The Ultimate Buyer’s Guide to Choosing a Cartoner Machine for Small Bottles

In the competitive world of pharmaceutical, cosmetic, and nutraceutical manufacturing, the secondary packaging stage is often where the most significant bottlenecks occur. If you are handling small bottles—such as 5ml essential oils, 10ml liquid supplements, or 30ml high-end serums—choosing the right cartoning machine is a critical decision that impacts your ROI, brand image, and operational scalability.

This comprehensive guide will go beyond the basics. We will dive into the technical nuances of small-bottle cartoning, provide a strategic comparison of technologies, and share a real-world success story involving a global cosmetics giant.

1.Why Small Bottles Require a Specialized Cartoning Approach?

Standard cartoning machines are designed for generic boxes. However, small bottles present three specific engineering challenges that general-purpose machines often fail to address:

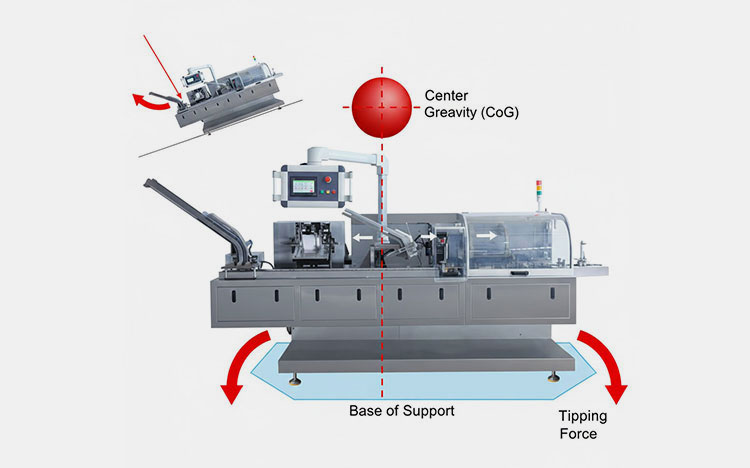

The "Tipping" Factor (Center of Gravity)

Small bottles are typically narrow and light. During high-speed conveyor transfers, the slight vibration or a sudden stop can cause them to tip over. Once a bottle is down, the entire line stops.

Expert Insight: Your cartoner must feature a synchronized star-wheel or screw-feeder that grips the bottle securely until it is safely placed into the carton or the bucket.

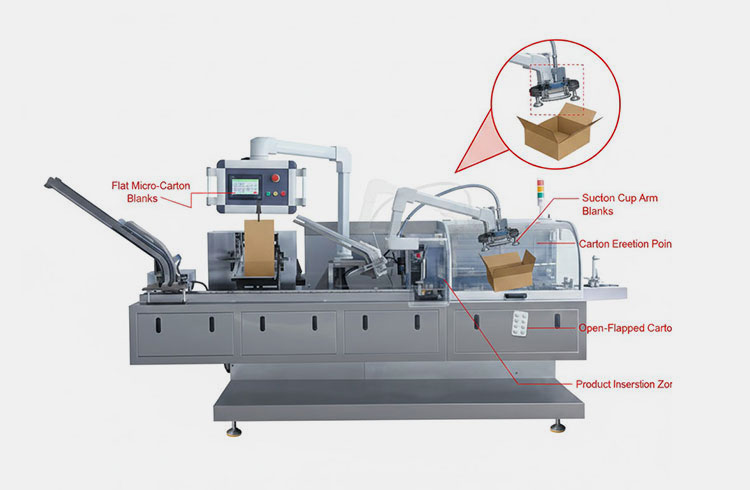

Micro-Carton Picking

When bottles are small, the cartons are also small and light. Standard vacuum suckers sometimes struggle to "open" these tiny boxes reliably without tearing the paper or double-feeding.

Expert Insight: Look for a machine with a rotary vacuum pickup system that uses mechanical force to pre-break the carton folds before insertion.

Low-Tolerance Insertion

In a 20mm x 20mm box, there is zero room for error. If the pusher is off by even 1mm, the bottle hits the edge of the carton, causing a "jam."

Expert Insight: Intermittent motion is usually superior to continuous motion for small bottles because it provides a stable "pause" for the pusher to enter the box with 100% precision.

2.Technical Comparison: Finding Your Perfect Match

To help you decide, we have compared the three most common configurations for small bottle packaging.

Comparison Table: Cartoner Technologies for Small Bottles

| Feature | Semi-Automatic Cartoner | Intermittent (APK100B) | Continuous Motion |

| Speed (BPM) | 20 - 40 | 30 - 100 | 120 - 300+ |

| Changeover Time | 10 mins | 15 - 25 mins | 60 - 120 mins |

| Bottle Stability | Manual loading | High (Mechanical Grip) | High (Vacuum) |

| Ideal For | Lab / Small Batches | SMEs / High-End Brands | Mass Market Pharma |

| Investment (ROI) | Low | Medium (Fast ROI) | High |

3.Case Study: Empowering a Brazilian Manufacturer to Secure a L’Oréal Contract

At AIPAK, we believe the best recommendation comes from understanding the client’s "End Goal."

The Challenge

In April 2025, we were approached by a manufacturer in Brazil.

Brazil customer factory

They were bidding for a contract with L’Oréal, the world’s leading beauty brand.

The requirements were brutal:

Perfect box integrity (no scratches, no visible glue).

Consistent 24/7 production stability.

Full traceability and GMP compliance.

The Consultative Solution

Many suppliers simply offered their cheapest machine. We took a different path. We requested:

Physical samples of the Brazilian-sourced paperboard (to test suction reliability).

Detailed dimensions of the 15ml glass bottles.

The viscosity of the serum (to account for potential leaks).

We recommended the WZH120 Intermittent Cartoning Machine. But we didn't stop there. We advised the client to integrate a high-precision domestic glue spray system instead of a traditional tuck-in flap. Why? Because L’Oréal’s premium branding required a tamper-evident, rigid seal that only hot-melt glue could provide.

AIPAK WZH120 cartoning machine in Brazil customer site

The Result

The machine was installed and calibrated via remote video support. The first batch of samples was sent to L’Oréal’s quality team. The result? Approved on the first try.

Thanks to the stability of the WZH120, the client secured the contract. Within months, they hit their capacity limit and ordered three more WZH120 units, effectively building a dedicated "L’Oréal line." They have already confirmed a new expansion plan for early next year.

4.Advanced Features Your Pharma Cartoner Must Have

If you are aiming for the "Premier League" of manufacturing, ensure your machine includes these modules:

Leaflet Folding & Insertion

Don't buy a separate machine for manuals. Our automatic cartoning machine integrates an automatic leaflet folder that can handle 1 to 4 folds, inserting the manual simultaneously with the bottle.

Vision Inspection Systems

A single empty box can ruin your reputation. High-end cartoners should be equipped with sensors to detect:

Missing bottle.

Missing leaflet.

Incomplete carton flap.

Wrong batch code (OCR).

III. 21 CFR Part 11 Compliance

For pharmaceutical exports to the USA or Europe, your machine’s HMI (Human Machine Interface) must have audit trails and multi-level password protection to ensure data integrity.

5.Maintenance: How to Ensure Your Machine Lasts 10+ Years

A cartoner is a long-term asset. Based on a decade of servicing clients in South America, here is our recommended maintenance schedule:

Daily: Clean the vacuum suckers. Paper dust is the #1 cause of picking failures.

Weekly: Lubricate the main drive chains and check the tension of the carton transport belts.

Monthly: Inspect the glue nozzles (if applicable) and recalibrate the bottle-pushing sensors.

Annually: Replace all wear parts (suction cups, pusher tips) to prevent unplanned downtime.

6.Frequently Asked Questions (FAQ)

Q1: Can I use the same machine for different bottle sizes?

Yes. Our WZH120 is designed for versatility. A full changeover usually requires replacing the "bottle pockets" and adjusting the carton guides, which takes about 20-30 minutes.

Q2: Do you provide IQ/OQ/PQ documentation?

Absolutely. For our pharmaceutical clients, we provide a full set of validation documents to ensure your factory passes GMP and FDA inspections.

Q3: Why choose a supplier from China for South American markets?

AIPAK has a proven track record in Brazil, Chile, and Argentina. We understand the voltage requirements (220V/60Hz), the import regulations, and we provide technical support in a way that bridges the time zone gap effectively.

Conclusion:

Choosing a cartoner machine is about more than just moving boxes; it’s about moving your business forward. As the success of our Brazilian partner shows, the right equipment can open doors to global giants like L’Oréal. At AIPAK, we don't just sell machines—we build the foundations for your expansion. With our high-quality products and dedicated after-sales support, we are confident in moving forward hand-in-hand with our clients.

Don't forget to share this post!

Buyer's Guide for Small Bottle Cartoning Machines

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours