Ultimate Barrier Protection: High-Speed Alu-Alu Strip Packaging for Sensitive Pharmaceuticals

Ensure product protection, extended shelf life, and efficient packaging for tablets, capsules, and pills.

AIPAK Automatic Alu-Alu Strip Packing Machine: High-Barrier Sealing Solution

AIPAK high-performance Automatic Strip Packing Machines are specifically engineered for the high-integrity packaging of hygroscopic, light-sensitive, and high-potency medications. While standard blister packs offer visibility, our advanced Alu-Alu strip sealing technology provides an absolute moisture and oxygen barrier, significantly extending the shelf life of sensitive pharmaceuticals.

Designed to meet the rigorous demands of modern pharmaceutical production, our systems utilize precision roller-type heat sealing to ensure hermetic integrity without compromising the structural stability of the active ingredients. Whether you are packaging effervescent tablets, capsules, or specialty granules, AIPAK equipment delivers a multi-track, high-speed solution that seamlessly integrates into your secondary packaging line. Every unit is constructed with AISI 316L stainless steel contact parts, ensuring full compliance with cGMP, CE, and FDA regulatory standards.

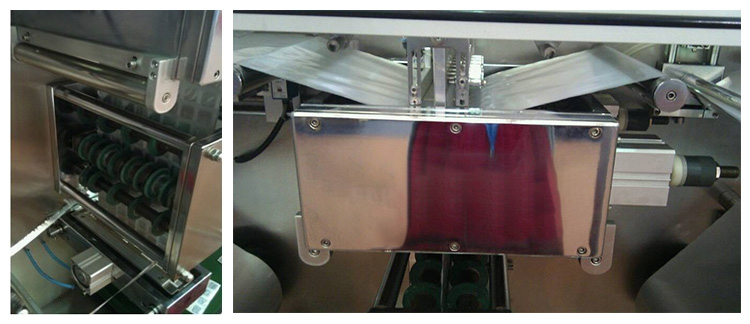

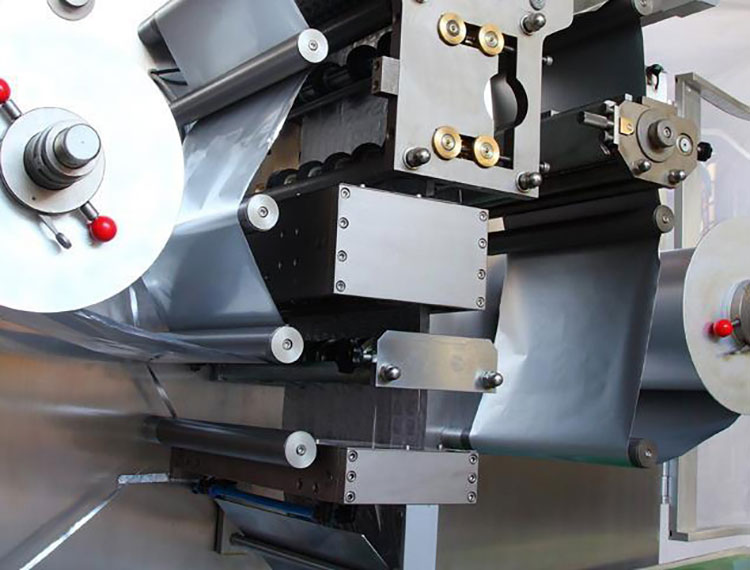

AIPAK Strip Packing Machine Details

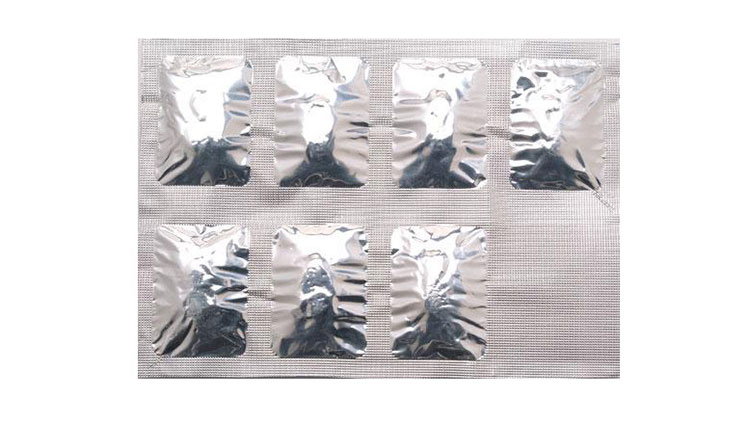

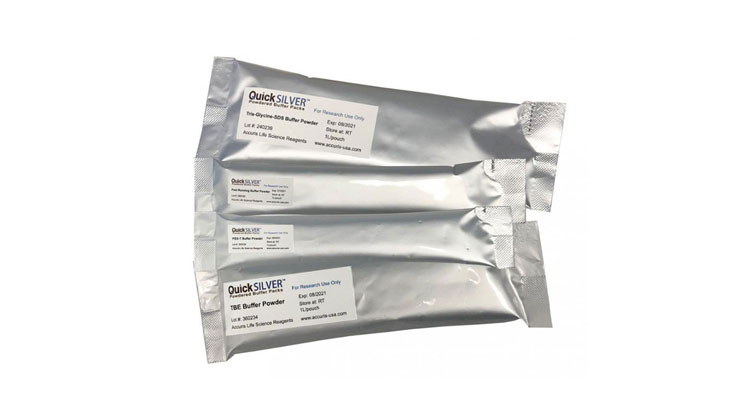

AIPAK Strip Packing Machine Products Display

Applications of Strip Packing Machine

Pharmaceutical Industry

Strip packing machines are widely used for tablets, capsules, lozenges, and solid unit doses. They provide strong protection against moisture, light, and oxygen, which is critical for maintaining the stability and shelf life of sensitive pharmaceutical formulations.

Nutraceuticals & Healthcare Supplements

In the booming nutraceutical and dietary supplement market, strip packs are used to pack vitamins, probiotics, herbal capsules, and functional tablets. The compact packaging improves consumer convenience and ensures that the product retains its nutritional potency throughout the supply chain.

Veterinary Medicine

Strip packing is also popular in animal healthcare for packing veterinary tablets, deworming pills, and nutritional supplements. The sealed packs make it easier for vets and farmers to store, transport, and administer medications without worrying about contamination.

Food & Confectionery

Food manufacturers use strip packs for small solid products such as chewing gum, mints, candies, and food supplements. The airtight packaging not only enhances freshness and flavor retention but also gives products a professional retail appearance.

Cosmetics & Beauty Industry

In cosmetics, strip packing machines are used for beauty capsules, collagen tablets, and skincare supplements. The packaging design provides luxury appeal while maintaining product quality against humidity and temperature fluctuations.

Chemical & Laboratory Products

Some chemical and lab-grade materials (such as diagnostic tablets or test chemicals) require safe, unit-dose packaging. Strip packs ensure accurate dosing, prevent contamination, and make handling safer for both laboratories and end-users.

AIPAK-Your Best Pharma Processing & Packaging Machinery Supplier In China

Download Our Latest Catelogue

Discover our full range of pharmaceutical processing&packaging machinery. Download the catalogue to explore specifications, features, and applicatons.

- Full product range

- Detailed technical specs

- Industry applications

Strip Packing Machine FAQ

1.What products can be packed with a strip packing machine?

AIPAK Strip packing machines are mainly used for tablets, capsules, lozenges, and similar solid unit doses. They can also be adapted for certain nutraceuticals, veterinary products, and small confectionery items.

2.What materials are compatible with strip packing machines?

A commonly used films include heat-sealable aluminum foil, laminated films, and plastic films. The choice of material depends on the product’s sensitivity to moisture, oxygen, and light.

3.How is a strip pack different from a blister pack?

AIPAK Strip packs provide superior moisture and light protection and are more compact. Blister packs, on the other hand, are easier to open and often used for high-speed mass production.

4.What is the typical output speed of a strip packing machine?

Depending on the model, output speed can range from 40 to 120 strips per minute. Higher-capacity models are suitable for large-scale pharmaceutical production.

5.Is the strip packingmachine GMP and ISO compliant?

Yes, our strip packing machines are manufactured according to GMP, CE, and ISO standards, making them suitable for regulated pharmaceutical and healthcare production.

6.Can the strip size and cavity layout be customized?

Yes. We can design custom strip sizes, cavity numbers, and layouts to meet specific product requirements, packaging standards, or branding needs.

7.How do I maintain and clean the strip packing machine?

Daily cleaning of the sealing area and periodic lubrication of moving parts are recommended. Our machines are designed with easy-access components for quick cleaning and maintenance.

8.Can the machine handle both pharmaceutical and nutraceutical products?

Absolutely. Strip packing machines are widely used in pharmaceuticals, nutraceuticals, and veterinary medicine, with adjustable settings to match different product types.

9.What are the common issues in strip packing, and how can they be solved?

Uneven sealing → Adjust temperature and pressure.

Film wrinkling → Check film alignment and tension rollers.

Tablet misplacement → Inspect feeding system alignment.

10.How can I choose the right strip packing machine model?

Consider production volume, product type, film material, and factory space. Our technical team can provide a tailored solution based on your specific needs.

The Buyer's Guide

The Ultimate Guide to Automatic Strip Packing Machines: Enhancing Pharma Integrity & Shelf Life

The first impression is extremely important. Indeed, your product packaging is one of them.

This unit of manufacturing system should never be overlooked.

Because consumer always gives importance to attractive and unique packaging that ensures product safety. Strip packing machine allows packing of pharmaceutical medications that are commonly available as over- the-counter. While certain special drugs such as Narcotics or drugs used for larger medical treatment cannot fit into this category of packing.

Also, it helps the patient to get the right medication at the right time. In a nutshell, if you get proper medication on assigned time then you won’t need to go hospital again and again.

Now a day, you can find the basic mandatory information printed on strip packing. Thus, you do not need to find information from other sources or seeking online guidance.

Strip packing machine is of prime importance as it helps you to simplify the drug products, hence you do not need caregiver or care-recipients. This provides a fast and safe medication that you can keep home for longer.

So, you can promote your business and gain customer satisfaction with secure strip packing.

If you’re planning to buy a strip packing machine, this blog is for you!

We will consider all required details and guidelines related to strip packaging machines that will help you before and after purchasing strip packing machines.

Let’s get into it!

1.What is strip packing?

Unlike standard blister packs, strip packaging uses two layers of flexible, high-barrier foils to create a hermetic seal. This provides 360-degree protection against moisture and oxygen, making it the premier choice for hygroscopic medications.

Thus, by attaining strip packing, you may increase the shelf life of pharmaceutical dosage form as well as 100% protection.

2.What is a strip packing machine?

A strip packing machine is a well-designed and highly advanced machine that is considered a demand of the pharmaceutical packing sector. A strip pack machine delivers highly sophisticated sealing around solid dosage form in various shapes and sizes. For instance, Capsules, tablets, lozenges. This machine is highly effective to execute multifunctional tasks simultaneously such as feeding, sealing, cutting, and discharging. Thus, as a result, you can get an instant result with less energy, labor cost, and time.

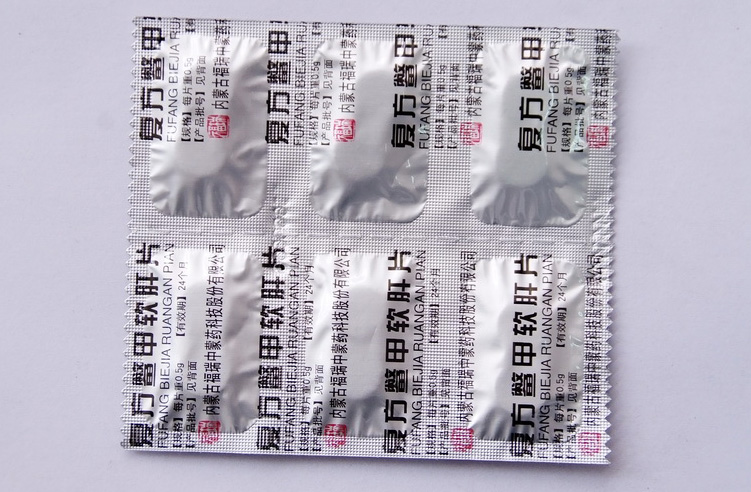

Strip packing machine

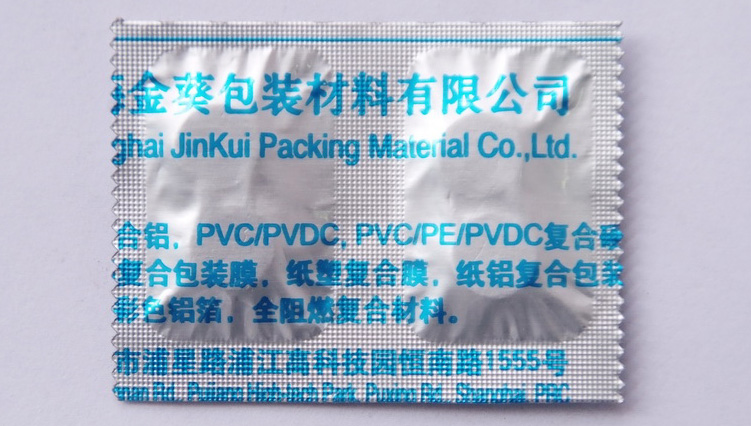

The packing material used for strip packing around pharmaceutical products is most often consist of Alu-Alu (cold-form), A PET foil (Polyethylene terephthalate), PVC or polyvinyl chloride, or paperback foil.

Material for strip packing- Aluminium foil/ Paper / Polyethylene

These are simpler and innovative forms of equipment that normally generate a high yield of production with reduced downtime. They give strip packing around dosage form in a single or double strip configuration along with perforation that helps you in the opening or unsealing of each tablet without damaging the rest of the product.

3.What are the main features of strip packing machines?

The basic features of the strip packing machine are as followed.

- It has automatic feeding, sealing, and cutting units that allow simultaneous functions.

- It is made up of stainless steel.

- An automatic control system with high production capacity, greater efficiency, and decreased labor cost.

- It encompasses the conveyor of various sizes and strips.

- It has the capability to handle various heat-sealable laminates.

- It has an advanced digital temperature control system.

- Entire components of strip packing machines can be easily replaced or removed.

4.What are the main supporting materials of strip packing machines?

The strip packing machine has the following supporting materials.

- Aluminium foil

- Paper

- Plastic and polyethylene

- Cellophane

- Heat sealing material

5.How strip designing is achieved?

Designing strip packing is very basic that varies in different units such as rectangular, square, round, or oval.

Furthermore, initial designing of pocket area for pharmaceutical packing is critical that focus on few factors such as diameter, shapes, and thickness of unit dosage form.

If a pocket area is too tight or not suitable according to the shape of tablets or capsules, it may cause product damage.

Not only this, but it is not ideal for sealing as well. Because pocket tightness may lead to cause clearing, perforation, and wrinkle formation in sealing. Therefore, in strip designing the sealing width of 5mm or above is preferred with all necessary dimension requirements.

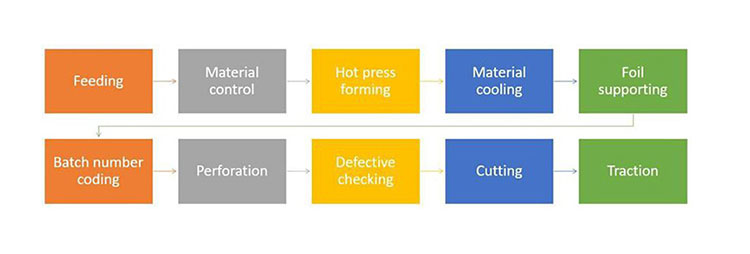

Processing -Strip Packing Machine

PLC Programmable Controller and a Finished Product

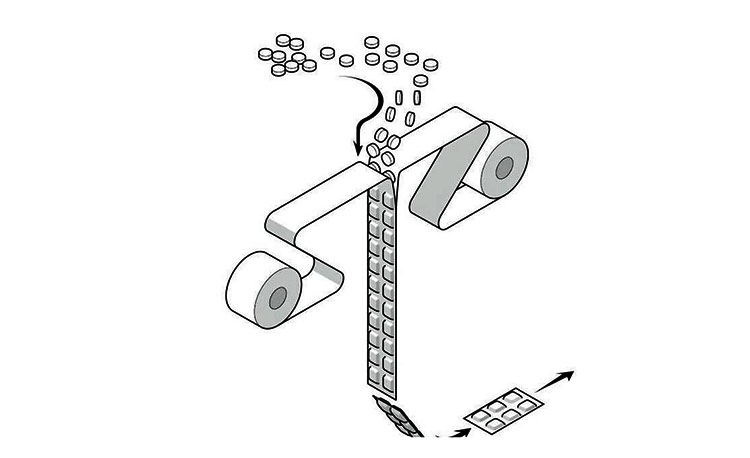

6.How does the strip packing machine work?

The modern strip packing process is a high-speed synergy of mechanical motion and thermal precision. Unlike traditional packaging, our systems integrate the entire production line into a seamless, automated cycle.

Step 1: Synchronized Feeding & Material Control

The process initiates at the Vibratory Hopper, where solid dosages (tablets or capsules) are aligned. Precision feeding tubes ensure that each unit is dropped at the exact micro-second onto the lower foil web. Simultaneously, dual Foil Unwinding Shafts release the packaging material (Alu-Alu, Paper/Alu, etc.) under constant tension to prevent wrinkles.

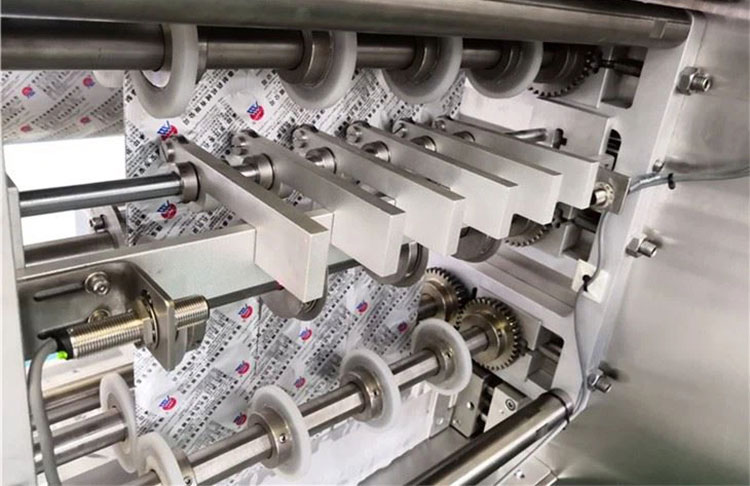

Step 2: Thermal Compression & Hermetic Sealing

This is the "heart" of the machine. The product is sandwiched between two layers of foil as they pass through Precision Sealing Rollers.

Technical Insight: The integrity of the pack depends on the PID-controlled temperature of these rollers. Our rollers apply uniform pressure and constant heat to create a hermetic seal. This ensures the foil is neither "burnt" (causing micro-perforations) nor "under-sealed" (causing leaks).

Step 3: Online Batch Coding & Perforation

While the strip is moving, an integrated Batch Coding Unit prints manufacturing dates and expiry information onto each individual pocket. Following this, the Perforation System creates "easy-tear" horizontal and vertical lines, allowing consumers to remove single doses without compromising the seal of adjacent tablets.

Step 4: Smart Inspection & Defective Rejection (NFD)

To ensure 100% compliance, the Non-Fill Detection (NFD) system scans the moving strips. If a pocket is found empty or a tablet is broken, the PLC registers the position and triggers the Automatic Rejection Unit at the end of the line.

Step 5: Precision Cutting & Traction

Finally, the continuous ribbon of sealed medication reaches the Slitting & Cutting Station. Pneumatic or mechanical cutters trim the edges and cut the strips into the desired lengths (e.g., 2x5 or 2x10 configurations) before discharging the finished products via the traction conveyor.

7.How to operate a strip packing machine?

To know how to operate a strip packing machine is very important. We are here to provide proper guidance for standard operating procedures. For this, you need to require the following steps:

Pre-Start Up Points

- Set up the machine and required material according to the product.

- Adjust strip sealing rollers on the shaft and tighten up the grub screw.

- Adjust the cutting and pinion gear as well as vertical cutting.

- Make sure the centreline of the rollers is just above the centreline of a draw of brushes.

- Utilizing stud and nut, regulate the sealing roller.

- Check the alignment of a cavity of the sealing roller and tighten up the pressure setting for sealing pressure.

- Make sure the functionality of the cam for cutting is working properly.

Start-Up Points

- Switch ‘ON’ the main connection and push a green-colored glowing button.

- Switch ‘ON’ a heating button and set the temperature as per your requirement for each batch using an electric panel.

- Before starting the final procedure, do a testing processing to check if strip packing is working correctly.

- Start the strip packing process and monitor the indicators on the PLC system to ensure the packing procedure is working satisfactorily.

- In case if heater lamp indicates excessive heat generation so you may cool down the heater.

- During strip packing monitor the strips at every half to one-hour interval to examine the sealing quality, pockets, leaking, and the number of cuts/minute.

End Up Points

- Perform the leak test to analyze the for each cycle.

- After completing the production cycle, switch ‘OFF’ the main supply.

- Make an entry in ‘Equipment Logbook’.

Note:

Never run the machine when it is empty. Always clean the roller using a soft brass wired brush.

8.What is the production line of the strip packing machine?

The production line of the strip packing machine is discussed below:

- Feeding

- Material Control

- Hot Press Forming

- Material Cooling

- Foil Supporting

- Batch Number Coding

- Perforation

- Defective checking

- Cutting

- Traction

Feeding

Generally, each strip contains a single dosage form available in variable numbers, which depends upon the setting of the feeding system of the strip packing machine. You can feed a unique design for the strip packing process by adjusting the feeding setup. A strip packing machine is constructed in such a way that provides a customized form of packing for various tablets or capsules.

Material Control

Material control can be decided before initiating the process. Strip packing materials include paper, aluminium foils, heat-sealable polyester, and regenerated cellulose, adhesive tapes. The following required materials are adjusted on the sealing roller and the remaining associated parts.

Hot Press Forming

A hot press forming causes depression on the foil that allows entrance of packing material between a zone of two-heated sealing rollers, The lateral stresses on filled strips are significantly lowered. This allows a perfect strip packing process suitable for large batch production.

Material Cooling

This is an optional step, that needs to implement after hot-pressing of strip packing. The material is cooled down by atmospheric air or using cooling stations so strip packing material can regain its toughness. This is most often preferred for those packing materials which are made up of plastic.

Foil Supporting

The safety guard is being recommended as an optional item. This is consisting of Acrylic/Polycarbonate Plates installed on a framework made up of extruded aluminium sections.

Batch Number Coding

After strip packing the batch, number coding is done via the following ways, such as Lot number, Date of manufacturing, Expiry date, and another customized prerequisite. Each pocket of a tablet should have this mentioned requirement with clear and visible printing.

Perforation

Perforation of strip packing is of prime importance as it enables the consumer to tear off the tablet easily. This is achieved by horizontal and vertical ‘interrupted cut’. So, the configuration of perforation is loaded in ‘dash-dash’ format facilitates easy tearing off.

This perforation also significantly displays an aesthetic look and secures the dosage form without any loss of sealing properties.

Defective checking

This is an optional approach that is integrated into certain strip pack machines that enabling automatic analysis of defective strips. After detection, the defective strips are rejected automatically. The following arrangement includes a sensing unit, PLC, HMI (Human Machine Interface), with an electro-pneumatically system and an activated auto-rejection unit.

Cutting

After checking of corrected strips, cutting, and trimming procedures take place by pneumatically mounted cutters that help to cut the foil or packaging material, which is very hard to tear.

A zig-zag cutting is done with several points at which tearing of packing can be initiated. Furthermore, the cutting configuration is easily displayed on every individual pack that allows the user to torn- off from the displayed ‘Ribbon’.

Traction

The finished product is discharged once they leave the sealing station.

9.What are the important components of a strip packing machine?

The components of strip packing machines are as followed:

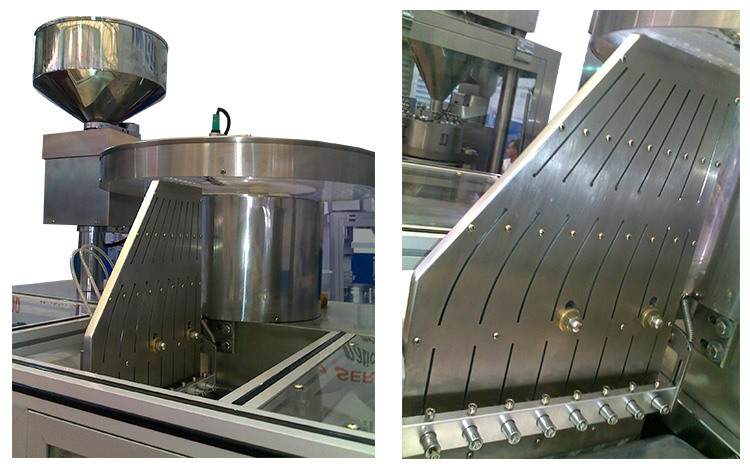

Feeding Unit

A feeding unit consists of a hopper, feeding tube, and reciprocating feeder. The solid dosage form is generally loaded into a feeding unit via hopper where through reciprocating motion they move into the feeder. The guard valve allows the flow of seamless flow of products that drops gently into the foil for sealing.

Hopper: It is a funnel-shaped unit of strip packing machine. It is used to provide packing material from one container to other.

Feed Tube: Most often a strip pack machine utilizes a feed tube as a vertical feed that works via gravitational drop. Sometimes, the feed tube is driven horizontally using a platen-type sweep mechanism.

Reciprocating Feeder: Raw Materials fed employing a hopper is discharged from the feeding tube via reciprocating motion. The frequency of discharging material in back-and-forth motion can be modified according to requirement.

Cutting Unit

A cutting unit comprised of blades that aids the continuous cutting of sealed material as per fed protocol for each batch. The cutting of sealing material is achieved pneumatically corresponding to the control setting.

The cutting unit is embraced with an electronic detector and a PLC.

The operator can easily modulate the number of pills at the long edge of strip packing. The cutting adjustment does not require alteration of cast aligning; only you need to adjust the setting on a touch screen. Furthermore, you can set an extra installed strip pack device to run a smooth conveying of strip packing.

Driving Unit

This unit helps in precise motion control of packed material; this unit consists of a drive motor, ball-lead screws, and conveyor belts for continuous movement.

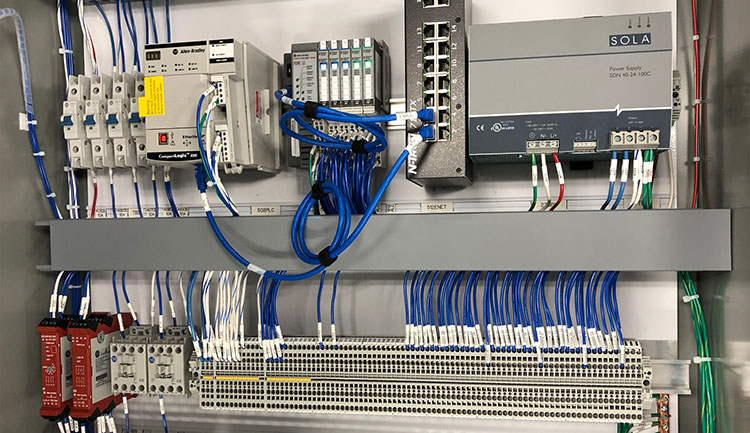

Electrical Operating Panel Box

This is an important unit of the strip packing machine that facilitates the entire operating procedure. in other words, it helps in the distribution of current for entire electrical circuits within a strip packing machine.

PLC- Programmable Logic Controller

An automatic strip packing machine using a PLC system that facilitates the advanced functions of

1-tablet counting,

2-vertical and horizontal embossing,

3-cutting of packed products,

4-trimming of edges if required,

5-the printing of batch numbers for each module.

The entire process is controllable by a user that feeds the requirement on the PLC unit.

Hence, you can change, add, or set the value on the touch screen. So many functions can work automatically without the need for extra operating interference.

If something goes wrong machine will notify you through an alarming system.

10.What are the classifications of strip packing machine?

| Feature | Manual Strip Machine | Semi-Automatic | Fully Automatic (High-Speed) |

| Best For | Labs / Small batches | Medium production | Large-scale pharma plants |

| Key Advantage | Low cost / Portable | Balanced efficiency | NFD System / High OEE |

| Labor Cost | High | Medium | Zero-to-Low |

11.What is an NFD system of strip packing machines?

An NFD system or Non-Fill-Detection system usually detects and rejects those strips packing material in which they detect the missing tablet or any assigned product.

This is an optional system, which is mostly present in automatic strip packing machines, consist of PLC and HMI units with the activated-auto-rejection unit.

A strip packing machine with an NFD system is designed in such a way to work simultaneously at a moderate working pace.

12.What are the industrial applications of strip packing machines?

Discussed below are important industrial applications of strip packing machines.

Pharmaceutical Industry

A strip packing machine is a popular machine among pharmaceutical manufacturing sectors. It is frequently required to utilize for advanced packing of manufacturing goods. Strip packing machine ensures, safe, secure, and tempered proof product packaging highly necessitates for patients or other health sectors.

Strip packing machines offer packing of unit solid dosage form free from contamination, with lower risks of microbial growth and extending the shelf life.

Strip packing machines not only ensure the durability of packed products but also enhance the potency of your manufacturing goods. You can use a strip packing machine for packing tablets, capsules, herbal supplements, multivitamins, nutritional supplements, etc.

Chemical and Pesticide Industry

Strip packing machine is extensively used in chemical and pesticide manufacturing industries for packing of chemicals or possible pesticidal products. Over the years, the goal of packing chemicals and pesticides is to offer significant packing that can protect the environment, with child resistance packing and high activity.

Thus, strip packing machine product design and labelling allow the user to understand handling and tapering properties.

Moreover, strip packing machines ensure high sealing properties that can protect ecological and biological systems against their interaction.

You can use a strip packing machine for packing mosquitoes’ repellent tablets, camphor, pH buffers, etc.

Pesticide strip Pack

Strip Packed Chemicals

Food Industry

Strip packing machines play an important role to conserve food items that are manufactured on an industrial scale. Strip packing machines offer leakage proof, extended shelf life, fresh and pilferage-free products.

The aluminium sealing around food products ensures a high protective barrier that locks the interference of external factors with the product. Thus, for some products, you do not need to add preservatives.

You can find strip-packed food items such as chocolates, candies, and others, across the globe.

13.What are the advantages of using strip packing machines?

The prime advantages of using strip packing machines are as followed:

Protection

Strip packing machines offer significant protection to sealing material especially those tablets or capsules which are hygroscopic. Such as Aspirin. Thus, a strip packing machine enables a high degree of safety and security to your product.

User-Friendly

Strip packing machine is a user and environment-friendly machine. You can just feed the entire requirement to run a protocol in a PLC unit, such as speed of packing, the temperature of heat- rollers, etc. You do not need to stand for the entire processing of strip packing. Because strip packing machine has a sensor detecting system that will allow you to know if any defect occurs.

Product Originality

Everyone prefers to administer those tablets or capsules which are dispensed in their original form. This is true if you find a product in a damaged form then there is a possibility you may discard them. A strip packing machine packs the solid dosage form considering perforating parameters, that enable product stability against wear and tear.

Preserving Active Ingredients

An active ingredient of therapeutic dosage form can enhance their curative effects. If product packaging is compromised it ultimately affects the potency of the drug. Therefore, strip packing is of prime importance as it preserves your product against physical and chemical calamities such as temperature, light, and humidity and may provide you 100% potent and effective therapeutic drug.

Extending the Shelf Life

The strip packing machine can help to preserve solid dosage forms in their optimized form. Due to this property, it induces a longer shelf life to manufacture goods.

Temper Proof Evidence

Through strip packing with designated prints can give you an idea if your product is in original form or not. Because strip packing can simply allow you to know if something has happened wrong with it. Thus, strip packing is not only beneficial to protect your manufactured goods but also helps to protect them against pilfering. Hence, intact sealing will ensure a high degree of product integrity.

Patient compliance

Strip packing machines provide a better packing of product in such a way that you can carry it from one place to another simply by placing it in your pockets. As a capsule or tablet is placed in one cavity therefore easy for a patient to get an accurate dose when required. Moreover, it allows the patient to count the number of tablets left or consumed which is not possible when taking from a bottle.

Appealing Look

Strip Packing machine offers several designs, shapes, and colored packing to a drug product promotes an aesthetic look that’s acceptable to consume by adults and children.

Error Free Dispensing

Strip packing machine has an integrated printing system with specific prints. Moreover, this type of packing provides mandatory information such as manufacturing, expiry, and batch number.

14.What are the disadvantages of a strip packing machine?

Expensive Form of Packing

As compared to other packing machines, the strip packing machine is comparatively a high-cost machine.

Patient Compliance

Packing from a strip packing machine is not suitable for an elderly patient which swollen or stiff fingers.

Highly Sensitive Form of Packing

Strip packing machine requires tablets to encounter with sealing rollers with high temperature. Thus, this is an intricate process, requires high maintenance and extra vigilance as improper packing leads to cause wrinkles and perforation.

15.What is the difference between a blister packing machine and a strip packing machine?

Most often people mix up the blister packing machine with strip packing machines.

Discussed below are the major difference that everyone must know before dealing with these machines.

1. Material Specification & Foil Substrates

Original: The blister packing machine can work with only hard aluminium foil...

-

Optimized: Strip Packing exclusively utilizes Soft Aluminum Foil, which is highly flexible and wraps tightly around the product. In contrast, Blister Packing typically requires Hard Aluminum Foil as the lidding material, paired with a thermoformed plastic (PVC) or cold-formed aluminum (Alu-Alu) base. This difference in substrate determines the machine's forming and sealing mechanism.

2. Production Throughput & Format Flexibility

Original: As compared to the blister packing machine, a strip packing machine allows packing...

-

Optimized: From an operational standpoint, Strip Packing Machines offer exceptional Format Flexibility, easily accommodating tablets and capsules of unconventional shapes and sizes without complex tooling changes. Additionally, due to its continuous roller sealing process, strip packing often achieves a Higher Throughput (BPM) compared to the intermittent forming-filling cycle of many blister machines.

3. Shielding Integrity & Barrier Properties

Original: Strip packing has strong protective properties whereas, blister pack has less potent shielding...

-

Optimized: Strip Packing provides Superior Barrier Integrity because the drug is fully encased in opaque, dual-layered aluminum. This is critical for preventing UV degradation. Blister Packs, especially those using transparent PVC, offer less shielding against light and can allow the physical environment to interact with sensitive drug products, potentially compromising their stability.

Blister Packing Machine- Picture courtesy- Shanghai Royal

Strip Packing Machine- Picture Courtesy-India Mart

4. Barrier Integrity for Specialty Formulations (e.g., Effervescent Tablets)

-

Strip Packing: The two foil webs wrap tightly around the product, eliminating "headspace" (trapped air). This is a massive advantage for Effervescent Tablets and other highly unstable drugs that degrade quickly when exposed to the trace moisture or oxygen trapped inside a pocket.

-

Blister Packing: The rigid "pocket" or "bubble" structure inherently leaves a small amount of air (headspace) around the tablet. For extremely sensitive products, this trapped air can compromise the drug’s potency over time.

5. Material Efficiency & Sustainability (Carbon Footprint)

-

Strip Packing: Since it doesn't require "thermoforming" or "cold-stretching" into deep pockets, it uses less peripheral material per unit. This translates to a smaller overall carbon footprint and lower material costs for high-volume production.

-

Blister Packing: Requires extra material width and specialized forming films (like PVC/PVDC) to create the structural pockets, which can lead to higher material waste and a higher cost-per-dose.

If your priority is absolute barrier integrity for unstable drugs (like Effervescent tablets) or minimizing packaging waste, a Strip Packing Machine is the technically superior choice over a standard Blister machine.

16.How to maintain a strip packing machine?

Mentioned below is a standard operating procedure for maintaining and managing strip packing machines.

Daily Maintenance

- Before and after using the strip packing machine ensure main electrical switches are completely disconnected to the main supplier. You can also check through the main supply panel board.

- Swipe the equipment if you find any dust or foreign particles over it.

- Use Equipment Manual File to record entry for machine usage.

Monthly Maintenance

- Examine Foil Running Shaft, release pin, sealing rollers, slip ring.

- Examine and adjust the Vertical Slitting of the machine.

- Examine the functionality of the V-belt and conveyor, apply alignment and tighten all nuts and bolts where required.

- Always lubricate all shafting, gear, sprockets, and chain of the machine.

- Furthermore, drain the oil from the gearbox and replace it with fresh oil if necessary.

- Check the electrical connection and tighten them if you find any loose electrical connectivity.

- Lubricate all mechanical parts of the machine such as motor bearing etc.

- Examine the rollerblades, edge cutter and replace them if required.

17.What is the technical troubleshooting of strip packing machines?

Even the most robust strip packing systems require precise calibration. Below are the most common operational challenges and the professional protocols to resolve them efficiently.

1. Sub-optimal Sealing Quality (Leakage or Micro-perforations)

-

Root Cause: Fluctuating electrical voltage or incorrect PID temperature settings. If the temperature is too low, the foil won't bond; too high, and you risk "burning" the foil (creating microscopic leaks).

-

Action: 1. Verify the stability of the main power supply. 2. Check the heating elements and thermocouples for carbon buildup. 3. Recalibrate the digital temperature controller (PID) to match the specific gauge of your aluminum foil.

2. Irregular Strip Cutting or "Jagged" Edges

-

Root Cause: Loose cutting blade mounting or misalignment of the feeding input data in the PLC. Dull blades are also a common culprit for "hard-to-tear" strips.

-

Action: 1. Tighten all pinion gears and vertical/horizontal cutting blade fasteners. 2. Use the HMI touch screen to verify that the "Cutting Length" parameter matches the mechanical gear ratio. 3. Replace blades with High-Speed Steel (HSS) or Tungsten-carbide coated blades if wear is detected.

3. Wrinkle Formation or Foil Misalignment

-

Root Cause: Uneven tension from the dual-web unwinding shafts or debris on the sealing rollers.

-

Action: 1. Adjust the Magnetic Powder Brake or the manual tension nut on the foil shafts. 2. Clean the sealing rollers using a soft brass wired brush (never use steel, as it scratches the precision texture). 3. Ensure the center-line of the rollers is perfectly aligned with the draw-brush guides.

4. Machine Fails to Start (No Power/Current)

-

Root Cause: Emergency stop engaged, tripped circuit breakers, or motor jam due to product obstruction.

-

Action: 1. Check the PLC error log for "Safety Circuit Interruption." 2. Inspect the distribution box for tripped switches. 3. Manually rotate the main drive shaft (with power OFF) to check for mechanical obstructions in the hopper or feeder.

18.Does the strip packing machine comply with international quality standards?

AIPAK strip packing machines are engineered to exceed the most stringent global regulatory requirements. We don't just build machines; we ensure your production facility stays compliant and audit-ready.

1. Data Integrity & 21 CFR Part 11 Compliance

For modern digitalized pharmaceutical plants, the Programmable Logic Controller (PLC) and HMI systems are configured to meet FDA 21 CFR Part 11 standards.

-

Audit Trails: Every parameter change is logged with a timestamp and user ID.

-

Multi-Level Access: Role-based security prevents unauthorized modifications to critical sealing temperatures or cutting speeds.

-

Electronic Records: Data can be exported for digital batch records, ensuring full traceability from raw foil to finished strip.

2. cGMP & Material Certification

-

Sanitary Design: All product contact parts are fabricated from AISI 316L stainless steel, featuring mirror-polished surfaces ($Ra < 0.4 \mu m$) to eliminate cross-contamination and facilitate easy cleaning.

-

Non-Toxic Substrates: All seals and gaskets are FDA-approved food-grade materials, resistant to the chemical interactions of high-potency drug formulations.

3. Professional Validation Services (FAT/SAT)

We provide a comprehensive "Validation Package" to simplify your commissioning process:

-

FAT (Factory Acceptance Test): Conducted at our facility before shipping to verify that the machine meets all technical specifications in your User Requirement Specification (URS).

-

SAT (Site Acceptance Test): Our engineers assist in the final installation and testing at your facility to ensure operational stability under local power and environmental conditions.

-

IQ/OQ/PQ Protocols: We provide detailed Installation, Operational, and Performance Qualification protocols to accelerate your regulatory approval cycle.

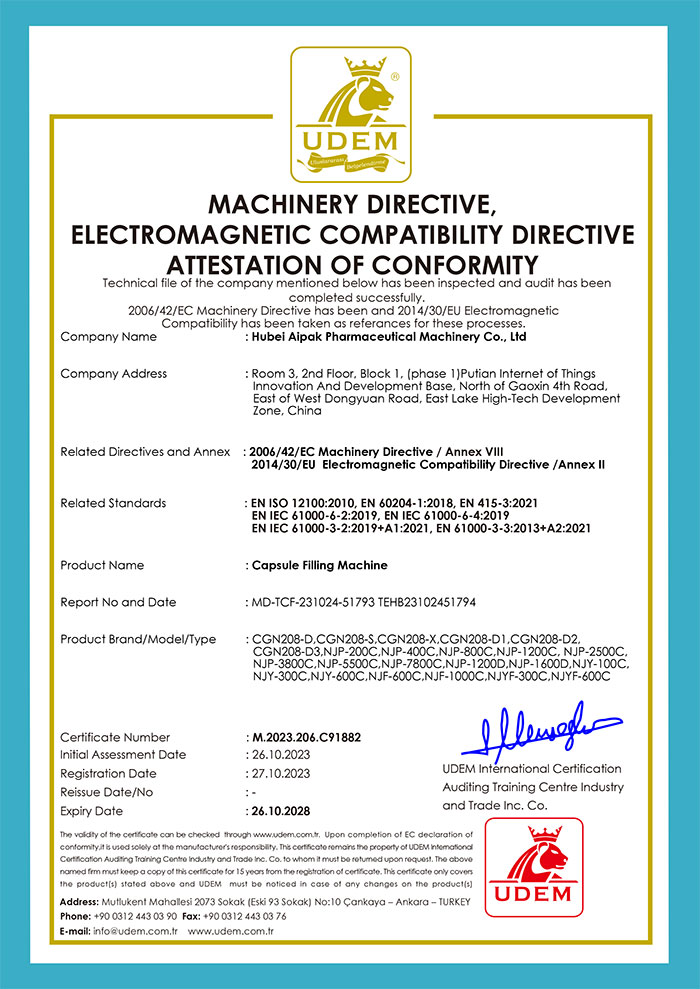

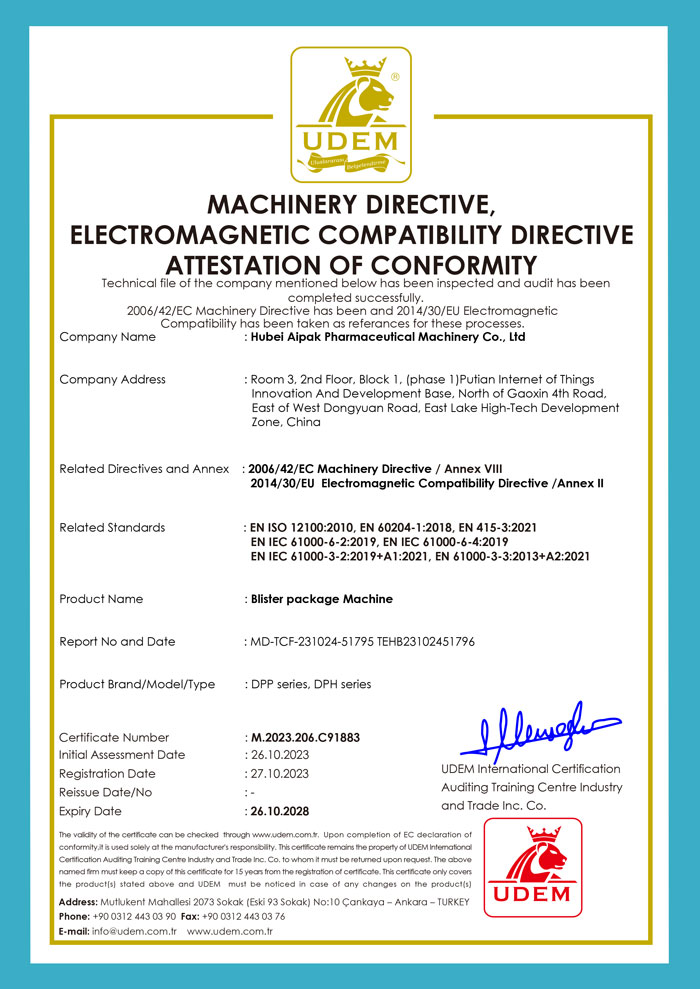

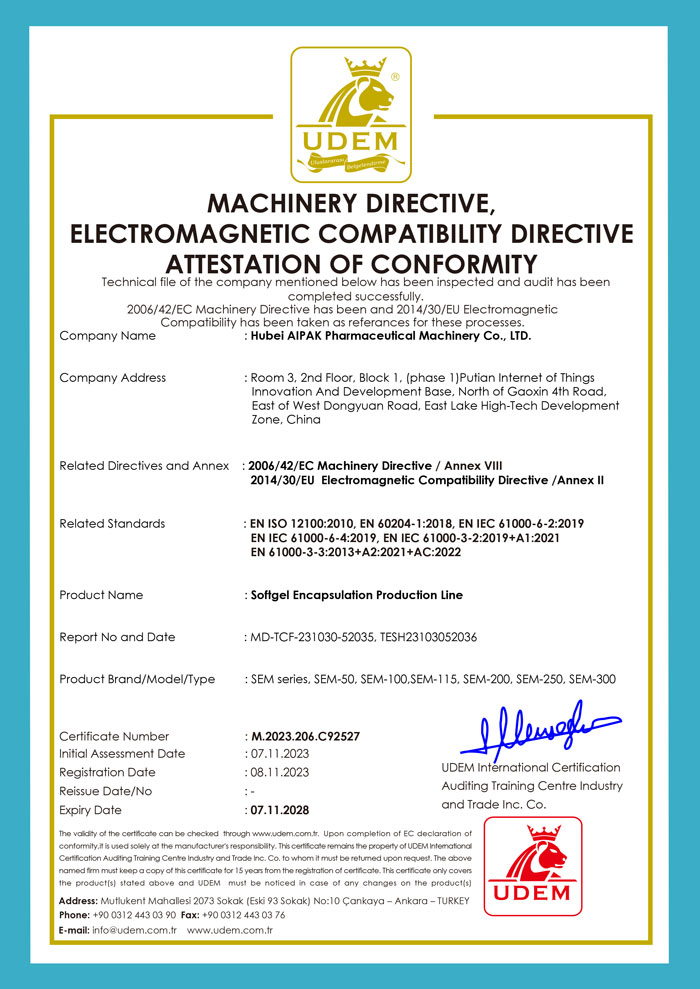

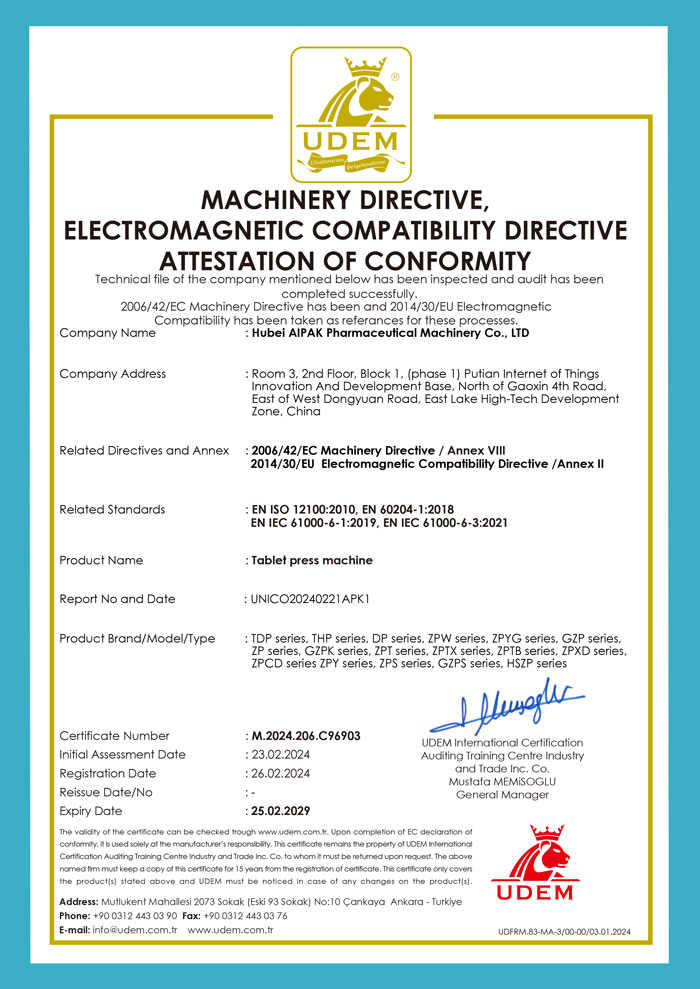

4. Global Certifications

-

CE Certification: Fully compliant with European safety, health, and environmental protection standards.

-

ISO 9001:2015: Adherence to international quality management systems for consistent manufacturing excellence.

Conclusion

Don’t let humidity or light compromise your product’s potency. Whether you need a standalone Automatic Strip Packing Machine or a complete cGMP-compliant production line, our engineers are ready to customize a high-barrier solution for your specific medications.

Strip Packing Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586