Automatic Cartoning Machinery ROI How Long Does it Take to Pay Back Your Investment

In the modern pharmaceutical and cosmetic manufacturing landscape, moving toward automation is no longer an "if," but a "when." However, for decision-makers in Russia, South America, and beyond, the financial justification remains the primary hurdle.

"What is the real ROI of an automatic cartoning machine?" This guide provides a comprehensive analysis of the Return on Investment (ROI), Total Cost of Ownership (TCO), and a real-world case study of how technical reliability saved a high-stakes project.

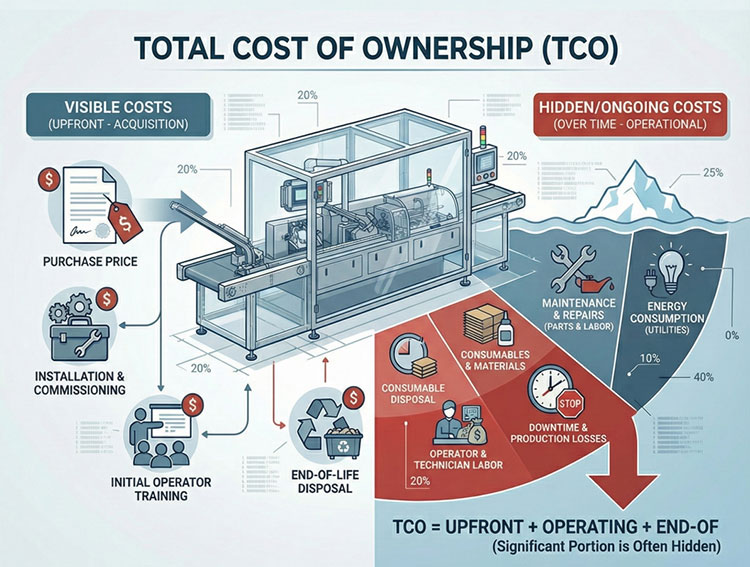

1.Beyond the Price Tag: Understanding Total Cost of Ownership (TCO)

To calculate ROI accurately, one must look beyond the initial invoice. A high-quality machine like the APK100 Series influences your financial health through its TCO.

The ROI Formula for Automation:

ROI = (Annual Labor Savings + Waste Reduction + Capacity Gain) / (Initial Investment + Annual Maintenance)

Breaking Down the Pillars:

Labor Cost Displacement

A manual cartoning line for small items (like adhesive bandages or vials) requires 4 to 8 workers. An automatic cartoner reduces this to one operator.

Case Example: If a factory worker earns $8,000 annually (base salary + benefits), replacing 5 workers saves $40,000 per year in labor alone.

Precision and Material Yield

Manual folding often results in a 2-5% rejection rate due to aesthetic flaws or improper sealing. Automation brings this down to under 0.5%. For high-value packaging, this 1.5% improvement can save thousands of dollars in wasted paperboard and adhesive annually.

Energy and Space Efficiency

Modern cartoners are designed with a compact footprint. Reducing the square footage of your production line lowers utility costs and frees up expensive factory space for additional equipment.

2.Technical Comparison: Why One Size Does Not Fit All

To help you choose the machine that offers the fastest payback, we have prepared a technical comparison of standard technologies.

Table: Cartoning Technology Performance Matrix

| Metric | Manual Cartoning | Semi-Auto Cartoner | APK100B (Intermittent) | Continuous High-Speed |

| Speed (Boxes/Min) | 5 - 15 | 20 - 40 | 40 - 100 | 120 - 300+ |

| Operators Required | 4 - 8 | 2 | 1 | 1 |

| Waste Rate | High | Medium | Minimal (<0.5%) | Minimal |

| Changeover Time | N/A | 15 mins | 20 - 30 mins | 60 - 120 mins |

| Est. ROI Payback | N/A | 18 - 24 Months | 12 - 18 Months | 24 - 36 Months |

3.Case Study: How Technical Resilience Accelerated ROI for a Russian Manufacturer

The fastest way to lose ROI is a failed installation. This is where the expertise of the supplier becomes your biggest financial asset.

The Project: A Complex Bandage Packaging Line

A client in Russia initially partnered with us for a simple Film Coating Machine. Their goal was to test our "reliability threshold." After a flawless execution, they launched a high-complexity project: a customized Adhesive Bandage (Band-Aid) Cartoning Line.

The Engineering Crisis

Midway through production, the client updated their SKU list. The new bandage sizes had different thicknesses and box geometries than the original samples. This is where most "cheap" suppliers would fail or ask for massive surcharges.

Our Response (The Reliability Factor):

Structural Re-Engineering: Our team redesigned the suction cup pick-and-place logic and the pusher stroke parameters to accommodate the new multi-specification requirements.

Software Optimization: We updated the PLC logic to allow for "one-button recipe switching," ensuring that different bandage sizes didn't require mechanical dismantling.

Transparent Delays: While the rework added 4 weeks to the timeline, we maintained daily video communication and shared raw test data.

The Financial Result

The client successfully launched their product without a single day of production halt upon arrival. By avoiding a "faulty start," the client secured a faster ROI than predicted. Today, they no longer look at our "price"—they look at our "solutions," involving us in their design phase for every new project.

4.The Hidden ROI Killer: Downtime and Spare Parts

A machine that costs $10,000 less but stays down for three weeks waiting for a proprietary sensor is a financial liability.

Global Brand Integration

At AIPAK, we use Siemens, Schneider, and Omron components. This means your ROI is protected because you can find replacement parts in Moscow, Sao Paulo, or Cairo within hours, not weeks.

Preventive Maintenance (PM)

Implementing a PM schedule (Daily cleaning of vacuum nozzles, weekly chain lubrication) can extend the machine's life from 5 years to over 12 years. This long-term durability effectively halves your annual depreciation cost.

5.Frequently Asked Questions (FAQ) for Global Buyers

Q1: Can one cartoning machine handle different sizes of bottles or sachets?

Absolutely. Versatility is a core feature of our equipment. The WZH-120 is designed to be highly adjustable. By using a combination of adjustable guides and interchangeable "pockets" (change parts), you can switch between various bottle heights, diameters, or sachet dimensions on a single machine. For most standard size changes, the process is tool-less and can be completed in 15 to 25 minutes, allowing you to maintain high production uptime even with multiple SKUs.

Q2: Does the machine support 21 CFR Part 11 for FDA export?

Yes. For clients aiming for European or North American markets, we provide HMI systems with Audit Trails and encrypted login levels to ensure data integrity.

Q3: What is the typical lead time from order to installation?

Standard machines take 30-45 days. Customized lines (like the Russian bandage project) take 60-90 days. We recommend factoring in 2 weeks for sea freight and 1 week for local commissioning.

Conclusion:

Calculating the ROI of an automatic cartoning machine requires a balance of short-term savings and long-term stability. While initial costs are important, the Russian case study proves that a supplier’s ability to navigate technical changes is the ultimate safeguard for your investment.

At iCapsulePack, we pride ourselves on moving from a "trial supplier" to a "long-term partner." We don't just provide a machine; we provide a foundation for your factory's growth.

Don't forget to share this post!

Maximizing ROI with Automatic Cartoning Machinery

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours