Oral Liquid Filling Machine:the Complete Comparison Guide in 2025

You are aiming to find the right machine for Oral Liquid filling different type of containers or you are finding it difficult to get precise filling in every bottle?

However, it is getting hard to find the right one that can meet your requirements.

Filling of oral liquid in the bottles with great stability and without wasting the product is very essential to make your production error free.

Here is the solution to all your problems to get rid of them and to get the perfect oral liquid filler for your production line. And in this guide I am going to explain about all aspects of oral liquid filling in bottles with the help of Oral Liquid Filling Machine.

The food and pharmaceutical industries are flourishing with the help of technology over the years. Many developing industries are using various machines in their everyday work for better outcomes. One of the leading appliances is a filling machine or filler, which has become a great help for such companies. Such fillers are helpful for food or beverage packing, but they are indispensable in pharmaceutical industries.

Packing industries are using several types of fillers. It is a little bit confusing to find an ideal machine for your specific purpose with so many choices out there. No matter if you are new to the world of oral liquid filling machines or an expert user. You might be searching to upgrade or replace your production line. Are you aiming to find the right machine for Oral Liquid filling different types of containers, or are you finding it difficult to get precise filling in every bottle?

However, it is getting hard to find the right one that can meet your requirements. Don't worry! This guide will cover all the aspects of oral liquid filling machines. You will get to know how to choose an oral liquid filler according to your needs.

You might need a machine that fills oral liquid in the bottles with great stability and less wastage in making your production error-free. Here is the solution to all your problems: getting rid of them and getting the perfect oral liquid filler for your production line. You can now quickly fill in the bottles without wasting the product. This guide identifies critical queries which will help you in narrowing down your search. Just focus on those approaches that meet your requirements.

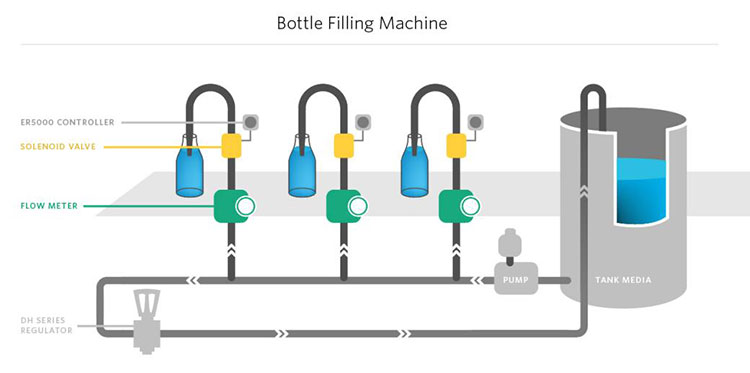

Q1. What Is an Oral Liquid Filling Machine?

Before getting into the complete guide, first, get to know about this machine.

AIPAK Oral Liquid Filling machine

The oral liquid filling machine packages the oral fluids finished products. In addition, it aids in the filling and sealing of various 2-25ml oral liquid bottles. Such machines fill up bottles or vials depending on the nature of the liquid. For instance, some oral drinks are foamy or creamy, and some are water-like. Bottles and other various types of containers are also useable such as cans, vials, tanks, and pouches, etc.

In an oral liquid filling production line, products go through many steps like spraying, cleaning, inflation, drying, cooling, and finally filling and capping. Bottles or containers move in a cycle, then get filled by this machine, and then go for the packaging.

Filling Machines always make your production easier and faster. They can fill up to 1,000 containers in less than a minute. You don't need to replace parts to adjust different-sized bottles. They are easy to control and work on the "No bottle-No Fill" principle. Thus, ensuring exceptional precision and fast delivery without liquid wastage. In addition, filling machines help in the packaging of the finished product.

Q2. How many kinds of Oral liquid fillers are there?

There are many kinds of oral liquid filling machines in the market. Each one of them has distant filling techniques. These features mainly depend on the type of container used and the properties of your desired product.

Production-Photo Credit: perwin

Keep on reading to know the primary difference between different filling machines. Following are some types based on filling, application, and design.

Based on Filling Technique

Some fill to a level, while others fill by volume. Most of the time, both these techniques will work for the same products. However, both give different benefits for packagers, but outsiders will not comprehend them easily. People who are not familiar with filling machines will only look at the appearance of bottles rather than their volume.

1. Volumetric Fillers

Volumetric Filler Machine-Photo Credit: indiamart

They fill the bottles with the accurate volume and not by level. Therefore, each bottle may not look the same due to variations in interior container volumes. It can be noticeable when inconsistent levels of the product are added from bottle to bottle. It can become an issue in clear containers. They include Gravity-fed filer, piston, and pump fillers.

However, their capability to fill different viscous products from water to heavy oils makes them unique. They apply to any container and work at high speed. But they are a bit expensive for small-scale industries.

2. Fill To Level Fillers

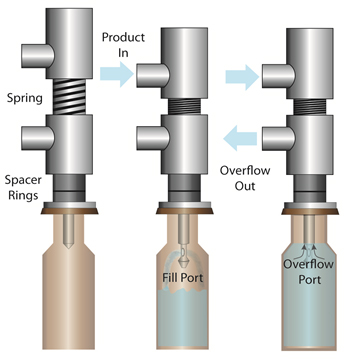

They focus on equal levels of oral liquids in all the containers. This method is cost-effective and results in an attractive appearance. Most liquid-level machines include pressure overflow fillers.

Filling Level-Photo Credit: allthingsfillchain

Overflow fillers fill at a fast rate and can handle low and medium viscous liquids. In case of any remaining product in the filling tubes, it is forced back into the tank. Therefore, ensuring no fluid overflow and spillage.

Based on Application

Following are the types of oral fillers on their working principle and application.

1. Overflow Fillers

They work on the fill-level principle that requires constant fill levels.

Overflow fillers use a nozzle that permits a level on each container. As soon as the liquid reaches its degree in the container, it overflows and returns to supply. Thus, they are ideal for filling lower viscous liquids in transparent containers.

2. Net Weight Fillers

Net weight machines use a weight scale to have consistent fill levels. Both automated and semi-automated types are applicable. They monitor the weight of the liquid as it is filled into the bottle. A bulk supply tank load the products. The accuracy of weighing and filling liquid is 5-30 kg. Each container has pre-set weight.

Net Weight Filling Machines-Photo Credit: buschmachinery

They can package black printer ink, precious perfumes, and valuable drugs like insulin. Specifically, products sold with weight labels in gallons are fillable. These fillers are suitable for bulk container filling uses. However, they are not helpful for small containers. Take a more prolonged time comparative to other fillers.

3. Gravity Fillers

They work on the volumetric filling principle. Filler Operational settings are pre-entered on the touch screen panel. Moreover, each pneumatic valve is timed to fill the bottle accurately. In such fillers, the force of gravity assists in packaging products.

Automatic Gravity Filler Machine-Photo Credit: indiamart

Gravity Fillers work with a time-based system. They have a tank above the filling heads to supply liquids. It is kept above to allow gravity to assist in the procedure. When the container is under the filling heads, the valve opens, and it will supply the container with the given pre-defined amount. The valves will close after their pre-fixed time and cut off the supply.

It is one of the most cost-effective machines among all other filling machines. Single heads, as well as multi-heads, can function well once the system is balanced. They are appropriate for liquids thin viscosity like water. However, they fill a limited range of products only.

4. Piston Fillers

Piston Fillers-Photo Credit: romaco

They work according to the volumetric filling technique. Check-valve piston and rotary piston fillers are used commonly. They can handle thicker products such as batters, pastes, and aerated fluids.

Piston fillers contain pistons and cylinders for more precise volumetric filling. They can function with many different-sized cylinders. When the piston pulls out of the cylinder, the oral liquid gets transferred in it. Now when the cylinder is complete, the piston again enters it. Thus, pushing the product to enter into the bottles.

The reason why it is more desirable than the pump fillers is that it also handles granular products. However, they take a longer time to execute the changeover and cleaning.

5. Pump Fillers

Pump Fillers-Photo Credit: youtube

They work using the volumetric principle rather than relying on gravity. Rotor, lobe, and gear pumps are various types of pumps.

Pump fillers pass the product into the waiting bottles using different pumps. They also offer customization fillings such as pulse and time-based fills. Time-based fills allow the pumping of products in bottles for a pre-fixed time. For more accurate fills, adjust each fill head individually. For example, in Pulse-based fillers, a pulse may include an entire or half turn of the gear with a gear pump. This volume allows a bit better volumetric accuracy over the time-based fill.

The pumps give an extra boost in moving the liquids. Moreover, versatility makes them suitable for filling a wide range of drinks. Thus, they are helpful for thick fluids, and the content of fill volumes is more excellent.

Based on Design

Apart from application and filling techniques, oral liquid filling machines are available based on designs.

1. Semi-Automated Fillers

Semi-Automatic Filling Machine-Photo Credit: pharmamchinery

They work way faster than manual filling machines. Unique functional parts include nozzle, syringe, and piston. All these components guarantee the maintenance of zero-drip operation.

They are best for small and medium-scale production lines. A partially manual filling is required able. You need to arrange vessels before the filling procedure. Moreover, some machines lack labeling features. You have to fix the labels by human labor.

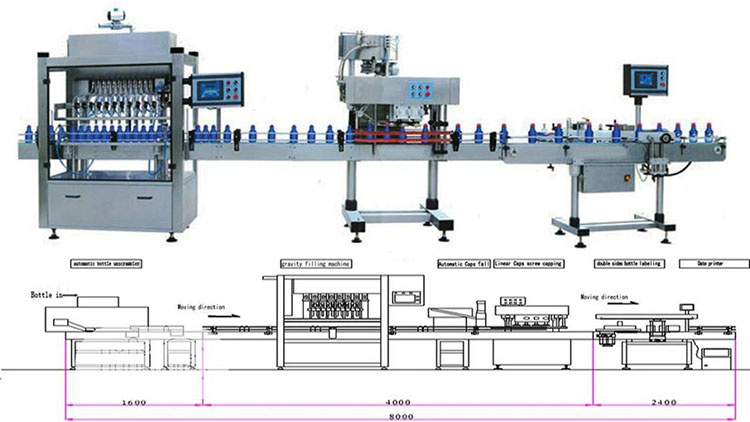

2. Fully Automated Fillers

Such machines are in demand for a large-scale production line. They also replace the need for human labor. Consider automated timing and fill rate settings before filling. Then the only job is to monitor the process. They can handle liquids will all viscosity.

Fully Automatic oral liquid Filling Machine

Fewer chances of leakages are there because they can fix the best sizes of syringes. They also have automatic speed and conveyor adjustments. Nevertheless, the addition of more filling heads boosts the production rate. After filling, such machines also provide capping and labeling of oral liquids.

All the operations are easy and reliable. However, with so much versatility, they are relatively costly.

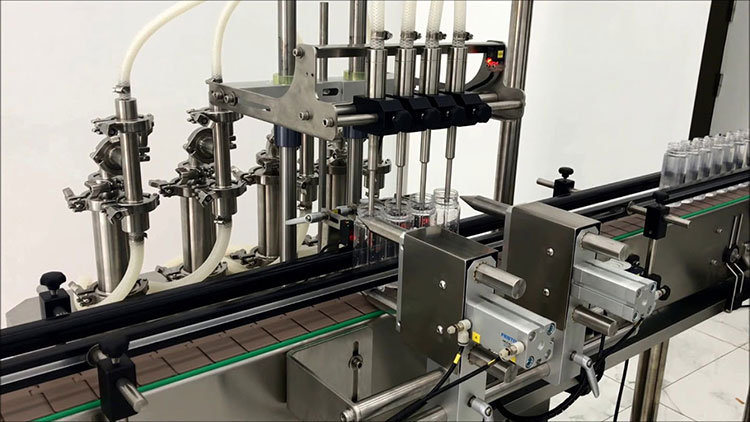

3. In-Line Fillers

In-line filling machines are best for filling containers in a line. All types of liquids in containers arrange into a single line over the conveyor belt. Their in-line filling feature makes them suitable for different-sized containers. Some models are customizable with additional filling heads as per the buyer's choice. Food and dairy products can be filled this way. Other than oral liquids, these machines are also valuable for cosmetics products.

In-Line oral Filler Machine

Appropriate for small and medium scale operations; however, not suitable for large scale production.

4. Rotary Fillers

Containers or bottles move along different circular stations. Each performs a specific function like filling, sealing, and capping. They are much larger and work at high speeds.

Such machines have vast applications in the food, oil, and beverage industries.

Rotatory Fillers-Photo Credit: sapli

Q3. What are the different benefits of Oral Liquid Filling Machine?

Using oral liquid filling machines will give you a lot of potential benefits. Some of them are listed below.

1. Easy To Use

Most oral liquid fillers are easy to operate. They have a simple operator network. The option of a Touch screen in these interfaces makes it easy for users. Even if you are inexperienced in filling machines, you can still operate them without any training. Just learn about different amounts and times to complete one cycle. When you enter these numbers, a recipe screen makes way for the data to be preserved. Thus, you can enter the recipe number on the interface quickly.

The only remaining job you have to perform is monitoring the process.

2. Consistent Fills

One of the main benefits of using an oral liquid filling machine is consistency and reliability. It gives safe and steady fills without wasting the product. You cannot achieve this functionality by hand filling—no uncertainties from the filling process. Therefore, filling machines have become a necessity in industries.

Safe, reliable, and consistent fillings are what your production line needs.

Consistent fills-Photo Credit: indiamart

3. Offers Versatility

You cannot just fill oral liquids of one type but more than one type. Many kinds of materials other than syrups and drugs are also packaged. Such materials include juice, floral water, vinegar, cooking oils and soybean sauce, etc. Manufacturers use multiple liquid products depending on their viscosity for filling. You can handle various bottles for a single or multiple products.

Oral liquid filling machines come in various types. These include twin-head liquid filler machine, four head liquid filling machine, six head liquid filling machine, eight head liquid filling machine, liquid filling machine for vials, liquid filler machine for bottles, electronic liquid filling machine, a liquid filling machine with capping feature, and liquid filling with rubber stoppering machine.

Such machines also offer versatility in packaging. Packaging is an essential part of a successful business. Undoubtedly, it is one of the most crucial factors in product selling. Designs are customizable, i.e., both glass and plastic bottles are applicable. They are suitable to wrap up all kinds of oral liquids in a specific style.

4. Adjustable

They are adjustable. You can adjust timings, amounts, speed, and filling capacity depending on the product's requirements. You can also change the speed of operation to slow (manual), semi-automatic, or fast (fully automatic). Start the machine and make your necessary manual adjustments.

Many oral liquid fillers come with adjustments for shifting from one type of bottle to other. They also work on the "no bottle, no fill" mechanism. Isn't it amazing?

5. Convenient Repairment

Don't worry if your machine needs repair. You don't need any professional repairmen from a foreign country because they are easy to repair. Anyone who knows about filling and packaging machines can repair broken parts. It saves time and lessens troubles.

6. Higher Speed

When working in a vast production line, your pace should be faster. Manual labor may not be sufficient for greater production in a given time. So, you might need a reliable filling machine for your oral liquids. For better results, you can do some modifications like multiple heads, capping, and labeling features.

With oral liquid filling machines, you can attain more bottles filled in a minute.

7. Cost-Effective

They are cost-effective and affordable for large-scale industries. You can achieve more large filling at a lower price with the help of these oral liquid filling machines.

Q4. What are the drawbacks of Oral Liquid Filling Machine?

Besides advantages, oral liquid filling machines also have some disadvantages.

1. Not valid for solid Products

Bottling and filling machines come in different varieties. No doubt that some are perfect to package liquid products. But they might not work for solid products. If your company packages both solid and liquid products, you will have to get two different machines. So, it can be challenging for many industries.

2. Requires some extent of expertise

Oral liquid filling machines are although easy to operate. But just like any other industrial machinery, it also requires some level of expertise. You should know how to manage it technically. Train your employees to avoid any negligence because any doubts and uncertainties can lead to prominent losses.

3. Needs additional care

Keep Machines in Good working Condition-Photo Credit: m&operry

These machines are helpful, but they also require intensive care. So you can't take them lightly as a slight negligence can lead to big troubles.

Here are some common problems that can affect the working of liquid filling machines.

- Insufficient seals can lead to foaming and dripping problems. It can waste oral liquids and result in tremendous loss of product over time.

- Imprecise Filling levels and Timings can result in product wastage. Therefore, you need to check operational settings timely to avoid such troubles.

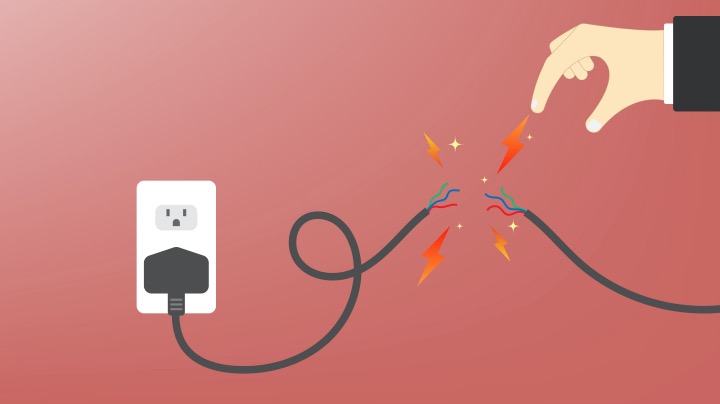

- Power surges can be another factor for the loss of productivity. Since it causes a complete breakdown in your production line, it will lead to product spoilage.

Work carefully to avoid such complications.

4. Expensive

Oral liquid filling machines are never cheap, especially for small-scale industries. Their price varies depending on the type of oral fillers.

You need to spend more on devices with more features and specifications. They are expensive in terms of power consumption and purchase.

Q5. What is the purpose of Oral Liquid Filling Machine?

The main goal of filling machines is to produce a maximum yield in less time. They ensure the packaging of liquids without wastage. If filing and capping are done manually, then industries would be at a loss. A lot of time, money, and product would be wasted due to spoilage. Such machines require less manual labor, so they work efficiently. They are not only valid for packaging oral liquids but can fill any liquid. They are perfect for bulk packaging applications.

Q6. Can you fill different size of bottles with same type of Oral Liquid Filling Machine?

Yes, you heard it right!

Different size of Bottles

You can fill the different sizes of bottles with the same type of oral liquid filler. It is one of the salient features that has increased its demand in the market. They are compatible with wrapping free-flowing liquids in different containers like vials, bottles, and ampoules. Its versatility makes this possible. In automatic oral filling machines, you can adjust the conveyor to accommodate bottles of various sizes. Fix the operational settings to ensure preciseness for the packaging of different liquids.

Consult with a trusted manufacturer and choose the type that suits well for your business needs.

Q7.Explain the working principle of Oral Liquid Filling Machine?

Working Principle-Photo Credit: jiji

The working principle of the oral liquid filling machine is similar to liquid fillers, but the machinery is different. Oral Liquid appliance needs bigger pump whereas eye drop fillers need a small and more accurate pump.

In the automatic production line, the bottles pass through a power conveyor system to the filling station. Here, a filling nozzle supplies the oral liquid product present in the hopper to the container. Different types of machines have other working principles such as fillers work by gravity, atmospheric pressure, and weight scale.

Here are the steps involved in the working of oral liquid filling.

1. Power Transmission

First, the motor transfers the power to the worm wheel via the lifter. Then this worm wheel passes the control to the dial shift, the filling part, and the rolling head through the gears. They all work synchronously, and the force gives to the bottle injecting gadget via bevel gear.

2. Filling Part

Filling Part-Photo Credit: edibleoil

A large dial wheel sends these oral liquid bottles to the transition wheel. Here, it further moves them to the timing belt to run ahead at a constant speed. The needle in the bottle mouth runs additionally for tracking filling synchronously. The filling needles give an anti-foaming effect and rise as the liquid level rises.

3. Covering Mechanism

This system consists of a cover rail, cover head, and cover mechanism. It works on the principle of electromagnetic spiral vibration.

4. Rolling Head

Here, the oral liquid bottle shifts into the rolling head turntable. Here the rolling knives centered on the bottle open. They rotate with the turntable forwardly, pressing the lid. By taper sleeves, they undergo rolling. Then they leave the cap and go back to the original position.

Most of the oral liquid fillers work in higher pressure. As in pressure filling, the oral liquid flows into the bottle according to its weight. It happens when the fluid storage pressure becomes equal to the atmospheric pressure of the bottle. Automatic fillers are easy to operate, and they fill the exact amount of liquid into containers. One function is to automatically stop the filling procedure when there is no bottle available on the conveyor.

Head of automatic Filling Machine-Photo credit: edibleoil

Different Categories of Oral Fillers Based On Working Principle

You can further divide Oral liquid fillers into the ordinary filling machine, pressure filling machine, and vacuum filling machine.

The ordinary oral liquid Filling machine works on the principle of gravity. The oral liquid fills due to its weight into particular bottles. You need to observe special needs to maintain the viscosity and gas bearing of the fluids. Examples are milk bottles and grapevines.

In Vacuum oral liquid filling machine, the atmospheric pressure is higher than the air pressure in the bottles. Also, it works excellent for liquids with high viscosity, such as syrup, oil, and wine.

Pressure oral liquid filling machines require higher or equal pressure than atmospheric pressure. In Equal pressure filling, the oral fluid storage pressure gets equal to the bottle pressure. Therefore, the liquid flows by its weight. On the other hand, higher pressure filling machine operates by the pressure difference.

Q8. What are the other liquid fillers along with Oral Liquid Filling Machine present in market?

Oral liquid fillers are helpful for many kinds of edible liquids. But other than oral liquid fillers, there are many more liquid filling machines, primarily for chemical packaging lines. Such fillers are helpful for chemical products like cleaning supplies, acid, corrosive products, paints, industrial and agricultural chemicals, cosmetic products and petroleum products, etc. They have unique capabilities to handle safely and package chemical products. Some fillers other than oral fillers are:

· Corrosive Fillers

Corrosive Products Filler-Photo credit: automationworld

These filling machines are designed to operate in highly corrosive surroundings. They are built using HDPE. Typical filling machines don't have proper filling processes for chemicals. So, acidic and other corrosive liquids can damage the machinery over time. Specialized corrosive fillers efficiently resolve these issues.

· Molten Fillers

Molten Fillers-Photo Credit: apacks

They use molten products such as candles. When filling candles, they need to be heated during packaging. Otherwise, candles become hard as they cool down. Therefore, molten filling machines help handle high-temperature fluids with risks.

· Eye Drop Fillers

AIPAK Eye Drop filling Machine

They have wide applications in the food, cosmetic, oil, and pharmaceutical industries. They are notable for various round-shaped and flat bottles.

· Isobaric Filler

These filling machines are used to fill carbonated drinks. Filling liquids include beer bottles, soft drinks, cider, and sparkling wine.

Isobaric filler-Photo Credit: lematec

Q9. How many working parts are there in Oral Liquid Filling Machine?

The different machine has their components. Their number and features depend on the model of the machine. Below are some of the main parts of liquid filling machines.

- The Cork collection tray is the point where the product for packaging is filled.

- The corking unit places the lids or caps for already filled containers.

- The command button panel is a touch screen for the human interface. Users give instructions through it.

- The bottle support tray holds the bottles in the intended positions.

- The start pedal is for starting the machine. This component is used to start the motor.

- Pivot wheels move the machinery in specific positions.

- A liquid collection tank holds oral liquids for filling.

- The filler tap has a nozzle that feeds the products into the bottles.

- The Inlet solenoid valve helps to regulate the flow into the filler taps. They are also used to prevent backflows.

- Tray lifting pneumatic cylinders keep the bottle support trays in position. It is also known as a corking area.

Q10. How accurate & precise filling is done with the help of Oral Liquid Filling Machine?

Along with other industries, the pharmaceutical industry also makes use of oral liquid fillers. Packaging with precision is essential when handling pharmaceutical products. User-friendly packaging makes it easier for users to drive these products carefully. The nature of medicines and different types of containers are necessary to consider. In this way, the filling is done correctly.

Use of Oral Filling Machine-Photo Credit: pharmaceuticalonline

Here are some uses of oral liquid filling machines in the pharmaceutical field.

- They ensure efficiency and high accuracy in filling liquid drugs. In addition, the correct quantity helps in efficacious administration.

- Pharmaceutical industries have to meet good hygiene standards. Such reliable machines are easy to clean, thus no contamination of medicines. In manual filling, human contact is maximum which can affect the product. They also minimize wastage and spoilage.

- Filling machines ensure tight capping, which conceals the drug. They also come with a labeling feature. Labeling prescription is crucial for all medical products.

- Oral liquid filling machines ensure optimal performance for each type of product. Each syrup and other liquid products vary in viscosity. Dental gels, cough syrups, and thick creamy medicines are also fillable.

Vial and Ampoule Fillings

Vial and Ampoule Filling-Photo Credit: cphlonline

There are different filling machines such as vial filling, tube filling, syringe filling machines, etc. They have several applications in the pharmaceutical field. For example, you may require a vial filling machine to fill the liquid medicines in a vial or ampoule. Filling in vials and ampoules with defined medical content is in great demand. Vial filling is essential when filling bottles with distinctly measured quantities.

Q11. What is the cost of Oral Liquid Filling Machine?

Probably there are many types of oral liquid fillers, but it's hard to choose the right one. There are certain essential considerations to be made to accomplish bulk liquid filling tasks. Right machinery will bring more profits for your business. First of all, list down all your requirements and your budget. Then look for the machines which have the facility to fill a vast range of liquid volumes. Desired customizations and optional features can be according to the buyer's choice.

There are many factors you need to consider when buying suitable oral liquid filling machines.

Q12. How to maintain Oral Liquid Filling Machine?

Like any other industrial machinery, oral liquid filling machines are also at risk of a potential breakdown. Every machinery requires maintenance. You should pay attention to its safety and cleanliness. Along with hygiene, there are other malfunctions to address. They are essential in the proper functioning of equipment. If they are not checked, they can hinder your entire filling line.

1. Examine Foaming Problems

You need to examine foaming and dripping problems thoroughly. Such situations occur due to insufficient seals. Tightening the seals is the best preventable measure. The use of a diving nozzle can also resolve foaming issues. Make sure that valves do not leak during or after the filling process.

If such problems are not checked carefully, they can waste products and lead to significant losses.

2. Ensure Accuracy

It is necessary to ensure accuracy to keep your machines in good condition. Incorrect filling levels can cause overflowing or insufficient filling of bottles. It is due to a bad seal. Tightening of seals might not work, so replace them. Inaccurate timings can be maintained by changing the operational settings of the machine.

Implementing safety measures on air hoses or other loose parts can help you avoid problems.

3. Keep Checking Power Problems

Inadequate power is not relatable to the equipment. However, it is vital to check power problems in your space. Power surges can cause a breakdown that results in loss of product. Your machine will work more efficiently in enough supply of power.

4. Regular Check and Balance

One of the fundamental ways is to perform regular preventive maintenance checks. So that you will be aware of any defective or malfunctioning parts of the machine. You will dig deeper into the problems that require your attention. In the case of uncertainty, consult the manufacturer or expert to monitor the filler's condition.

Develop a maintenance schedule regularly to prevent any loss.

Q13. What is the use of Oral Liquid Filling Machine in pharmaceutical field?

1. Level of Automation

Oral liquid filling machines come with different levels of automation. Therefore, it's ultimately the buyer's choice whether he opts for automatic or semi-automatic fillers.

Automatic filling machines will provide more packaging fewer times. There is very little human labor, high accuracy, and versatility. Products are safe from contamination since human contact is minimal. In contrast, semi-automatic filling machines require comparatively more human work and a bit longer time. Semi-automatic means partially manual. You need laborers to arrange the vessels before filling. They also lack a labeling feature; fix the labels manually.

Working Accuracy-Photo Credit: emerson

2. The viscosity of Oral Liquids

What is viscosity? It means the ability of the oral liquids to flow freely. Each oral fluids have different viscosities. For instance, water has a thin consistency and shows less resistance in flowing. Thick or high viscous liquids don't move freely, for example, honey.

Each oral liquid requires a different type of filling machine. Therefore, identifying the correct one according to your product is the first thing to consider.

- Low Viscous Oral Products

Low Viscosity Product-Photo Credit: cultbeauty

Oral liquids which flow quickly require overflow fillers and Gravity Fillers. They work appropriately for frothy or low-viscous oral liquids such as water, vinegar, and syrups. Gravity fillers find their use in food processing companies to fill alcohols, milk, juice, and soda. Other than oral liquids, ink and paints can be served.

- High Viscous Oral Products

Such oral liquids require pump and piston fillers for packaging. Pump fillers and rotary piston fillers are special for very thick products requiring extra speed to move. Piston fillers are ideal for creamy and chunky products. Other than oral liquids, they are also valuable for packaging cosmetics creams, waxes adhesive, heavy shampoo gels, and heavy oils.

3. Filling Rate

Another important determinant is the number of filled bottles per hour.

In semi-automatic oral fillers, the filling completes at a slower rate. Manual labor is required for bottle replacement and then removing the filled ones. In comparison, automatic filling machines package oral liquids at higher speeds.

If your machine is willing to fill more bottles per minute, you will reach your production demands faster.

4. Capability for Different Volumes of the Liquid

Fill volume determines the level at which your vessel fills. You have to choose whether you want liquid level filling machines or Volumetric filling machines.

Liquid level fillers concern the level of oral liquid on the container. The nozzle allows the fluids to enter a bottle until they reach the desired level. They ensure no overflowing and keep the fill at the same level when the cycle is completed. It is helpful for clear containers. You must prefer them if uniformity is essential.

Accurate in Every Bottle-Photo credit: indiamart

Volumetric filling machines are concerned with an accurate volume of liquid in each container. The need for additional instruments for timing, calibration, and balance makes them relatively expensive.

Not everyone knows about filling techniques. The fluid may appear at different levels due to inconsistencies in the volumes. Imagine bottles each on the shelf with different liquid levels in a grocery store. Although the quantity is the same, the customer will prefer a high-filled bottle because customers don't understand this technique and think they are cheated.

It's your choice whether you would like the bottle's volume in the bottle to be the same or whether all containers need to LOOK the same.

5. Type of Container

The kind of bottle or container being used is also an essential factor to consider. For clear containers, overflow fillers are a good choice. They fill each bottle to the same level irrespective of small variability in the inside volume of the container.

Another thing to know is the material you are using. Commonly used materials are glass, plastic, and aluminum. Each of them requires a different filling technique.

6. Shape of Container

The Size and shape of the container also influence the choice of nozzle and machine in packaging. If your container is wide, don't go for the fillers that grip from the side of the bottles. If the container does not have a standard lid, then automatic oral fillers are not appropriate. It is because they grab bottles from the top.

Shape of Container-Photo Credit: apex

Q14. What you should remember when buying Oral Liquid Filling Machine?

- Consider the process execution and time interval of filling in one cycle.

- The flexibility of machines and Cost-effectiveness help in the selection.

- The Size of your working space also determines the choice of machine.

- Your growth prospects, current budget, and future products also give you the correct solution.

- The amount of fluid and its properties are other fundamental aspects.

- Always look for companies that have guaranteed equipment and after-sales services.

- Look for the advanced technology in machines. A little research is always fruitful.

- Along with all these factors, remember that purchasing from the best supplier is also essential. Always describe your product and container details. Your provider can only help you choose the best machine.

Q15. What type of liquids can be filled in bottles using Oral Liquid Filling Machine?

One of the best properties of this machine is to fill different kinds of liquids in a bottle. All fluids are not the same. Liquids can differ in viscosity and nature. It can be volatile or non-volatile, paste or foam, stable or unstable, and explosive or not explosive. Some liquids are free-floating, whereas some don't flow easily. They may also change when the temperature changes. Herbal supplements are also packaged using oral liquid filling machines.

Liquids-Photo Credit: firesafe

Level filling machines find their uses in filling syrups, water, light gels, sauces, vinegar, and medicines.

Volumetric filling machines are helpful to package milk, glycerin, wine, juice, cooking oils, and high viscous syrups.

Q16. What are the manufacturing standards that Oral Liquid Filling Machine must fulfill?

Some quality standards need to be fulfilled by manufacturers. These standards are internationally recognized. Purchase high-quality filling machines that adhere to the following criteria.

- Food and Drug Administration Quality Standards (FDA)

- International Standards Organization Quality Standards (ISO)

- Current Good Manufacturing Practices (cGMP) Quality Standards

- CE Quality Standards for the Electronic Applications

Final Words

Oral liquid filling machines are in demand with the increasing days. They have become essential for every large and small production line. A lot of potential benefits and their versatility make them the best equipment. The ability to fill every large or small and low-viscous or high-viscous liquid product enhances success. Be it a carbonated drink or medicinal drug; these machines will help you in packaging.

They are the primary growth enhancers in the food, beverage, dairy, oil, and pharmaceutical industries. Engineers have designed such machines after constant research. They have manufactured them with the perspective of future growth. Thus, these latest technology-based filling machines are available to you after many efforts. Your job is to maintain them regularly.

Each type has its features depending on the nature of the product. You need to figure out the best option for your production line. Ensure your budget, floor space, and other described factors when buying. Remember that a suitable machine will guarantee you are meeting your production targets.

A lot of choices are available in the market. Pick wisely!

E-liquid Filling Machine Related Products

E-liquid Filling Machine Related Posts

E-liquid Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine