8 Trends That Are Challenging The Shrink Sleeve Label Format

Shrink Sleeve Label Format adds worth to packaging containers on retail shelves. These are graphical 360° coverage around container to create eye-catching and striking look. They have quite traction over the recent years and the numbers are still coming. This format has amplified the sales of various brands ranging from nutraceutical or food, personal care to high-end spirits. However, there are number of challenges faced by shrink sleeve label format that hampers their growth. In this blog, 8 Trends that are challenging the shrink sleeve label format are detailed. Before opting for this format, you should know about the issues that create hurdle in successful labeling. Let’s start learning.

1.Sustainability Concerns

Sustainability and recyclability are the major concerns when choosing labeling and packaging materials. Consumers, manufacturers, and retailers are following the guidelines of circular economy in green-friendly world and shrink packaging being no exception to rule to this.

People all across the world are making effort to eliminate and decreased plastic wastage. Shrink sleeve labeled films are largely formed by polyvinyl chloride (PVC), Polyethylene terephthalate (PET), and Polyethylene Terephthalate Glycol (PETG) that impacts the sustainability efforts.

Phthalate and chlorine contents are leaked in surrounding and are the cause of dangerous carcinogenic toxins in environment when these films are not recycled properly. Shrink sleeves are difficult to be removed from PET thus leading to lower recycling yield and product contamination.

New film and ink materials for shrink sleeve labeling are continuously innovated and discovered so that this labeling does not impede go-green efforts. For instance, now shrink sleeve labeling film is made of Polylactic Acid (PLA), a bio-based polymer that is biodegradable and climate-friendly alternative to PVC.

2.High Labeling Cost

The main issue with shrink sleeve skins is their high printing expenses. Printing techniques and film material employed in shrink sleeve labeling format are expensive. PETG film used for forming shrink sleeve wraps is fairly costly.

In flexographic (flexo) printing, each design has its own printing plate which is finically taxing for small business. Digital printing is expensive for longer production shifts.

Coating of solvent called varnish slip is applied to unprinted area for lowering the slippery surfaces. This procedure is reasonably pricey since this requires further treatment of shrink film. This treatment is essential in preventing hazy look of clear regions by varnish slip.

Moreover, the embellishment in design increases the labeling cost per sleeve. This is because custom-made coatings, UV metallic inks, and embossing add in end price of shrink sleeve wraps. However, these elegant and customized designs enhance the worth of your products on store-shelves consequently making expenses justifiable.

3.Contour of Packaging Containers

Shrink sleeve labeling format works great for rectangular, round, or square shaped containers. But designing usually errors occur in shrink sleeve skins when containers have complicated geometry involving many contours and curves.

Issue of distortion should be kept in mind when you package containers having dramatic curves and multiple diameters at various points. Custom shaped containers require more engineering effort to minimize the chance of error in graphical text upon shrinkage.

Professionals have to keep in mind details of every contours and percentage of diameter alteration at each curve so that they can adjust image accordingly. This is time consuming process that requires going over each point so that labels are clearly visible after film compression. To achieve this, brand owner work closely with design agencies to create unique labels for their personalized shaped containers.

4.Competition with Other Labeling Formats

There are various competitive labeling and packaging types that pose challenge to market expansion of shrink sleeve labeling. Two most recent packaging technologies (direct-to-container printing and stand up pouches) are quite in rage and are in continuous battle with shrink sleeve labeling format for top-quality status.

In direct-to-container printing graphical content is directly printed on container which removes the need of labeling ink and film therefore this technology is eco-friendly.

Standup pouches is a kind of packaging that is manufactured using 40-70% less plastic film polymers than rigid containers with labels. These are light-in weight consequently saving transportation expenses.

Despite boosting many benefits, plastic employed in producing standup pouches is not recyclable. This drives various consumers and brand owners away from standup pouches towards firm containers with shrink sleeve labeling.

5.Low quality Concerns

This is the legitimate concern that drastically hinders the growth of shrink sleeve labeling format. Shrink sleeve labeling format is still being plagued with quality issues since its advent. Several problems such as errors in labeling seams, distorted adhesives, wrinkles in labels etc are involved in this kind of packaging.

Faulty folded seams are caused by employing wrong solvent for joining the labels consequently producing issues like lifting of labels, splitting of seams from corner and falling off of entire sleeve.

Fuzzy graphics or folding lines appear upon shrinkage creating tacky labels. These containers are usually discarded resulting in wastage of time and money.

This pose a huge challenge in market expansion of shrink sleeve labeling as numerous consumers shy away from mediocre quality labeled products.

6.Designing Mishaps

Task of designing and producing shrink sleeve wraps is filled with number of challenges. When the graphics are not per container specifications and designers did not proof read the drawing then graphical art distorts upon shrinkage of shrink sleeve films.

This happens because plastic film material contracts around containers upon drying which causes the printed text to shrink accordingly. Secondly, shrinking involves color saturation and uneven coloring. Colored dots contract on ink compression and bunch together creating darker regions of art than others.

Beside this, there is chance of errors in complicated design and complex geometrical details could leave the bad impression on buyers.

Professionals tend to avoid intricate detailing and complicated pictures while creating graphics for shrink sleeve labeling format. Moreover, they precisely take image measurement by using various manual and automated approaches to prevent distortion.

7.E-commerce Platforms

E-commerce and online shopping have become a megatrend since before the start of pandemic. People fancy on-net purchasing over regular shopping because the former saves time and has convenience. It is projected that US e-commerce sales will cross the mark of USD 1 trillion in 2022.

Online shopping has notably lowered the success of shrink sleeve skins. The main advantage of shrink sleeve skins is their striking look. These items catch the attention of consumers when latter move around various aisles in stores.

But with virtual shopping people cannot get the look and feel of shrink sleeve labeling product and they lose their attention grabbing advantage.

However, research shows that a good packaged product has more value in e-commerce business. This indicates that shrink sleeve labeled format market may continue to grow because of consumers’ demand for vibrant packaging.

8.Specialized Equipment

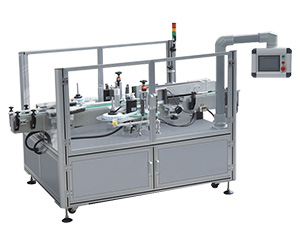

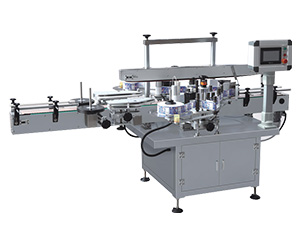

The need of specialized equipment for each design application further challenges the rise of shrink sleeve wrapped products. Particular design require special their own special set of equipments such as label applicators and tunnels.

Numerous kinds of shrink sleeve labelers are available in market such as direct applicators, rotary type, tamper evident machines, etc. This creates confusion while selecting the shrink sleeve equipment.

Moreover, setting up and installation of shrink sleeve labeling machines need considerably large time and workforce. For instance, digital printing machines while relatively low priced than flexo ones but have lower production rates. This increases the investment budget especially if you are labeling products with multiple designs.

Conclusion

8 Trends that are challenging the shrink sleeve label format have a significant impact on the sales of consumer goods since their initiation. Nonetheless, there are numerous challenges like sustainability of film material used in shrink sleeve labeling, huge investment expenses, convoluted shaped containers, competition with other technologies, quality and design issues etc that hamper the growth of shrink sleeve labeling market. If you have additional queries related this topic, do not hesitate and contact our customer service.

Don't forget to share this post!

Automatic Labeling Machine Related Posts

Automatic Labeling Machine Related Products

Automatic Labeling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine