15 Questions To Answer Before Requesting A Packaging Machine

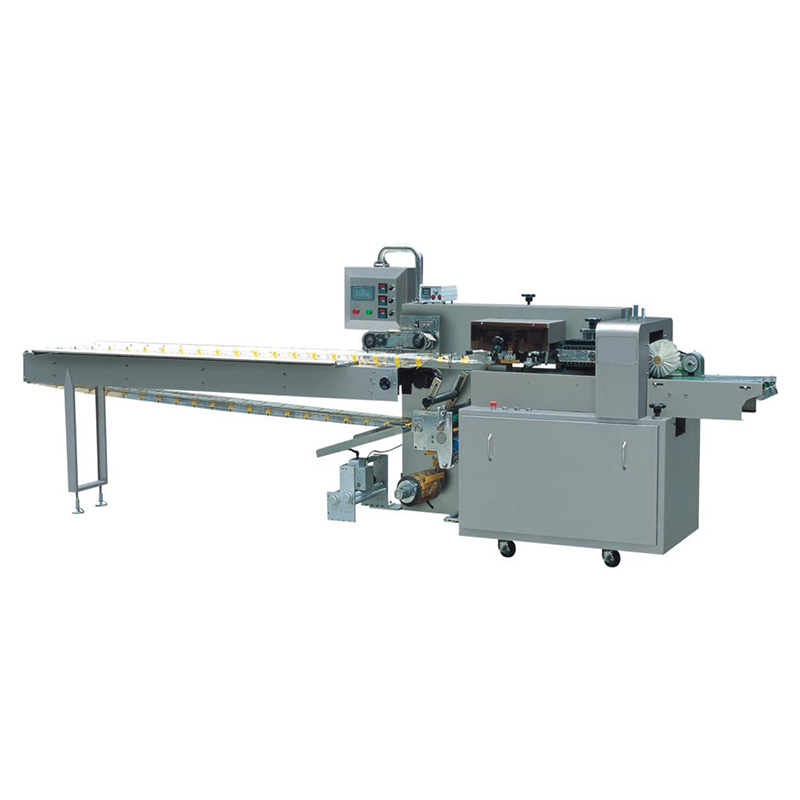

A packaging machine is a quintessential tool for the versatile and safe packaging of products. Thinking about your chosen packaging format is a major determining factor that will keep you on the right path. You will find several leading companies offering the same machines may seem staggering. You need to be prepared to make the right decision when analyzing a cluster of technologies, prices, and quality.

If you’re beginning your journey as a buyer, you need to determine 15 Questions to Answer Before Requesting a Packaging Machine. To help you get started, we have enlisted common questions and useful tips best for procured equipment and business goals.

1.What are you packaging?

Since there are many advanced packaging methodologies, packaging equipment, and materials, it is beneficial to have a thorough assessment of how it can improve upon or potentially embiggened.

If you’re embarking on a new product or new line, it is recommended to work with the manufacturing team and inform them what product you want to pack, e.g., tea, powders, granules, semi-solids, or customized products. In response, a team can offer valuable guidance, expertise, and complete buying guidelines that can help your requirements for both now and in the future.

This acquires a comprehensive linkage of communication between technicians, marketing, purchasing, engineering, and suppliers. This step is of prime importance as you’re able to take look at various options that are the best fit for the accomplishment of the production line.

2.Do you have any packaging speed requirements?

Packaging machine speed indicates how many finished bags can be formed by the machine in a certain period of time. Speed is usually mentioned in bags per minute. This number gives you an exact number of finished bags completed by a machine/per minute.

Machine optimum speed solely depends on the product, type, and size of bags and of course the degree of automation you have ordered or requested. If the machine is operated with moderate to high human interference skills of an operator is also one of the factors that need to be considered in evaluating machine speed.

Before purchasing the equipment, you should consider your requirements thoroughly. It is better to take into account 5 years in advance. For small businesses or lab scale purposes buying fully automatic equipment will prove to be a costly deal in terms of money and underutilization.

3.What is your product’s specification?

An automatic packaging machine must be designed according to your product’s specifications. Before recommendation, you must acknowledge your manufacturer about the following points:

Solids:What are the average dimensions? What is the consistency of your product e.g sticky, fresh or frozen?

Liquid:Is your product viscous or dense?

Powders:What is the bulk density of your product? Is your product free-flowing or non-free-flowing?

Filling temperature: What should be the filling temperature during the procedure?

4.What bag specifications do you require?

Your business requires a packaging machine that must comply with the exact specifications of your bag. You should know the exact properties such as size, style, weight, and format before deciding on the packaging machine quotation. Because each packaging machine is associated with pre-defined parameters hence you will be asked to inform the manufacturer about relevant information.

Mentioned below are some queries that might be asked by the manufacturer before recommending the best fit machine to you:

Package Dimensions

For flat bags, height and breadth are necessary factors. Similarly, gusseted or stand-up bags are required with width, height, and depth.

Package Weights Or Volumes

For powders, bulk, and solid products, how heavy must be your packed filling? similarly, for liquid, you must assess the filling volume of packaging.

Legal Requirements

Has your country stated certain packaging specifications? For instance, pharmaceutical and cannabis production lines are confined to child-resistant closures.

5.What packaging machine have you experienced previously?

Introducing new packaging machinery is ideal for the entire production set up include safety, speed, maintenance, cleaning, QA, and management as it scales up the production growth with little to no supplementary training. Plus, you must share your previous experiences with used machinery and seek modern equipment features that can possibly improve your working network.

In certain conditions when the machine is entirely unknown to you or your staff, it is perfect to seek suppliers in your surroundings to share their valuable thoughts with relevant equipment. Because people are usually glad to discuss with a manufacturing company is doing a great job or which is giving poor customer satisfaction.

6.What are your packaging goals?

Knowing your packaging goals and how to implement modern packaging aspects must be determined before sending a quotation to a vendor.

Is your goal to improve productivity? Do you want to introduce an entirely unique packaging element?

Advancement in packaging technologies is growing more and more than ever before, but always remember that your entire packaging dreams cannot be fulfilled by a single machine. If yes- then you can be sure that there will be long list of setbacks in the term of set-ups time as well as changeover that will definitely cost, you in the term of time and skilled personnel. Furthermore, you must know; the packaging sizes, speed output, and packaging type that the machine needs to handle.

7.What is your available space?

You need to have a knowledge of what you can adjust in your facility. You might find a premium machine great for your product’s packaging- but then find out it’s too huge to fit in actual available space.

Furthermore, you can’t ignore employees’ movement around and optimal space to have for easy working. Can you open the panel easily for maintenance? or is there a walking passage next to it?

8.Are you using pre-made pouches or Roll stock films?

The most important objective behind purchasing any packaging machine is to determine whether the company or machine specializes in manufacturing or transforming packaging film or bags. A flexible packaging machine can produce bags either utilizing a plastic film or roll stock or it can fill and seal products in pre-made pouches.

Do you know the basic difference between these two formats?

Rollstock Film

Rollstock is not mainly made from plastic, when you wrap a gift with paper it comes on a roll. But in the packaging industry, customers mainly prefer plastic roll stock film for long-term packaging purposes. For example, dairy products, meat packaging, and pharmaceutical items are wrapped up finely where a clear film protects their items against contamination. A packaging machine creates various bagging styles up to your choice. In a nutshell, a roll stock film is not only an economical choice but can proceed with operation at a higher speed.

Premade Bags

These bags are prefabricated that allowing the operator to simply load a stack of pre-made bags into the machine and let it perform the rest of the job. The automatic packaging machine opens a single pouch, fills it with the product, and hermetically seals the top of the pouch. All of these actions are performed in one machine.

This process generally increases productivity up to a high level. This machine has capabilities to treat hundreds to thousands of bags per hour at a very high speed that requires only a single technician to load pouches.

9.What are the packaging types of your production line?

There are many bag styles that can be formed using a flexible packaging machine. Discussed below is a short summary of frequently used types:

Pillow Bags

A pillow bag is the most popular packaging format used in pharmaceutical, foods, and healthcare setups. This type of packaging is comprised of two flat sealed panels on the top and bottom given with a vertical seal down at the back. You must have noticed such packaging while eating chips or an opening pack of biscuits.

DoyPack Bags

They are also known as sand pouches formatted with an oval-shaped base. These premium quality bags are becoming now popular choices, especially for food packaging.

Quad Seal Bags

Quad seal bags have two sides gussets with differentiating features from which they are derived with their name. This is formatted with the gussets and two panels that are merged by four vertical seals. So, the bag can stand unassisted due to a firm rectangular bottom.

Flat Bottom Bags

They are similar to quad seal bags that features two gussets with a single vertical seal instead four. Have you ever noticed a coffee or tea bag? Such packaging format is known as a flat bottom style.

Gusseted Bags

Gusseted bags are an extra internal space that makes bags roomier. This enables a popular choice of packaging among restaurants, supermarkets, bakeries, and other businesses.

Three Side Seal Bags

This is a flat pouch sealed over three sides. They are commonly used for a single serving, or for one-time use such as instant soup, nutritional supplements, etc. They can be included with pre-applied zippers that can be expanded into a pouch to ensure a multi-usage.

Sachets Package

Sachet packaging is a popular option for various products such as cookies to cosmetics. They are made by sealing flexible barrier films around four sides to protect the ingredients against light, moisture, and oxygen.

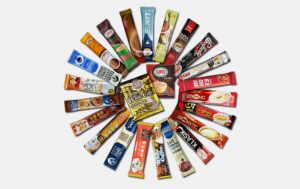

Stick Packs

A stick pack pouches are typically flexibly and characterized by a small-sized narrow shape pouch. They are used to pack dry, semi-solid, and liquid content.

Stick pack is the most supportable packaging and economical single-serve format.

10.What additional/integrated assemblies does it support?

Some packaging might need equipment integration and installation to get the exact production line you’re looking for. You must have proper knowledge of what machinery and where setup is required. Some machine works efficiently when assembling with additional equipment, so you must be taken this into account when deciding for enhancing the packaging line.

Also, consider when you require the machinery to be functional and what is the leading time you must be anticipated? If the vendor offers you available options to improve the machinery, know what they are and will it be capable to upgrade it if your needs change.

11.How does a machine support ergonomic outcomes?

If you want to protect the front-line workers against unwanted mishaps and boost productivity, then the equipment’s ergonomic support must be important to you to consider. Safety is crucial when you’re seeking a new packaging machine.

- A good scale-up in machinery is creating a safe zone, so each component of the machine would be in a safe state and the machine can run a continual normal operation. A safe zone will maximize your up-time and limit scrap.

- Examine a lock-out process so it would be cleared when a machine is facing trouble and at being normal process.

- The machine must be compliant with Arc-Flash- A newer OSHA regulation (Occupational Safety and Health Administration).

- A report of Convergence Training suggests that all electrical wiring and operator training must be in accordance with regulations.

- Prefer a see-through panel interface outside of the electrical cabinet so when making any change to the program will help you to monitor visually the working of entire inputs and outputs. You can discuss such modification prior to delivery and installation of new machinery. So be sure to speak supplier in advance.

12.How fast can the machine run VS your bandwidth?

You must take into account that you’re not only focusing on the number of products but planning to exceed them. The more you can produce in s shorter time, the bigger you can get contract opportunities. So, you don’t need to forget about managing the growth. Will your production line and the team would be capable enough to sustain business demands and control over-load?

Be absolutely strategic when planning to maximize the volume. When choosing packaging equipment, you must have proper knowledge of how fast it can turn around the packaged product and future growth. Be sure to have an understanding of particular features that will help you to yield the maximum volume.

13.What are the special features packaging machine offers?

You can ask about each and every feature that will improve the machine’s value to you as a manufacturer. For instance, you can analyze the metrics or business intellect information that packaging machines provide via the Internet of Things (IoT), or a machine-to-machine (M2M) networking

.

Knowing fully about the machine’s specifications regarding packaging is crucial to specify the appropriate machine and to get an accurate packaging quote. You must consider the packaging parameters as each machine has pre-defined limitations and possibilities.

14.What’s the packaging machine interface like?

The visual display zone such as Human Machine Interface (HMI) is the heart of the packaging machine that demonstrates the whole processing to human operators. You must ascertain the facts that how easy it will be training the people and what sort of functionality will it supports.

With advanced HMI hardware interventions, today’s industrial touchscreens must give you the standard features. However, this feature should offer you enough options to support a huge range of applications.

15.How long might you expect continual production to last without maintenance?

How long your machine will capable enough to give you a quality operation time. Be sure your vendor offers you an understanding of each component assembled in the machine.

Generally, packaging machines have an unlimited number o moving parts and a robust design that can control producing of unwanted vibration with time.

The vibration creates problems like stress, bearing issues, loosening wires, and increased parts replacements expenditure.

Hence, this is necessary to know all major maintenance factors. Ask about other points like wash-out time and rigorous cleansing. Do your best homework; ask to seek reliable professionals and discuss their past experiences regarding equipment and suppliers.

CONCLUSION

Buying a packaging machine is a major investment. Apart from 15 Questions to Answer Before Requesting a Packaging Machine, there are various sensitive dynamics in choosing packaging machinery for your company. For instance, safety, budget, good vendor, physical layout, materials, and much more can make your head spin.

Aipak is not just another ordinary packaging machine manufacturing company from China, they are dedicated to creating No-Risk equipment and Professional One- Stop-Solution. Each of their packaging machines fully complies with CE certification. From pre-sale to post-sale, you will be welcomed by a high-tech expert engineering team to help 24/7/365.

Don't forget to share this post!

Stick Packing Machine Related Posts

Stick Packing Machine Related Products

Stick Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine