How To Master The Plate Process Of Soft Gelatin Capsule?

Have you ever wondered how these soft, smooth and soft capsules are made?

How these powerful and smooth nutrients based capsules that slide down your throat are manufactured and by which process? The plate process is efficient and effective technique which is often used in labs, small batches and R & D settings for its formation. Mastering the plate process of soft gelatin capsule not only involves the accurate precision but also involved to careful handling of the materials and the environmental conditions.

In this AIPAK blog, we will provide you a complete detail of gelatin preparation to capsule sealing and then its drying procedure. If you are worrying about how to make high quality soft gelatin capsules, then you don’t need to worry and read this blog completely. So, let’s start!

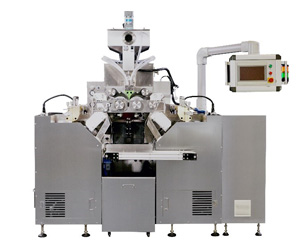

1.What is the plate process in soft gelatin capsule manufacturing?

Soft gelatin capsules-Picture courtesy: 100percentpure.com

The plate process is an early and traditional method for the manufacturing of soft gelatin capsule (also known as soft gels). It is manual or semi-automatic process in which the two flexible sticky sheets are used. One gelatin sheet is molded into cavities. The cavities are filled with a filling material like suspension. Then, the second sticky sheet is placed over a filled cavities.

It is then sealed with the help of pressure and heat.

Due to the use of metal die plate that contains cavity molds and are filled these cavities with liquid and then sealed, this process is known as plate process.

2.How does the plate process differ from the rotary die method?

The plate process differ from the rotary die method in terms of efficiency, automation and scale. The detailed comparison between two are as follows:

| Feature | Plate process | Rotary die method |

| Automation | The plate process is an early day method which is manual or semi-automatic method for gelatin capsule production. | The rotary die method is a modern pharmaceutical method which is fully automated and continuous process. |

| Production scale

Production scale-Picture courtesy: 29secrets.com |

This process is widely used in lab-scale and small scale for the manufacturing of capsules. | This method is used for large scale production or used in industries for large volume capsules production. |

| Speed

|

The production of gelatin capsules is slow. | It is relatively high speed production due to fully automation procedure. |

| Accuracy | As this process involve human effort so, less accuracy and variable filling of liquid in capsules occur. | The machine is doing all the steps automatically so, the capsules have uniformity and high accuracy. |

| Equipment cost | The equipment used is simpler and is less expensive. | The equipment is more complex and is expensive. |

| Capsule quality

Capsule quality |

The labor effort is involved in this process so, also the capsules formed are of variable quality. | The machine has given a command of capsules production and hence, it produces consistent and professional capsules. |

| Use case | This method is suitable for R&D and also for formulation development. | This method is used for the gelatin capsules production in industrial scale. |

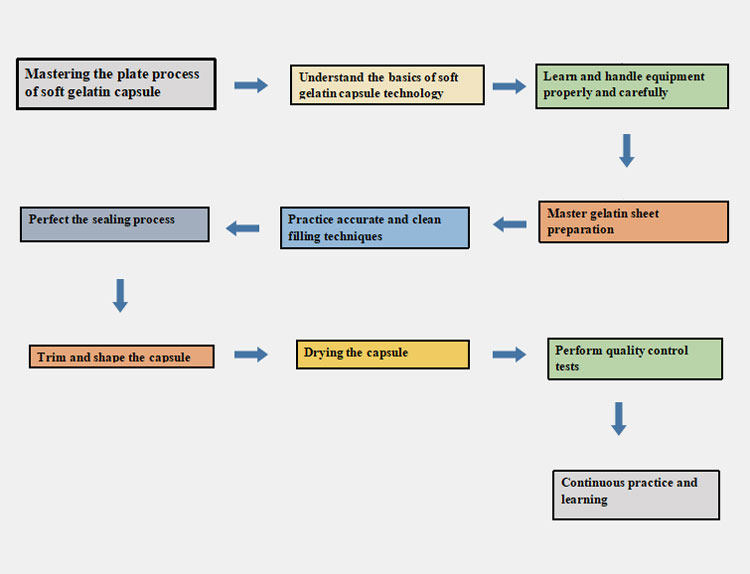

3.How to master the plate process of soft gelatin capsule?

To master the plate process of soft gelatin capsules, you must know the careful handling of both theoretical principles and hands-on handling. Here is a detailed information on how to master the gelatin preparation, filling it, sealing it, drying and quality control techniques.

Understand the basics of soft gelatin capsule technology:

Before starting the plate process, you must be aware of its basic understanding, and that is gelatin composition, filling materials, and soft gel structure.

| Gelatin composition

Gelatin-Picture courtesy: furtherfood.com |

The ingredients used to form soft gelatin capsules are gelatin, plasticizers, colorants and water. The amount of these ingredients affect the formation of capsules, their elasticity and sealing process. |

| Filling materials

Filling material-Picture courtesy:smhs.gwu.edu |

The filling materials for filling the capsules are liquid, suspension, pastes and oils. The viscosity of these materials affects the most, for the filling in capsules and capsules integrity. |

| Softgel structure | You must have complete information about the shell components sensitivity to temperature, moisture and sealing compatibility. |

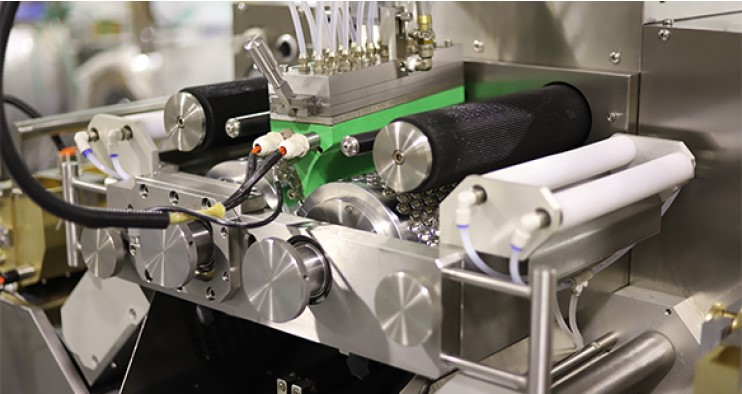

Learn and handle equipment properly and carefully:

Your mastery in plate process demands an understanding of the tools. Do you know, which tools are used? Well, let us discuss it in detail:

| Tools | Detail |

| Die plate | Die plate is a tool where the sheet is placed having cavities. These cavities need to be filled with a fill material. You must be familiar with the proper alignment and the filling procedure. |

| Gelatin sheet applicator | The gelatin sheet applicator is used for the preparation of flat gelatin sheets. As for the formation of capsules, its uniformity plays a crucial role. This applicator is responsible for the formation of sheets of uniform thickness. |

| Sealing plate | The sealing plate is a heated metal plate which is used for the sealing purpose. The combine effort of heat and pressure, it can seal the top and bottom gelatin sheets to ensure that the filled material is effective and safe. |

| Trimming tools | The sealed structure is then allow for intact capsule integrity and cut the extra sheets for prevent it from rough look. The trimming tool is used to cut the excess gelatin. |

| Drying chamber | To reduce the moisture content of the capsule, the drying chamber is used in post-processing to dry the extra moisture. |

Master gelatin sheet preparation:

Gelatin-Picture courtesy: ovenandchalice.com

This step is crucial as the gelatin sheet determines the final appearance of the capsules.

For the preparation of gelatin mass, you have to mix 25-35% gelatin and 15-25% plasticizer and the rest should be water. To eliminate the air bubbles, you must mix them under the vacuum.

After this, pour this gelatin mass into a leveled and smooth surface to obtain a uniform thickness sheet under the controlled temperature.

To avoid the crack in the sheet, a controlled humidity environment is required. So, stored the sheets at controlled humidity.

Practice accurate and clean filling techniques:

Practice accurate and clean filling techniques-Picture courtesy: mypsoriaticarthritis

The die cavity should be filled with a pipette, syringe or dropper. The environment and tools should be clean and free of germs. With the help of a dropper, fill each die cavity carefully and make sure not to create an air bubble or overfilling because due to these factors, the sealing process can be hindered.

Perfect the sealing process:

Perfect the sealing process-Picture courtesy: blog.capscanada.com

For obtaining the perfect capsule, you should be sealed it and handled very carefully. For this purpose, put the sheet over the filled sheet professionally. For sealing purpose, you must keep the high temperature to soften the gelatin sheet. But make sure not to melt it or burn it.

Apply the consistent pressure so that the sheet is evenly and securely sealed. The applied pressured usually lasts for second and it greatly depends upon the gelatin sheet composition. You should also investigate the sealed capsule and ensure that there is not leak, deformation or incomplete sealing.

Trim and shape the capsule:

Trim and shape the capsules-Picture courtesy: aboutsocialanxiety.com

After the sealing is completed, you should trim or cut the extra sheet of gelatin to ensure that you obtain smooth and good shaped capsules. During trimming procedure, trim it very carefully to avoid damaging the seal.

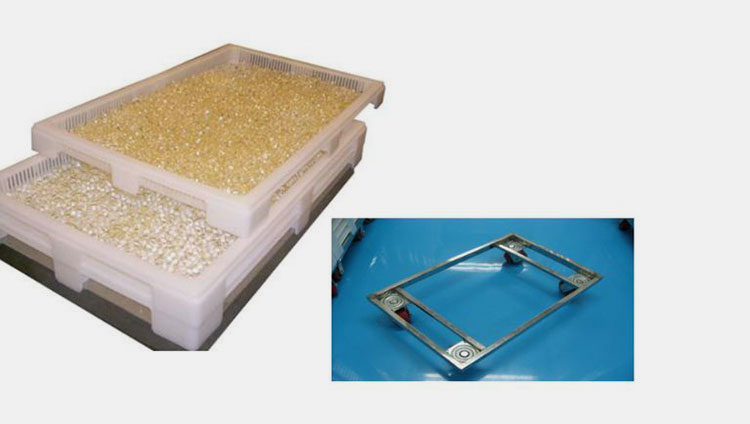

Drying the capsule:

Drying the capsules

You must be ensure that the capsule have no moisture content. For this purpose, the sealed capsules are then placed in drying try or drying chamber at controlled temperature and relative humidity. The drying procedure should last for about 24 to 48 hour.

After drying the capsule, you will get flexible and the shell will be firm and stable.

Perform quality control tests:

Perform quality control tests-Picture courtesy: ilgiornale.it

You should inspect visually and experimentally to get high quality capsules. For this purpose, you can check the color, shapes and filled material is capsules visually. You should also check the sealing of each capsule to ensure that each capsule is properly sealed and free from leakage.

The final gelatin capsules shells usually have 6-8% moisture content so also inspect the moisture content.

Continuous practice and learning:

You should work under the supervision of well-experienced or skilled professionals. You should also regularly try it to ensure you build skills of handling this procedure. It is also suggested that experiments with different filling materials and gelatin formulation to know which factors affect the most in good quality gelatin capsule production.

You should also have the complete information regarding different techniques and procedure to handle the tactics.

4.Do you know the advantages of using the plate process for small-batch production of soft gelatin capsule?

Have you ever wondered how those small, smooth and easy-to-swallow capsules are crafted on small scale? While huge modern machinery are dominated in industries but there is some captivating and hands-on method that is still ruling in industries for experimenting or small- scale production. That is plate process.

The plate process holds many hidden advantages. Let’s unravel them:

Low equipment cost:

Low equipment cost

The tools used for processing the plate method is of low cost. That’s why if you want to setup or experimenting with different filling materials or you wants to produce small scale production of capsules then, this make it budget friendly. By less investment, you can obtain smooth soft gelatin capsules.

Simple and manual operation:

Simple and manual operation

The plate process is usually manual or semi-automatic operation which is perfect for the beginners or for those, who wants an experiments. For this purpose, the plate process allows you to hands-on operation and precise control.

Great for formulation development:

Great for formulation development

If you wants to test new formulation, shell thickness or thinness required, or different capsules size are require then the plate process is suitable for R&D purpose. You can inspect them by their shape, color and thickness etc.

Minimal material wastage:

The ingredients used in the formation of gelatinous capsules are expensive but you can save them by using plate process. The plate process is suitable for small batch production which means less wastage of ingredients possibility. This process allows you to handle everything carefully.

Flexibility and customization:

Flexibility and customization of soft gelatinous capsules

In plate process, you can easily handle various filling materials, colors, and capsule size and thickness. It does not need proper and major equipment so, quick and easy switch between formulations are possible. Due to these factors, you can easily customize the capsules and also a flexible process.

5.How does mastering gelatin sheet preparation impact the final capsule quality?

The beauty of these perfect capsules lies in the glistening sheet which is strong and durable. Behind flawless shapes of these aesthetic and eye-catchy capsules lie a craft and that is mastering the art of gelatin sheet preparation.

Let’s explain why does this step is so important.

Uniform thickness leads to consistent capsule size:

Uniform thickness leads to consistent capsule size

If you handle the gelatin sheet carefully and prepare it well, then it would lead to consistent capsules formation. Due to this reason, the accurate dose in every capsule occur.

Optimal plasticity means flawless sealing:

Optimal plasticity means flawless sealing

If the gelatin sheets have right moisture content and elasticity then it helps you to seal the capsules properly. Due to these reasons, the capsules are properly sealed without cracking and the filled material is preserved in these golden glistening sheet.

Surface smoothness leads to professional appearance:

Surface smoothness leads to professional appearance-Picture courtesy: gesund-leben.info

If the sheet formed is free of air bubbles and smooth then it can result in shinny and polished capsules. Due to rid of the air bubble and smooth texture, the customers are attracted towards them and consumers trust developed.

Mechanical strength leads to durable capsules:

If the gelatin sheets are well prepared then, it have no chances of cracks results in proper folding and sealing. The filling material is properly encapsulated into these sheets which reduce the product waste.

Controlled drying results in long shelf life:

The proper moisture level in gelatin sheets help to maintain capsule stability over time. Due to this balanced moisture, brittleness is avoided and results in long shelf life of the capsules.

6.How can you consistently produce uniform capsules using the plate process?

Every capsule tells the high precision, balanced and controlled sheet thickness in which unique craftsmanship lies. The plate process is manual and measured, which is the talent of both artist and alchemist. Here are the steps to ensure the uniform capsule production with the plate process.

Maintain consistent gelatin sheet thickness:

Maintain consistent gelatin sheet thickness-Picture courtesy: cuerpomente.com

For the formation of uniform capsules, the gelatin sheets must have uniform thickness. For this purpose, you must have to maintain the uniform spreading and use balanced heat to ensure that consistent gelatin sheet thickness produce. By this, whole batch have uniform thickness.

Control temperature and humidity:

The sheet should be formed under the controlled temperature and humidity. This will prevent variation in gelatin behavior and the whole batch produced is of high quality.

Use precise fill volume:

Use precise fill volume

For the uniform capsule formation by using plate method, you should precise measured volume of filling material by using syringe or dropper into the cavities in the sheet. By precise filling, variation in weight of capsules not occur.

Standardize pressure during sealing:

During sealing, you should apply the uniform pressure from top and bottom of the sheets. By uniform pressure, the capsule is well-sealed and having accurate shape.

Work quickly but carefully:

You should quickly handle every step. If exposure to open air occur for a long time, then it will leads brittleness and might cracks occur. Exposure to open air cause drying and lost the effect of flexibility.

Regularly inspect and calibrate tools:

You should clean the tools, plates and all molds before processing the plate method. Also you should calibrate the tools to maintain the consistency of all the capsules in the batch.

7.What common mistakes should be avoided when handling the plate process of soft gelatin capsule?

The plate process, which is hands-on and traditional method in which the final capsules production craft lies a careful handling. To create a perfect and aesthetic capsules, you should not only learn what to do but also learn what to avoid.

The most common mistakes to avoid in the plate process of soft gelatin capsules are as follows:

| Mistakes | Impact | Remedy |

| Some time you spread the gelatin mixture inconsistently, somewhere the layer is thin and somewhere it is thick. | By this, the thickness of sheet is not uniform. Due to this, the appearance of each capsule and the dosage in it also effected. | You should spread the gelatin sheet uniformly on the die cut plate. |

| You work in an environment where there is not controlled temperature. You can say the environment can be too hot or too cold. | Due to vary temperature condition, the gelatin sheet may be too hard or too soft. The handling and sealing of such sheet cause hurdles. | You must calibrate the controlled temperature environment for flexible gelatin sheets procedure. |

| The common mistake that you may can do is not balancing the gelatin moisture content. | Due to uneven moisture content in the gelatin sheet, it may dry too fast resulting in cracks or it may stay wet results in stickiness of the sheets. | You must carefully handle the ingredients. |

| Sometimes, for filling material inconsistent filling technique is used. | This results in non-uniform filling of dose occur and size of capsules are also not consistent. | You should must used the precise measuring filling techniques |

| The top and bottom gelatin sheets are not well aligned or misalignment occur. | The misalignment of sheets can leads to improper sealing due to this, the leakage of dose occur. | You should must carefully align the top and bottom gelatin sheets. |

| After the sheet preparation, sometimes you take too long time to start the sealing procedure. | The gelatin sheet dry, despite the temperature and pressure, it results in ineffective sealing procedure. | You should start the sealing procedure immediately. |

| Some people don’t clean and sanitize the tools and reuse them for next batch. | This can results in contaminated capsule production. Also the quality of capsule deteriorates due to inconsistent results. | You should must clean and sanitize the tools with food-grade cleaner and sanitizer. |

| The most common mistake people do is before drying, they do not to check the sheets, fill and seal. | The faulty capsules make it into the drying chamber or tray, which results in wastage. | Before drying, you must have to check the sheets, fill and seal. |

8.Do you know the key signs that indicate a well-prepared gelatin sheet?

Do you know before the capsule is born, the golden, glassy and gelatinous sheet whispers the attribute of each capsule prior to a single drop sealed in it? To an expert, a well-prepared and well -crafted gelatin sheet speaks a lot for a good quality capsules production.

The key signs that indicate a well-prepared gelatin sheet are as follows:

Uniform thickness:

Uniform thickness-Picture courtesy: pagnutrition.com

For the formation of silky and smooth gelatin sheet, the sheet must have uniform and consistent gelatin sheet. How should you know that the sheet is uniform? Well, for this purpose, you must be inspect the sheet. The sheet should have a consistent thickness, neither too thick at some spot nor too thin at the other spot.

You might be wondering what’s the purpose of uniform thickness? By obtaining uniform thickness of the sheet, the equal dose and size of the capsules will be obtained.

Glossy, transparent surface:

If the capsules obtained from a high quality and well prepared sheets, then your trained eyes will observe the sheet as a shiny and smooth without any air bubbles, and cloudiness.

Do you know what happens when the sheet is having air bubbles? The capsules may not filled and sealed in a professional way.

Soft yet firm structure:

Do you know the unique and exceptional property of the well-prepared gelatin sheet? If not, then let me tell you that it is thin but strong and soft but it has a flexibility and strength to molds and handle it without tearing and leakage.

With proper temperature and handling, you can get soft yet firm structure of the capsules.

Even coloration:

Even coloration

The ingredients or the starting materials should be mixer very well and ensure that the mixture is free of air bubbles. The temperature also plays an important role in the formation of well-prepared gelatin sheet. At controlled temperature, you can get good quality sheet and hence, the even coloration is obtained.

No air bubble or foreign particles:

Have you ever wondered what will happen if you don’t handle the process carefully? Or what if you don’t clean the tools before carrying the process? Well, the chances of air bubble in the sheet or the foreign debris may be trapped in the gelatin sheet, which can leads to rough capsules production.

The customer’s satisfaction and health issue can be at risk.

Proper moisture content:

Proper moisture content in the gelatin sheet is crucial. If you ever touched a capsule, you will feel the surface is slightly moist but not too sticky. This indicates that the gelatin sheet has the right amount of moisture content and it has filled and sealed in a good way.

9.How do environmental conditions affect your success in mastering the plate process?

Have you ever wondered that the air or environment around your mastering has impact on the plate process? The air, temperature, humidity and atmosphere are not just the background, they are the collaborator of your plate process which are silently and invisibly affecting the plate process.

Soft gelatinous capsule-Picture courtesy: healthcareradius

If you control your environment, you will control the outcomes. Let’s discuss how these environmental conditions affect the success in mastering the plate process:

| Elements | Why it is important |

| Temperature control | The ideal range of temperature for the plate process is 20-25 C. If the temperature is high, the gelatin sheet will melt and results in too soft sheet obtaining. Due to softness, the sheet is difficult to fill and seal.

On the other hand, if the temperature is low, the sheet obtained can easily dry and during sealing, cracks may be occurred in the capsules. |

| Humidity balance | The ideal humidity condition for plate process is 40-60%. If the gelatin sheet has too much humidity then, the sheet is too soft and may not set properly.

If the humidity content is too low, then the sealing is not properly and evenly occur. Cracks may took placed and the capsule came out are hard. |

| Airflow and ventilation | The poor airflow during the drying process may results in inconsistent drying. The controlled ventilation condition promotes the even drying of your gelatin sheet and moisture retention is expected. |

| Cleanliness and air quality | Working in the clean and good air (having no dust) can leads to acquiring of good quality capsules. If the dust particles packed in the gelatin sheets, the appearance and sealing of the capsules can affect. |

| Lightening and visibility | The rhythm of the room, lightening and visibility during hands-on working plays a crucial role. With proper lightening, the sheet thickness, the air bubbles and dust particles can easily be observed.

In this way, the environmental conditions impact the mastering of plate process. |

10.What are the best practices for drying soft gels after plate processing?

Soft gels-Picture courtesy: iPharmachine

The gelatin sheets are formed, the capsules are filled and sealed but yet, the finale is remaining and the journey is not over. Do you know, the drying procedure preserve the strength of the capsules, their elegance, and shelf life increases? But what would happen if poorly handled the drying procedure? It will waste all your hard works.

Here are some of the best practices for drying soft gels after the plate processing.

Use a well-ventilated drying room:

For good drying of the soft gels, you must ensures that the clear and filtered air is in the room. Ventilation should be good to prevent the moisture buildup in the room. For drying procedure, the air flow should be even.

Control temperature and humidity:

The temperature and humidity should must be controlled. At control temperature and humidity, the capsules hardening or shrinkage should be avoided.

Use drying trays with proper spacing:

Drying trays-Picture courtesy: capsulefiller.com

The drying chamber or drying trays are used for drying of capsules. For this purpose, you can use mesh trays. Keep the capsules with proper spacing and single layer of capsules are suggested. By doing this, the stickiness or deformation of the capsules are avoided and also, better air flows through the capsules are procured.

Rotate or turn capsules:

Drying of the capsules

The drying process usually last for about 24-48 hour. You can rotate the capsules after 12-24 hour because this will results in equal drying of capsules from all the sides. Also flat spots should be prevented.

Avoid direct sunlight or heat:

You should avoid direct sunlight or heat because by doing this, the upper sheet may dry very soon but the inside will remain moist, and can cause cracks or leakage during storage.

Inspect regularly:

Inspect the appearance

You should inspect regularly. Check for the surface smoothness etc. don’t be in hurry, always be patience during drying. Let your capsules rest and you’ll obtained a capsules having full strength and high power.

Conclusion:

By reading the above blog of AIPAK, you must be reached at the point that mastering the plate process is the combined effort of the artists and alchemists. From poring the gelatin sheet to the final filling, sealing, and then drying procedure needs a careful handling, discipline, care and respect for the materials at your hand. Every step of this handcrafted process, each step is a reflection of love and patience. By carefully handling each step, you can elevate your work and capsule to elite status.

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine