Bottle Cartoning Machine: The Complete Buying Guide In 2025

Have you ever wondered how thousands of bottles are sealed, packed and ready for shipping in just a minute? A sleek machine swiftly package bottles into the cartons with high precision and speed. Do you know which machine is doing all the heavy lifting?

Welcome to the fascinating world of bottle cartoning machine. In 2025, this machine is a game-changer technology in every industry that are transforming packaging, like never before. Either you are a manufacturer, a packaging specialist or curious about how your favorite bottle be packaged in a carton that is clean, durable and eye-catchy, the cartoning machine is a best investment.

Before investment in this machine, this complete buying guide will take you on the journey to know everything about this amazing machine. Let’s unbox!

1.Do you know about the bottle cartoning machine?

AIPAK bottle cartoning machine

A bottle cartoning machine is a type of packaging machine that automatically place the bottles into the carton and seal them. The sealed cartons are then ready for shipping.

This machine is widely used in different industries like pharmaceutical industry, chemical industry, cosmetics and food industry for packaging of various items into the cartons.

The products like medicine bottles, chemical containers, shampoo and skincare products and sauces etc. are inserted into the cartons and ready for the consumers.

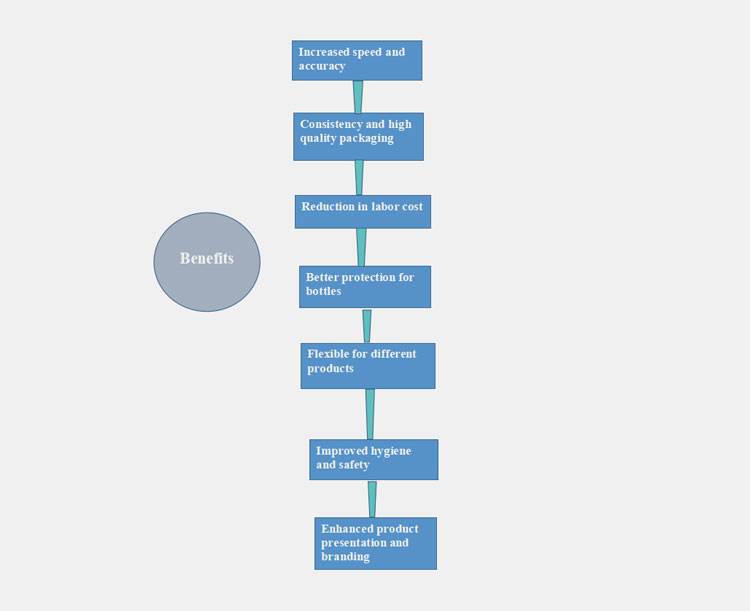

2.What are the benefits of using bottle cartoning machine?

Behind every neatly and perfectly sealed items of medicine bottles, cosmetics and sauces lies a silent workhorse that works faster and smarter than a human hand. It can protect, pack and polish your product journey from factory to customers. Welcome to the world of bottle cartoning machine!

Let’s dive into the detail benefits of using bottle cartoning machine.

Increased speed and accuracy

Increased speed and accuracy

Bottle cartoning machine is designed in such a way that it can automatically place products into the cartons with high accuracy. If you pack bottles into the cartons manually then it takes a lot of time and is laborious. This machine have the capability of packaging thousands of products in a very short time with high accuracy. In this way, your products will be populous in the market.

Consistency and high quality packaging

Consistency and high quality packaging-Picture courtesy: priorpackaging.com

Do you want a high quality and consistent packaging? The human hand packing can leads to inconsistent because some of the cartons might be overpacked or underpacked or some may be not properly sealed. A pioneering device which can insert your desired product into the carton, insert leaflet and sealed them with high precision without compromising on the quality.

Reduction in labor cost

Reduction in labor cost-Picture courtesy: checkeeper.com

Everyone wants a smart work, not a hard work. If you are running your own business, then you have to hire the workers for the packaging etc. This cartoning machine is highly expert in packing operation so, in this way you can save the money on the wages, training and management of the workers. You just need some operators to handle the machine.

Better protection for bottles

Better protection for bottles-Picture courtesy: lucasluxurypackaging.com

As this machine ensures that every bottle is properly placed and cushioned by the cartons, therefore, it reduced the damage caused during the storage and transportation.

The materials inside the bottles either it is liquid vials, products of skincare or sauces in bottles, these all provide extra protection in order to prevent the leakage during storage. The durable cartons do its wonderful job by protecting them.

Flexible for different products

Flexible for different products

Some companies are handling various shaped, sized and materials (plastics, glass and metals) products. Do they need different machines for packaging of them?

This machine is flexible in molding the carton according to the size, shape and style of the products. Investment on the cartoning machine is the smart financing in industries.

Improved hygiene and safety

Improved hygiene and safety

The automated cartoning machine can handle every task of packaging. It is very essential if you are dealing with pharmaceutical products, cosmetic products and food products, that it must be free of germs. This machine can do all the task of packaging and sealing. So, it guarantee the safety and hygiene of the products.

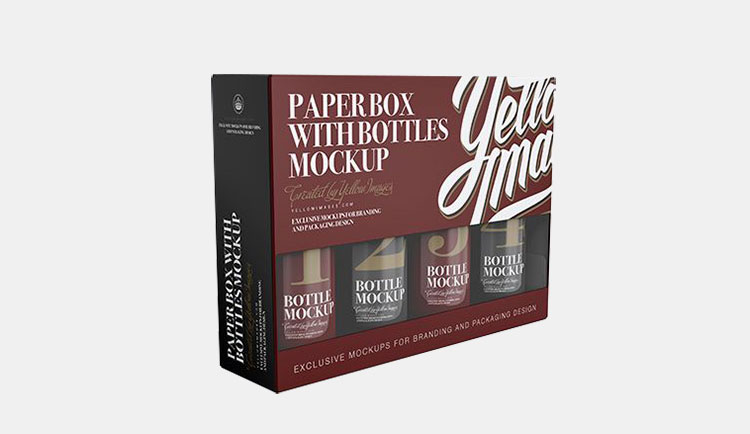

Enhanced product presentation and branding

Enhanced product presentation and branding-Picture courtesy: autumnaleister.tumblr.com

You mostly visit to the store, what kind of packaging seems to be eye-catchy for you? Obviously, the well-sealed and neatly packed cartons on the shelves seems to be very aesthetic. This machine neatly packed and professionally sealed the cartons having proper logos, and other essential information are very professionally pasted on the cartons and your brand presentation and your products get viralized in the market

3.What is the application of bottle cartoning machine in different industries?

From a life-saving medicines to luxury perfumes, are perfectly packed inside their boxes. Only one intelligent cartoning machine performs well tirelessly to ensure their safety, stylish and secure packaging. Its application is as diverse as the industries it serve. Here is how this machine fits into different industries:

Pharmaceutical industry

Pharmaceutical industry

Bottle cartoning machine packs medicinal products as well as medical products.

It can insert the syrups, eye drops, tablets, capsules, vitamin supplements and liquid drugs into the individual or grouped cartons. It not only insert product into the carton but it also ensures the most important leaflets into the carton as well.

Food and beverage industry

Food and beverage industry

When you go into supermarket and find your favorite cereal into well-designed box, have you ever wondered who the hero behind this awesome packaging is?

This bottle cartoning machine is made up of stainless steel which is considered as food-grade. Also this machine package the food and beverage hygienically and prevent the contamination.

Cosmetic industry

Cosmetic industry

In the cosmetic section of the boutique, you are attracted towards the most stylish and sophisticated boxes of the makeup, skincare or other cosmetic products.

These cartons or boxes are made smooth, chic and luxurious which are appeal to the customers in bottle cartoning machine. The damage free and well-presented cartons can boost your branding.

Chemical industry

Chemical industry-Picture courtesy: labelmaster.com

Cartoning machine is widely used in chemical industry by packing various chemicals, laboratory reagents and agrochemical products in various cartons to ensure its safety and chemical integrity. It ensures that the cartons provide safety, correct labelling and leak-proofing during transportation to avoid accidents.

Household products making industry:

Household products making industry-Picture courtesy: poshmark.com

Household products making industry used cartons for the packaging of items like hand sanitizer, detergents, oil, and liquid soaps in various cartons to ensure its safety during transportation from the industry to the market. By adding aesthetic visual aids resonate your products in the market.

Nutraceutical and health supplements

Nutraceutical and health supplements-Picture courtesy: dssmith.com

In the growing world of health and wellness, neutraceutical are packaged with great care to ensure safety. The bottle cartoning machine ensures the safety and hygienic standards. It also ensure the leaflets insertion into the bottle in order to provide complete information regarding the product. It is also expert in handling a wide variety of bottle sizes and shapes like small liquid tonic, large vitamin supplement bottles and slim energy shots etc.

Luxury goods and gifting industry

Luxury goods and gifting industry-Picture courtesy: themailerbox.com

Bottle cartoning machine is used for the packaging of luxury bottles and gifting bottles. When you are presented with a beautifully packaging gift, and you wondered the attention to detail and thinking about the craftsmanship that create such a visually appealing presentation.

Veterinary and pet care industry

Veterinary and pet care industry-Picture courtesy: thedieline.com

As the global demand for the pet healthcare grows, and so the need for professional packaging, and efficient packaging of veterinary products. The bottle cartoning machine efficient and smartly pack the animal vaccines, vitamin and mineral tonics for pets, deworming syrups for dogs and cats, and pet shampoo bottles for pets in liquid form etc. in the cartons.

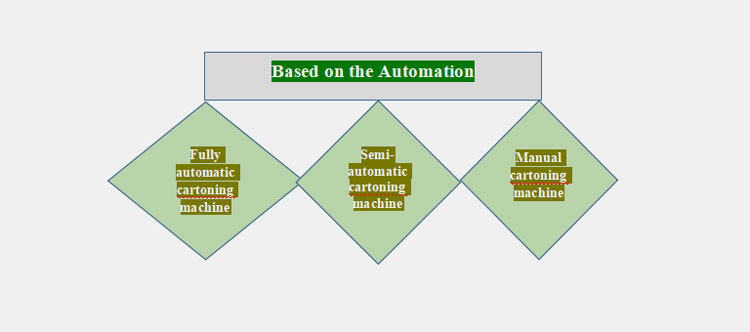

4.Enlist the types of bottle cartoning machine?

For the making of bottle carton design, modern technology is like a game-changer in the world. Various machines are used for the manufacturing of bottle cartons. These are given below:

Division based on the automation of the machine:

You know some machines do all the tasks exclusively while some needs an operator for proper handling of the process. According to the automation, the machines used for bottle cartoning design are as follows:

Automatic bottle cartoning machine

AIPAK automatic bottle cartoning machine

The automatic bottle cartoning machine do not need an operator for its operation. This equipment conduct all the task by own, each and every step from picking products and placing and up to discharging the cartons by itself. By using this machine, you can get bundles of your desired cartons in a very short time.

You can get a perfect packaging of bottles in an intact cartons with high precision. As the contact of human being is very less with the products so, the risk of contamination is also very low.

Semi-automatic cartoning machine

Semi-automatic bottle cartoning machine

In semi-automatic cartoning machine, the machine automatically picks and erects the carton. The operator is needed in this machine as the operator is manually places the bottles into the cartons. The machine automatically sealed the cartons either by hot-melt glue or tuck-in procedure. The sealed cartons are then discharged outside and the operator may collect the cartons now.

Manual cartoning machine

Manual cartoning machine

A manual cartoning machine is suitable for small-scale production or startup businesses. This machine is majority operated by the human being. The operator manually opens the carton, placed the bottles in to it and flaps are closed manually. The finished carton is then placed on the conveyor or collected in a bin.

Division based on the speed of packaging of the machine:

Based on the speed of packaging of bottles in the cartons, they are categorized into two types:

Continuous bottle cartoning machine

Continuous bottle cartoning machine- Picture courtesy: sedpharma.com

As the name indicates, the continuous bottle cartoning machine works in a non-stop manner. It works in uninterrupted way from flat carton insertion into the conveyor to flapping of it, bottle insertion, final sealing and discharging of bottle cartons occur in a continuous and persistent way.

Intermittent bottle cartoning machine

Intermittent bottle cartoning machine-Picture Courtesy: medicalexpo.com

Unlike continuous bottle cartoning machine, intermittent cartoning machine pauses at every steps to perform its task. It automatically place the flat cartons, flaps them into boxes, place the bottles in the cartons and then sealed and discharge them but at each station it stops and ensures that each and every step has done with high precision.

Division based on the insertion of bottle into the cartons:

Bottles can be placed into the cartons according to their shape and size. Some bottles are required to insert into the cartons from the side and some needs to place in the cartons from the top. Based on bottle insertion into the cartons, there are two main types:

Horizontal bottle cartoning machine

AIPAK horizontal bottle cartoning machine

In horizontal bottle cartoning machine, the bottles are placed into the cartons in horizontal position. In this type of cartoning, the products are visible to the consumers. You can easily inspect the bottles that are packaged. It is recommended for packaging of irregular shaped bottles like packaging of sauces bottles and vials.

Vertical bottle cartoning machine

Vertical bottle cartoning machine- Picture courtesy: saintyco

In vertical bottle cartoning machine, the bottles are placed from the top into the cartons. It can support single or multiple bottles into the cartons. The major benefit you can gain by using it to reduce the risk of damage for sensitive bottles. Cooking oil and syrups are packed into the cartons by this machine.

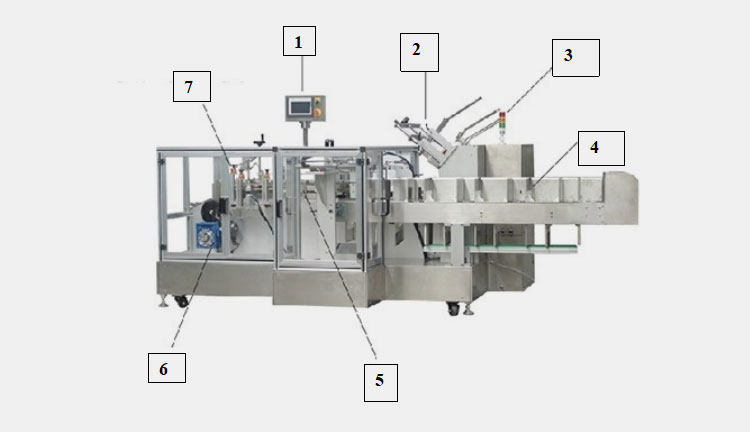

5.What are the components of bottle cartoning machine?

AIPAK bottle cartoning machine

In order to smoothly operate the bottle cartoning machine, it is essential to become familiar with the key components of the bottle cartoning machine. Below is the detailed notes of the components of the bottle cartoning machine.

| 1. Control panel | The control panel is the brain of the bottle cartoning machine. It contains HMI (touch screen), buttons and switches, emergency button, indicators and display. In HMI, the operators adjust parameters, put commands and can also handle troubleshoot errors.

Buttons and switches are for the start and stop the machine. The purpose of the emergency button is to stop the machine in case of any emergency. LED indictors are used to observe the operation of the bottle cartoner and indicates that faulty conditions. |

| 2. Box holder | The box holder section consists of many areas like carton magazine, adjustable guides, suction cups and spring loaded clips. In carton magazine, there are trays in which flat cartons are fed into the machine to make cartons for the bottles. The adjustable guides are the section where different sizes carton are made. Suction cups or mechanicals fingers are used to pick your cartons, one carton at a time into the forming area. The spring loaded clips helps to firmly hold the carton in place to place bottle into the carton. |

| 3. Warning light | Warning lights are used for alarm the operator in case of faulty operation. Usually green, red and yellow lights are place at the top of machine. By turning on red light and the operator can hear an alarm also. This alerts the operator to stop the machine. |

| 4. Bottles pushing mechanism | This section transfer the bottles from the conveyor into the cartons. This section include pusher arms, synchronization unit, guide rails, and bottle sensors. The pusher arms are used to push the group of bottles into the carton. The synchronization unit ensures that your bottles are only pushed when the cartons are fully opened. When the cartons are fully and correctly positioned, now, the alignment of bottles occur. And this job can be done by guide rails.

The number and size of bottles to be placed into the cartons are detected by the bottle sensors before the pusher do its job. |

| 5. Forming mechanism | In this section flat cartons are erected into boxes. This section includes suction pickers, erection arms, flap folding section, sealing system. The suction picker or cups picks up a flat blank carton from the box holder. Then the flat blanks are pull into the shapes with the help of erection arms. Now, the top and bottom folds flaps are done in flap folding section. After that, the sealing is done either by hot melt glue or tuck-in-flap mechanism. |

| 6. Serve motor | The serve motor is used for the high precision and the operation of machine in controlled way. This includes the placing of flat cartons, folding it into carton shapes, and integrates with different programme for smooth and adjustable speed of forming cartons and packaging. |

| 7. Position adjustment display | In this portion, adjustable knobs, mechanical indicators, and locking mechanism are present. In adjustable knobs, the operator adjust different parameters manually. The dials are done for quick reference in mechanical indicators and the locking mechanisms like locking of components in a specific positions. |

6.Do you know the working principle of bottle cartoning machine?

AIPAK Bottle cartoning machine

There are various types of bottle cartoning machine are available but the working principle of the machine is almost similar. So, it is essential to know the working steps involve in bottle handling, arrange and securely enclose the bottles within the cartons. The steps involved in the cartons formation and feeding of bottles are as follows:

Blank cartons feeding

In the magazine portion, the stack of blank cartons are placed in it. Then, with the help of suction cup, they pick the flat carton one at a time and transferred it to the next station for forming carton for the bottle, desired to be packaged.

Carton forming

In the next step, the open and flat cartons are erected to the open carton. In this step, the mechanical arms pull the open carton and guide rails stabilize the carton position. Then the opened carton is placed firmly for bottle insertion into it.

Bottle feeding

The conveyor pushes the bottles and sensors within the machine detect and count the number of bottles to be packaged in the cartons.

Bottle insertion

In this step, bottles are inserted into their cartons with the help of mechanical pushers. The insertion of bottles may be horizontal or vertical into the cartons. In vertical cartoning, your bottles are inserted from the top and in horizontal cartoning, bottles are fed from the side in to the cartons.

Carton flap folding

Once the bottles are placed in the carton, the top and bottom flap is done by rotating arms to ensure the correct way of closure.

Carton sealing

For proper sealing of cartons, hot-melt glue or tuck-in mechanism is done to ensure tight and uniform sealing.

Discharge of finished bottle cartons

The discharged conveyor transport the sealed cartons outside the machine. Now, you can collect the sealed bottle cartons.

7.What types of bottles can be packaged with the cartoning machine?

The versatility of usage of bottle cartoning machine in different industries is very important. It can accommodate a variety of materials, bottles etc. due to this property, it is widely used in different industries.

Based on shape

Based on shapes of the bottles, they are divided into the following types:

Round bottles:

Round bottles-Picture courtesy: exactprinto.com

You have seen round bottles in your home and markets frequently. They are most commonly used because they can easily handle for pouring and liquid dispensing.

The round bottles are majority used for pills, beverages and cosmetics etc.

They key challenge you may face while handling is that, as they can roll easily so proper sealing is essential. But the innovative equipment like cartoning machine have bottle holders, and spacers that can easily hold and roll the round bottles into the cartons.

Oval or elliptical bottles:

Oval or elliptical bottles

The oval shaped bottles give visually appealing to the customers. Due to its aesthetic look, it is mostly used in the packaging of the shampoo and personal care.

Due to its irregular shaped, it need precision placement into the cartons to maintain uniformity inside the cartons.

Square or rectangular shaped bottles:

Square or rectangular shaped bottles –Picture courtesy: flushpackaging.com

The benefits of using square or rectangular shaped bottles is that they don’t roll and have high stability. They easily arranged into the carton.

These type of bottles you came across in lotions and sauces.

In order to package them in the carton, you must be careful to precisely align the corners in order to prevent any damage.

Irregular shaped bottles:

Irregular shaped bottles-Picture courtesy: designerpeople.com

They are irregular shaped bottles specially designed for elevating the branding as it give it creative look. It needs custom molds (require special handling). The designer perfume bottles and niche pharmaceutical products are placed in unique carton design for branding purposes.

For securely placed them into the cartons, custom trays or inserts are used within the cartons to securely hold the products.

Based on size

Based on the size of the bottles, they are divided into different types:

Small-bottles:

Small bottles- Picture courtesy: whereandwhatintheworld.com

The small bottles having holding capacity up to (10mL- 100mL ) are usually used in eye drops, essential oils etc.

The cartoning machine have gentle mechanical arms, and fine-tubed controlled mechanism so, in this way it can securely packed these products into the cartons.

Medium bottles:

Medium bottles

The medium bottles usually have the holding capacity of the products from 100mL-500mL. These bottles are widely used in syrups and shampoos etc.

The bottle cartoning machine has adaptable grippers to accommodate slight variation in the bottle dimensions. Due to this quality, cartoning machine is ruling the industries and companies.

Large- sized bottles:

Large-sized bottle carton-Picture courtesy: the home depot

The holdings capacity of large-sized bottles are from 500mL to 1L or more. Do you know what kind of products are packaged in these bottles? Well, you came across the detergents and sauces. That is packed in the large bottles.

For large bottles may need reinforced cartons or inserts. For pushing them into the cartons, strong mechanical pushers and durable conveyor belt is required and you have cartoning machine that has both.

Based on materials

Bottle cartoning machine is used for the packaging of wide variety of bottles. They are categorized into plastic bottles,

Plastic bottles:

Plastic bottles –Picture courtesy: core77.com

As the plastic bottles are light weighted and due to this, it is widely used in different industries. The examples of plastic bottles are HDPE, PET and PP.

Has your mind ever crossed it that how plastic bottles are beautifully crafted into different styles? Well, the plastic bottles care deformed under pressure, so it is the key challenge for this machine to carry the bottles gently yet firmly.

Glass bottles:

Glass bottles-Picture courtesy; salazarpackaging.com

Glass bottles can preserve the chemical stability. Have you ever wondered why the products in the glass bottles looks so artistic? If you want a chemical stability and product quality perception, then you have to pack the products into the glass bottles.

Perfumes and essential oils, injectable vials, and wine, spirits are packaged in glass bottles. The glass bottles are fragile so they may need an additional padding or partitioning.

The key challenge while operating the cartoning machine is often include soft gripping arms, cushioned supports, and precise placement system to prevent leakage.

Metal bottles:

Metal bottles-Picture courtesy: yellowimages.com

The bottles made up of aluminum and tin can also be handled by the bottle cartoning machine. The metal bottles provide the excellent barrier properties. Due to this property, it is frequently used in the packaging of aluminum water bottles and sprays etc. in order to provide them protection.

As the metal bottles are strong but they can be dented, the main challenge you may face while handling metallic bottles is to carefully handling on order to ensure to maintain the products aesthetics.

Based on bottle content

Based on the bottle content, they are divided into different types:

Liquid:

Liquid material in bottle

The liquid material include medicinal syrups, cooking oil, and beverages.

For the packaging of these materials, leaf-proof seals must be verified before cartoning.

Powders or granules:

Powder or granule in bottle

The examples of powders or granules are infant formulas, protein powders, and cosmetic powder bottles.

You must be precaution about the packaging of these types of materials by tightly sealed the bottles to prevent contamination and leakage of fine particles.

Viscous products:

Viscous product in bottle

Viscous products include lotions, hair gel and shampoos.

You must ensure that the bottles are properly sealed to avoid pressure leaks.

Machine design considerations:

According to the type and size of bottles to be packaged, following machines can be used for the cartoning. These are as follows:

Horizontal cartoning machine

AIPAK horizontal cartoning machine

As the name of machine indicates, in horizontal cartoning machine, bottles are laid horizontally into the cartons. This machine is used when lying down is acceptable or optimal.

Vertical cartoning machine

Vertical cartoning machine-Picture courtesy: endflex.com

In vertical cartoning machine, the bottles are inserted in the cartons in vertical or in upright direction. This machine is important for packaging of liquid product bottles or fragile bottles.

Wrap-around cartoning machine

Wrap-around cartoning machine-Picture courtesy: hualianmachinery.com

In this cartoning machine, products are not loading into the pre-glued cartons. Infact, the cartons wrap around the bottles. In this way, the cartons protect the bottles.

Carton features that affect compatibility:

Cartons with inserts/ partitions

Carton with inserts/partitions-Picture courtesy: bunnings

Some of the cartons are designed having partitions. Each partition protect the bottle. This type of cartons are useful for packaging of glass bottles.

Multi-pack cartons

Multi-pack carton-Picture courtesy: boxpackingsolution.com

Multi-pack cartons are designed that holds multiple products in a single carton. These cartons are used for grouping several bottles. The benefit of this carton is that consumers purchase several items once, and can save their energy and time.

Cartons with windows/ display cut-outs

Carton with windows/display cut-outs-Picture courtesy: cosmeticboxes

This type of cartons have a transparent section and the customers can see the product inside the carton. These cartons are used for the packaging of

cosmetics and premium packaging. The benefit of using this carton is

visual appealing and customers satisfaction.

Special consideration:

Some of the special consideration are as follows:

Bottles with pump heads or sprayers may need taller cartons or custom flaps.

The bottles having tamper-evident caps or seals need care during loading into the cartons to avoid damage.

The irregular shaped or high-friction bottles may need robotic or pick-and-place loading into the carton.

8.What kind of hurdles do you face while operating bottle cartoning machine?

The hurdles that you may face while operating the bottle cartoning machine are as follows:

Bottle misalignment:

Bottle alignment

The major hurdle you may face while operating the bottle cartoning machine is that the bottles may not be positioned correctly. If the positioning is not proper then it may cause jamming or improper cartoning.

Carton feed issues:

Carton feeding-Picture courtesy: wayneautomation.com

You may noticed sometimes that the cartons may not be properly picked up properly by the suction cup from the magazine. Or may also find the misalignment of the cartons.

Sensor failure:

Sensor failure-Picture courtesy: agelecrepair.com

The sensors are used for the detection of cartons malfunction. If sometimes broken bottles or cartons are present, then sensors may not detect it and causing errors in the process.

Mechanical jams:

Lubrication to prevent mechanical jams-Picture courtesy: braidwoodgear.com

If the machine parts are not properly lubricated, then you may find the moving parts jamming. So, in order to avoid such an issue, then you must lubricate and replace the damaged parts.

Inconsistent bottle size:

Inconsistent bottle size

This machine can handle a variety of bottles, it may varies in bottle size and shapes. By this, there may be chances of rough or not smooth operation of the machine.

Glue or sealing problems:

Sealing of carton-Picture courtesy: mahisa.com

The glue is used for the sealing of bottle cartons. If the glue applicator is not properly cleaned then the glue may clog in it. This can affect the sealing process. You may not get a well prepared sealed bottle cartons.

9.What kind of maintenance does bottle cartoning machine typically needs?

Maintenance of machine

For the smooth and safely operating the bottle cartoning machine, you must have to look after the machine as your friend, who can do a lot of task for you but also needs love in return. Similar is the case with bottle cartoning machine, following are the maintenance for this machine.

| Daily maintenance | Cleaning | After operating the process, you have to remove the dust, glue debris and unwanted cartons from the machine surfaces. |

| Visual inspection | If you find abnormal noises in the machine, you must have to stop the machine. | |

| Lubrication | You must have to apply oil or grease in the machine parts to ensure safe operation of bottle cartons making and sealing. | |

| Weekly maintenance | Check alignment | Once in a week, you must have to inspect and adjust the alignment of bottle guides and carton magazine. |

| Inspect sensors | For proper alignment of the cartons, you must have to clean and test the sensors to ensure the dust-free sensors and misalignment of the cartons. | |

| Tighten fasteners | If the nuts etc. in the machine are loose then it may leads to vibration. For unwanted vibration, you must ensure all nuts, bolts and fixture are secured. | |

| Monthly maintenance | Inspect drive components | For the maintenance of the machine, you have to check the conditions of the motor, and timing belts. |

| Test electrical components | Electrical system play an important role in the machine functioning. Once in a month, you have to inspect the electrical wiring, and PLC for overheating. | |

| Verify safety factors | Emergency button is the most important button to ensure secure functioning of the process. You must ensure that the emergency button should correctly functions. |

10.What factors to be considered when buying bottle cartoning machine?

If you are going to purchase or investment on the bottle cartoning machine, it is important to consider some key factors to ensure the machine meets your production capacity and accuracy.

Some of the key points to be considered while buying bottle cartoning machine are as follows:

Identify your product requirement

This point will identify and ensure you to choose physically and functionally compatibles with your products. What factors to be considered of your products?

The bottle types (plastic, glass), their shapes, and sizes of the bottles. You must also know what kind of cartons it can handle like paperboard thickness, and how can it seal the cartons either tuck-in or glued.

The sealing style is also important because in some carton style, you need glue sealing while in others tuck-in closure procedure etc.

Assess production capacity

Production capacity-Picture courtesy: www.mdi.org

You must be evaluate the speed and volume of your production line to ensure uninterrupted and smooth production. You must be considered that how many bottles do you need to pack per/ minute or per hour.

You must also make sure to match the machine with filling and labelling phenomenon.

Decide on automation level

You must make sure that your budget fits into the selecting of the machine. Manual bottle cartoning machine is suitable for small batches production. Semi-automatic bottle cartoning machine is suitable for medium scale production. Fully automatic machine has high speed and best for large scale production.

Check compatibility and flexibility

Flexible machine is crucial for preventing too much money on the investment of new equipment for every new production line. So, look for that machine that is adaptable to handle different sizes and cartons and is easy to change the setting for smooth production line.

Evaluate vendor support

Choose a reputational supplier or industry who offers proper setups and give training to the operator. The machine should also meet the industry safety and quality standards.

This will ensure to smooth operation of the product production and protects your investment.

Conclusion:

It is concluded that businesses are investing in the bottle cartoning machine aiming for high efficiency, maintaining material integrity and high speed of packaging production. It can pack various bottles into the cartons with intact quality. When investing in the right machine, consider different factors to ensure you achieve the production goals and future scalability. Trusting a reputable provider like AIPAK guarantees you consistent quality and comprehensive service to support your packaging needs. If you have any queries, feel free to contact!

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine