Hydroeye Softgels Making Machine: The Complete FAQ Guide In 2025

Are you familiar with the term Hydroeye Softgels? Or hearing it for the first time? In any case, you must be engaged in the production of softgel capsules. If so, the need for a Hydroeye Softgels Making Machine is no exception!

This machine is highly specialized in making all kinds of softgels especially hydroeye softgels. Its advanced structure, innovative technology, and convenient operation have made it a must have equipment in pharmaceutical field. You can take the best advantage of a Hydroeye Softgels Making Machine by going through all the relevant information provided in this detailed FAQ guide. So, let's start to explore it!

1.What Is A Hydroeye Softgels Making Machine?

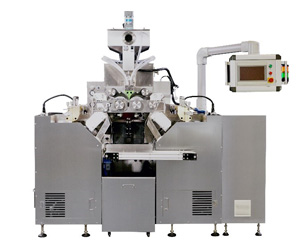

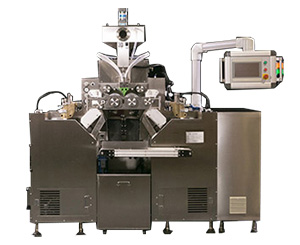

Aipak SEM-200C softgel encapsulation machine

Hydroeye softgels refer to the capsules which are used to treat dry eyes. These are nutritional supplements containing essential vitamins, fatty acids, and antioxidants aiming at comforting eyes. These capsules consist of a shell and inside liquid. The machine used for their manufacturing is called hydroeye softgels making machine.

It is an automatic machine tailored with innovative features to carry out the encapsulation of hydroeye softgels. The machine has electromechanical working mechanism that form the shell, fill precise dosage amount, and create a hermetic seal. It ensures production efficiency, quality retention, and consistency throughout the operation.

2.Explain The Advantages Of A Hydroeye Softgels Making Machine?

Are you waiting to know how can a hydroeye softgels making machine be beneficial for you? Then let us provide a detailed list of the potential advantages of this machine which makes it a must have equipment for softgels encapsulation. From high production efficiency to precision and flexibility, all are explained below:

Production Efficiency

Abundant of softgels- Picture Courtesy: Willings Nutraceutical

One of the primary benefits of a hydroeye softgels making machine is its high automation that has made it possible for manufacturers to produce high amount of softgels in short time. It in turn increase the output that leads to increased revenue.

High Accuracy

Softgels falling from bottle onto a human hand- Picture Courtesy: Vitalpax

Another significant advantage of the machine is high accuracy and precision which is of paramount importance in pharmaceutical industry. It is capable of dispensing accurate amount of hydroeye formulation into each capsule and seals them tightly. Therefore, every produced capsule is consistently finished that shows high quality.

Flexibility

Various shapes of softgels- Picture Courtesy: chemtech-us.com

Most of the manufacturers believe that having one machine for multiple tasks is the best choice. In that case, hydroeye softgels making machine offers greater customization as compared to manual filling methods. For instance, the machine can fill different substances such as liquid, powders, and granules. It may also be integrated with other machines for efficient performance.

Convenience

Convenience is the foremost attribute of a hydroeye softgels making machine both in terms of operation and maintenance. The machine has intuitive touch screen interface that display over it information and is easy to use. Similarly, it requires minimum maintenance on regular basis due to its automatic functioning.

Cost Effective

Low cost icon- Picture Courtesy: ahcaccounting.com

The machine is highly reliable for several reasons among which its cost-effectiveness is the major one. Unlike manual filling methods, it requires low labor force, less working area, and have filling zero error. Ultimately, you just need to pay for the machine and other expenses are reduced.

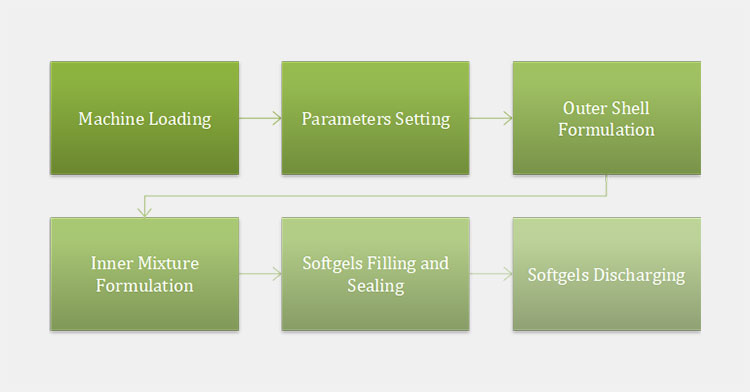

3.Write Down The Working Principles Of A Hydroeye Softgels Making Machine?

The working principles of a hydroeye softgels making machine involves several steps upon which the machine function and make softgels. We have tried to make these working principles easy to understand. So, let's explore in the upcoming paragraphs!

Machine Loading

The very first step include loading the adequate amount of required material into the machine. These substances include ingredients for outer shell and inner filling mixture. The ingredients for former including gelatin, water, glycerin, preservatives, and pigments are loaded into the melting tank, while as, active pharmaceutical ingredients along with excipients are loaded into the preparation tank.

Parameters Setting

Pharmacist setting machine parameters- Picture Courtesy: Technophar

Now, after the required ingredients are loaded into the respective units, it is time for parameters setting. At this point of hydroeye softgels making, operator shall use the control panel and fix mixing time and temperature for formulation preparation. Similarly, the amount of liquid to be filled in each capsule is also fixed at this stage.

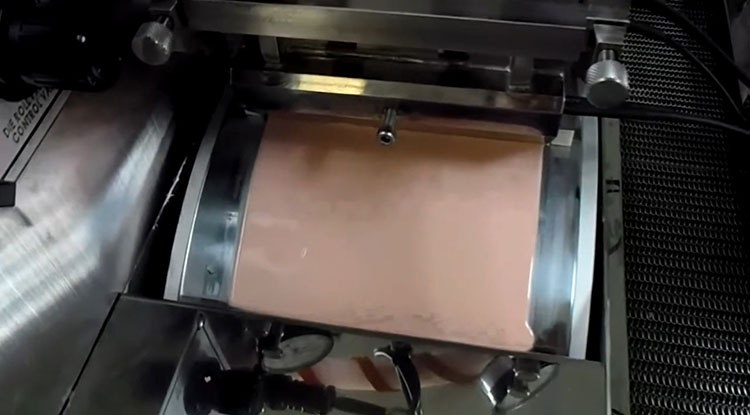

Outer Shell Formulation

Outer gelatin shell formulation- Picture Courtesy: fenixcoge

Once the setting of machine gets done, it is ready to begin forming outer shell for softgels. For this, all the ingredients are thoroughly mixed and boiled under controlled temperature. The prepared mixture is then moved to gelatin box with the help of pressure device.

Inner Mixture Formulation

Inner mixture formulation- Picture Courtesy: Aipak

This step involves the preparation of liquid filling mixture that goes side by side with outer shell formulation. Here, the active ingredients together with excipients are turned into a standard solution which is then used for softgels filling.

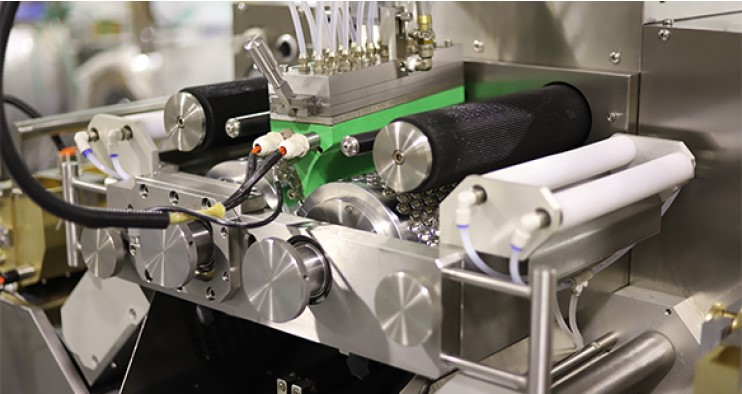

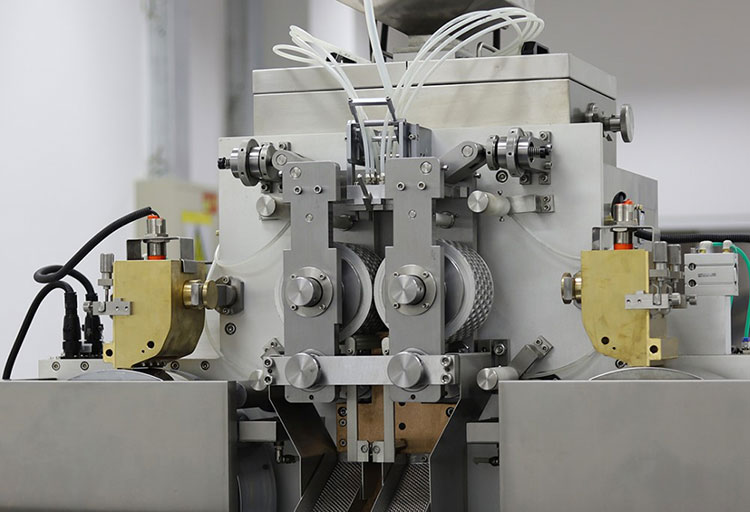

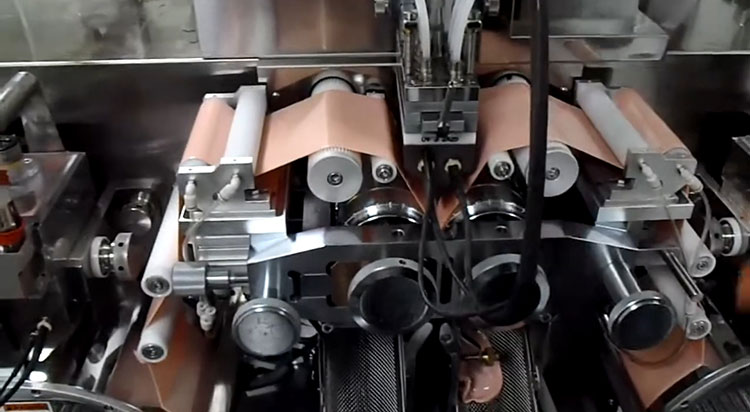

Softgels Filling and Sealing

Softgels filling and Sealing- Picture Courtesy: fenixcoge

Moving forward, softgels filling and sealing is a critical step where the formulations turned to finished capsules. It takes places when the gelatin liquid is coated on the rolling mold which is then cooled to make gel film. The continuous rotation of rolling mold forms the outer shell of softgels and liquid formula is introduced into it. Similarly, the filled hydroeye softgels are sealed tightly.

Softgels Discharging

Softgels discharging- Picture Courtesy: Aipak

Now, finished hydroeye softgels keep discharging from the machine which are collected into a container. These hydroeye softgels are then dried, polished, and packed into bottles and blister packs.

4.Describe The Structure Of A Hydroeye Softgels Making Machine?

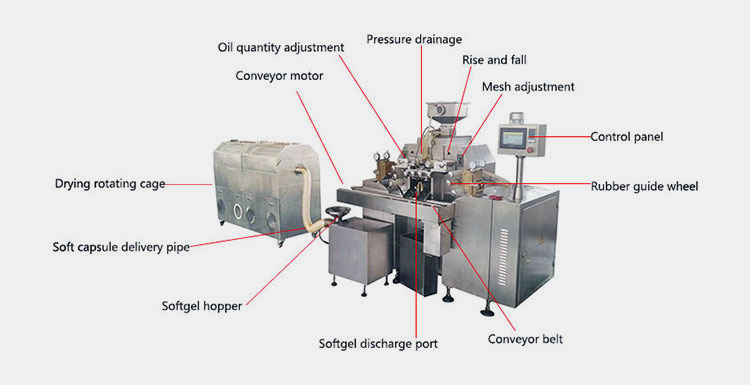

Hydroeye softgels making machine is composed of several components which together enable the machine to function properly. These parts are described below:

Control Panel

Control panel is the brain of the machine where machine functioning related setting is done. It consists of knobs and a touch screen that display over it multiple information regarding the temperature, speed, and filling amount of hydroeye softgels. It is user-friendly and can store multiple settings.

Rubber Guide Wheel

Rubber guide wheels are various in numbers. These wheels are present on both sides of the encapsulation unit. The main function of rubber guide wheels is to guide the gel film perform its unwinding towards rolling mold.

Conveyor Belt

Conveyor belt is situated below the working area. It is used to take the finished hydroeye softgels and convey them towards softgel hopper.

Conveyor Motor

Conveyor is located near to the conveyor belt. It is used to regulate the movement of conveyor belt such as its speed.

Mesh Adjustment

It refers to the tool that is used to adjust the gelatin mesh which is the remaining gel film that is left after softgels are formed.

Pressure Drainage

Pressure drainage is a device used to control the flow of liquid solution for softgels filling. The inside formulation is transferred from hopper towards the softgels via narrow plastic pipes.

Oil Quantity Adjustment

This component of hydroeye softgels making machine is used to adjust the oil quantity which is used during the production of softgels.

Softgel Discharge Port

It refers to the part where finished hydroeye softgels are separated from the gel film. The formed softgels are then discharged from the molds.

Softgel Hopper

It is a small stainless steel hopper where produced hydroeye softgels are gathered. Softgel hopper is located right below the conveyor belt.

Softgel Capsule Delivery Pipe

Softgel capsule delivery pipe is attached to the softgel hopper from one end and to the drying rotating cage to another end. It is used to transfer the finished hydroeye softgels from hopper towards the drying unit while using pressure air.

Drying Rotating Cage

Drying rotating cage is also known as tumble dryer. It is one of the crucial components of the machine that is used to eliminate surplus moisture from the newly formed hydroeye softgels.

5.What Are The Types Of A Hydroeye Softgels Making Machine?

Hydroeye softgels making machine is available in automatic technology, however, it may be divided into two types based upon its production capacity. These types are explained below:

Small Scale Hydroeye Softgels Making Machine

Aipak SEM-50 Softgel Encapsulation Machine

Small scale hydroeye softgel making machine is mainly used for laboratory and research institution. It has compact structure and precise design that cover less space and therefore minimum maintenance is required. This machine is best suitable for small scale production as it can produce up to 6,000 softgels in an hour.

Large Scale Hydroeye Softgels Making Machine

AIPAK SEM-300 softgel encapsulation machine

Large scale hydroeye softgels making machine is an automatic solution designed to deal with large volume of production. It works automatically and does not require any manual intervention for carrying out hydroeye softgels manufacturing. The machine is suitable for large scale pharmaceutical and dermatological industries. It has greatest production efficiency, accuracy, and consistency. The machine can give output over 120,000 softgels in an hour.

6.What are The Uses Of A Hydroeye Softgels Making Machine?

When it comes to highlight the uses of a hydroeye softgels making machine, there is a long list. It is not only used in pharmaceutical industry rather several other fields also utilize this machine for their manufacturing. These are explained below:

Pharmaceutical Industry

Hydroeye softgels bottle

Pharmaceutical industry is one of the largest manufacturing industries in the world whose constant focus is on revolutionizing ways for drug administration. Similarly, softgels are among these ways which can be only made by using a hydroeye softgels making machine.

Nutraceutical Industry

Nutraceutical capsules and softgels- Picture Courtesy: Adobe Stock

Hydroeye softgels making machine is also applicable to nutraceutical industry where enormous supplements are safely encased in softgels. These are beneficial for boosting immunity, gut health, and eye health etc.

Beauty Care Industry

Beauty softgels- Picture Courtesy: OSKIA

The sphere of use of the machine is not only confined to medical realms, however, it has extended to beauty care industry as well. Now, range of cosmetic related ingredients are delivered in form of softgels. These contain essence oil, vitamins, and other nutrients for enhancing overall beauty.

Hardware Industry

Paintballs

You may get surprised after reading the term hardware industry but that's true. Hydroeye softgels making machine may also be used in industry for making toys such as paintball. These products can be made by using this machine.

7.What Are The Quality Standards A Hydroeye Softgels Making Machine Should Comply?

Hydroeye softgels making machine is an equipment that is used to make medicines. For undertaking such a responsible task upon which the lives of consumers depends, it is necessary for a machine to be certified by internationally renowned quality standards. These quality standards ensure that the machine is made up of high quality components and is fully safe. Some of the notable ones are as follows:

Icons of various quality standards- Picture Courtesy: sapheneia.com

ISO:International Organization for Standardization is a global standard-setting body that establishes strict regulations for businesses to follow. Equipment certified by ISO represents highest quality.

GMP:Good Manufacturing Process is another significant standard with international presence. It basically deals with the construction material of the machine that must be 304 or 316 stainless steel which is food grade and corrosion resistant.

FDA:Food and Drugs Administration is a US agency responsible for regulating safety related principles for products in food and medicine industry. It supervises the effectiveness of equipment, thus, a hydroeye softgels making machine must be certified by FDA.

CE:CE is the certification mark for products which adhere to the safety rules of European Union. Manufacturers aiming to sold their machines in European countries must comply to its principles.

8.What Auxiliary Devices Will Integrate With A Hydroeye Softgels Making Machine To Form A Complete Production Line?

There are other machines which, if integrated to a hydroeye softgels making machine, can form the complete production line and increase the production efficiency as well as reduce manual labor. These equipment are described below:

Prepare Tank

Preparation Vessel, Reactor & Storage Tank- Picture Courtesy: chitramechtech.com

Another equipment to be used in the production line for making hydroeye softgels is prepare tank. It is a stainless steel plain jacket for heating and cooling with stable main frame, motor for mixing, and a lid. The tank has large capacity with up to 25,000 liters. It is ideal for making liquid formulation for softgels by using controlled temperature.

Gelatin Melting Tank

Gelatin Melting Tank- SECP Softgel Technology

Gelatin melting tank is a device used to prepare the formulation for making gel film. It consists of a stainless steel vessel, stirrer, lid, motor, and temperature system etc. It works automatically by heating the mixture and moving the stirrer inside tank to create smooth mixture free from bubbles.

Colloid Mill

Colloid Mill- Picture Courtesy: ibcmachine

Colloid mill is an excellent equipment used to reduce the particle size. For some filling material, which is difficult to mix with the solution, then colloid mill is used to make them uniform size. It works on a rotar-stator principle.

Tumble Dryer

Tumble Dryer- Picture Courtesy: SECP Softgel Technology

Tumble dryer is a specialized equipment used in pharmaceutical industry for the removal of excess moisture from capsules like hydroeye softgels. It consists of one or more units inside which rotating basket or drums are located. Each unit has its own control panel to fix parameters related to drying. Other parts include drying fan, electric motor, heater, and exhaust duct. The tumble dryer can be directly integrated with the main machine.

Vacuum Pump

AIPAK gummy making machine transfer pump

Vacuum pump is also called LOBE pump that is used to transfer liquid mixture from prepare tank into the main machine. The capacity of vacuum pump depends upon the synchronous reverse rotation of the two rotors. It has various seals in it including water cooling mechanical seal and oil lubrication mechanical seal.

Drying Trays

AIPAK Gummy manufacturing drying trays

Mostly, for drying softgels, tumble dryer is used. However, the use of drying trays is also prevalent. In this way, drying trays provide convenient way for you to put the newly produced capsules and let them fully moisture free.

Light Inspection Table

Table Model A-109P-LT – Illuminated Top Light Tables / Inspection Table

Light inspection table is a tool that allows for the inspection of various objects and materials. It is also used for the detection of softgels. This device has a table that lightened from below. Over the table, hydroeye softgels may be placed for inspection purpose which is a crucial step for maintaining the quality and adhere to the standards.

Drying Car

AIPAK gummy making machine tray dollies

Drying car is another significant tool for drying produced hydroeye softgels. It consists of a stainless steel structure, universal wheels, and food grade tray dollies made up of polyethylene (HDPE) and polypropylene (PP). The softgels can be easily spread over the dollies and left for drying. The dollies are resistant to low temperature and high temperature.

9.Explain The Troubleshooting Of A Hydroeye Softgels Making Machine?

When operating a hydroeye softgels making machine, you may encounter spontaneous errors. In that case, you need to understand the problem and then take the right action. For this purpose, we have highlighted some of the common problems and their solutions. These are discussed below:

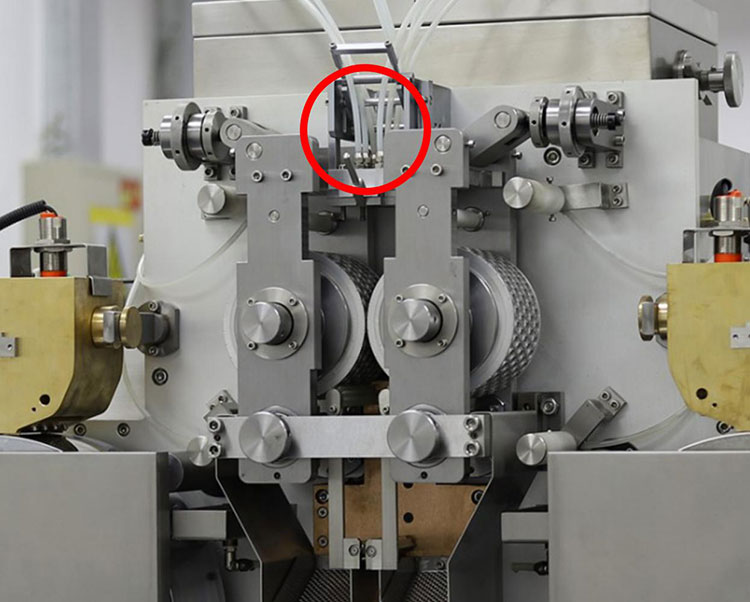

Inconsistency in Dosing

Encircled mini pump- Picture Courtesy: Aipak

Causes:

There may be any issue with the mini pump of the machine.

The dosing system may be inappropriately calibrated.

Solution:

Check the mini pump for error and adjust for correct dosing.

Make sure that all parts are properly calibrated.

Clumping of Softgels

Clumping of softgels- Picture Courtesy: iStock

Causes:

Glycerin excess for making gelatin film may cause softgels to stick together.

Inadequate drying and cooling of the softgels after production.

Solution:

Make sure to use the suitable amount of glycerin for gelatin shell formulation.

Allow adequate time for the drying and cooling of softgels to remove out excess moisture

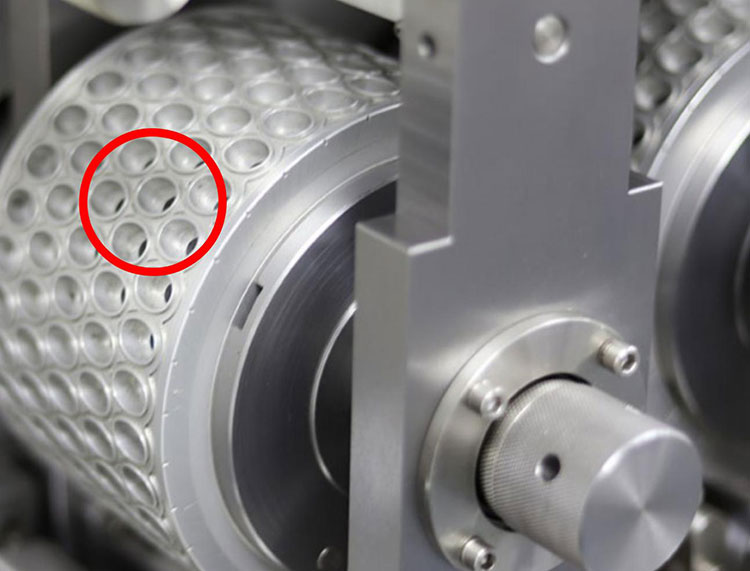

Gelatin Shell Deformation

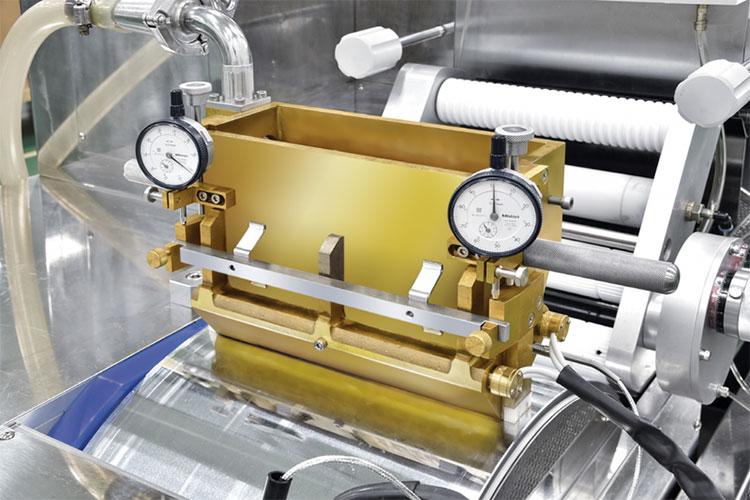

Highlighted molds- Picture Courtesy: Aipak

Causes:

The gelatin formula may lack ingredients or their ratio is not suitable.

The molds may be contaminated or unsettled.

Solution:

Make sure to consider the formula for gelatin shell by using all the necessary ingredients with suitable ratio.

Clean the molds and set them properly for smooth functioning.

Softgels Degradation

Gelatin shell deformation- Picture Courtesy: paintballruinedmylife.com

Causes:

The temperature during drying and cooling is improper.

The gelatin formula may not be right due to which chemical reaction occurs.

Solution:

Keep the temperature to moderate level during drying and cooling.

Make sure that the gelatin formula is right one to avoid any sort of deterioration.

10.What Are The Maintenance Requirements Of A Hydroeye Softgels Making Machine?

To keep your hydroeye softgels making machine on track, it is inevitable to conduct regular maintenance. It involves cleaning, lubrication, and parts changeover. So, let's know these maintenance requirements one by one!

Softgel encapsulation machine adjustment- Picture Courtesy: Pharmagate Solutions

Cleaning

Cleaning is the most important step to be carried out for removing residues and dirt from the machine. For this, you should disassemble the parts of machine and wash these parts thoroughly while using non-acidic water and recommended detergent. After washing, leave the parts to get dry and then assemble each component in the right place.

Lubrication

Lubrication is necessary for ensuring the smooth performance of movable parts of the machine. However, before adding new oil make sure you remove the previous one. It thus reduce friction and prevent sticking of the parts such as rolling mold and gearing systems.

Parts Changeover

To ensure optimal machine performance, it is crucial to replace the defective parts of the machine that includes components like die rolls, ribbon stripper, and gelatin box etc.

Adjustment

Regular adjustment of the machine is essential to improve precision and efficiency. It involves the structural adjustment of machine such as parts placement and fixation and the parameters adjustment that include setting the machine temperature and speed etc.

11.Factors To Look For When Buying A Hydroeye Softgels Making Machine?

If you want to become a successful businessperson, then it is always necessary to consider several factors whenever making any purchase. Similarly, we have highlighted some of the important factors regarding hydroeye softgels making machine. These are enumerated as under:

Production Scale

First of all, you should determine your production scale on the basis of which you will be able to opt for the suitable machine. For instance, if you are running large scale manufacturing then fully automated large scale machine is suitable for you. However, in case of laboratory and research institution small scale machine is good for you.

Quality Adherence

Adherence to quality standards icon- Picture Courtesy: VectorStock

Another significant factor that must not be overlooked is to check the quality adherence of the machine to different international standards such as ISO, GMP, and FDA.

Budget

Budget presentation idea- Picture Courtesy: AllBusiness.com

Before you select any machine, make sure to estimate the overall cost of machine price along with operation and maintenance cost. It will help you to go along with your budget.

Warranty

Warranty icon- Picture Courtesy: Alpcour

Buying a hydroeye softgels making machine means choosing an equipment for long time. Therefore, you should look for a reputable brand that offers warranty and other services such as after sale service.

Conclusion

To conclude, we hope that this FAQ guide about Hydroeye Softgels Making Machine has been an informative one. Today, the mode of drug delivery has been changed and one such method is softgels. It offers numerous advantages including convenient administration of drug and others. Similarly, the demand for manufacturing softgels is also increasing as their production cannot be carried out manually. So, if you are interested in purchasing hydroeye softgels making machine or related equipment, feel free to contact us!

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine