What Is Working Principle And Technology Of Tablet Press Machine?

Think about what you obtain when you get sick and don't want to be hospitalized?

Yes, you'll get a lot of tablets, capsules and granules prescribed by the doctor.

There is no doubt that tablets are the most common drugs in your daily life. Do you know why? Because they are easy to take and carry.

So, do you know how tablets are made? Or how a small tablet generates so much energy?

This is actually related to particles and powders. Why did you said that?

Because the tablet press presses the granules or powder materials placed in the mold holes into tablets through its punch.

Do not underestimate this small tablet press machine. You should know that it is an indispensable pharmaceutical equipment in the pharmaceutical process of Chinese and Western medicines.

After listening so much, are you really eager to have a deep understanding of the tablet press machine?

First of all, the first point is undoubtedly to understand his working principle, Otherwise, when there is a problem in the operation of the tablet press, you can't even figure out what the problem is

As mentioned at the beginning, the punch dies of the tablet press machine pressed those powders and particles into tablets.

The punching dies, just as its name implies, it is a mould in tablet press machine to compress the tablet.

It is easy to understand that when you squeeze an object, the upper and lower sides of the mold are the surface of the object, and the size of the mold you choose becomes the size of the object.

The working surface of the upper and lower punching dies is the final shape of the tablet surface, and the size of the middle hole is the diameter of the tablet.

This is why the pills you take every day have different sizes, patterns, symbols or numbers.

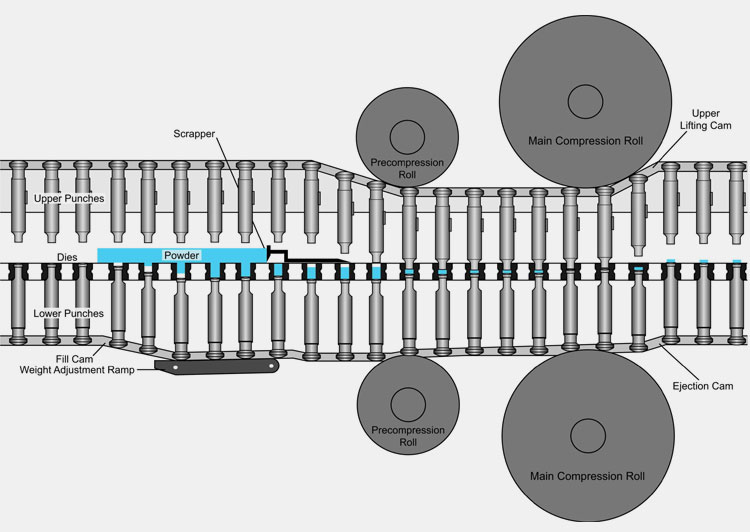

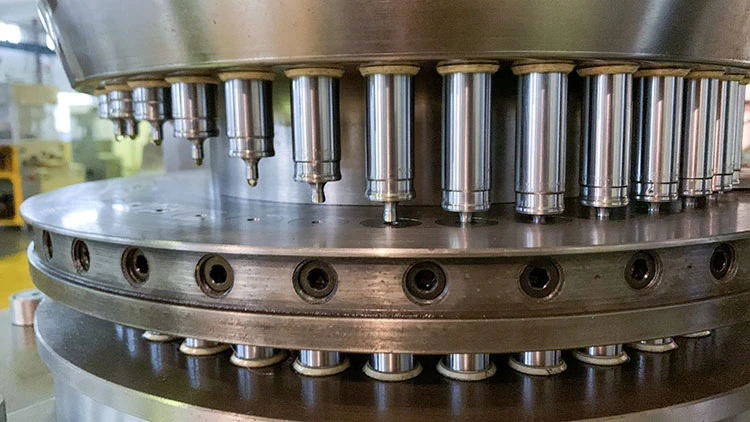

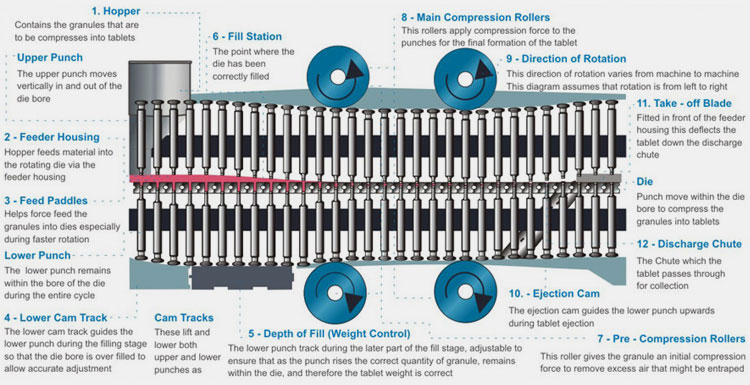

Three parts constitute a pair of punching dies of the tablet press. That is, the upper punching die, the middle punching die and the lower punching die.

Among the three dies, the upper and lower dies are similar in structure and the punch diameters are the same.

Among the three dies, the upper and lower dies are similar in structure and the punch diameters are the same.

In the tablet press, the diameters of the upper and lower punches are consistent with the holes of the middle die, and they can slide up and down in the holes of the middle die without restrictions.

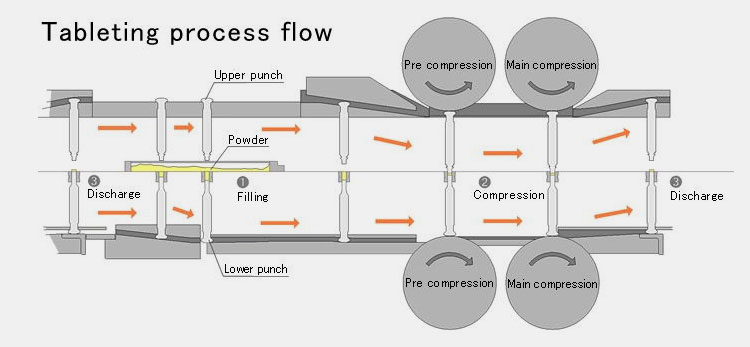

After knowing the main component of the tablet press machine, it obvious that many working processes of the tablet press machine are carried out around the punching dies.

So how many steps can be divided into? You can use the following as a reference:

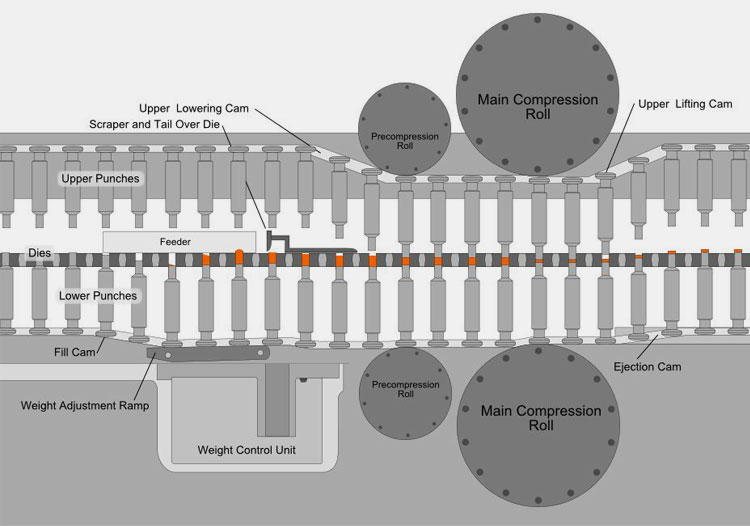

First, the head of the lower punch in a tablet press machine (its working position should be upward) stretches into the middle die hole through the lower end of the middle die hole.

Second, you need to make use of the feeder to fill some drugs into the middle die hole.

Third, the head of the upper punch(its working position should be downward) falls into the middle die hole through the top of the middle die hole and goes down for a certain distance, compressing the powder into tablets.

Fourth, the upper punch ups and lifts out the hole. The lower punch rises and pushes the tablet out of the middle die hole. Since then, the first tablet pressing of the tablet press machine has been successfully completed.

Fifth, the lower punch drops to the original position and prepares the next drugs filling.

After you have sorted out the workflow of the tablet press, there is another problem that you can't despise.

Can someone tell me the answer? Yes, it is the production principle of the tablet press.

As you know, in the course of daily medication, the tablets with different effects are not only different in size, but also different in thickness.

Therefore, understanding the production principle of the tablet press machine, in-depth learning and mastering more tablet pressing details are essential for producing a batch of high-quality tablets

How to adjust the dosage of tablets? The key is to select different dies with different punch diameters.

After you select the size of the punch dies, the micro dose adjustment is to adjust the depth of the lower punch into the middle die hole.

So as to change the actual length of the middle die hole after the back sealing, so as to adjust the filling volume of the medicine in the die hole.

Therefore, the tablet press machine should have a mechanism to adjust the original position of the lower punch in the die hole to meet the dose adjustment requirements.

It is well known that the dosage of drugs is determined according to the prescription and pharmacopoeia and it can not be changed.

In order to meet the requirements of storage, preservation and disintegration time limit, the pressure of a certain dose is also required during tablet pressing, otherwise it will have an influence on the actual thickness and appearance of the tablets.

There is no doubt that the pressure regulation is very significant when the tablet press machine presses

This process is mainly achieved by adjusting the drop of the upper punch in the die hole.

Some tablet presses machine may have not only upward and downward movements but also downward and upward movements during tablet pressing.

The tablet pressing process is completed by the relative movement of upward and downward movements. However, the pressure adjustment is mostly realized by adjusting the up and down amount of the mechanism.

In the continuous progress of industrial production, what do you think is the material basis of pharmaceutical field?

Perhaps tablet presses machine and other pharmaceutical equipment will give you the answer

In the future, with the increasing demand of pharmaceutical enterprises for pharmaceutical equipment.

Pharmaceutical companies should achieve two standardization, namely standardization and systematization.

These two requirements are also applicable to the specifications, parameters and parts matching of tablet presses and other equipment.

In addition, the rapid development of multi-functional tablet presses machine also marks the continuous improvement of the R & D level of pharmaceutical equipment companies and reflects the personalized needs of customers.

Tablet press manufacturers should pay more attention to product quality, constantly enhance service awareness and brand competitiveness, and learn to constantly optimize and innovate.

Only in this way can the enterprise last for a long time.

As a consumer or operator, it is most important to learn how to understand the machine, control the machine, learn more about the machine, and then solve the problems in the daily use of the machine.

No matter how the machine is upgraded, its working principle and production process will not change too much.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine