Your Best Seed Coating Machine Supplier

Batch Treating&Continuous Treating Machine

Utmost Precision &Careful Handling

The most Accurate And Consistent Seed Coating

AIPAK Seed Coating Machine

AIPAK Seed Coating machine is used to coat the seeds to protect them from moisture and spoilage so that it can be stored for a long time and can be used whenever required.The machine can coat film for peanuts,garlic,corn,wheat,soybeans,seeds,cotton seed,vegetables,and other seeds.After the coating process,the seed quality will be improved,and will be saved for disease prevention,anti-pest and the seed appearance will also be improved.The seed coating machine is easy to operate, corrosion resistance, has low consumption ,the coating rate can reach 99%.

The Buyer's Guide

Seed Coating Machine: The Complete Buying Guide in 2025

Have you heard the well-known proverb, “What you sow, so shall you reap?” Wouldn’t you want to sow something that reaps perfect results? Well, it is entirely possible in modern farming! Visualize sowing not just seeds but the promise of perfection in every yield. In this day and age, farming is a strategic art; cultivating success from the ground up.

The key lies in the revolutionary world of seed coating machines. In this ultimate buying guide, you will embark on a journey through the details of seed coating machines, uncovering the secrets that can revolutionize your farming game. From understanding the alchemy behind seed coatings to decoding the diverse world of coating types, you will be immersed into the core factors that every astute farmer should consider. Explore the key questions and unravel the latest technologies in seed coating machines.

1. What is a seed coating machine?

Seed coating machine

A seed coating machine is a sophisticated agricultural tool in modern farming. It is designed to enhance the performance of seeds by applying numerous kinds of coatings. There are various coatings in the market and each of them serves a different purpose. They often comprise of materials such as polymers, nutrients, fertilizers, and pesticides. This in turn leads to better germination rates and an improvement in disease resistance. You will discover various types of seed coating machines as you read along.

2.What are the benefits of using a seed coating machine?

There are various benefits of using a seed coating machine that we will discuss below.

VERSTAILITY

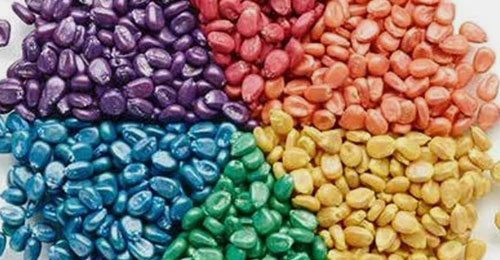

Various types of seeds– Photo courtesy: casamiatours

The versatility of seed coating machines allows you to customize the coatings based on the specific needs of different crops and environmental conditions. Seed coating machines have proved to be a game changer for the modern agriculture industry. They provide a multitude of advantages to the farmers.

UNIFORM COATING

Uniform coating on various seeds – Photo courtesy: incotec

Firstly, seed coating machines make it possible to uniformly coat the seeds with a protective layer that shields them from environmental stressors, pests and diseases. Since the seeds have an added layer of protection, it helps seeds to grow during critical germination period and increases the chances of a robust foundation for healthier plants.

SEED PROTECTION

Treated and untreated soybean seeds – Picture courtesy: science.lu

Furthermore, seed coating machines enables the uniform application of coatings possible. They ensure that each seed gets the exact amount of nutrient and protective layer of fertilizer and pesticide that is required.

REDUCED WASTAGE

Multiple types of grains – photo courtesy: healthyeating

This precise application not only promotes optimal plant development but also minimizes resource wastage and environmental impact. Hence, the seed coating machines give each seed an equal opportunity to thrive in the field and maximize crop yield leading to sustainable and efficient agricultural practices.

3. What are the steps involved in seed coating process?

It is imperative that farmers understand the seed coating process in order to make informed decisions about their crop outcomes. Comprehension of the seed coating process equips you with the knowledge to tailor seed coatings to the requirements of different crops and the environmental factors. This customization involves applying the right number of coatings, avoiding overuse of resources and minimizing environmental impact.

If you grasp the intricacies of seed coating, it aids you in troubleshooting issues during application and makes you well positioned to improve yield and contribute to sustainable farming practices. Here’s a general step-by-step process overview for the seed coating process.

Loading Seeds

Loading seeds – Photo courtesy: glatt

The seeds to be coated are loaded into the coating drum of the machine. This drum is usually perforated to allow for air circulation during the coating process.

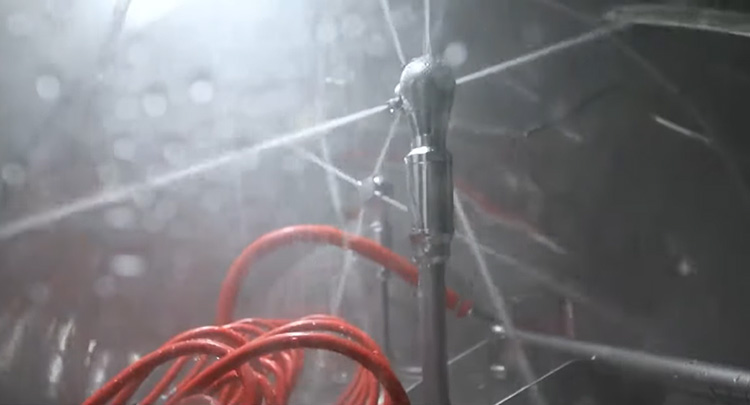

Spraying the Coating Solution

Spraying Seeds – Photo courtesy: glatt

The coating solution is sprayed onto the seeds as the drum rotates. The spraying is done using a spray gun or a series of nozzles. The speed of rotation and the rate of spraying are carefully controlled to ensure an even and uniform coating.

Drying and Curing

Drying seeds – Photo courtesy: glatt

After the coating is applied, hot air is introduced into the coating chamber to facilitate the drying and curing process. This step is crucial for solidifying the coating and ensuring that it adheres properly to the surface of the seeds.

Cooling and Discharge

Coated seeds discharged – Picture courtesy: glatt

Once the coating process is complete, the coated seeds are allowed to cool. The coating machine's drum is then stopped, and the coated seeds are discharged.

4. What are the different parts of a seed coating machine?

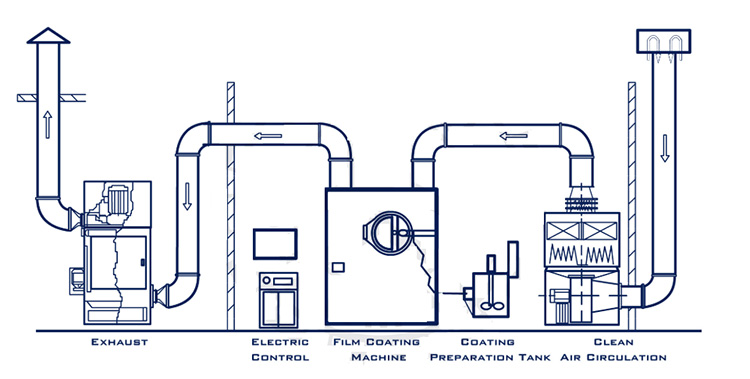

Seed coating machine – Photo courtesy: paragoncn

Now that you know the seed coating process, let’s go through the different parts that a seed coating machine typically has. It is important to note that specific design and features may vary from machine to machine depending on the type of seeds being coated and the required coating. You will uncover the different types of seed coating machines as you read along. Here are the common parts of a seed coating machine.

| Clean Air Circulation | The circulation system includes air flters and a circulation system that keeps the air within the machine freee from dust, impuities and other contaminants. It helps to maintain a controlled and sterile environm ent during the Coating proces. |

| Coating Preparation Tank | The tank includes agitators or mixers to stir and blend the coating material, as well as temperature control systems to maintain the optimal conditions for the coating solution. The coating preparati on tank is where the coating material is mixed and prepared before appli cation. It ensures a consi stent and homogeneous mixture of the coating solution. |

| Film Coating Machine | It consists of a rotating drum or chamber where the seeds are placed along with a system for spraying or dispensing the coatig material onto the seeds. The coating is sprayed through a series of nozzles. The rotation of the drum ensures even coverage.This is the core component responsible for applying a thin and uni fom layer of coating material onto the surface. |

| Electric Control | The electric control system is the bain othe sedcciag macame, responsible for regulating and controlling various param eters of the coating process, such as rotation speed, temperature. and duration. Control panels, sensors, and programmable logic controll ers (PLCs) are common components that fa11 under electic cotrol |

| Exhaust | The exhaust system is designed to remove fum es. gases. and any particles generated during the coating process. Exhaust fans, ducts, and filters are essential components of the exhaust system. |

5. What are the different types of seed coating machines?

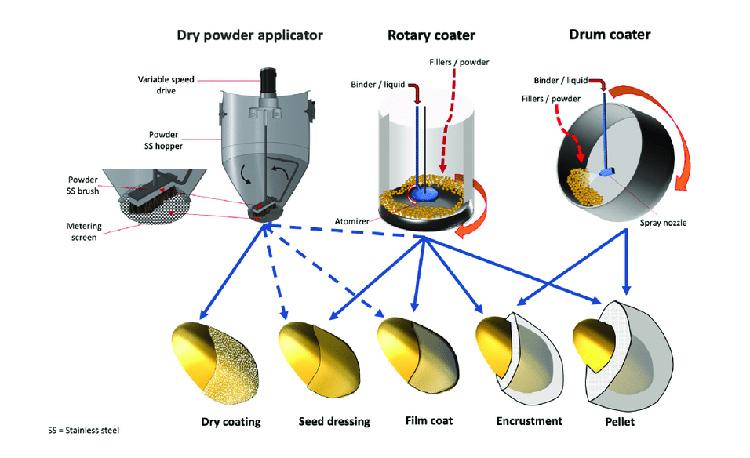

Types of seed coating machines – Photo courtesy: researchgate

Different types of seed coating machines have now been introduced in the market and each of them offers innovative solutions to enhance seed performance and optimize crop yields. They operate on different principles and cater to specific applications. The following table introduces you to the four different kinds of seed coating machines and provides you a comprehensive overview of Drum Coaters, Batch Mixers, Fluidized Bed Coaters, and Pelleting Machines.

| Type of Seed Coating Machine | How it works? | Application | Key Features |

| Drum Coaters | It operates with a rotating drum to apply coatings to seeds. | It is suitable for larger seeds | Simple

Efficient Cost-effective Uniform coating |

| Batch Mixers | It blends precise mixtures for customized seed coatings. | It is ideal for creating tailored coatings for various seed types. | Flexible

Precise Versatile Handles various materials |

| Fluidized Bed Coaters | It suspends seeds in a fluidized coating material for uniform application. | It is ideal for smaller seeds that require a consistent and uniform coating. | High coating uniformity

Precise control Adaptability to different seed sizes |

| Pelleting Machines | It molds seeds into larger, coated forms for enhanced handling | It is used for small or irregularly shaped seeds | Enhanced seed visibility during planting

Improved seed flow |

6. What are the industrial applications of a seed coating machine?

Seed coating machines have widespread applications in many industries.

Agriculture Industry:

Different type of seeds – Photo courtesy: Instacart

One of the most important applications is enhancing seed performance. Crops in different region have varying requirements and seed coating machines make it possible to tailor coatings to the seeds’ requirements based on specific crop needs and environmental factors.

Various types of seeds

Pharmaceutical Industry:

Coated tablets

Seed coating machines can also be used in the pharmaceutical sector for coating tablets with a thin film of polymer or other materials. This coating helps in masking the taste of the drug, improving stability, and facilitating controlled release.

Nutraceutical Industry:

Nutritional supplements

In the nutraceutical industry, seed coating machines can play an important role in applying a protective and often aesthetic film on various nutritional supplements and health products. This helps in preserving the integrity of active ingredients and enhancing the overall appeal of the products.

Cosmetic Industry:

Polished compact powders

Seed coating machines are applied in the cosmetic industry to enhance the appearance of cosmetic products. They can be used to create a thin, uniform film on the surface of cosmetics, providing a polished and attractive finish.

7. How to maintain seed coating machines?

Cleaning

Automatic Washing – Photo courtesy: glatt

There is a cleaning system at the base of the drum, featuring an automated drain controlled by a computer after the cleaning process. There is also strategic placement of multiple nozzles for online machine cleaning, ensuring efficient cleaning of various machine components. With PLC control, the seed coating machines can be programmed for multiple cleaning procedures and enable fully automatic washing and drying processes, including the controlled drying of residual water from each nozzle using compressed air.

Air Handling System

Ensure that the air handling system, encompassing both the exhaust and inlet, is kept clean and unobstructed. Effective airflow is essential for the drying process during finishing.

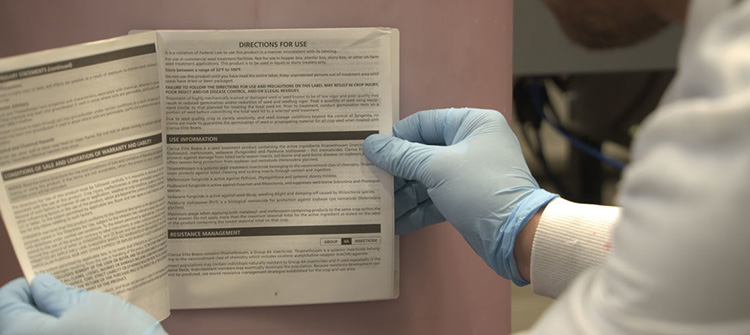

Safety Inspections

Safety Manual – Photo courtesy: syngentaseedcare

Regularly perform safety inspections to verify the machine's compliance with safety regulations. Confirm the presence and functionality of all safety guards to uphold a secure working environment.

Replace Wear Parts

Replacing parts – Photo courtesy: syntegon

You should keep an inventory of wear parts such as gaskets, seals, and bearings. It should be a normal practice to replace these components at normal intervals to prevent unexpected failures.

Recalibration

Seed coating machine recalibration – Photo courtesy: syngentaseedcare

Before shutting down after use, you must adjust the pressure to a no-pressure state, turn off the heating system, maintain the conveyor belt, and then set delayed cooling or automatic shutdown.

Recalibration stands as a critical maintenance practice for seed coating machines, ensuring precision and consistency in the application of coatings to seeds. For this, operator must have accurate knowledge of the machine’s electric control to do fine-tuning of the machine to meet the desired specifications.

Operator Training:

Training – Photo courtesy: syntegon

Provide training for operators on correct equipment procedures and maintenance practices. Ensure a clear understanding of the equipment's limitations and emphasize the importance of regular maintenance and safety protocols.

Record Keeping:

Keep comprehensive records of maintenance activities, encompassing cleaning, inspections, and repairs. These records play a crucial role in monitoring the machine's efficiency and facilitating organized maintenance.

Preventive Maintenance Schedule:

Preventive maintenance – Photo courtesy: syntegon

Establish a preventive maintenance schedule that outlines routine tasks and their frequency. This schedule serves to ensure that maintenance is consistently and promptly conducted, contributing to the optimal functioning of the equipment.

8. What are the industry standards for a seed coating machine?

Seed coating machines must undergo rigorous testing and evaluation to ensure that it meets predefined criteria for performance, safety, and environmental impact. Specific certifications are required for seed coating machines depending on the region you are located in. These certifications serve as evidence that the seed coating machine is compliant with industry standards and regulatory requirements.

ISO 9001 Framework- Photo courtesy: smartsheet

One of the required certifications is the ISO 9001. This certification demonstrates the quality management systems of the manufacturer. It assures you that the seed coating machine has undergone strict quality control measures in its design, production, and service. The certification process involves a comprehensive audit encompassing everything from the initial design stages to the production processes and ongoing service and support. Having ISO 9001 certification means that the manufacturer has systematic processes in place to guarantee that the machine is conceptualized with precision and efficiency in mind.

Additionally, certifications related to environmental impact and safety, such as ISO 14001 and OHSAS 18001, are also relevant. These certifications demonstrate a commitment to sustainable and safe manufacturing processes. Regulatory bodies in different countries may impose specific certifications or compliance measures for agricultural machinery.

9. What are some common issues with seed coating machines, and how can they be addressed?

You might face a challenge or two while dealing with seed coating machines. Seed coating machines have advanced technology but are not immune to issues. If you are able to recognize and address common issues that may occur while using a seed coating machine, you will be able to run them seamlessly for a long period of time.

| Sr # | Problem | Root Cause | Troubleshooting |

| 1 | Uneven coating application | It roots from incorrect calibration of the seed coating machine and inconsistent coating material | you can develop regular calibration checks and careful process for coating formulation preparation. |

| 2 | Blockage in the delivery system | It roots from not cleaning the machine regularly | This issue can be solved by regular cleaning and inspection of the machine. |

| 3 | Damaged Seeds | This happens when the seed coating machine is not suited to the type of seed that needs to be coated. | It is imperative to select the right machine for your seeds and the coatings that you require in order to avoid damage to the seeds. |

All the above-mentioned challenges can be addressed by timely and proactive troubleshooting. You should stay informed about updates and best practices and regularly consult the user manual of the seed coating machine. Staying in touch with the manufacturer’s customer support is also an effective strategy to resolve any issue that your machine might experience. You can maximize the efficiency of your seed coating machines, ultimately cultivating a more fruitful and robust agricultural landscape.

10. What are the future prospects of seed coating machines?

Coated Pumpkin Seeds

Seed coating machines have very promising future prospects with the trends and developments suggesting a positive trajectory for this industry. Seed coating machine play a crucial part in ensuring successful germination and optimal crop yield. Therefore, the research and development endeavors to enhance existing machinery is inevitable.

Technological Advancements

Seed Research

With artificial intelligence and data analytics on the rise, these technologies will be incorporated will be incorporated in seed coating machines in the near future. This integration will enhance the efficiency and precisions of seed coating machines, allowing you to customize seed coatings even more accurately.

Sustainable Coating Solutions

Biodegradable seed coating- Photo courtesy: borregaard

There is a growing emphasis on the development of eco-friendly and biodegradable coating materials. It is likely that the seed coating machines will be equipped with sustainable solutions in the future, reducing impact on the environment.

Highly Customized Coatings

Coated soybean seeds- Photo courtesy: seedpoly

Different crops have unique needs according to local conditions. Seed coating machines in the future will allow you to highly customize coatings according to your requirements. They will be highly flexible in terms of coating formulations.

Collaboration with Biotechnology

Biotechnology experiment on seeds

There has been quite an advancement in biotechnology. In the future, it is likely that a collaboration between biotechnology and seed coating will lead to innovative solutions. You might witness integration of genetic traits directly into seed coatings. This could lead to enhanced resistance to pests and diseases.

Integration with Precision Agriculture

Precision agriculture – Photo Courtesy: usda.gov

In the future, it is anticipated that you will be able to optimize seed coating based on real-time data, such as soil conditions, weather patterns, and crop health. Seed coating machines will be integrated with precision farming more seamlessly.

Conclusion

We hope that seed coating machine the complete buying guide in 2023 has been helpful for you. This article strives to help you choose the best seed coating machine for your needs. Do you know by now which seed coating machine is right for you? If yes, contact Allpack today to get your hands on the most advanced seed cutting machine of your choice! If you are still deciding and are not sure which machine will suit your needs best, do not worry. Contact Allpack’s customer support today for more guidance. We will help you make an informed decision about which seed coating machine suits your operation perfectly.

Seed Coating Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586