Top 10 Machineries for Manufacturing Capsule Medicine

Have you ever wondered that a small, and glossy capsule has been passed by a series of production lines?

It is not a single machine that can perform all these actions. For instance, pulverizing, powder blending, grinding, granulating, filling, sorting, and packing a capsule.

We are presenting here information about the top 10 pharmaceutical types of machinery used in capsule medicine manufacturing.

This review gives you the basic description of each machine, its benefits, and major industrial applications. For more information about individual machines please contact us.

Table of Contents

Ⅰ.High Series Pharmaceutical Pulverizing Machine

A pulverizing machine (comminution, crush, and grind) acts as a size reduction tool. It reduces coarse material such as gypsum, coal, salts, crystals, etc., into tiny granules used for multiple applications.

The centrifugal force of the pulverizer helps in the grinding of feeding material down to the specific particle sizes.

AIPAK Pulverizing Machine

1.Working Principle

The pulverizer machine uses a static plate and a movable plate that works in the opposite direction that captures the particles in the adjustable gaps and by using compression force it breaks them down.

2.Benefits

- Universally acceptable machine for various pulverizing or grinding jobs.

- The pharmaceutical pulverizing machine is a very convenient and economical machine to use.

- Ingredient’s wastage is easily cleaned up to a certain extent to avoid non-uniformity and cross-contamination.

- A dust-free design that prevents dust formation ensures environmental and user safety.

3.Applications

The common application of pharmaceutical pulverizing machines is to reduce sizes of :

Pharmaceutical Industry: pharmaceutical pulverizer is created according to GMP norms used for crushing powders widely required in the pharmaceutical production sector.

Chemical Industry:for reducing sizes of hard material into acceptable form.

Food Industry:to grind powders in a simpler and finest substance. For instance, crushing raw wheat, rice, spices, etc.,

Wood Industry:to make forest wood and same size that fits for all purposes.

Limestone:efficiently reduces limestone material into reduced size.

Coal Crushing:Pulverizing machine is dedicatedly applied in the coal industry for crushing and pulverizing jobs.

4.Why Do You Need Pulverizer?

This is the first step for beginning any pharmaceutical formulation. The raw ingredient is available in random sizes and different flowability. Thus to make them ideal a pulverizing machine is used for crushing, grinding, and beating them to form small size particles.

5.Next Step

After pulverizing raw ingredients, you need to focus on the screening of products before it enters the system. Using the finer grades, screening of the ingredients takes place. Read on next step to know the type of machinery used for this purpose.

II.Vibro Sifter

A Vibro sifter is efficient equipment that filters, or sieves ingredients to the required particles sizes for further process steps.

A Vibro-sifter is a circulatory vibrational sifting process specially designed to offer you sorting and scoring procedures for various industrial applications.

You require a Vibro sifter when separation, scalping, and grading during the capsule manufacturing process are needed.

The Vibro-sifter is one of the acclaimed equipment that offers efficient Vibro-screening because of its unique structure and construction.

AIPAK Vibro Sifter

1.Working Principle

A Vibro sifter works by following gyratory vibrations that help in the separation of material based on particle size via screens and sieves.

2.Benefits

- A Vibro sifter is considered a superb machine due to its acute design.

- This is a high-speed device, that generates low noise too; built of high stainless steel.

- A small-structured machine with a flameproof motor.

- You can adjust the vibratory motion of the machine.

- Available in various types: single, double, and multi-layered Vibro-sifter.

- Vibro-sifter is a compact machine that gives long-span services.

3.Applications

Pharmaceutical Industry:Vibro sifter is used to segregate the mass-composition of matters belonging to different states such as solid-solid, solid-liquid and utilized for material grading as per the requirement of formulation (powders, capsules, tablets, etc).

Food Industry: sifting orsieving food items such as flour. This machine is useful in eliminating lumps widely used in the food industry in the bakery section for small as well as large batches.

Chemical Synthesis:highly applicable for the chemical plant to provide chemical products in the finest form.

Plastic Industry:used in the plastic, polymer industry to segregate chips, fine impurities, as well as dust substances present in the required product.

Agriculture & Fertilizer Industry: You need a clear crop after being harvested prior to packing. This machine is ideal for this purpose. similarly, sieving and grading of fertilizers efficiently required Vibro sifter.

4.Why Do You Need Vibro Sifter?

Certain raw materials tend to form lumps or agglomerates. For instance: sugar, salts, can interrupt the conveying system. This ultimately leads to blockage of production lines. Therefore sifting machines are used for raw material before imparting the capsule medicine production process.

5.Next Step

Particle size has a greater impact on the production of capsules. Powders are mostly granulating to improve the flow behavior and tensile strength. For this, you’ll need the granulation technique by using roller compaction or high shear mixer granulator.

III.Roll compactor/High shear mixer granulator wet granulation

A). Roll Compactor

A roller compactor is a commonly used machine of powder compaction into a solid mass called a ribbon. This process is achieved by introducing powder via a set of directly opposed and counter-rotating rollers. Roller compaction is also known as dry granulation.

Roller Compactor Machine

1.Working Principle

The Roller compactor works by powder compaction into a solid mass called ribbon. This is achieved by feeding powder over counter-rotating rollers.

2.Benefits

- More binding and smoothness without using an excessive quantity of binders.

- This process reduces the stickiness of mix to compression tooling.

- A wet granulator is ideal for treating sensitive and delicate drug content.

3.Applications

Pharmaceutical Industry:Roller compactor is applicable in the pharmaceutical industry in the manufacturing of tablets, powders filling for capsules & sachets.

Herbal Industry:Dry herbal extract are hygroscopic in nature and shows poor flow properties therefore, a compaction step is required before capsule or tableting.

4.Why Do You Need Roller Compaction

For pharmaceutical preparation, roller compaction is used for capsules, tablets, and powdered fillings. This machine evenly agglomerates powder particles (active and excipients) in a uniform granule.

5.Next Step

After roller compaction or dry granulation, you’ll need a grinding and granulating machine to achieve homogeneity of the mix, elimination of large constituents, and glued ingredients that will improve biological effects.

b) High Shear Mixer Granulator Wet Granulation

A wet granulation process is achieved by using a high-shear mixer. A high shear mixer is the most intense procedure used for wet mixing, homogenizing, and drying powdery particles.

This process is involved with the massing of dry powdery particles with the help of granulating fluid. This granulating solvent must be non-toxic and eliminated from mass after drying.

AIPAK HLSG Series High-Speed Wet Mixing Granulator

1.Working Principle

A high shear granulator agitates the powder via impellers and forms high-density granules.

2.Benefits

A wet granulator ensures more uniform and even mixing than other procedures.

A high shear mixer is an excellent machine that produces perfect homogenization of granules and ensures safe and secure products.

High shear mixer forms effective granules without the requirement of extra binding agents.

An advanced machine gives the finest output in a lesser time.

3.Applications

Pharmaceutical Industry:the high shear mixer is required in the manufacturing process of oral medicines like tablets, capsules, syrups. Besides this, the formulation of topical creams, ointments, and ophthalmic solutions also requires high-shear mixing.

Chemical Industry:the high shear mixer is high in demand for the manufacturing of paint, coatings solution, pigments, polishers for automotive and reactive products like acids, bases.

Cosmetic Industry:this tool is of high significance during the formation of topical creams, lotions, shampoos, sunscreens, lubricant, serum, nail colors, soaps, sanitizers as well as toothpaste.

Food & Beverage Industry:the high shear mixer is extensively used in the manufacturing process of protein milk, cheese, mayonnaise, soft drinks, energy drinks, etc.,

4.Why Do You Need High Shear Granulator

Wet granulation is a modern and most preferred method in pharmaceuticals as it offers significant uniform mixing, high binding, reduces sickness of blend with compressing tools, and gives you better content uniformity.

5.Next Step

You can’t proceed with the manufacturing process if wet content. Therefore, you need to dry all the ingredients that impart the process. For this read on step 4 to know what's ahead.

IV.Fluid Bed Dryer

A fluid bed dryer or fluidized bed dryer is a superior machine broadly used in the formulation and production of pharmaceutical industries. This process is necessary to overcome the moisture content present in powders and granules. Previously conventional fluidized bed dryers were used that have been modified and applied into an advanced form that encounters previous problems. For instance, vibrated fluidized bed dryer, spouted bed dryer, fluidized bed freeze dryer, etc.,

AIPAK FL Series Fluidized Granulating Drier

1.Working Principle

A fluid bed dryer works on the fluidization principle. It is a process where a particle is transformed from a static solid to a dynamic state by the use of hot air.

2.Benefits

- High-rate moisture can be eliminated via gas-particle constant ultimately resulting in high heat and mass transfer rates.

- Minimum capital and maintenance expenditure.

- Lesser contact time with a product for drying.

- High loss of moisture content and short resident time.

3.Applications

Food Industry: fluid bed dryer machine is required for a variety of foods to preserve their quality via removing the moisture content up to an optimum level such as Rice, breadcrumbs, vegetable and fruit pulps, spices, protein milk, etc.,

Pharmaceutical Industry: deals with powders, granules, capsules, tablets formation. To maintain ingredient shelf life and potency, fluidization is of prime importance.

Chemical Industry: to improve the value of chemical products fluidization is required. such as metal salts, sodium sulfate, polymer, fiber, detergents.

Biomass Industry: extremely required fluid bed dryer for drying of biomass to make their life long, such as paper sludge, poultry, RDF, etc.,

4.Why Do You Need a Fluid Bed Dryer?

In capsule manufacturing, a fluid bed dryer is needed to achieve the desired moisture content of granules. In pharmaceuticals, it supports improved shelf life of manufactured products via overcoming the risk of potential microbial growth, etc.

5.Next Step

After the drying procedure, the grinding and granulating step is required to transform the material into smaller pieces with help of grinding and granulating machines.

Ⅴ.Grinding And Granulator

A grinding and granulating machine is ideally used in the pharmaceutical industry for reducing the size of particles and making them even.

For this purpose, a pharmaceutical ‘cone mill’ is popular and acceptable equipment. It is named ‘cone; because of its shape and it is available in various diameters. Besides this, the grinding machine is well-suited for wet, dry as well as fine milling. All you need to opt for is a suitable granulating screen.

Cone Mill

1.Working Principle

Granulator works on the principle of rubbing by using cone blades and rotation within cone screeners that reduces the particle size.

2.Benefits

- A low-energy machine suitable for size reduction is ideal for fatty acid, sticky and moist substances.

- Highly productive, easy to operate, and diverse grinding machine.

- Sieve, as well as an impeller, can easily be replaced.

- A cone shape structure makes it difficult for residual particles to be accumulated.

3.Applications

Pharmaceutical Industry:for every formulation whether ophthalmic, nasal, topical, or inhalers, all required substances must be properly ground and sieved. A cone mill or grinder and granulator machine are ideal for this purpose.

Research & Development:for research work or clinical trials, you always needed different doses and different particle sizes to assess the potency and perfect experiment design. The grinder and granulator tools are of extreme importance in this zone.

Nutraceuticals:You always required, low RPM, low energy, and less heat when dealing with nutraceutical items such as vitamins, prebiotics, etc., Grinder and granulators are suitable for the machine to meet nutraceutical demands.

Food industry: grinder and granulator give high throughput and makes the process highly efficient when dealing with materials such as spices, herbs, flakes, dried fruits, etc.,

Cosmetic Industry: cosmetic items preparation always required the finest, glossy, and smooth material to formulate an amazing product that has high consumer acceptance. For this purpose, a grinder, and granulator is required to produce fine-sized particles.

4.Why Do You Need Grinding and Granulator

We use a grinding and granulating machine to obtain an appropriate particle size distribution and give you particles size is as low as 180µm (80 mesh). This step is mandatory and helpful as it improves flow properties and easy handling of powders.

5.Next Step

All the raw ingredients are combined with the help of mixers. Pharmaceutical mixers are constructed in a way that handles small to large mixing ingredients. Mixers are very important equipment in the manufacturing of pharmaceutical medicines.

ⅤI.Pharmaceutical Mixer

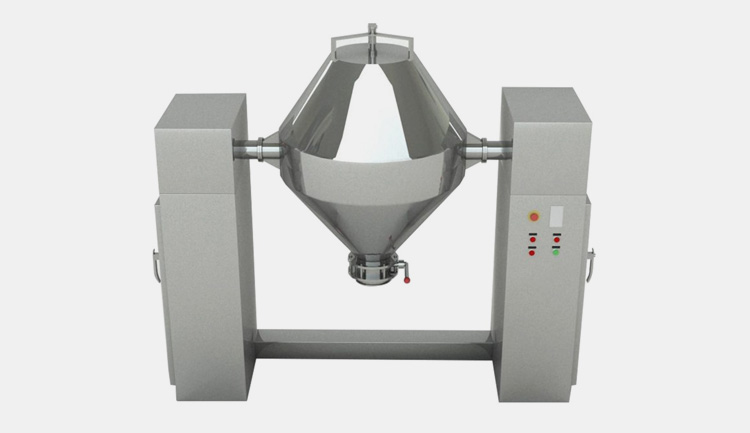

Pharmaceutical mixersare essential equipment that attributes the quality of mixing products. There are several pharmaceutical mixers are available in markets such as double cone, V-blender, octagonal, bin, vertical-screw, paddle, ribbon, plow, fluidization, planetary, double-arm, dual arm triple shaft mixer, etc.

AIPAK Model W Series Double Taper-shaped Mixer

1.Working Principle

There are several pharmaceutical mixers that works on different working principle depending on the type of particles. For instance, some mixer involves agitation, while some work using agitator, blades, chopper etc.,

2.Benefits

- Suitable for fragile to sticky, free-flowing to non-flowing.

- Mixer gives high shear to low shear mixing without attrition and excessive fines.

- From low to high-capacity substances, such as octagonal (highest capacity) to V-blender (small to moderate mixing).

- Gives smooth, effective, and cost-economical outcomes for mixing dry solids, dry-liquid-solid mixing, etc.,

3.Applications

Pharmaceutical Industry: formation of creams, lotions, tablets, capsules (shell and powder), ophthalmic, intravenous preparations, gels, etc.,

Food Industry: gummy bear, sodas, cake, bakery, pizza, wheat, rice, cocoa powders, etc.,

Chemical Industry: Paint, pigments, buffers, acid, base, and corrosives chemicals, etc.,

Agriculture Industry: preparation of fertilizers, insecticides, pesticides, etc.,

Cosmetic Industry: face powders, hair gel, body lotions, shampoos, soaps, etc.,

Paper and Pulp Industry: need a mixer to disperse, improve and agglomerate the ingredients to alter functional properties.

4.Why Do You Need Pharmaceutical Mixer

Mixing is one of the important pharmaceutical operations. The entire quality of the product is based on pharmaceutical mixers. This is a significant factor that can induce your formulation success, potency, and efficacy by mixing equal distribution of active pharmaceutical ingredients in the formulation.

5.Next Step

A hard gelatin capsule is composed of an empty shell that needs to be filled by using a capsule filling machine. This is available in fully-automatic, semi-automatic, and manual forms. You can pick them according to your production requirements.

Ⅶ.Capsule Filling Machine

A capsule filling machineis a mandatory tool for the encapsulation process. They are available in manual, semi-automatic, and automatic forms.

Capsule filling machine fills the capsule shell either with powders or liquid, can deal different sizes capsules shells and offer greater output. This machine is commonly used in the pharmaceutical industry for hard gelatin and soft gelatin capsules.

AIPAK Capsule Filling Machine

1.Working Principle

The working principle of the automatic capsule filling machine involved capsule loading, capsule separation (dislocation of body and cap), capsule filling via automatic filling stations, capsule locking, and automatic capsule existing into capsule tray.

2.Benefits

- An automatic capsule filling machine is an extremely durable and robust machine, suitable for continuous and large batch production.

- Fast and cost-effective.

- Meets hygienic demands and trouble-free operations.

- compact housing and easy to clean.

3.Applications

Pharmacies and Hospitals: capsule filling machine is highly in demand in pharmacies and inpatient department of the large healthcare sector.

Ayurveda : Ayurvedic preparation required a capsule filling machine to ensure safe and potent medicine.

Herbal and Dietary: capsule filling machines are popular in nutraceutical and herbal industries where day-to-day hard gel encapsulation takes place.

Cosmetic Industry: requires a capsule filling machine for encapsulation of cosmetic ingredients.

4.Why Do You Need Capsule Filling Machine

You need a capsule filling machine to fill substances in empty capsules. This machine is fast and efficient that offers you precise and accurate encapsulation in no time.

5.Next Step

Indeed, uncleaned, brittle, and rough capsules won't be acceptable to anyone. To enhance cleaning properties, shininess, and glossiness in capsules, you’ll be required a capsule polisher.

Ⅷ.Capsule Polisher

Capsule polisheris a tertiary step required after forming a capsule. This step is used to enhance aesthetic and glossy effects using a capsule polisher. A capsule polisher is a compact, and small machine most often integrated with a capsule filling machine where prepared capsules are automatically fed into a machine hopper. Capsule polisher dedusting system clears the capsule with excessive dust or any foreign particle. the machine has the ability to reject faulty capsules as well.

AIPAK Capsule Polishing Machine

1.Working Principle

Capsule polisher works by rotating brush that is used to polish and dedust the capsule ultimately produces a glossy and clear appearance.

2.Benefits

- Capsule polisher ensures removing of loose powdery particles.

- Sort good and bad capsules using a sensor detecting system.

- With high precision, low production cost, and more flexibility.

- Easy installation, portable, and help the pharmaceutical industry to produce premium quality products that enhance consumer compliance.

3.Applications

Pharmaceutical Industry:deals with the massive production of soft gelatin capsules, hard gelatin capsule, and various capsules of all sizes.

Veterinary Industry: requires the application of capsule polisher for veterinary capsules supplemented free from unwanted particles.

Cosmetic Industry:Good cosmetic brands use capsule polisher to enhance their product quality.

Herbal Industry: capsule polisher plays a pivotal role by improving herbal capsules ultimately increasing consumer acceptance.

4.Why Do You Need Capsule Polisher?

A capsule polishing machine ensures manufactured capsules are cleaned. Capsule polisher blocks the transfer of any residual or foreign particle onto the packaging equipment. Besides this, the polisher ensures the capsule is scrubbed from trace elements and safe to consume.

5.Next Step

It is important to count the capsules and tablets before their packaging. Of course, you don’t need to do it manually. For this, we’re featuring a high-technology capsule counting machine. Read on step number 9 to see about counting machines.

Ⅸ.Capsule Counting Machine/Blister Packing Machine

Now we come to the final steps of capsule counting and its packaging.

A) Capsule Counting Machine

A capsule counting machine using a photoelectric sensor system accurately counts the capsule and transfers them into a collecting box.

Where it is integrated with the packaging machine; the blister packaging machine is a special packaging machine that uses unit dose for capsules.

AIPAK Capsule Counting Machine

1.Working Principle

The capsule counting machine works by sensing each capsule that passes over its optical detectors.

2.Benefits

- The capsule counting machine has improved counting and increased work efficiency.

- Capsule counting machine offers simple running and less maintenance.

- The capsule counting machine is easy to clean and available in diverse forms.

3.Applications

Retail Pharmacies:day to day capsule dispensing highly demands capsule counters.

Pharmaceutical Industry: automatic capsule counting machine with an IR detector is capable to sense faulty capsules and transfer them into a rejection bin. It allows accurate and correct capsules for the next step.

Veterinary Industry: capsule counting machine is a premium solution for counting capsules for veterinary productions.

Cosmetic Industry: this machine is advantageous for counting cosmetic capsules accurately.

4.Why Do You Need Capsule Counting Machine?

A capsule counting machine supports counting capsules that you’ve produced. Indeed manual technique is not acceptable in the production of large batch sizes. Hence, the capsule counting machine fulfills your needs and is accepted by leading pharmaceutical industries for the easy counting and filling process.

5.Next Step

It’s turned to protect the capsules using a multifunctional blister packing machine. This is pharmaceutical packaging equipment that is utilized for capsules, tablets, and other healthcare products packaging. You can find them in various forms such as tabletop, semi-automatic, and automatic blister packaging machines.

B) Blister Packing Machine

A blister packing machineis a special machine used for packaging small and large batch production. Blister packing machine has extensive applications due to their amazing properties such as product freshness, security, temper evident, safety, etc., This machine is available in manual, semi-automatic, and automatic form, as well as available in small, medium, and large form.

AIPAK PVC Flat Plate Blister Packing Machine

1.Working Principle

Blister packaging machines have a component of a cavity or pockets made up of thermoform plastic. This cavity or pocket is formed by heat and pressure. After filling a blister will be pressed to assess the formed blister is filled. An aluminium foil and PVC are heated and sealed together.

2.Benefits

- Blister packaging machines secure the capsules and enhance their potency.

- A unit dose packaging is ready to use whenever required.

- Blister packaging machine ensures the product is original and tamper-evident.

3.Applications

Pharmaceutical Industry: requires blister packing machine for packaging of capsules, suppositories, tablets, etc., to improve shelf-life and protection.

Toys Industry:requires blister packaging machine for protection and easy transportation of their goods.

Hardware Industry: requires blister packaging machine for hard nuts, bolts, screwdrivers, etc.,

Cosmetic Industry:requires a blister packaging machine for attractive and safe packaging of cosmetic products.

4.Why Do You Need Blister Packaging Machine?

Every pharmaceutical production system requires a blister packaging machine for capsule packing as it offers high- protection against physical and chemical factors such as humidity, oxidation, cross-contamination, etc.

5.Next Step

Smooth, and shiny capsules are now safely packed. But for transportation, you need to transfer them into suitable cartons. For this, a highly flexible and efficient cartoning machine is required to make a special cartoning package to improve the standard of your product.

Ⅹ.Cartoning Machine

Pharmaceutical cartoning machinesare suitable for packaging blister strips, bottles, inhalers, etc. A carton machine is an innovative and advanced machine that automatically performs opening and folding, batch numbering, and cartoning sealing jobs. This machine is integrated with other equipment to make a complete production line.

AIPAK Full-Automatic Medicine Plate Packing Box Production Line Machine

1.Working Principle

The cartoning machine selects a piece from the stack of the folded carton, unfolds them, fills it with the product through the opening, and closes the end by flipping the carton with help of glue or adhesive.

2.Benefits

- The cartoning machine offers a wide range of packaging.

- Ensure product protection and feasible transportation.

- A multifunctional machine performs many complicated tasks at one time.

- A quick change over time, and easy to operate for variable product sizes.

3.Applications

Pharmaceutical Industry: requires cartoning machine as the anti-counterfeiting solution for packaging products like blister packs, oral liquids, vials ampoule, etc.,

Food Industry:all the processed foods, milk bottles, biscuits, cookies, etc., packaging requires a cartoning machine for their safe and efficient transportation to the end-user.

Cosmetic Industry:horizontal and vertical cartoning machine is required for packaging cosmetic products like facial masks, soaps, sanitary cotton, sanitary pads, etc.,

Electrical Appliances: vertical automatic cartoning machines is of prime importance for packaging chargers, bulbs, bearing, etc.,

Toy or Stationery Items: cartoning machines are in high demand for packaging staplers, pencils, markers, toys, printer paper, etc.,

Plastic Industry:requires cartoning machine for packaging of products like clings, fresh films, etc.,

Automobile Industry: cartoning machine is required for packaging automobile parts such as piston rings, light bulbs, spark plugs, etc.,

4.Why Do You Need Cartoning Machine?

Cartoning machine is a case packer line used for automatic packaging of medicines into cartons. This is a speed and flexible machine that helps you in increasing overall product quality by enabling good branding, transportation, and your business. In pharmaceuticals, foods, and nutraceutical cartoning machine helps you in the safe distribution of a product.

Conclusion

We hope you’ve found our informative review a promising one. Indeed, this diversified article is of extreme importance for someone who owns a business related to capsule manufacturing and required extensive knowledge about required machinery. Thus, you must have significant information on all relevant machinery to offer high-quality and potent products to your client. Do you want more technical assistance before purchasing a machine? Our high-tech staff is always HERE to assist you with a free consultation; let begin your amazing experience with us.

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine