3 Points To Guide You Understand The Stick Packing Machine

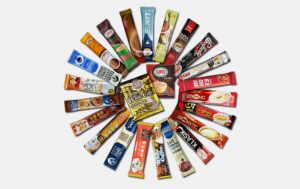

Do you know how to make the outer packing of coffee powder, milk powder and flavoring powder in our daily life?

It was the stick packing machine that successfully created these things.

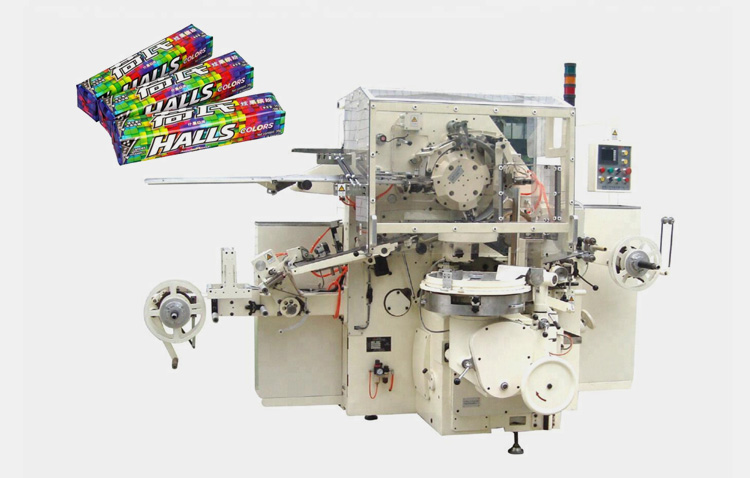

You should know that the stick packing machine is a new type of packing machine under the powder packing machine, which is a new machine for packing and sealing powder products.

Such as coffee, milk powder, chocolate powder, flavoring powder, medicine, granulated sugar, desiccant, etc.

What are the characteristics of such a wonderful machine? It's worth finding out more about it.

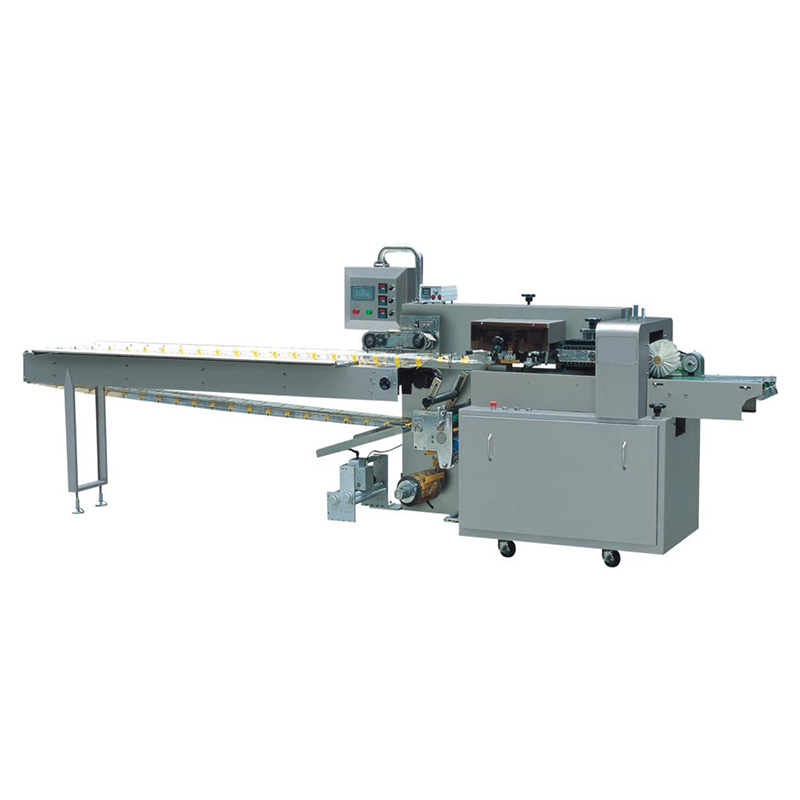

First, the stick packing machine is a device that integrates machinery, electricity, light, and instruments.

It is mainly controlled by a single chip computer and has features such as automatic quantization, automatic padding, and automatic adjustment of measurement errors.

First of all, the stick packing machine is a device integrating machine, electricity, light and instrument.

It is mainly controlled by a single chip computer and has the functions of automatic quantitative, automatic filling, automatic adjustment of measurement error, etc.

Second, the stick packing machine is fast: it adopts spiral blanking and light control technology.

Third, the stick packing machine has high precision: it adopts stepping motor and electronic weighing technology.

Fourth, the packaging range of the stick packing machine is wide: the same quantitative stick packing machine can adjust and replace the blanking screw of different specifications through the electronic scale keyboard within 5-5000g.

Fifth, the stick packing machine is widely used: it is suitable for powder and granular materials with certain fluidity.

At the same time, it is also suitable for quantitative packaging of powder in bags, cans, bottles and other packaging containers.

Sixthly, the stick packing machine can track and correct the errors caused by the change of material proportion and material level from the east.

Seventh, the stick packing machine is mainly controlled by the photoelectric switch, only manual bagging is required, and the bag opening is clean and easy to seal.

Eighth, the parts in contact with materials are made of stainless steel, which is not only easy to clean, but also can effectively prevent cross contamination.

Ninthly, the machine is equipped with a feeding apparatus, which makes it more convenient for you to use the stick packing machine.

If you want to have a comprehensive understanding of the stick packing machine, your first task is to understand every important component of the stick packing machine.

What are the main components of this machine? You can see the following:

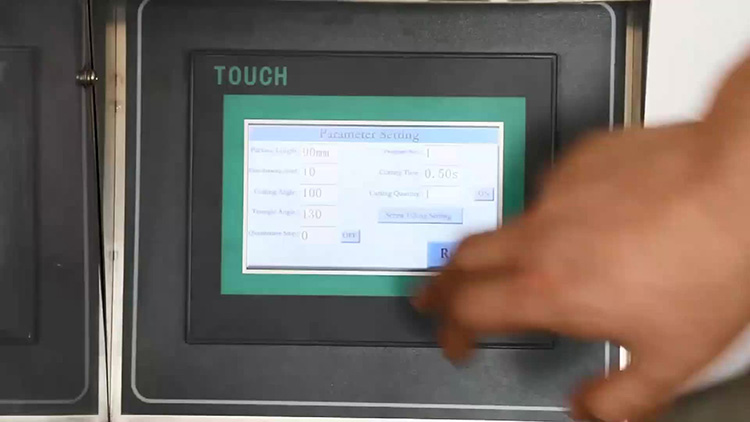

The stick packing machine is controlled by an electronic display touch screen and PLC control system, which is stable in operation.

Manual touch adjustment is used to set packaging parameters, which is simple in operation. At the same time, it is equipped with a ribbon printer.

An independent temperature control system controls the ribbon for tracking printing. The printing speed is high, the printing area is wide, the type setting is flexible, and the encoding is accurate and error-free.

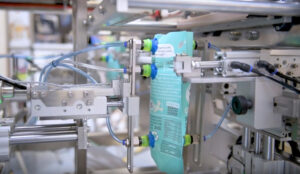

The servo motor of the stick packing machine controls the linkage film reel shaft to coordinate the die drawing link for die drawing operation, which can accommodate more film rolling materials, making the film rolling smoother and effectively preventing film rolling bias.

Round buckets are used to hold liquid materials. The bucket is also equipped with a heating device that can pack materials in different climates.

The stick packing machine adopts a high-precision cursor electric eye, which can accurately track the roll film color block, accurately locate, and effectively prevent roll film deviation.

At the same time, the stick packing machine also has a single degree configuration barrel heating controller, which can adjust the heating temperature through manual touch, and the operation is simple and efficient.

The stick packing machine adopts elephant trunk customized metal bag maker, you can better shape the roll film through customized cup shaped bag formers, which can make the packaging molding more convenient.

At the same time, the independent PLD temperature system in stick packing machine can seal the two sides of the cutter bed for free heating, which can better seal the back of the packaged products and ensure the sealing of the products.

The end seal cutting area of the stick packing machine uses a thermostated heat sealer to seal the upper and lower ends of the packing product to avoid curling or leaking in the sealing position.

At the same time, the finished product delivery panel is configured to reduce manual operations in the packing process and improve packing efficiency.

You know, no matter what kind of machine it is, there's going to be a set of problems in the long-term operation. Finding and fixing problems is very important, but so is the day-to-day maintenance of a stick packing machine.

First, you need to check the parts of the stick packing machine regularly to see if the machine can be rotated flexibly and if the stick packing machine is worn. Once defects are identified, they should be fixed in a timely manner.

Second, when a stick packing machine has been out of service for a long time, it is necessary to clean and wipe the entire body of the machine, to coat the smooth surface of the machine with anti-rust oil, and to cover it with a cloth tent.

Third, you should pay attention to the moistureproof and anti-corrosion work of the stick packing machine electrical parts.

The electric control cabinet and terminal block shall be kept clean to prevent electrical failure.

Fourth, when the stick packing machine is out of service, you should wash the residual liquid in the pipe with clean water in time, and wipe the stick packing machine clean in time to keep it dry and tidy.

In a word, the maintenance and repair of stick packing machine is very important for the production and even development of enterprises.

Regular maintenance and repair of stick packing machines and equipment can greatly reduce the rate of equipment failure, so we need to pay attention to it.

Don't forget to share this post!

Stick Packing Machine Related Posts

Stick Packing Machine Related Products

Stick Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine