Types Of Sealing Machine

Sealing machines are employed to limit oxidation and cross- contamination of your product. There are different sealing designs for different products. This is why; you will find many sealing machines options available in the global market. Pharmaceutical industry likewise other industries use different types sealing machine for protection, stability, ease of transportation and smooth supply chain of products.

In this article, you will explore types of sealing machines, major differences, applications and prime benefits. Let’s go:

1.TYPES OF SEALERS AND SEALING MACHINES

Discussed below are different types of sealers and sealing equipment frequently used for day-to-day industrial applications. For your understanding we have categorised them according to structure and functions:

| SEALERS | SEALING EQUIPMENT |

| Band Sealers | Tube Filling and Sealing Machine |

| L Bar Sealer | Capsule Filling and Sealing Machine |

| Taping/Carton Sealers | Suppository Filling and Sealing Machine |

| Clamshell Sealers | Hard Capsule Liquid Filling and Sealing Machine |

| Cap Sealers | Vial Filling and Sealing Machine |

| Vacuum Sealers | Soft Gel Capsule Filling and Sealing Machine |

| - | Pouch Filling and Sealing Machine |

2.SEALERS

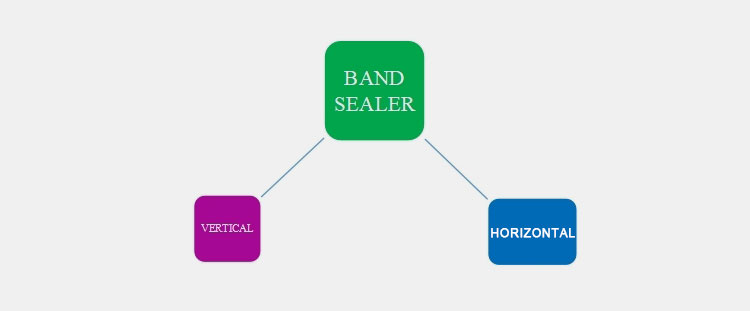

BAND SEALERS

As it names shows, a band sealers holds the pouch with a band and carries it to the machine. The sealing station in the machine seals plastic film to the pouch.

The process of band sealer is so continuous can be used for high production volumes keeping temperature at controlled and adjusted state. Band sealers has further horizontal and vertical types depending upon the movement of pouch. Band sealers are usually present in Pharmaceutical Industry, Food manufacturing industry and general merchandisers.

Vertical Band Sealer

Vertical band sealer the pouch is moved on the conveyor in vertical position with the machine.

Horizontal Band Sealer

Similarly, a horizontal band sealer also works same as vertical sealer. The only difference is in the movement of pouch that travels horizontally on the conveyor to the machine. It is preferred to do the process one by one when using any type of a band sealing machine.

L Bar Sealers

L bar sealer is one of the best solution for applying seal shrink wrap film around items. These are designed for high volume and fast production lines.

L bar sealers creates three edges seal that is kept in a double layered film. The film dispenser smoothly rolls the film to the working table. The material is then inserted in the film and creates L shape seal. Shrink channel heat the film for proper application.

Taping/Carton Sealers

Adhesive tape is applied on both sides of cases and cartons using tape sealer. Two taping heads are present in the machine. As the carton moves on the conveyor, both the taping head apply tape on it and perform proper sealing operation. This type of sealing machines is globally used in almost every industry where packages are enclosed and sealed for long travelling.

Clamshell Sealers

Clamshell sealers are mostly handheld devices that are designed to form vacuum sealing on containers and provide them temper resistance. The temper resistance makes the container self-locked to save from environment. A clamshell sealer is widely used in a food manufacturing industry and also places where a hard goods packaging is done.

Cap Sealers

Cap sealing is one of the most abundantly used sealing machines in the world. Mostly these are used in the pharmaceutical industry where syrup bottles are manufactured. The cap is placed on the subject and then it enters the sealing machine to provide tamper proof closure and proper cap lock.

Vacuum Sealers

A vacuum sealer is used to pack materials that are to be kept safe from microbial attack. It keeps low level of oxygen in it and further saves from any bacteria. These sealers are widely used in pharma and food industry to increase the life of product. Vacuum sealers are present in all manuals, semi-automatic and automatic type depending upon the requirement of production.

3.SEALING MACHINES

Tube Filling and Sealing Machine

Tube filling and sealing machines are widely used in pharmaceutical and cosmetic industry. The machine is available in both single and double headed design based upon the filling and sealing of tube.

Medicated creams, lotions can be produced in no time using this machine. Sealing machine provides plastic and aluminum sealer on the tube which helps to preserve it for long time

Capsule Filling and Sealing Machine

A capsule filling and sealing machine are used mostly in pharmaceutical industry to be used for production of large number of capsules. Companies that have high volume of production prefer this machine because it has the capability to produce equal sized, same weight and high-quality capsules.

The system is highly automated that no faulty or damage capsule can exit the production setup. It ensures proper filling of material with quality standards.

Suppository Filling and Sealing Machine

One of the latest methods used for drug intake in human body are suppository medicines. These suppository drugs are carried inside the body through rectum, vagina or anus.

A suppository filling and sealing machine fills the material in powder, tablet or liquid form. Cut down in different shapes. Cools the process to a standard temperature and finally seals the suppository medicine that can easily enter human body.

Hard Capsule Liquid Filling and Sealing Machine

Hard capsule liquid filling and sealing machines can easily be used to fill solutions and suspension into hard capsule. Its stepless converter of frequency make its operation easy. Pharmaceutical industry is using this machine on a high scale to produce better health care supplements.

Its human machine interface and automatic process ensure proper filling and sealing of capsule without any compromise on quality. Highly precise pumps and servo motors are used to control the input of material at both upper and lower end.

Vial Filling and Sealing Machine

Around 2000 different types of vial filling and sealing are used around the globe in which pharmaceutical industry itself uses 86% of it. These machines are highly reliable and safe in their processes. Liquids, substances, solids and solutions are filled in these vials and then sealed in a proper way to avoid any contamination.

Vials for oncology and biopharmaceutical industries are the most common used in the whole world. These machines are very efficient that they properly seal the while with heat, rubber or foil so it’s better prevention. Machines these days can give an output of 650 vials per minute which is a huge number when it comes to bulk production.

Soft Gel Capsule Filling and Sealing Machine

An electromechanical machine which fills gelatine shells with liquid, solutions and suspensions. Depending upon the dosage, Softgel capsule filling and sealing machine makes best suppository or oral medicines. Softgel material is entered in system of die, there the solution or substance is injected in it and them finally properly sealing is done.

Industries like pharmaceutical where production capacity is too high, these Softgel encapsulation machines provide much benefit to them.

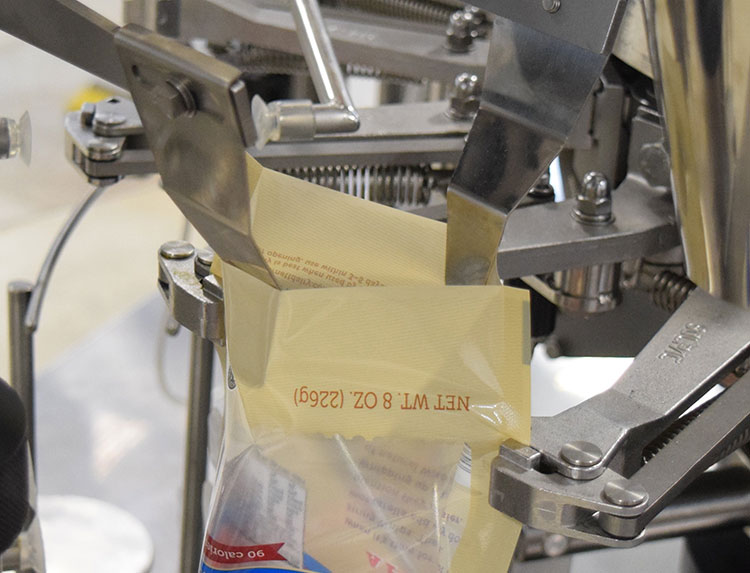

Pouch Filling and Sealing Machine

Pouch filling and sealing machines are mostly used in food, cosmetic and pharmaceutical industry. Medicines, dugs and other hair products are packed in these pouched and sealed with melting by high temperature.

4.BENEFITS

Sealing machines have numerous benefits. No matter they are used in any industry, despite of their usage they are now becoming a much popular sealing option worldwide. Some of the benefits are:

| Fast Sealing Option

|

Sealing machines are highly efficient and work with high production capacity. They provide fast sealing options depending upon the thickness of material and can be varied according to the situation. |

| Material Safety | Sealing options keep material safe for a longer period. They allow the product to avoid any wastage and environmental attack. |

| Low Maintenance

|

The design and configuration is so simple that it requires low maintenance. |

| Cost Reduction | The machine initially requires high budget, but it gives its return in no time. Long time and productivity can be obtained from these sealing machines. |

| Preservation from Loss | Sealing of products also avoid any material loss. This is one of the biggest benefits of these machines that the quantity of material remains same even after when it travels long distances. |

| Quality Standards | High quality standard products are carried out even when hundreds of products are produced; the quality standard remains the same. This makes the consumer attract towards the product and help the industry to maintain its standards. |

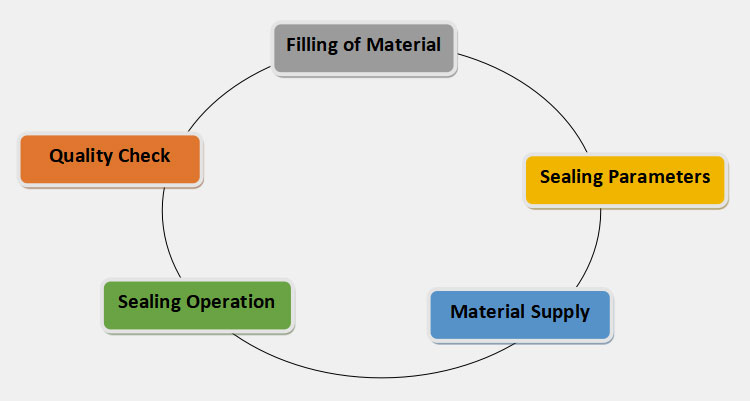

5.WORKING PRINCIPLE

| Material Filling

|

The material is filled in the packing material, film or carton as per the size and standards required. |

| Sealing Parameters

|

Sealing parameter is the most important factor to be considered. Either heat or temperature monitoring, supply of tape for carton packing and automatic film induction in machine. All parameters are monitored and controlled according to the situation with keen observations. |

| Material supply

|

After setting the parameters and material filling, bags, pouches or cartons are entered in the machine. In automatic sealing machines there are proper conveyers for travelling while in manual sealing machines this is done by the operator. |

| Sealing Operation

|

When the material enters in the machine, sealing operation is carried out. High temperature induction melts the film is a clean manner and forms sealing. In case of taping both tapes are forced to seal the carton. |

| Quality Check | On a random pace quality check is done after sealing option to verify the heating parameters and alignment of machine. |

6.APPLICATIONS AND INDUSTRIES

Applications of sealing machines are:

Food Manufacturing Industry

Food requires secure packaging and sensitive care. To maintain longer duration of food products prevention, global food manufactures are using sealing machine for better protection of products.

Pharmaceutical Industry

One of the leading industries in using sealing machines is pharmaceutical industry. Drugs need to be packed in a way that no bacterial or microorganism attack can change its chemical composition. These sealing options prevent drug, syrups, liquids, tablets from any damage as well as contamination. Capsule sealing, tube sealing, band sealing, tapping sealing are some of the applications of sealing machine in pharma industry.

Cosmetic Industry

Cosmetic industry on the other hand also uses sealing machines to pack their products and make them airtight.

Logistics and Packaging Industry

Products while travelling from one place to another can take a lot of duration. These products need high level of protection so that they may not be damaged in their journey towards the destination. Tape sealing machine and other machine best help to achieve this aim.

Beverages

Beverages industry also uses cap and band sealing machines to avoid any wastage of liquid or juices. Proper sealing of aluminium and thin foil is carried out on the top of bottles to protect them and extend their life span.

Electronics

Globally there are few giant countries like Hong Kong, China, Germany, and Taiwan which are popular in supplying electronic equipments to the world. These equipments require high level of safety and that why they are sealed in a proper way that they might not get damaged. Tape sealing on cartons is also done afterwards to make them more secure to travel.

CONCLUSION

The requirement of sealing machine is increasing day by day in every industrial sector. Due to greater productivity and consumer requirement, industries are now removing traditional sealing methods and replacing it by different type of sealing machine options available. This article completely explains all types of sealing machines available and their usage in global market. How they can be useful for pharmaceutical industry and why are they preferred. If still you find any query and find any difficulty, you can feel free to Contact Us. We are 24/7 available for your guidance and assistance.

Don't forget to share this post!

Induction Sealing Machine Related Posts

Induction Sealing Machine Related Products

Induction Sealing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine