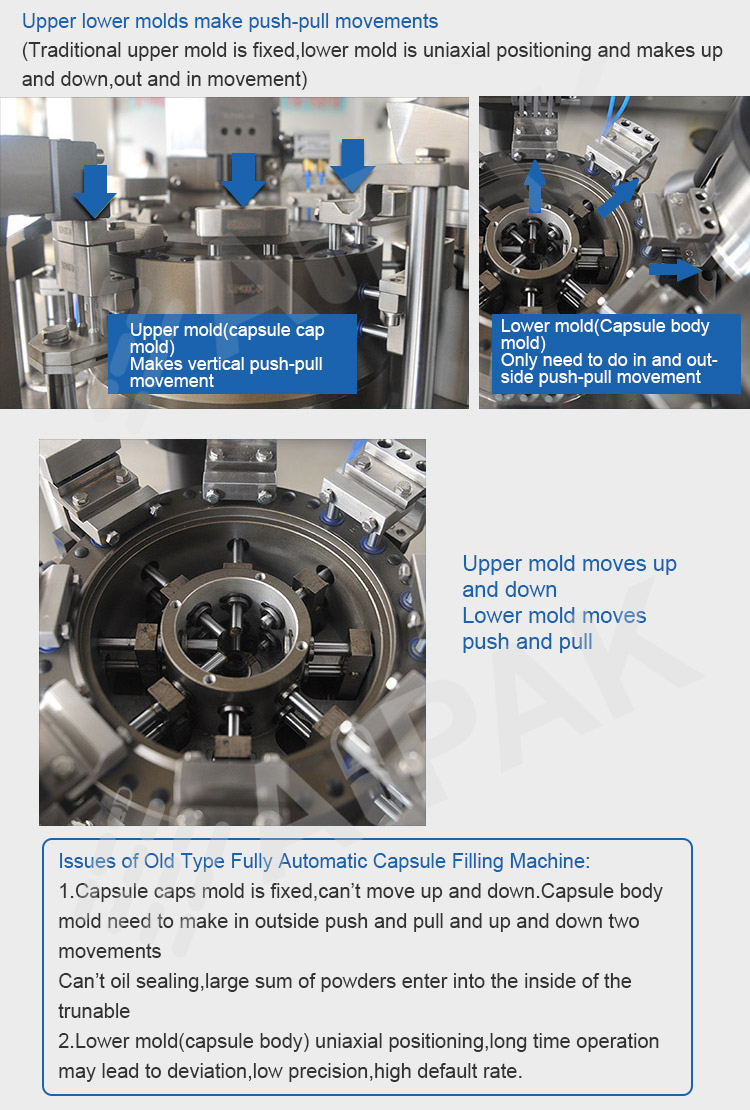

Second generation of fully enclosed station turntable

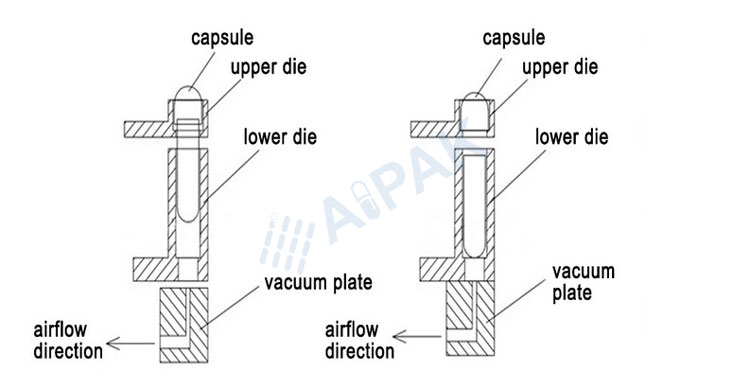

You will find in NJP-1200 works stable and its filling accuracy is high due to its upper mold adopts double axis for circular up and down movement, and the lower mold adopts double axis for circular in and out movement, all of which are equipped with imported silica-gel sealing ring, so as to reduce the situation of back and forth expansion of powder.

Besides, both the upper and lower die shafts are fixed by a gland, which is convenient for disassembly and cleaning. And you need not to open the rotary table to replace the sealing ring;

So you will conclude that it solves the tedious task of assembling and disassembling the mold, reduces the labor intensity of the staff, and increases the service life of the working table.

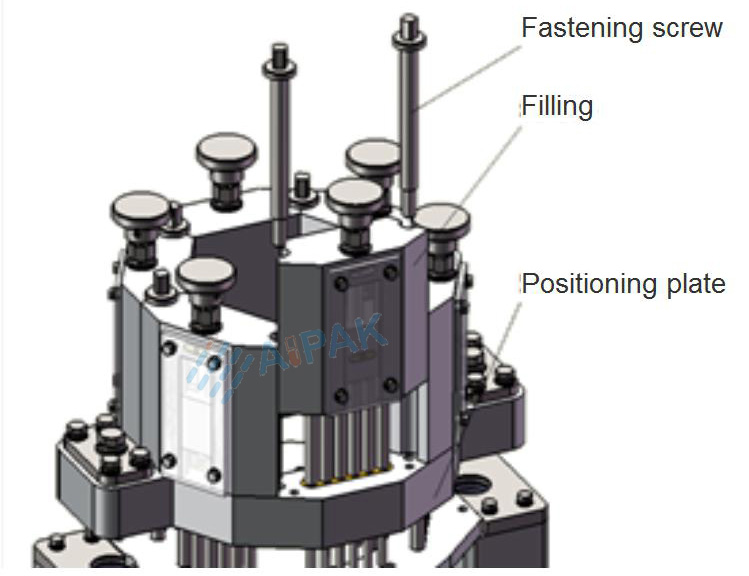

II. Three- dimensional adjustment mechanism

You will find these two parts make the filling cap even and reduce the leakage of powder. It is easy to disassembly and clean.

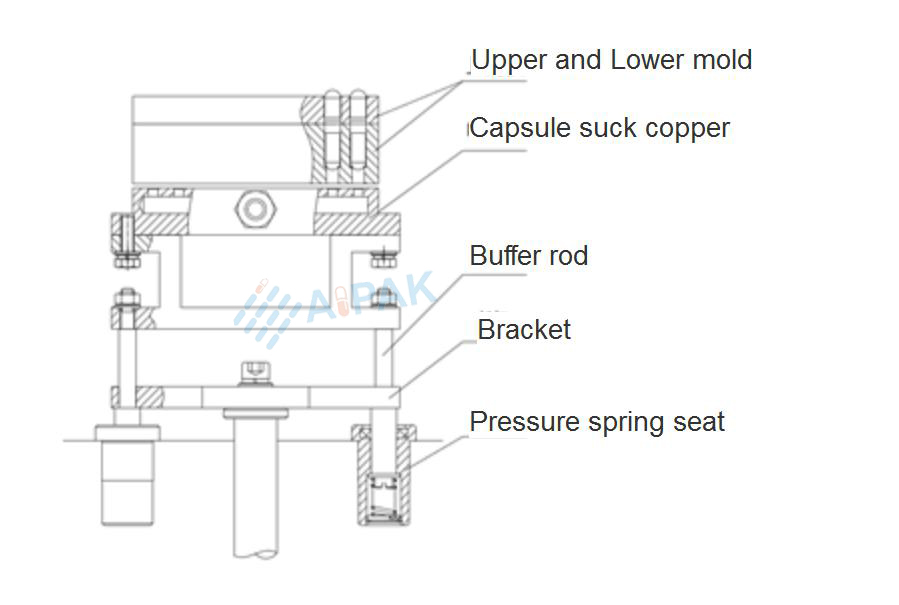

III Vacuum separation mechanism

You will the added Spring seat structure has improved the fit between the suction seat and the capsule mold, which will make the empty capsule more effective separate.

On the other hand, reduce the impact of sound and loss.

11.2 Advantage of using a Semi-auto Capsule Filling Machine

AIPAK CGN-208N Semi-automatic Capsule Filling Machine

When using the semi-automatic capsule filling machine, you will experience the following benefits:

- You can use the machine to fill different filling materials, such as particles, powders and granules.

- It is faster than a manual capsule filling machine because it provides a certain degree of automation.

- The cost of purchasing and installing a semi-automatic capsule filling machine is lower than that of a fully automatic capsule filling machine.

- Compared with manual capsule filling machine, you will eliminate the demand of redundant labor force, thus reducing the production cost.

- Compared with the manual capsule filling machine, the semi-automatic capsule filling machine is a faster and more accurate machine.

- It is safe for your use because it is qualified for safety and has security-enhancing components.

- It doesn't make a lot of noise, so it's a more efficient machine for peaceful working environments.

- Because the machine is semi-automatic, it is safer for you and your employees because of its sensors and other safety features.

Chapter 12:Does a semi-automatic capsule filling machine have any drawbacks?

Yes, just as other machines, a semi-automatic capsule filling machine has disadvantages:

- Since it is not fully automatic, you will have to hire additional people, which can be expensive.

- You will spend more money on the purchase and installation of the machine than on manual capsule filling machine.

- It may be difficult for you to remove some parts of the machine, which will make some trouble for cleaning and maintenance.

- You may not have the opportunity to work or walk on the bench due to the weight.

- Because the machine is not fully automatic, there are many challenges in integrating it with other machines.

Chapter 13:Parts of fully capsule filling machine & semi-auto capsule filling machine

13.1 Parts of the fully automatic capsule filling machine

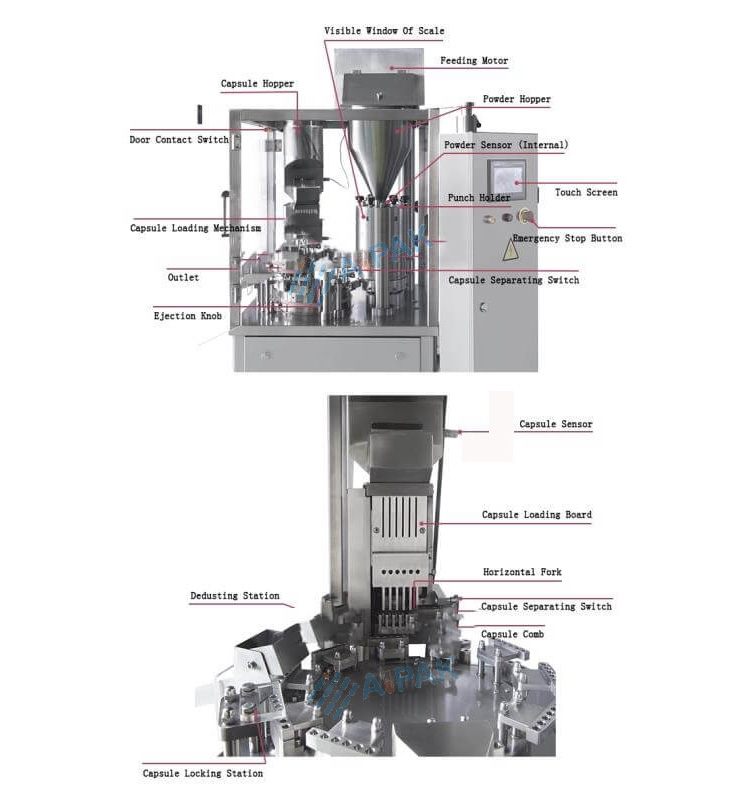

Parts of a fully automatic capsule filling machine

A fully automatic capsule filling machine is composed of different parts that enable different high efficient fillings of capsules.

Capsule Loading Mechanism

It is composed of a hopper and conveying pipeline, you will use it to store empty capsules and make them enter into capsule sub-main device vertically one by one.

Capsule Separating Switch

This part is to make the empty capsule enter into the selective feeding fork of the distributing device. When the selective feeding fork moves downward once, six capsules will be delivered, and the rubber cap is on it.

At the same time, the vacuum separation system put the capsule into the module and separated the body and cap.

Powder Hopper

It is composed of powder hopper, powder hopper screw, blanking conveying pipe, etc.

It mainly controls the stored powder into the metering plate under the action of screw and mixing.

Punch Holder

According to the specifications of the capsule and the matching of the filling capacity. The powder is filled and compacted five times in the intermittently rotating metering disk to form the medicine column, and pushed into the capsule of the lower module.

Capsule Locking Station

You will push the drug into the capsule body, then the upper module cap and the lower module body will be locked.

PLC control system

This PLC control system displays the technological elements of each capsule filling.

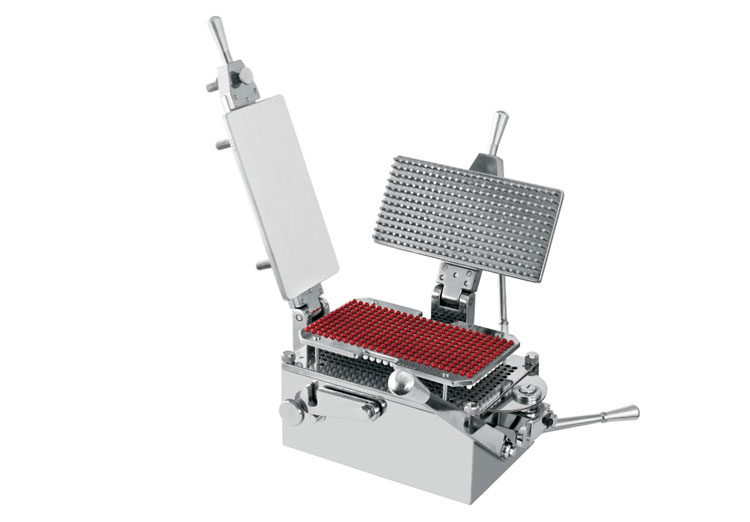

13.2 Parts of the semi-automatic capsule filling machine

The semi-automatic capsule filling machine includes different parts that can effectively fill the capsule. The following are the enhancements of the semi-automatic capsule filling machine.

PLC control system

You will use the PLC control system to configure and program the semi-automatic capsule filling machine.

You will enter the production specifications from the PLC control panel.

Filling auger

The filling auger is the main control system to determine the filling speed of the semi-automatic capsule filling machine.

It will determine the speed or speed of the semi-automatic filling machine to fill powder and particles into the empty capsule.

Powder feeding port

The powder hopper is the main part of the machine, in which you will fill powder or particles before starting filling.

It has a special design to help remove particles and powders before the filling process begins.

Loading system

This is part of the machine that will load empty capsules as well as filling materials and place them accordingly.

Body and lid tray

The tray is divided into two parts and you can use it to automatically separate the lid from the body of the empty capsule.

Pneumatic system

This is the main air pressure system or compression drive that pushes the packing into the empty capsule.

Filling table

With the filling table, you can control the filling speed because it changes endlessly and allows for a more precise dosage.

Transportation system

The device includes guiding light and conveyor belt, guiding the capsule through the correct channel.

Capsule opening system

The device allows more accurate and faster opening and closing of empty capsules before and after filling.

Chapter 14:Functional Principle of fully capsule filling machine & semi-auto capsule filling machine

The NJP Series utilizes a high-precision, intermittent rotary motion to achieve automated encapsulation. The process is divided into twelve distinct stations to ensure maximum accuracy and hygiene.

14.1 The 12-Station Encapsulation Cycle

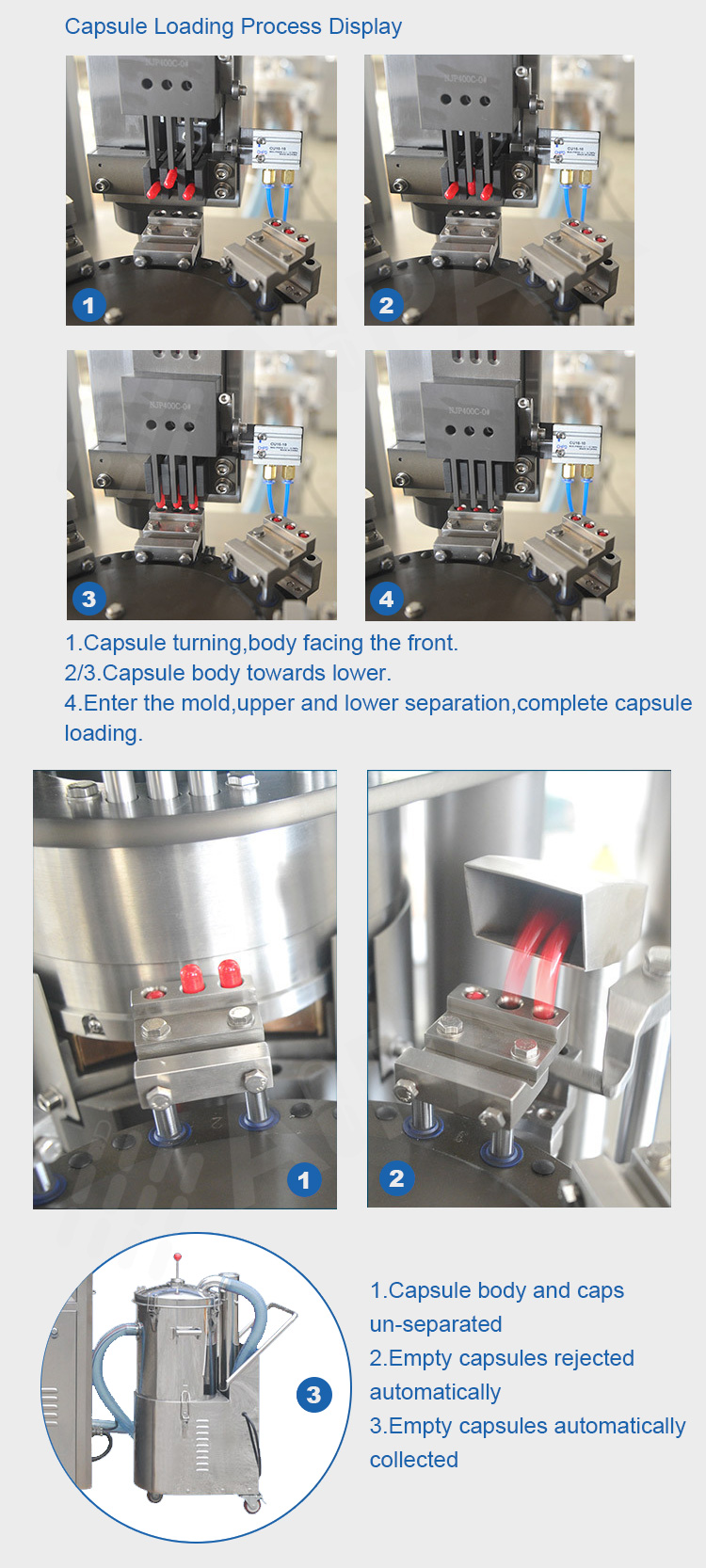

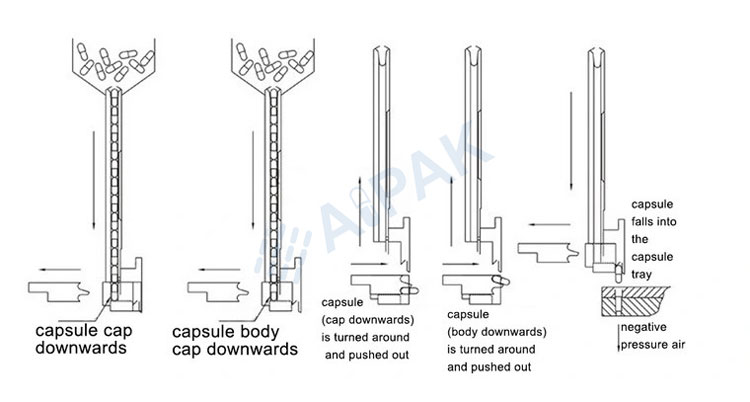

Station 1 & 2: Capsule Feeding & Vacuum Separation: Capsules are fed vertically into the main board assembly. A vacuum separation system then draws the capsules into the mold holes, effectively separating the capsule body from the cap.

Station 3 & 4: Offset Preparation: The upper mold rises while the lower mold extends outward, creating a strategic offset required for the subsequent filling process.

Station 5: Precision Dosing: The tamping rod pushes a pre-compressed powder plug (formed through a five-stage tamping process) into the waiting capsule body.

Station 7: Defective Rejection: Any capsules that failed to separate in the first stage are identified and removed by a specialized waste suction nozzle.

Station 9: Capsule Joining & Locking: The upper and lower molds align as the capsule joining push rod locks the cap and body together securely.

Station 10 & 11: Finished Product Discharge: Successfully locked capsules are ejected through the finished capsule outlet for collection.

Station 12: Automated Cleaning: An air-blowing column combined with a vacuum system cleans the mold holes, preparing them for the next production cycle.

14.2 Semi automatic capsule filling machine working principle

The semi-automatic series (such as the CGN-208 series) is designed for pharmaceutical R&D, pilot plants, and medium-scale production where flexibility is essential. It combines automated material feeding with manual tray management to provide a cost-effective yet precise encapsulation solution.

Step 1: System Initialization & Material Loading

-

Inspection: Perform a pre-operational check to ensure all components, especially the loading trays and vacuum seals, are in optimal condition.

-

Loading: Load empty capsules into the capsule hopper and the active ingredients (powder or granules) into the powder hopper.

-

PLC Configuration: Power on the machine and input critical operating parameters—such as vibration frequency and auger rotation speed—into the PLC control system to ensure batch consistency.

Step 2: Vacuum-Assisted Orientation & Separation

-

Rectification: Empty capsules are fed from the hopper through a delivery system that aligns them vertically into the round capsule tray (loading ring).

-

Vacuum Separation: The machine utilizes a vacuum-assisted station to pull the capsule bodies into the lower tray while the caps remain in the upper tray.

-

Manual Transfer: The operator separates the upper and lower trays; the cap tray is temporarily set aside while the body tray is moved to the filling station.

Step 3: Auger-Driven Dosing & Filling

-

Precision Filling: The body tray is placed on the rotating filling table. The machine initiates the flow of medication through an Auger Screw mechanism.

-

Weight Control: The fill weight is determined by the speed of the auger and the rotation of the table. This system allows for precise dosing across a wide range of material densities.

-

Automatic Retraction: Once the 360-degree filling cycle is complete, the filling nozzle automatically retracts to prevent powder spillage.

Step 4: Mechanical Locking & Product Discharge

-

Alignment: The operator repositions the cap tray directly onto the body tray.

-

Pneumatic Locking: The joined trays are moved to the compression zone, where pneumatic pressure is applied to lock the capsules to their specified "locked length."

-

Ejection: The final step involves discharging the locked capsules for de-dusting, polishing, and final quality inspection.

Chapter 15:How to use a fully & semi-automatic capsule filling machine?

15.1 Operate steps of the fully automatic capsule filling machine

You will refer to below steps to operate the machine well:

AIPAK NJP-1200D capsule filling machine

Check whether all parts of the machine and equipment are in good condition.

According to the process requirements, select the disc specification, powder or particle filling system.

Installation and adjustment: the support and the material tray shall be kept parallel, and the filling rod shall be perpendicular to the support, so as to ensure that the filling rod can freely enter and leave the filling hole of the material tray.

Loosen the set screw, turn the lock nut to the required height, then tighten the screw and nut, and adjust the height of the filling seat.

After all the safety settings are correctly equipped and adjusted, turn the machine 1-3 times in the running direction with the handwheel without capsule and medicine.

And then, under all normal conditions, put the capsule and medicine powder (or particles) into their respective containers respectively, with the filling height of 30mm below the edge of the container.

Adjust the depth of the filling rod inserted into the material tray. The large filling volume of the capsule is determined by the size of the capsule, the height of the material tray and the compaction degree of the filling rod to the powder.

Adjust the height of the filling rod.

In the beginning, the lower end faces of six groups of filling rods shall be on the same

horizontal plane.

The insertion depth of the filling rod is determined by the thickness of the material tray.

The particle filling system relies on the rotating adjusting shaft to move the adjusting parts left and right, and achieves the purpose of adjustment through the volume change. Start the machine and it will work normally.

Protection of filling mechanism: check the metering bucket regularly and remove any sediment stuck on it.

Apply a thin layer of grease to the track on the convex roller once a month. Gear and groove cam shall be cleaned and coated with grease once every two weeks.

15.2 Steps to operate a semi-auto capsule filling machine

As the above functional principle, you will easy to understand how to operate a semi-automatic capsule filling machine.

Below is more details for your reference:

Press the green button in the "power switch" to turn on the power.

Slowly adjust the "vibration strength adjustment knob" and turn it clockwise.

At this time, the finishing disk, which is connected with the "vibration support", starts to vibrate. Touch the finishing disk with your hand and adjust the vibration strength according to your feeling.

Put the powder-filled capsule shell into the "powder-filled capsule shell finishing disk", about 300 capsules each time. Put the capsule cap into the "capsule cap finishing plate", about 300 capsules each time.

The finishing plate is made of plexiglass plate, on which there are many circular holes with big upper and small lower funnel shapes, the diameter of which corresponds to the diameter of the capsule number.

At this time, the capsule shell of the working platform plate moves stably and slowly, so that it can enter the hole of the platform plate one by one.

In about 30 seconds, the powder-filled capsule shell and capsule cap fall into the round hole with the opening facing up. If the individual opening is facing down, the capsule cap can be used to press the sleeve down gently, and then the sleeve can be pulled out.

Horizontally hold the connecting plate of powder loaded capsule shell, push it in the lower part of the finishing plate, the powder loaded capsule shell in the finishing plate will fall into the circular hole of the connecting plate.

And then take out the connecting plate. In the same way, take out the capsule cap with the capsule cap connecting plate.

A powder square plate with a bottom area of 500 × 500mm and a height of about 10 mm on four sides can be prepared in advance, which is filled with powder, and the connecting plate of powder-filled capsule shell can be placed in the powder square plate horizontally. Then cover the plexiglass frame matched randomly on the powder filling capsule connecting plate, put the powder into the frame with a small bucket shovel, and fill the powder with a scraping on the edge of the frame, and scrape off the excess powder.

Use the capsule cap cover set plate (as shown at the end of the figure, there are round holes on the set plate), put it on the capsule cap cover joint plate, with alignment holes, easy to place.

Turn over the capsule cap connecting plate, make the opening of the capsule face down, and cover it on the powder loaded capsule shell connecting plate, which also has a contraposition hole, so it is easy to cover.

Put the assembled capsule plate into the cavity under the "capsule cap forming plate", pull down the "pressing rod" with your hand and put it in place, do not need to be careful of excessive force, because there is a positioning mechanism to control the pressing height.

Take out the sheathed capsule plate, pour out the capsule, and fill it. You can cycle to the next board.

Chapter 16:Fully vs. semi-automatic vs. manual capsule filling machine

16.1 Fully vs. Semi-automatic capsule filling machine

A fully automatic capsule filling machine is more faster and automatic to perform most of its functions.

However, You will need some professional and technical personnel to assist in some activities. To some extent, the semi-automatic capsule filling equipment depends on automation and needs manpower. You will need more manpower to help operate the semi-automatic capsule filling machine to affect the speed.

And fully automatic capsule filling machine is a fast, efficient and accurate large-scale capsule filling equipment.

Last semi-automatic capsule filling machine can be only used to fill hard capsules. Fully automatic capsule filling machine is suitable for filling hard as well as soft capsules.

16.2 Automatic vs. manual capsule filling machine

- The manual capsule filling machine is a device that you can use to fill empty hard capsules with drugs and nutrients.

An Automatic capsule filling machine can fill empty hard or soft capsules.

- With these two machines, it is easier to fill empty capsules of any size with various nutrients or drugs according to your specific requirements.

- When using a manual capsule filler, you need to hire people to help with most activities.

- Manual capsule filling machine is slower than an automatic capsule filling machine, which is not conducive to large-scale production.

- The automatic capsule filling machine is faster, you will only need the least human assistance, but it can carry out large-scale capsule filling efficiently.

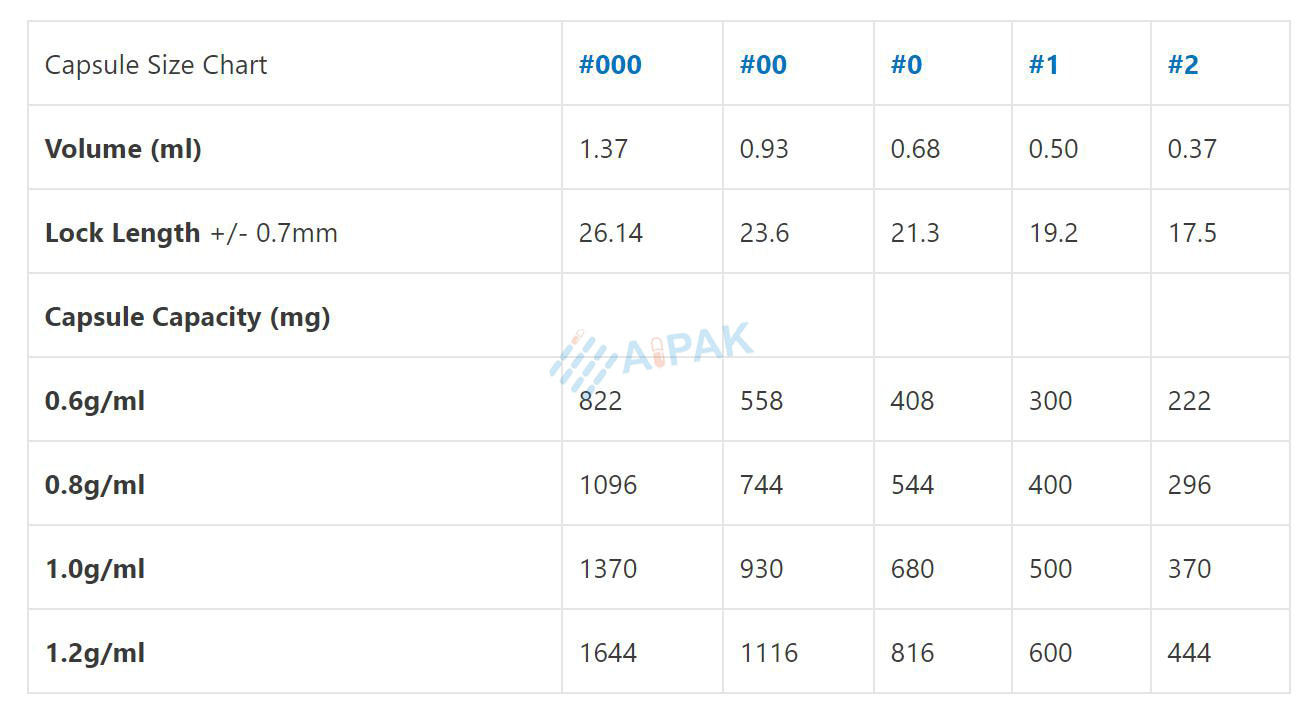

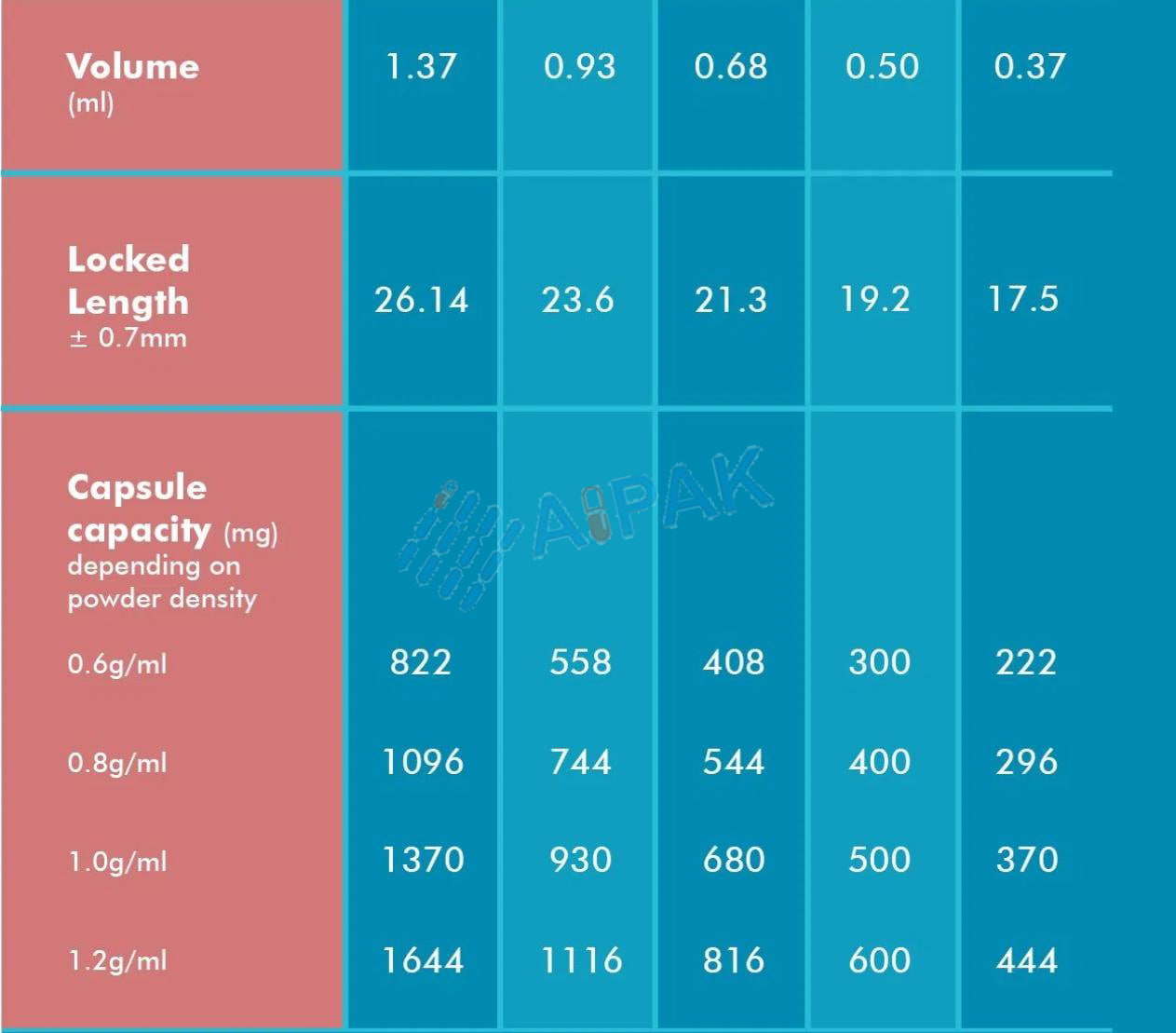

Chapter 17: Capsule size chart fill weight and capacity comparison

You may often want to know how much does a capsule hold?

Let me tell you "000" holds about 1000 mg., "00" holds about 735 mg., "0" size holds about 500 mg., #1 holds about 400 mg., #3 about 200 mg.

One teaspoon will fill about 7 "0" capsules and about 5 "00" capsules.

Then you may would like to know each capsule size and filling weight.

The fill weight depends on the powder density and particle size. Some powders can be much denser than others. But it also depends on how fine the powder is. Because of this, a good way to check is to know the powders mesh size.

Capsule Size Chart

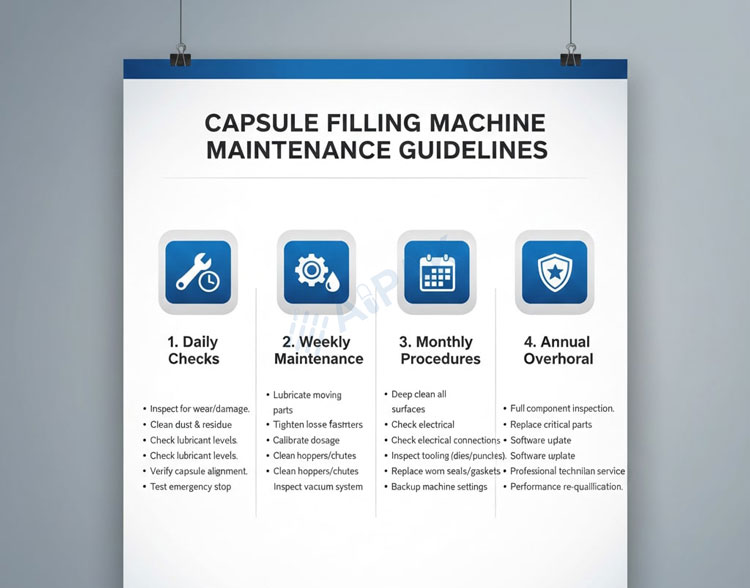

Chapter 18: Maintenance & Cleaning SOP

18.1 Equipment Maintenance Guidelines

To ensure the longevity and precision of your NJP series machine, follow these specific technical maintenance protocols:

-

Transmission System: Check the oil level of the main transmission reducer and feeding reducer monthly. Replace the lubricating oil (Mechanical Oil 46GB443-89) every six months.

-

Indexing Gearbox: For the cam indexing gearbox, replace the lubricating oil after the first 1,000 hours of operation, then once per year thereafter.

-

Weekly Lubrication: Apply a layer of Lithium Grease No. 2 to cam roller working surfaces, sprockets, and chains weekly to prevent premature wear.

-

Safety Clutch: Regularly inspect the safety clutch for slipping. If slipping occurs during normal operation, slightly tighten the clutch lock nut to maintain its protective function.

18.2 Standard Operating Procedure (SOP) for Cleaning

Cleaning must be performed when changing product types, after each production run, or if the machine has been idle for more than three days.

-

Cleaning Agents: Use purified water and 75% ethanol for standard cleaning. For disinfection, alternate between 75% ethanol and 3% hydrogen peroxide weekly.

- Critical Areas: Use a vacuum cleaner to remove powder residue from the worktable. Disassemble removable components and clean upper/lower die holes and dosing plate holes using a small brush dipped in alcohol.

- Evaluation: Visually inspect the machine inside and out; no visible foreign matter or powder residue should remain.

Chapter 19: Technical Troubleshooting & Weight Accuracy Optimization

In pharmaceutical production, maintaining fill weight accuracy is critical. This accuracy is influenced by equipment condition, environmental factors, and material properties.

19.1 Common Fault Diagnosis & Solutions

| Fault Phenomenon | Possible Cause | Professional Solution |

| Capsule Body/Cap Separation Failure |

Vacuum suction seat misalignment or blocked filters. |

Adjust suction seat position; clean the vacuum system and filter membrane. |

| Capsule Splitting |

Misaligned upper/lower modules or burrs inside mold holes. |

Realign modules using the adjustment rod; remove burrs with a specialized scraper. |

| Large Fill Weight Variation |

Poor powder flowability or inconsistent material height in the dosing ring. |

Adjust material sensor height; add excipients (e.g., magnesium stearate) to improve flow. |

| Clutch Overload |

Excessive powder buildup causing moving parts to seize. |

Regularly clean the worktable and maintain the gap between the dosing disc and copper ring at 0.08–0.12 mm. |

19.2 Factors Affecting Fill Weight Accuracy

-

Material Properties: Ideal materials should have a particle size of 80–100 mesh, moisture content below 3%, and moderate flowability (Angle of Repose: 30–35°).

-

Environmental Control: The machine environment must be maintained at 21 ℃ ± 3 ℃ with 40%–60% relative humidity to prevent powder sticking.

-

Mechanical Precision: The gap between the isolation block and dosing disc must be strictly set between 0.05–0.1 mm to prevent material mixing and ensure dosing accuracy.

-

Tamping Consistency: All filling rods within the clamp bodies must exhibit consistent elasticity and "jumping" movement to apply even pressure to the powder columns.

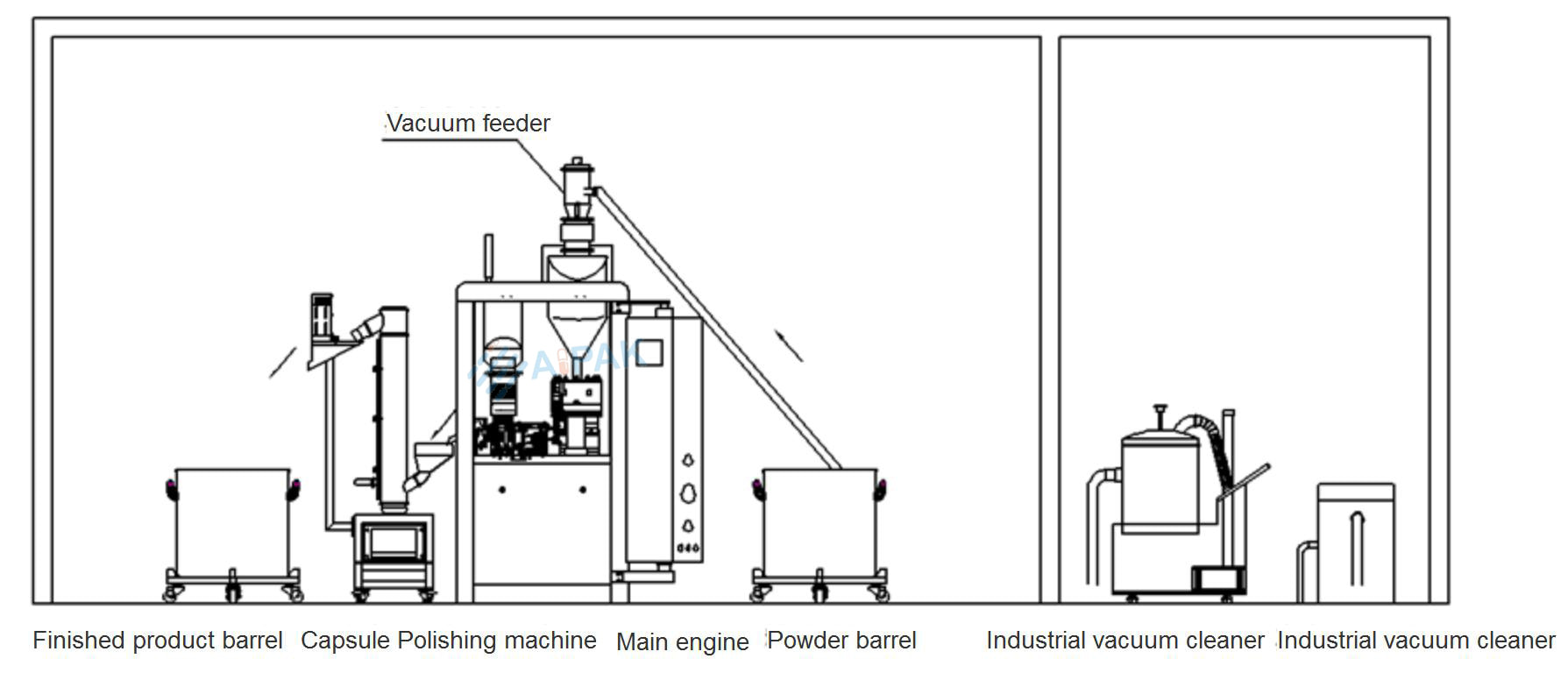

Chapter 20: The Ultimate Support Equipment List for Capsule Filling Machine

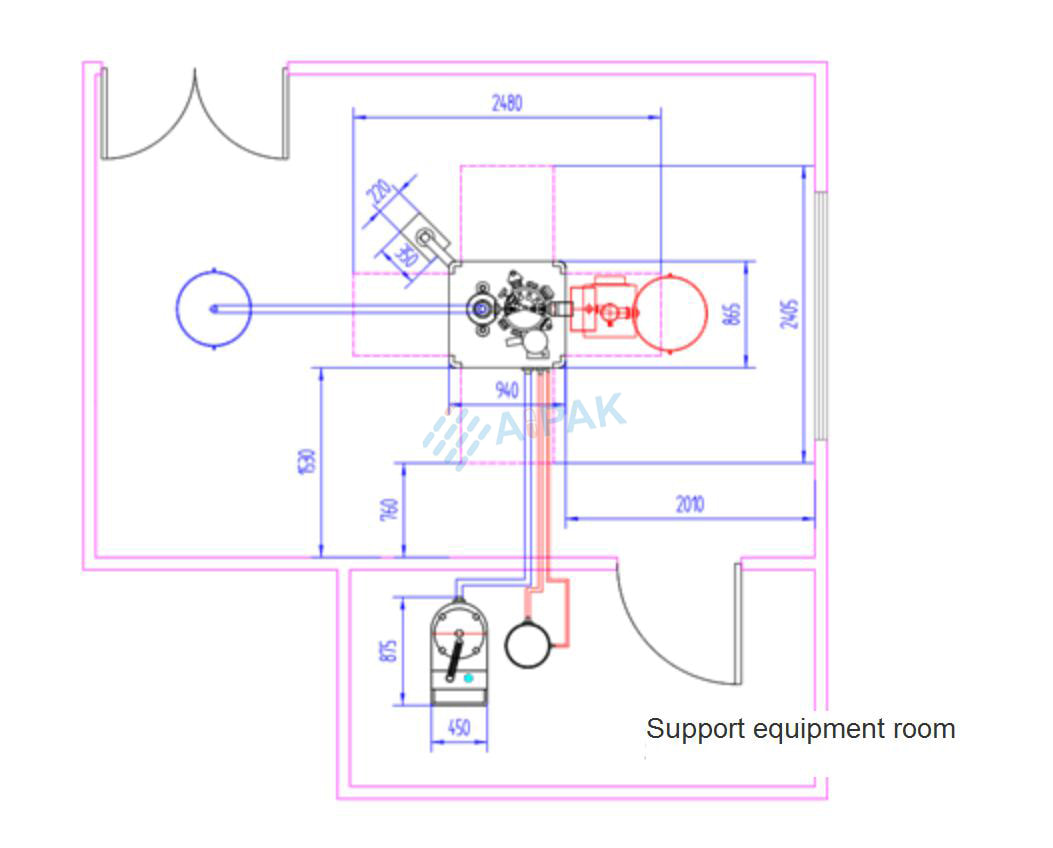

You will need support from other devices to help you during the capsule filling process. Above you can clearly see what equipment you need are.

The main types of equipment used in preparing materials are:

- Granulator

- Hammer crusher

III.Vibrating screen

- Vacuum feeder

- Fluidized bed processor

Vacuum feeder

Final capsule processing equipment after filling

Some of the devices used after filling empty capsules include:

- Automatic capsule feeder

II Drying system

III.Capsule sorter

IV.Capsule printing machine

V. Capsule polisher

IX.Capsule packaging machine

- Other support equipments include:

- Metal detector

2. Industrial vacuum cleaner

Chapter 21: New Technologies and Innovations in Capsule Filling Machine

As an automatic capsule filling machine manufacturer, you may focus on technologies that improve safety and optimal production.

Below you will get to know what exactly to focus on when buying capsule filling machines:

21.1 Technologies that Improve Productivity, Performance and Efficiency

Some of these technologies include:

- Colored touchscreen HMI panel, allows for easy system control and production management. They are basically the PLC systems.

- Enclosed dosing, electrical and moving systems for efficient and consistent capsule filling process.

- Vacuum cleaning system for easy and fast cleaning

Auto lubrication system, automatically lubricates moving parts to prevent possible wear and tear.

Obviously, this will increase the service lifespan of your automatic filler machine.

Variable frequency drive system, for easy speed control of the motor and hence that of the machine.

Whenever you are shopping for an automatic encapsulation machine, it is important to go for those that feature modern technologies and innovations.

Mold cleaning and blowing device Micro dehumidifier

Capsule inserting switch

Apart from these, another aspect to consider is the:

21.2 Capsule Filling Machine Technologies that Guarantee Safety

Safety is also an integral aspect in any capsule filling process. Therefore, you must find out whether the machine you are about to import guarantee safety or not.

should be the safety of both the capsule filling machine and that of the technicians. Below are some essential technologies:

Using a transparent solid polycarbonate sheet to enclose the dosing station.

In most machines, these doors are interlocked such that, they cannot be open when the machine is ON.

They have a door check sensor. Therefore, the machine will not run when the door is open.

Alarm for door opening, low powder and capsules level emergency switch, this will help to stop the machine in case of any emergency situation.

With all these features, your machine will not only guarantee seamless and optimal performance but also ensure better returns.

But, this is not enough, to ensure a seamless encapsulation process, you need support equipment.

These are very vital accessories that you cannot survive without.

Chapter 22: Quality Inspection & Installation

22.1 Installation and Module Adjustment

Proper installation is the foundation of filling accuracy. Before operation, ensure:

-

Module Alignment: At the filling station, use the lower module adjustment rod to align the mold holes with the filling rod seat. Tighten screws only once the adjustment rod can freely drop into the fixed module.

-

Vacuum Suction Seat: Manually rotate the handwheel to raise the suction seat to its highest position. Ensure it makes tight contact with each lower module to prevent separation failure.

-

Chain Tension: All sprockets on the same chain must be in the same plane with a lateral deviation of less than 1 mm.

22.2 Working Environment Requirements

For pharmaceutical-grade results, the production environment must strictly adhere to:

-

Temperature: Maintained at 21 ℃ ± 3 ℃.

-

Relative Humidity: Kept between 40% and 60%.

-

Powder Level: The powder in the hopper should always be maintained at least 60 mm below the top edge of the container to ensure consistent feeding pressure.

Chapter 23: Ask for Full Technical Support

Technical support is a critical aspect that you must not forget at all costs.

As first, you will need to install the machine and maybe at some point in the future, you may need to upgrade or maintain the machine.

Then you will know the most important support include:

Installing and commissioning

If it is possible, the machine supplier should send their technicians to install and make test for the machine on-site for you.

This is even crucial for very large capsule filling machines as if not, you may need to spend much read the instruction and then assemble most parts by yourself.

Maintenance and troubleshooting

In most cases, the machine should have at least some time’s maintenance, you may ask it carefully when you are purchasing a capsule filling machine.

Apart from this, the troubleshooting capsule filling machine also needs whatever on-site or online.

You need to contact the technical persons immediately once trouble occurs, that means the machine supplier should have available contact technical person for you.

Or normally, they do indicate simple troubleshooting procedures.

Chapter 24:Great news about capsule filling machine market

According to the data, the global pharmaceutical market size in 2018 is preliminarily estimated to be $1.17 trillion, and is expected to exceed $1.2 trillion by 2019.

As a large pharmaceutical production country, China's consumption level has been upgraded in recent years.

With the growth of global pharmaceutical market, China will also get a lot of development space. This will also bring good development opportunities for related medical equipment.

Among them, the full-automatic capsule filling machine is a set of machine, electricity, gas as one of the equipment, suitable for filling all kinds of domestic or imported capsules.

It is an economic and practical equipment for filling capsule products in the pharmaceutical industry and health product industry.

It is reported that the full-automatic capsule filling machine adopts microcomputer programmable controller, touch panel operation, frequency conversion, and speed regulation, equipped with an electronic automatic counting device, which is sensitive in action, accurate in filling dose, novel in structure, beautiful in shape and convenient in operation.

It can automatically complete the positioning, separation, filling, locking and other actions of capsules, reduce labor intensity, improve production efficiency, and meet the requirements of Pharmaceutical hygiene requirements.

Capsule Manufacturing-Photo Credits:Lan Labs

At present, the full-automatic capsule filling machine has achieved good development in the field of medicine and health care products, and the competition among manufacturers is increasingly fierce.

With the continuous development of the pharmaceutical industry, pharmaceutical enterprises also put forward higher requirements for filling equipment, such as higher conditions in filling stability, dosage accuracy, product quality, in addition to inconvenient removal and cleaning of the mold and other problems also need to be solved by the capsule filling machine manufacturers.

Hubei AIPAK pharmacy as one of the largest capsule filling machine manufacturers according to the needs of users, improve and upgrade the full-automatic capsule filling machine.

The machine is a full-automatic hard capsule filling equipment with the intermittent operation and hole disk filling.

According to the personnel of the Hubei AIPAK, the machine has been optimized and designed in combination with the characteristics of traditional Chinese medicine and the requirements of GMP.

"It has the characteristics of compact structure, small model, low noise, accurate filling dose, complete functions, stable operation, etc., and can simultaneously complete the actions of seeding, splitting, filling, discarding, locking, finished product discharging, module cleaning, etc."

At present, the improved equipment is the ideal hard capsule filling equipment for pharmaceutical, health products and other manufacturers.

In terms of the characteristics of the equipment, in view of the difficulty of removing and cleaning the mold and the difficulty of adjusting the accuracy of the assembly mold, the manufacturer adopts the fully closed technology for the working table of the full-automatic capsule filling machine, which makes the removal and cleaning easier and the accuracy adjustment simpler.

In the aspect of dose adjustment, the dose adjustment mechanism adopts the support adjustment technology, which can fine-tune the dose without stopping the machine, so as to meet the requirements of dose adjustment.

In order to solve the user's concern about the service life of the equipment, the full-automatic capsule filling machine of the enterprise adopts the structure of the lower slot cam, which has good lubrication performance and small wear degree, thus prolonging the service life of the parts.

In order to improve the automatic control level of the equipment, the machine adopts the microcomputer control technology, which is safe and advanced, and improves the automatic control level of the production process.

The blanking mechanism is set to realize the automatic feeding, so that the materials in the storage room are always kept at a certain height, so as to ensure the accuracy of the dosage.

Last but not the latest, from this post, it is apparent that a capsule filling machine is something worth investing especially if you are "health" conscious.

These capsule filling machines can make your own unique capsules and bring can bring you considerable benefits.

As we wind up, I would like you to share it with loved ones including friends that would love to explore the capsule option.

Again, in case you want to share your experiences or ask questions:

Just leave a quick comment to us.

Capsule Filling Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586