From Essential Oils to Cannabis Softgels: A Complete R&D Production Solution

Expanding your product line from essential oils to softgels can feel risky and complicated if you lack manufacturing experience. You might worry about wasting money on the wrong equipment or failing to produce quality capsules. We turn this complex transition into a simple, guided process for you.

We provide a comprehensive R&D production solution that includes the SEM-50 softgel machine, custom facility layout design, and precise formulation support. This helps cannabis companies successfully launch new softgel products, ensuring high-quality results from the very first batch while minimizing startup risks.

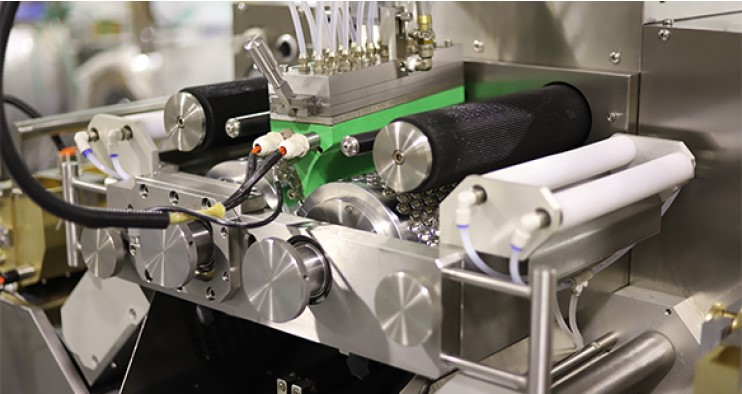

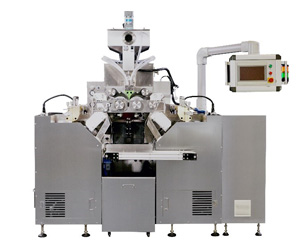

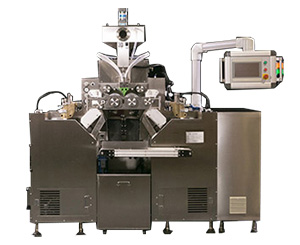

SEM-50 Softgel Machine for Cannabis R&D

Many manufacturers sell you a machine and walk away, leaving you to figure out the rest. That is not how we work. We stay with you to ensure your production line actually works.

1.How Do We Handle Inquiries from New Softgel Manufacturers?

In 2023, I received an inquiry from a client in California who wanted to make cannabis softgels. They were worried about choosing the right machine for a new product launch.

We analyze your background and market needs immediately. For this client, we identified they were a top cannabis brand moving from oils to softgels. We recommended the SEM-50 lab scale softgel machine as the perfect entry-level tool for testing the market without a massive initial investment.

When we receive a new inquiry, we do not just look at the product request. We look at the company behind it. I did a background check on this California client immediately. I found out they were already a very strong player in the cannabis industry. They had a solid reputation for essential oils and hard capsules. However, softgels were a completely new territory for them. They wanted to test the waters. They did not want to buy a massive production line immediately. This is a very smart approach for a new product launch.

Based on this, I knew they needed a machine that was precise but not too large. I recommended our SEM-50 Laboratory Softgel Encapsulation Machine. This machine is small, but it works exactly like the big ones. It is perfect for R&D (Research and Development). It allows you to make small batches to test your formula. If the market likes the product, you can scale up later.

Optional mold shapes from AIPAK

We also discussed molds. The shape of the softgel is very important for branding. I sent them a list of optional mold shapes. We looked at round, oval, and oblong shapes. We helped them choose a standard shape that is popular in the market. This helps them keep costs down for the first run. This step is critical. It saves the client from buying a machine that is too big or too expensive for their current needs.

| Feature | SEM-50 (R&D Model) | Standard Production Model |

| Purpose | Lab testing, small batches, R&D | Mass production, high volume |

| Speed | Lower speed, high precision | High speed, continuous output |

| Cost | Low entry cost | Higher investment |

| Space | Compact design | Requires large facility space |

| Material Usage | Low waste (good for expensive oil) | Higher material consumption |

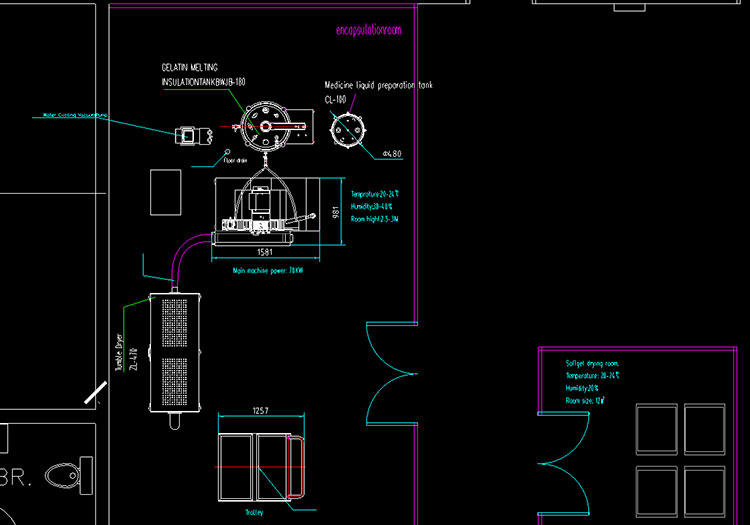

2.Why Is Factory Layout Planning Crucial for Softgel Production?

The client had a factory, but they did not know how to arrange the equipment for softgel production. Poor layout leads to production failures and wasted materials.

We requested their factory blueprints and created a custom machine layout for them. We also provided strict temperature and humidity requirements. This ensures the environment is perfect for drying and storing softgels, which is the most critical part of the process.

Softgel Factory Layout Design Blueprint

Softgel production is not like making hard tablets. The environment matters almost as much as the machine. This client had no experience with this. They thought they could just put the machine in a room and turn it on. I explained that this would lead to sticky capsules that never dry. To solve this, we asked for their factory drawings. I personally worked on drawing a layout for them. I showed them exactly where to put the gelatin melter, the main machine, and the tumble dryers.

We also organized a video conference. This was very important. We did not just talk; we showed them the machine. We walked them through the advantages of our technology. During the call, they asked many technical questions.

"How do we control the gelatin thickness?"

"How do we clean the hoses?"

"What is the power consumption?"

I answered every question.

The most important advice I gave was about the room conditions. Softgels are very sensitive to moisture. I told them they must control the temperature between 20°C and 24°C. The humidity must be around 20%. If it is too humid, the shell will not form correctly. If it is too hot, the gelatin will melt. We provided a detailed chart for this. The client was very happy with this level of detail. They felt safe ordering from us because we understood the science, not just the hardware.

| Parameter | Recommended Range | Why It Matters? |

| Room Temperature | 20°C - 24°C | Prevents gelatin from melting or becoming too brittle |

| Relative Humidity | 18% - 22% | Ensures the softgel shell dries hard and does not get sticky |

| Air Cleanliness | ISO Class 7 or 8 (GMP) | Prevents contamination of the pharmaceutical product |

| Airflow | Laminar flow | Keeps dust away from the open gelatin ribbon |

3.What Steps Ensure the Machine Is Ready for Production?

You cannot afford for a machine to arrive and not work. This causes delays and hurts your launch schedule. We test everything before it leaves our factory.

SEM-50 softgel machine shipping

We performed a full performance test on the machine before shipping. We recorded a video of the test and sent it to the client for confirmation. We only shipped the machine after they said "yes." We also included detailed wiring diagrams to make installation easy.

Testing SEM-50 Before Shipment

Shipping a machine from China to the USA is a long journey. We must be sure it works perfectly before it goes into the box. For this order, we set up the machine in our testing facility. We loaded it with dummy materials that simulate the viscosity of cannabis oil. We ran the machine for several hours. We checked the filling accuracy. We checked the sealing of the capsule. We checked the cooling of the drums.

I recorded a video of this entire process. I zoomed in on the die rolls so the client could see the capsules forming. I zoomed in on the control panel so they could see the settings. I sent this video to the client. They watched it and confirmed that everything looked correct. This gave them peace of mind.

Documentation before shipping

We also prepared the documentation. A machine is useless if you do not know how to hook it up. We printed out the user manual in English. We also printed the pneumatic (air) and electrical diagrams. We put these documents in the box with the machine. We also sent digital copies by email. This way, their local electrician could prepare the factory before the machine even arrived. This preparation minimizes downtime. It ensures that when the crate arrives, they can plug it in and start working.

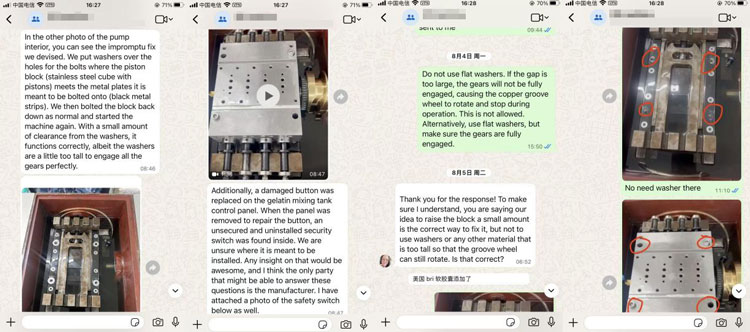

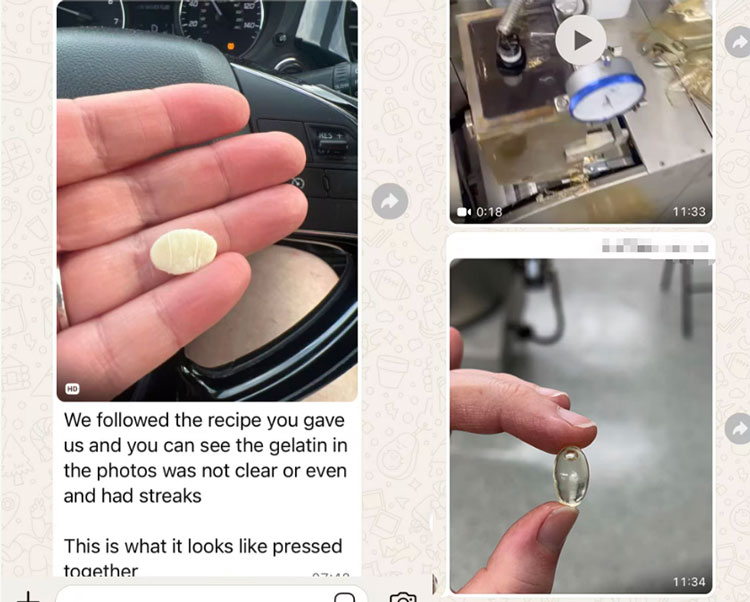

4.How Can Custom Formulations Solve Production Quality Issues?

Even with a good machine, you might face issues with materials. The client complained that their gelatin ribbon was not transparent enough, which affected the product's look.

We did not blame the operator. Instead, we analyzed their material and created a new custom gelatin formula for them. This adjusted the ratio of gelatin, water, and glycerin. With this new recipe, they produced crystal-clear capsules.

Clear vs Cloudy Softgel Comparison

After the machine arrived, the client installed it quickly. However, they faced a quality problem. The softgels were forming, but the shell looked cloudy. It was not the beautiful, transparent golden color they wanted. In the premium cannabis market, appearance is everything. If the capsule looks bad, customers think the oil is bad. The client was worried. They thought the machine was broken.

Customer issues after receiving the machine

I investigated the issue. I asked them for their gelatin recipe. I looked at the ratio of water to glycerin to gelatin powder. I realized their formula was standard, but their local water and specific gelatin bloom strength were slightly different. This caused the opacity.

I did not tell them to "figure it out." I worked with our chemical engineers. We adjusted the formula. We changed the cooking temperature slightly. We also adjusted the vacuum time during the melting process. Air bubbles can make the ribbon look cloudy. I sent them a new, specific recipe.

"Try this mix," I said. "Cook it for exactly this many minutes."

They tried it. The result was perfect. The capsules came out clear and shiny. The client was relieved. This proves that we solve problems. We do not just sell iron and steel; we sell the knowledge to make a final product. This is the difference between a vendor and a partner.

| Problem | Potential Cause | Our Solution |

| Cloudy Shell | Air bubbles or wrong water/glycerin ratio | Adjusted vacuum time and formula ratio |

| Leaking Seam | Temperature too low on wedge | Adjusted PID temperature settings |

| Sticky Capsules | Humidity too high in drying room | Advised on dehumidifier settings |

| Shape Distortion | Drying too fast | Adjusted drying basket speed and air flow |

5.When Should You Upgrade from R&D to Mass Production?

Starting small allows you to learn the process and build a customer base. Once your product is successful, you need to increase capacity to meet demand.

The client was so satisfied with our service and the machine's performance that they are now planning for the future. They told us they will expand their capacity in 2026. They plan to order a larger production line from us to handle volume orders.

Large Scale Softgel Production Line

This case study is a perfect example of how a business should grow. You do not start with a Ferrari if you are learning to drive. You start with a reliable car that teaches you the road. The SEM-50 was that car for this client. It allowed them to enter the cannabis softgel market with low risk. They learned how to manage the gelatin. They learned how to control the filling. They learned how to package the product.

Now, they are confident. Their product is in the market. It is selling well. They know that the current machine will soon be too slow for their sales volume. Because we helped them through the hard times—the layout, the installation, the formula issues—they trust us. They are not looking for other suppliers. They told me directly, "In 2026, we are coming back for the big machine."

This is our goal at AIPAK. We want to grow with you. We treat a small order with the same seriousness as a big order. We know that the small client today is the big client tomorrow. We provide the full lifecycle of support. From the first drawing on a piece of paper to the mass production factory floor, we are there. We are ready to help them scale up when the time comes.

6.How to scale cannabis softgel production from R&D to commercial manufacturing?

The key is starting with a versatile R&D softgel encapsulation machine (like the SEM-50 pilot models). These machines allow you to test specific formulations—such as cannabis oil or essential oils—using minimal raw materials. Once the process parameters (temperature, ribbon thickness, and filling volume) are validated, they can be directly transferred to larger production lines without re-developing the process, ensuring a smooth transition from lab to factory.

7.What are the challenges of encapsulating essential oils or CBD in softgels?

High-value oils like CBD and essential oils require high-precision filling pumps to ensure dosage accuracy and minimize waste. Additionally, these oils can sometimes react with standard gelatin. A complete solution often involves testing different shell materials (such as Tapioca or Carrageenan for Vegan options) and using equipment designed to handle volatile or viscous liquids without leakage during the sealing process.

8.What equipment is included in a complete softgel R&D pilot line?

A complete R&D solution typically includes a compact softgel encapsulation machine, a gelatin melting tank (small capacity for lab use), rapid tumble dryers, and a cooling system. For specialized products like cannabis softgels, additional integration for oil preparation and visual inspection systems may be recommended to ensure every capsule meets quality standards before mass production.

9.Can your R&D machines handle Vegan (Starch/Alginate) softgel production?

Yes, modern R&D softgel machines are designed with flexibility in mind. They can handle specific temperature controls and die roll designs required for plant-based gelatin alternatives. This is crucial for cannabis and essential oil markets, where consumers frequently prefer clean-label, vegetarian-friendly capsule shells.

Conclusion

We support you from the first inquiry to full-scale production, offering machines, layouts, and technical solutions to ensure your business grows successfully.

Don't forget to share this post!

R&D to Scalable Softgel Production

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine