How To Make a Soft Gel Capsule?

Have you ever wondered how those glossy and smooth softgels you swallow so easily are actually made? The secret lies behind a meticulous process that combines science, art and precise control at every step.

There is no doubt that soft gel capsules have changed the method of delivering medicines and supplements. The unique manufacturing process of these capsules makes us curious to learn more about them. This article sheds light upon manufacturing, significance, application and other important information of soft gels capsules. Let’s explore!

1.What makes soft gel capsules so popular in the pharmaceutical and supplement industries?

Soft Gel Capsules In Pharmaceutical & Supplement Industries

Now day’s softgel capsules are getting popular in the pharmaceutical and supplement industries. This makes us think about particular aspects that are behind the preference of soft gel capsules.

Quick absorption:

First thing is the ability of soft gel capsules offer quick absorption of active ingredients especially the fat soluble ones. It results in faster onset of action and enhanced bioavailability.

Effective delivery of liquids or oils:

Another crucial reason of giving importance to this type of capsule is the way it delivers liquid or oily formulations effectively to the body. Such formulations are not easy to handle in other dosage forms, as perfectly they get encapsulated in soft gel capsules.

2.Why are more manufacturers switching from hard capsules to soft gels?

Soft Gels And Hard Capsules

Manufacturers are moving from hard capsules to soft gels, and the reasons are quite evident.

Soft gels provide higher absorption rate since they dissolve faster than hard capsules.

While hard capsules are mainly used for dry formulations; soft gels are ideal for encapsulating liquids and oils.

Moreover, soft gels offer better stability, a more appealing appearance, and greater ease of swallowing as compared to hard capsules, placing them ahead in preference.

3.What materials and technology are needed to produce soft gel capsules?

Material And Technology Of Soft Gel Capsules

To understand the manufacturing process of soft gel capsules, it is essential to have an idea about the material and technology involved. The production requires pharmaceutical-grade gelatin, purified water, plasticizers, colorants and active ingredients such as liquid or oil formulations.

The main technology employed is softgel encapsulation machine for making and filling softgel capsules. Additional equipment like preparation tanks, gelatin melting units, dryers and inspection machines ensure preparation of gelatin solution and fill material, proper drying, fine shape and quality control. The use of automated machines further enhances product uniformity, stability and entire production efficiency.

4.How does softgel manufacturing differ from other capsule types?

Softgels Manufacturing

There are many factors that make softgel manufacturing differ from other capsules type. Let’s discuss!

Filling material:

Softgel manufacturing is regarded as ideal for enclosing liquid or semi-liquid filling material; where as other capsules are mainly used to fill dry powder or granules.

Capsule material:

In softgel manufacturing, the capsule material is designed to be soft and flexible, allowing it to hold liquids or oils with ease, whereas hard capsule material is rigid and better suited for encapsulating dry blends.

Process of making capsule:

Softgel capsules are manufactured through a continuous process, where filling and sealing take place simultaneously using rotary die encapsulation. In contrast to this, the hard capsules are produced in multiple steps, as shells are filled and capped separately.

Process of sealing:

The sealing of softgels is performed to create hermetic seal that prevents leakage and oxidation. This type of sealing can withstand any pressure or atmospheric conditions effectively. In contrast, hard capsules are sealed by joining two halves and such sealing is more susceptible to pressure or moisture.

5.What advantages do softgel capsules offer for consumers and manufacturers?

Advantages Of Softgel Capsules

Softgel capsules offer a variety of advantages to the consumers and manufacturers, making them the formulation of choice.

Easy oral intake:

Softgel capsules have a smooth, slippery surface that allows easier swallowing compared to tablets or hard capsules.

Palatability enhancement:

The gelatin shell of these softgels prevents the unpleasant taste or odor of active ingredients from reaching the consumers, thereby improving palatability of the product.

Attractive appearance:

Softgel capsules are available in different sizes, colors and shapes. These features enhance their aesthetic appeal and help in easy identification during use.

Precise dosing:

Each softgel capsule is filled with accurate amount of drug or supplement, ensuring consistent and precise dosing.

Faster therapeutic action:

Since the drug is filled in liquid or oil formulation, it quickly dissolves in the stomach, resulting in faster therapeutic action.

Improved bioavailability:

Softgel capsules contribute in improving bioavailability of less soluble active ingredients like fat soluble vitamins.

Protection from air, moisture and tampering:

The airtight sealing of softgel capsules protects the medication from degradation caused by air, moisture and possible tampering.

6.What ingredients are used to prepare the gelatin solution?

Ingredients Of Gelatin Solution

There are certain important ingredients that are used to prepare the gelatin solution. Let’s have a look!

Gelatin: it is main ingredient that forms the shell of capsules.

Purified water: it helps to dissolve the gelatin and forms a homogenous solution.

Plasticizers: glycerin or sorbitol is used as plasticizer, used to make capsule texture soft and flexible.

Colorants: it gives a vibrant and appealing look to the capsules. Also helps consumer to differentiate between them.

Opacifiers: it contributes in making capsules opaque that safeguards the sensitive drug from light exposure.

7.How do you prepare the fill material for a soft gel capsule?

Procurement of raw material:

As you learn that soft gel capsules encapsulate liquids or oils, so it is necessary to procure all ingredients from an authentic source.

Weighing and measuring of all ingredients:

The preparation process starts with precise weighing of all ingredients of formulation. Active pharmaceutical ingredient (API), vehicle and excipients must be present in desirable amount to produce profound effects.

Melting solid ingredients:

Some formulations contain solid ingredients like beeswax that are needed to be melted. Water bath or heating kettle is used to melt them at a controlled temperature.

Forming the liquid base:

The ingredients that can be used as liquid base are mixed well to form a homogenous liquid base. Mixing vessels are used to carry out this step.

Incorporating the active ingredients:

This step involves the complete dissolution or dispersion of active ingredient in prepared liquid base. To achieve an even consistency, active ingredient is added slowly and gradually in liquid base along with stirring.

Adding the excipients:

It is equally necessary to add required excipients like suspending agent, emulsifiers or anti-oxidants to get desirable quality. Continuous stirring is recommended while mixing to get a uniform mixture.

Homogenizing the mixture:

The mixture is passed through the homogenizer or colloid mill to get a perfect consistency.

Removing the air bubbles:

The process of removing air bubbles from mixture is known as deaeration. Prepared mixture is placed under vacuum to eliminate the air bubbles and avoid any related defects during encapsulation.

8.How does the softgel encapsulation process work?

Softgel Encapsulation Process

The softgel encapsulation process takes place in following order:

Creating gelatin ribbons forming capsules sealing capsules

Creating gelatin ribbons:

The gelatin solution is prepared by mixing gelatin with purified water, colorants, plasticizers, and opacifiers. This prepared solution is fed into the encapsulation machine and two gelatin ribbons are created by using rotating rollers.

Forming softgels:

The two gelatin ribbons move towards each other between rotating dies that have capsule-shaped cavities. In a continuous manner, an accurate amount of fill material, either liquid or oil, is introduced between two ribbons through a dosing pump. At the same moment the die pockets align, and the capsules are formed, filled and sealed in a single operation.

Sealing capsules:

The edges of softgel capsules are sealed with the help of heat or pressure applied by rotating dies. A perfect hermetically sealed capsule is produced by encapsulation process. The formed capsules are then cut off from the ribbons and collected on a tray for drying.

9.What are the key steps in drying and finishing softgel capsules?

Drying And Finishing Of Softgel Capsules

The key steps in the drying and finishing softgel capsules are:

- Tumble drying

- Room or tunnel drying

- Inspection

Tumble drying:

This drying is carried out using tumble dryers. After encapsulation, softgel capsules are soft and contain a high amount of moisture, so they are transferred to tumble dryers. These dryers pass a stream of warm air that removes the moisture present on surface. This initial drying step helps to prevent stickiness and keep the capsules separate for further drying and processing.

Room or tunnel drying:

This is known as secondary drying and is achieved by spreading the softgels evenly on drying trays and placing them in a drying room or tunnel under controlled temperature and humidity conditions. The softgels remain there until they attain the desired moisture content and a stable form.

Inspection:

As the drying process is completed, the softgels are inspected either visually or by using inspection machines. Defective capsules are separated and uniform ones are transferred for the polishing.

10.How is quality control performed during softgel production?

Quality Control During Softgel Production

Quality control is performed at every step of softgel production to ensure product uniformity and adherence to mandatory standards. The process follows the following sequence:

Ingredient quality check:

It is always ensured that ingredients used for softgel production meet the required standards. They are tested for purity, identity and quality before being used in manufacturing.

Evaluation of gelatin solution:

The gelatin solution is evaluated for parameters like viscosity, pH and temperature to ensure its suitability for desirable film formation.

Fill material inspection:

The fill formulation is inspected for even consistency, homogeneity and stability to ensure accurate encapsulation.

Encapsulation assessment:

Some aspects are monitored during encapsulation process such as fill volume, sealing, ribbon thickness and capsule uniformity.

Drying control:

During the drying process, softgels are evaluated to ensure they contain the appropriate moisture content. In addition, temperature and humidity also kept strictly controlled to prevent deformation or leakage of the capsules.

Visual and mechanical inspection:

The softgels are inspected for parameters such as shape, color, uniformity, cracks, leaks and the absence of air bubbles. An inspection table or automated inspection machines are used for this purpose.

Weight uniformity:

Softgels are randomly selected and tested to ensure that they have uniform weight.

Disintegration and stability tests:

The softgels undergo disintegration and stability tests to assess their functional performance and determine their shelf life.

Microbiological testing:

The finished softgels are examined to confirm the absence of any microbial contamination.

11.Can you show a real example of a softgel production line in operation?

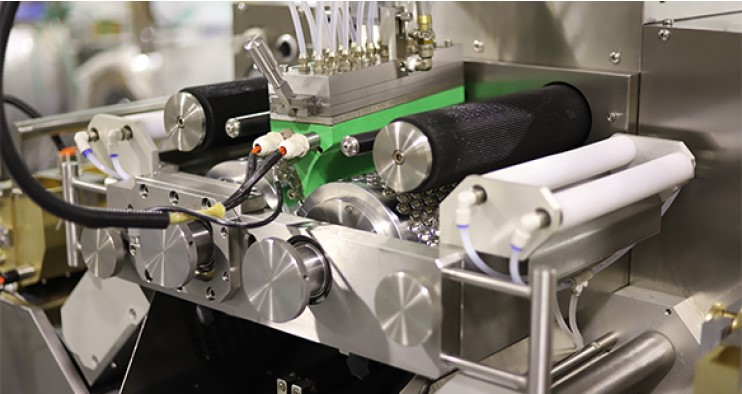

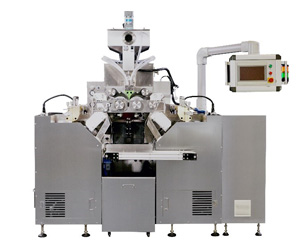

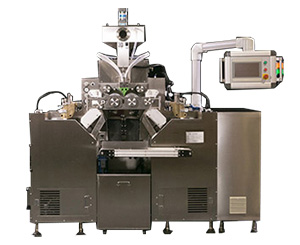

AIPAK SEM-300 Softgel Encapsulation Machine

The AIPAK SEM-300 is highly potent, fully automated softgel encapsulation machine and is created to deal with the large-scale production. It is flourishing as an important part of pharmaceutical, nutraceutical and cosmetic industries. It provides accurate regulation of all encapsulation parameters, including fill volume, ribbon alignment, and sealing pressure. It ensures uniform capsule quality and optimized production efficiency.

Important components of AIPAK SEM-300 softgel encapsulation machine are:

Medicine hopper and pump:

The hopper collects and delivers the fill material to the encapsulation area where the softgel capsules are formed. The pump ensures the precise dosing and maintains a uniform flow of the fill material throughout the process.

Injection wedge:

The injection wedge is mounted between the die rolls to ensure accurate placement of fill material by injecting it into the gelatin ribbons during capsule formation.

Casting drum:

The casting drum plays a vital role in gelatin ribbon formation. The gelatin solution is evenly spread over its surface, and both its rotation and temperature are carefully controlled to obtain the desired ribbon thickness.

Lubrication rollers:

The lubrication rollers help prevent the gelatin ribbons from sticking together by applying a thin layer of lubricant to their surfaces. This process ensures smooth movement and contributes to efficient capsule formation.

Die roll assembly:

The die roll assembly is comprised of two rollers containing forming cavities that shape the capsules. It ensures uniform capsules size and contributes to precise and reliable sealing.

Cooling drum:

The cooling drums are used to lower the temperature of the freshly formed softgels, which remain soft and moist immediately after encapsulation process. This step ensures proper gelatin solidification and strengthens the softgels structure. During the cooling process, temperature is carefully monitored to prevent any deformation.

Control panel:

The control panel is recognized as central operating unit of the machine. It is equipped with a large touch screen interface and an integrated fault diagnosis system. The panel records multiple operating parameters and includes a reserved network interface for data connectivity and future upgrades.

12.What are the production capacities of small, medium, and large softgel machines?

Production Capacities Of Softgel Machines

Here is an overview of the production capacities available today for small, medium and large softgel machines currently on the market.

Small softgel machine:

This machine is typically used for laboratory scale production or for producing validation batches. Its production capacity generally ranges from 5,000 to 20,000 softgels per hour.

Medium softgel machine:

This machine is designed for manufacturing moderate or commercial scale batches. Its production capacity ranges 25,000 to 60,000 softgels per hour.

Large softgel machine:

This machine is employed for large scale or full industrial production. It is capable of producing bulk quantities of softgel capsules, with capacities ranging from 80,000 to more than 200,000 softgels per hour, depending on the machine model and capsule size.

13.How do leading supplement brands produce their softgel capsules efficiently?

Tips Of Producing Softgel Capsules Efficiently

We often see a variety of supplement brands in the market, and many of them prefer to present their product in the form soft gelatin capsules. Have you ever wondered what tips these leading brands use to produce softgel capsules efficiently? Let’s find out!

Choosing automated machines:

They use fully automated machines to carry out every step of softgels production, from gelatin preparation to capsule formation and alignment. This reduces the chances of human errors and ensures product uniformity.

Consuming high quality raw materials:

The ingredients used in capsule production are of pharmaceutical grade quality and are procured from reliable and approved sources. Each component is measured accurately before use, ensuring consistent capsule quality and stability.

Optimizing process parameters:

There are certain key parameters like gelatin viscosity, ribbon thickness, temperature and fill material weight, that are meticulously controlled during the capsule production.

Integrating drying systems:

Continuous dryers are used that help achieve the desirable moisture level efficiently. This process also reduces the overall drying time and enhances the finals product quality.

Monitoring quality:

Advanced inspection systems are used to detect shape, color or leakage defects during production, ensuring only flawless capsules move forward.

Making reliable packaging:

Softgels are immediately shifted to automated blister or bottle packaging lines under controlled and hygienic conditions.

14.After understanding the process, how do you choose the right softgel encapsulation machine?

How Do You Choose Right Encapsulation Machine?

After gaining a clear understanding of the process, the right machine is chosen by aligning production needs, formulation characteristics and automation requirements. The process of selection involves assessing the intended production scale, whether small, medium or large along with machine’s accuracy and dependability. It also takes into account essential technical aspects like dosing precision, control mechanism and drying performance to ensure an efficient encapsulation process.

15.What factors should be considered when selecting equipment for softgel production?

Factors That Are Considered To Select Equipment For Softgel Production

There are certain key factors that must be understood to help you select the appropriate equipment for softgel production.

Capacity of your production:

You need to evaluate the production capacity as it is crucial for selecting equipment. Production capacity may be small, medium or large, so selection of the machine must be coherent to the manufacturing size.

Type of fill material:

It is necessary to consider whether you are producing oil based, paste or suspension type fill materials, as machine specifications may differ accordingly.

Level of automation:

You must choose between semi-automated or fully automated machines based on your desired efficiency, labor availability and production size.

Technical features:

You always need to look for important parameters like accurate dosing pumps, temperature control systems and fault diagnosis functions as they help achieve consistent product quality.

Ease in cleaning and maintaining:

You should choose equipment that can be easily disassembled as this facilitates proper cleaning and replacement of spare parts. Thoroughly cleaned and well maintained machine are essential to meet GMP guidelines.

Authenticity of manufacturer:

You have to prefer machines from reliable manufacturers that offer technical support, accessibility to spare parts and after sale services.

16.Where can manufacturers get professional softgel production solutions?

Softgel Production

Manufacturers can get professional softgel production solutions by consulting machinery suppliers or industry experts that have extensive experience in this field. These specialists provide complete support, from choosing and installing equipment to operator training and machine maintenance. With their guidance, manufacturers can attain consistent softgel quality and efficient production.

17.How can you contact a supplier to customize your softgel encapsulation line?

Customization Of Softgel Production Line

Manufacturers can reach a supplier by visiting their official website or email to discuss further production requirements. Sharing detailed specifications like production size, gelatin formulation and automation level helps the supplier prepare a suitable customized plan. After analyzing the production needs, the technical team of company provides machine modifications or complete production line designs accordingly.

18.What resources or guides can help you start your softgel manufacturing business?

What Helps You To Start Your Softgel Manufacturing Business?

The resources or guides that can be particularly helpful when you are intending to start a softgel manufacturing business are discussed below:

Equipment suppliers:

You can lean on the guidance provided by professional equipment manufacturers like AIPAK pharmaceutical machinery, which offers complete manufacturing solutions. Their service includes plant layout designing, machine installation and operator training. AIPAK’s instruction manuals and demonstration videos explain the entire process clearly, helping new manufacturers to get a deep understanding of process.

Regulatory guidelines:

It is essential for you to follow the guidelines issued by regulatory bodies like FDA, WHO and ICH. These documents outline the GMP standards, covering hygiene practices, proper documentation and process validation.

Workshops or seminars:

You also benefit from attending technical workshops and industrial seminars organized by professional in the softgels manufacturing field. Such sessions provide close exposure to equipment handling, process trouble shooting and optimization of production conditions.

Conclusion:

This topic shows that softgel production requires precise control at every step, either its gelatin or fill preparation to encapsulation, drying and quality inspection. With the guidance from reliable and authentic sources you can confidently start your softgel manufacturing business. For further information, you can visit AIPAK at any time.

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine