Start-up Guide: Free Formula & GMP Layout Design for Your First Softgel Production Line

Many new manufacturers feel stuck when moving from outsourcing to in-house production. You worry about the lack of formulas, factory layouts, and technical experience. This fear often stops your business growth.

We recently helped a client switch from contract manufacturing to owning their own line for vitamin hair oil. We provided a complete SEM-200 softgel line, a free gelatin formula, and a customized 12m x 4m GMP layout design to ensure they hit a capacity of 25,200 capsules per hour.

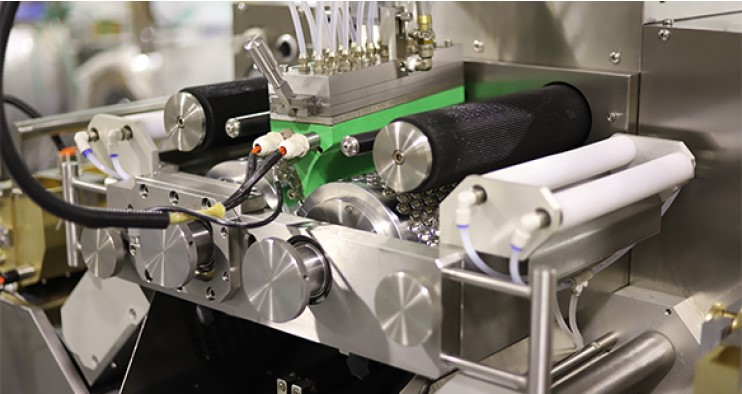

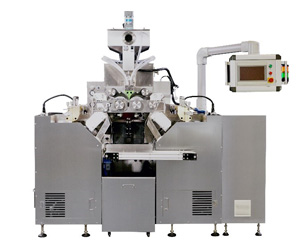

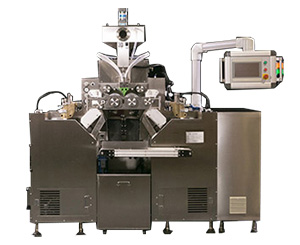

Softgel encapsulation machine production line

Moving production into your own facility is a big step. It gives you control over costs and quality. However, it also brings many questions. You might ask, "Do I have enough space?" or "How do I make the gelatin mix?"

We faced these exact questions recently. A client approached us wanting to make vitamin hair oil softgels. They had the market, but they did not have the machines. They relied on third-party factories before. Now, they wanted to keep the profit. We guided them through every step. Let me share exactly how we did it.

1.Can we match your specific softgel shape and capacity requirements?

Most startups worry that their unique product shape will be hard to manufacture. You might think that standard machines cannot handle your specific design or volume needs.

We confirmed the client's 1ml vitamin hair oil shape was perfectly compatible with our equipment. We provided a full solution including the melting system, mixing tanks, encapsulation machine, tumble dryer, and recycling system to meet the 20,000-30,000/hour target.

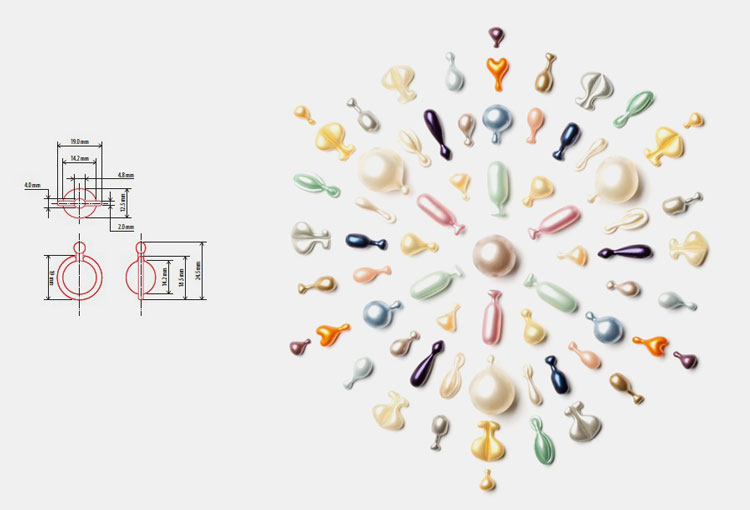

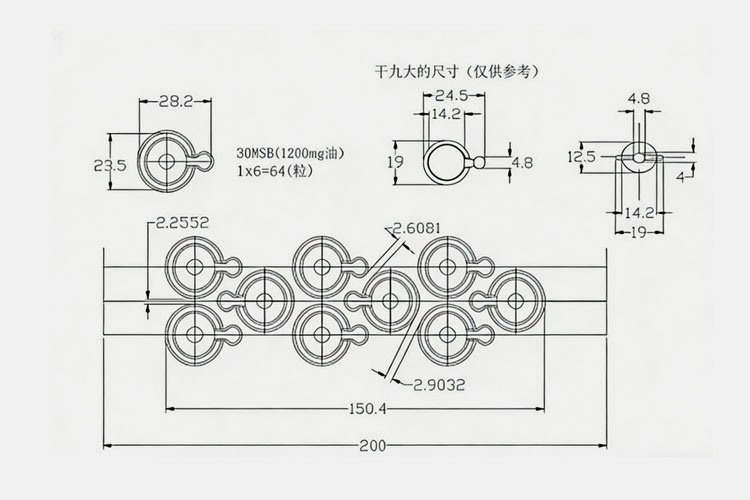

Customer softgel die roll and sample shape

When this client contacted us, they sent a specific design drawing. It was a 1ml softgel for hair care. It looked like a small bead with a twist-off top. They asked a critical question immediately. They wanted to know if we could make this specific shape.

I told them, "Yes, absolutely." We have manufactured this exact shape many times before. To prove it, I sent them a video. It showed our machine running a test with that exact mold. This gave them confidence right away.

But the machine is only one part of the story. The client was new to this. They did not just need a machine; they needed a process. I explained that we supply the whole line. This includes the gelatin melting system to prepare the shell. It includes the liquid preparation tanks for the medicine inside. It includes the tumble dryer to harden the pills. We even include the recycling system to save money on wasted gelatin.

We do not just sell a box of metal. We sell the ability to produce. For a client moving from outsourcing to in-house work, this "turnkey" approach is vital. They do not have to shop around for five different suppliers. We handle the integration of the chemical mixing and the mechanical pressing. This ensures the capacity target of 20,000 to 30,000 pills per hour is not just a theoretical number, but a reality.

2.How do you fit a GMP-compliant line into a small 12x4 meter room?

Space is often the biggest constraint for new factories. You might believe your current workshop is too small to host a professional, GMP-standard pharmaceutical production line.

We designed a linear layout specifically for the client's 12-meter by 4-meter room. We advised separating the melting, encapsulation, and drying areas with independent doors to strictly control temperature and humidity for GMP compliance.

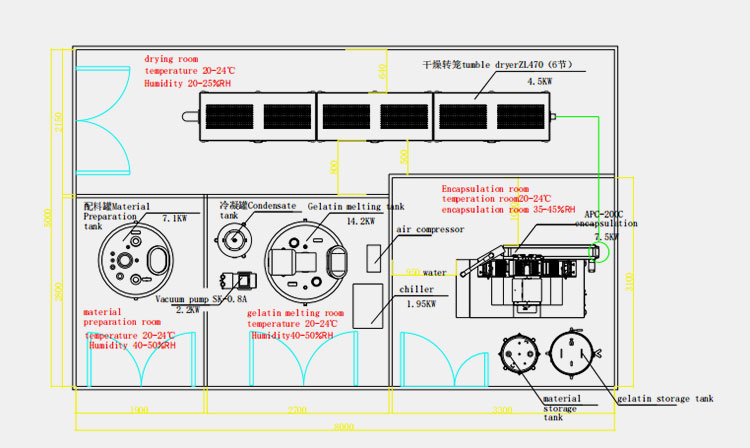

Factory layout design for softgel line

I The client had a big concern. They had a room, but it was not a huge warehouse. It was 12 meters long and 4 meters wide. They asked me, "Is this enough?"

I looked at the dimensions. It is tight, but it is possible. I drew up a "Linear Layout" for them. This means the machines are arranged in a straight line to save width. However, simply fitting the machines in is not enough. You must think about the environment.

I gave them very specific advice. You cannot put the gelatin melter and the tumble dryer in the same open room. Why? Because the melter creates heat and steam. The tumble dryer needs cool, dry air. If they are together, the softgels will never dry properly.

I advised them to build partition walls. We divided the 12-meter room into three distinct zones.

The Melting Room: This is for preparing the gel.

The Encapsulation Room:This is where the machine runs.

The Drying Room:This is where the final product hardens.

Each room needs its own door. This is a requirement for GMP (Good Manufacturing Practice). It prevents cross-contamination. It also allows you to control the air conditioning in each room separately. We marked the specific temperature and humidity requirements on the blueprint for them.

| Room Type | Temperature Requirement | Humidity Requirement | Reason |

| Melting Room | 60°C - 80°C (In Tank) | Standard | High heat needed to melt gelatin powder |

| Encapsulation Room | 20°C - 24°C | 40% - 50% RH | Gelatin ribbon must be cool to form the shell |

| Drying Room | 20°C - 22°C | 20% - 30% RH | Low humidity is critical to remove moisture |

The client was very happy with this. They used my drawing to renovate their room. It saved them from making expensive construction mistakes.

3.How do we calculate production speed and why use servo motors?

New producers often struggle to calculate exact output and choose the right motor technology. You need to know exactly how many pills you can sell and ensure the machine runs smoothly.

We calculated that with an 84-cavity mold running at 5 RPM, the output is 25,200 caps/hour. We recommended servo motors for the main drive and die rolls to ensure precise speed control and easier operation.

Servo motor configuration on softgel machine

The client looked at the layout and asked, "Okay, but how much can I actually make?" They needed to plan their sales.

I broke down the math for the SEM-200 model. It depends on the size of the pill. For their 1ml hair vitamin, the mold is standard.

Cavities:One rotation of the mold cuts 84 softgels.

Speed:The stable running speed is 5 Revolutions Per Minute (RPM).

The formula is simple:

84 pills*5 RPM* 60min = 25,200 pills/hour

This met their requirement perfectly. However, I gave them an honest warning. I told them, "Do not run at 5 RPM on day one." A new machine needs a break-in period. I suggested they run at 3 RPM for the first month. This allows the gears to settle and the operators to learn the system.

Then we discussed the motor. Standard machines use simple frequency motors. They are cheap, but less precise. I suggested upgrading to **Servo Motors**.

Why spend the extra money?

Synchronization:The two die rolls must hit each other perfectly. Servo motors do this electronically. It is much more accurate than mechanical gears.

Adjustment:You can change the injection timing on a touchscreen. You do not need to open the machine and use a wrench.

New softgel size

The client accepted this advice immediately. They understood that ease of use was worth the small extra cost. This decision will save them hours of setup time in the future.

4.Why is visual inspection of the tanks and tooling essential before buying?

Buying expensive machinery from overseas requires trust in the material quality. You need to verify that the equipment meets sanitary standards and that the supplier understands the process.

We hosted a video conference to show the actual encapsulation process, the tumble dryer, and the 3-layer SUS316L mixing tanks. This confirmed the equipment quality and GMP compliance, leading to the final purchase order.

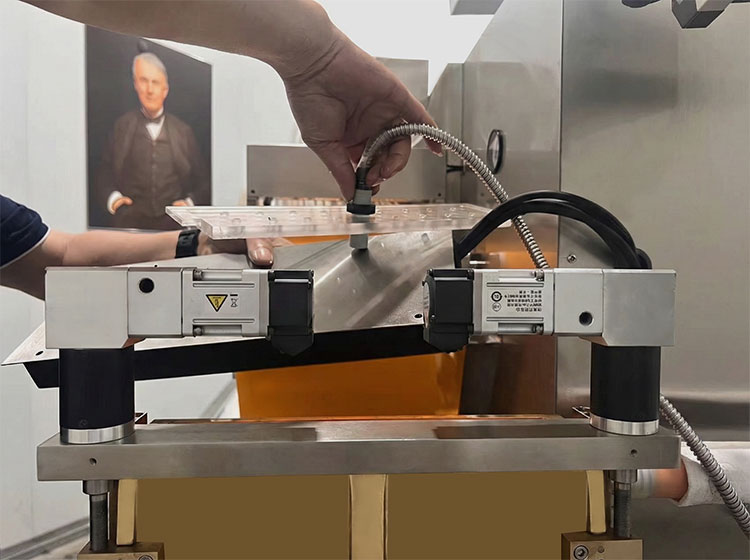

Stainless steel mixing tanks

The final step was a video call. The client wanted to see the "real thing." We set up a meeting to show them our factory floor.

I walked them through the whole process on camera. First, I showed them the service tanks. These are not just simple pots. I explained they are **3-layer tanks**.

Inner Layer:Touches the medicine.

Middle Layer:Holds hot water for heating.

Outer Layer: Insulation to keep the heat inside so you do not burn your hands.

AIPAK softgel encapsulation machine

I tapped the metal and told them, "This is all SUS316L stainless steel." This is a higher grade than the standard 304 steel. It is more resistant to acid and salt. For pharmaceutical products, this is non-negotiable. It is the only way to meet GMP standards.

PVC Tray

Die roll

Then I showed them the tumble dryer. I spun them by hand so they could see the smooth movement. I showed them the die rolls (the molds) and how shiny and sharp they were.

The client was previously a bit nervous because they had no experience. But seeing the machine, the tanks, and the layout gave them peace of mind. They realized we were not just selling a machine; we were teaching them how to use it.

They saw that we had the formula (which we gave for free), the layout plan, and the high-quality hardware. That video call was the turning point. Shortly after, they started the internal order process and sent the PO.

Conclusion

Starting softgel production requires more than just buying a machine; it requires formulas, GMP layouts, and capacity planning. We provide all of this to ensure your success.

Don't forget to share this post!

Frequently Asked Questions about Softgel Production

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 156 0710 8630

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine