Essential Oil Extraction Machine: The Complete Buying Guide in 2024

Revealing the Power of Nature!

Welcome to the world of essential oils! No one can deny the wonders of essential oils.

Essential oils are used in folk medications throughout history. They are also known as volatile oil or ethereal oil which is accompanied as a fragrant extracted from different parts of the plant used for various purposes.

Why have you called it essential?

Because it holds the essence of several fragrances and properties of those plants from which they are originated.

The essential oils are widely used for manufacturing of cosmetic, fragrances, food, and beverages as a preservative. At the same time, they retain outstanding therapeutic applications in the health sector or pharmacology, alternative medicines due to multiple benefits on biological activities.

Cumulatively, with a number of crucial applications, essential oils are now becoming a key ingredient of every manufacturing unit of industries.

Have you wondered how essential oils are made?

Let us explain, they are not manufactured but extracted from different plant sources. They are generally a liquified version of plant sources and works faster in blood than a raw plant that’s why we are not intended to consume it without knowing their doses.

READ more to understand how they are not manufactured but are somewhat extracted from plants sources.

This blog is intended for those who are interested to gain a more solid understanding of essential oils and their extraction machines.

You’ll find essential oils are not made though they are extracted from valuable plants sources with the help of essential oils extraction machines.

This blog will provide adequate knowledge that you should get before purchasing an essential oil extraction machine.

Let’s get into it!

1.What is an essential oil?

Scientifically, it is a class of ‘volatile oil’ that gives plants their characteristic widely applied in cosmetics, flavoring, therapeutic, and aromatherapy.

Do you know the meaning of volatile?

It means any substance that can easily evaporate at the normal temperature.

Typical essential oil is composed of more than 100 chemical constituents and each of them is created from the plant. They are mainly extracted from specific parts of plants such as leaves, herbs, petals of flowers, barks, or rinds.

The manufacturer of essential oils utilizes various methods to concentrate them into an oil form.

To better understanding, we will look at how they are manufactured later in this blog.

2.What does essential oil consist of?

In general, a pure essential oil is sub-categorized into two distinct units related to its chemical constituents.

- A) Hydrocarbons

A hydrogenated group is composed of terpenes such as mono-terpenes, di-terpenes, and sesquiterpenes.

- B) Oxygenated group

An oxygenated group of essential oils composed of; a) alcohols,

- b) aldehyde,

- c) ketones,

- d) phenols,

- e) esters,

and

- f) oxides.

Each constituent has its own significant physical, chemical, and therapeutic property.

3.What are the health benefits of essential oils?

Several scientific studies reported the prime benefits of essential oils. The main benefits of essential oils are as follow:

- Helping in Inducing Sleep

Yes, this is a common problem of today’s life. Therefore, people most often prefer sleeping pills.

But if you observe the magical wonder of essential oil for inducing sleep. You would probably love to use these oils for this purpose. This is mainly recommended for heart patients and post-partum depression in women. You can use lavender oil, rose, bergamot, and chamomile for this purpose.

Essential oils for inducing sleep

- Relieve stress and anxiety

A soothing aroma of essential oils produces calming effects and relieves stress and anxiety symptoms efficiently. Such as rose, orange, lemon is the prime examples that fall in this category.

Essential oils are considered the best therapy for relieving anxiety and stress

- Reduce headaches and migraines

Using essential oils on your skin definitely alleviates the unwanted symptoms of headache and migraine. For instance, applying peppermint, lavender, eucalyptus, or chamomile is best known for this purpose.

Essential oil headache roll-on

- Relieve inflammation and skin problems

There are many essential oils known for their effective therapeutic activity against acne, inflammatory problems, and so on.

Tea tree, bergamot, and rosemary have popular therapeutic remedies against this problem and are best known for acne and dermatitis. Furthermore, peppermint and wintergreen are useful in treating muscle tension.

4.What are the different types of extraction methods used for essential oils?

To get a better-quality essential oil, it is of great importance to opt for a proper extraction method. Because utilizing an inaccurate method can yield very little and non-quality products.

Discussed below are some specialized methods of extraction mainly used to obtain good-quality essential oils.

1. Steam Distillation

Steam distillation is a very common method of extraction employed for extracting aromatic essential oils. According to an estimation, 95% of essential oil extraction is carried out using steam distillation. Hence, due to different insoluble properties, you can get essential oil and pure dew.

A steam distillation machine- Essential oil Extraction Machine

2. Steam Diffusion

A steam diffusion method is similar to steam distillation. This method is also called an expression method. For steam diffusion, you are required to introduce steam from the top of the distillation tank while a liquid tank is present at the lower part. A steam diffusion has a significant extracting effect and gives a higher yield for wood, barks as well as a rhizome.

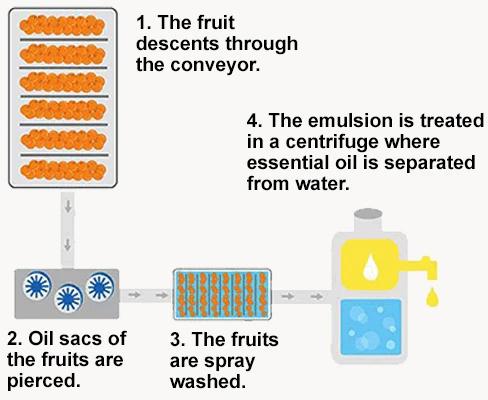

3. Cold Pressed Extraction Method

Citrus essential oils like oranges, grapefruit, or lemon are extracted via cold-pressed. The reason for using this process is to protect heat-sensitive components of natural compounds.

4. Solvent Extraction

A solvent extraction involved the utilization of solvents in order to extract and separation of essential oils. This method is preferred if you want to retain the original aroma in essential oils without harming the useful components due to heat processing. In the solvent extraction process a little quantity of leftover is considered as an absolute form rather than essential oils.

A solvent extraction machine for extracting essential oils- Picture courtesy-SRS

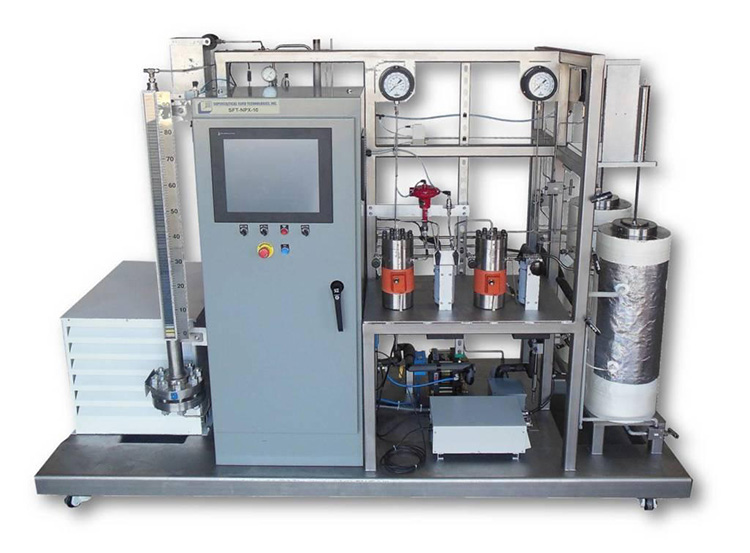

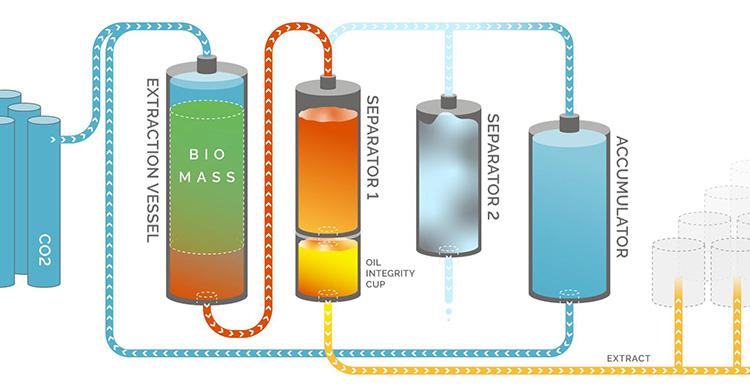

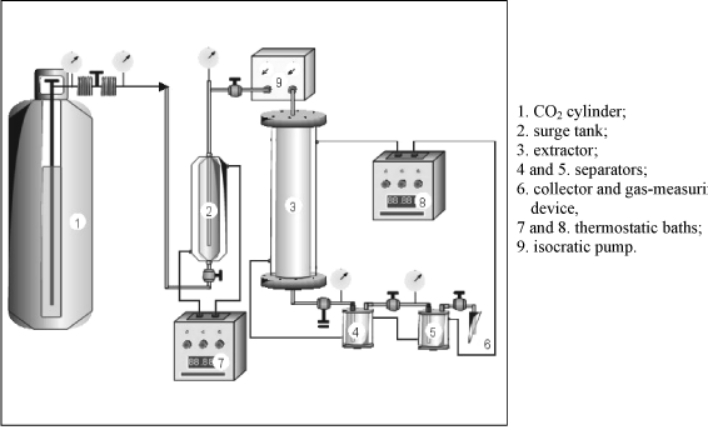

5. Supercritical CO2 Extraction Method

This is the latest and well-acknowledged method of extraction, that involves the utilization of temperature as well as pressure. Carbon-di-oxide can be used in liquid form (from gas to liquid) to obtained essential oils and their separation components. This is an expensive process but yield high-quality natural components from plants.

A SuperCritical CO2 Extraction Machine

6. Low-Temperature & Low-Pressure Steam Distillation

This is an optimized method that originated from the conventional method of steam distillation. In this process, you can lower the steam temperature to rupture the oil storage cell. This is a useful method that facilitates the great extent of essential oils without damaging the heat-sensitive ingredients.

5.Can you explain the difference between the extraction and distillation methods?

The method of extraction and distillation is commonly used for the physical separation of many pure compounds utilized in many applications as mentioned above.

Based on the procedure, they are somewhat different. For instance, a key difference between extraction and distillation is that, for extraction we use suitable solvent systems for separation of different components whereas in the distillation process you can apply temperature on the liquid mixture and collect the vapors of the liquid mixture at their boiling temperature and condense them to obtain a pure substance.

6.What is an essential oil extraction machine?

An essential oil extraction machine is extensive equipment refer for the extraction of essential oils and dedicated natural dew. Supercritical CO2 essential oil extraction machine most often used to isolate multiple components of plants as it facilitates a pure, safe and cleaned product.

A utilization of CO2 essential oil extraction process is commonly preferred way to pull out the desired natural phytochemicals content of plants. For instance, you can extract out terpene oils, waxes or cannabinoids from cannabis using an efficient method of CO2 extraction process.

This is highly extensive way to extract the ingredient as carbon dioxide gas gets super critically into the minor spaces in the form of gas and dissolves the advantageous components. When a molecules are in supercritical state it demonstrates the properties of both liquid and gas. So, CO2 gets into a super-critical state at 107psi and 31.1°C temperatures.

The manufacturer would rather choose this method as it is the most versatile and adjustable process. A supercritical CO2 essential oil extraction machine acts as a solvent at acquired temperature and pressure but it does not have any harmful factors that mainly associated with other extraction methods such as using chemical solvents like butane or hexane.

Users can get safe and premium quality machine that is commonly used in pharmaceutical, food, and beverages industry. For instance, you must have observe sprinkling of soda in water, this is due to presence of CO2 that stimulates fizz to drinks.

7.What does the meaning of ‘Supercritical’?

CO2 is most common usable gas present naturally in the earth’s atmosphere.

Though, it can also be transformed into liquid form and to facilitates this CO2 is treated in a specialized machinery that ultimately put an immense pressure and temperature. At this state, CO2 becomes neither liquid nor gas, and termed as a ‘supercritical state’. A supercritical state of CO2 is very effective in extraction of many useful components from planetary sources.

8.How can you explain supercritical CO2 extraction VS solvent extraction?

- A CO2 essential oil extraction machine is safe equipment as it does not involve with usage of organic solvents such as ethanol, butane etc. So, it gives high feasibility to operator especially if they’re working under high temperatures. Whereas, in solvent extraction that involves in CBD extraction process are comparatively flammable and you should require a high safety precautions while extracting and storing the materials.

- CO2 essential oil extraction machine passes CO2 gas via trim and then operator can recycle it back into a its original tank for reusing. Therefore, CO2 is considered as safer and environment friendly than other organic solvents.

Supercritical CO2 Essential Oil Extraction Machine

- CO2 essential oil extraction machine has high initial cost when compared to remaining extracting equipment. Whereas initial cost of solvent extraction machine is very low.

- CO2 essential oil extraction machine require a specialized training to operate the system for production, but solvent extraction machine need far-less specialized trained staff as well as their operating procedure is easier.

Solvent Extraction Machine- Picture Courtesy- OPM

9.What are the pilot-scale and commercial scale essential oil extraction machines?

On an industrial scale, there are basic two categories of essential oil extraction machines that are used for extracting components of plants implemented for a variety of purposes.

- The Pilot-Scale essential oil extraction machine

- The Commercial Scale- essential oil extraction machine

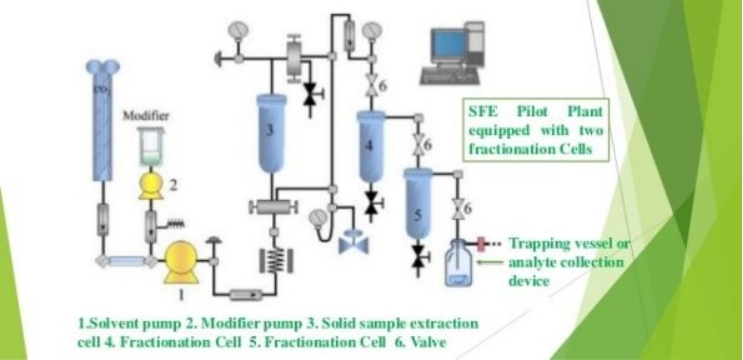

A)- The Pilot Scale Essential Oil Extraction Machine

Small essential oil extraction machines are widely used to obtain a high-quality extraction, purification, and separation processes.

These machines are highly efficient used in herbal, cosmetic, and biological manufacturing units to get high value herbal extracts, terpenes, and other valuable compounds such as CBD.

This equipment uniquely helps you in research laboratories, colleges, and universities for multiple collection and extraction processes. This system also facilitates an efficient way to control pressure, temperature and run time to collect various fractions of desirable components. The small-scale essential oil extraction machine allows you to continue rapid extraction process with short cycle time.

The Pilot Scale- Essential Oil Extraction Machine- Picture Courtesy: Accudyne systems

B)- Commercial Scale- Essential Oil Extraction Machine

A large essential oil extraction machine is a highly extensive and widely used equipment for manufacturing of large batch production related to medicinal, food, cosmetic, and other sectors.

The Commercial Scale Essential Oil Extraction Machine- Picture Courtesy: Accudyne systems

A large-scale production system of CO2 essential oil extraction machine is well-instrumented and controlled process. Each and every component of the system is automatic, controlled with a help of touchscreen interface. You just have to require a pre-load the extracting set up, load the material into the extracting vessel and initiate the run.

So, you do not require overwhelmed manpower until the whole reaction is complete. After completing the extraction process, you will be required to emptied and reload the system. This system is feasible to run single as well as multiple extraction vessels. The recovery of extract is carried out into a single as well as multiple separating vessels.

10.What are the important components of essential oil extraction machines?

Main Components of CO2 Supercritical essential oil extraction machine are:

- CO2 Feed Tank

The CO2 feeding tank temporarily stores or reuses CO2 which is recycled from the extraction process. They are efficient in converting CO2 gas from one state to other such as gas to liquid.

They are as fine pneumatic and significantly effective so, lessens the need for recurrent maintenance and development.

- CO2 cylinder

A CO2 cylinder should be properly fitted with a ‘siphon type cylinder’ or dip tube. This allows to extract from the cylinder bottom, and you can get CO2 in its liquified form instead of vapor.

The topmost valve can easily move and opened with help of the handwheel of the valve in a counterclockwise dimension. Similarly, it can be closed via turning clockwise till it stops.

You will also see a pressure-relieving valve used to release the pressure when rises above pre-set levels that automatically discharge the cylinder.

- Condenser

The condenser is a very important device in the extraction process as without it you cannot run the extraction procedure. It is essential for CO2 recirculation and can be utilized to transform the physical state of CO2 from gaseous to liquid. For a small system, a condenser has a double pipe configuration while a pipe configuration on an industrial or large-scale system. So, you do not require a plate exchanger because it clogs easily, and it cannot resist a standard CO2 pressure.

When CO2 comes from the separator in the gaseous state it transfers into the condenser where it liquifies and is stored, waiting to be pumped yet again in the circuit.

- CO2 pump

This machine has especially constructed CO2 pumps that are hydraulically driven by giving high pressure. As CO2 is capable to transform rapidly into a gaseous state, therefore, strict regulation of temperature and pressure on the inlet and discharge valve will facilitate proper maintenance of CO2 in a liquid state.

A CO2 pump- Picture Courtesy- MIC

- CO2 Pre-Heater

A CO2 pre-heater is used to avoid the condensation within the heat recovery system, where condensation can cause problems.

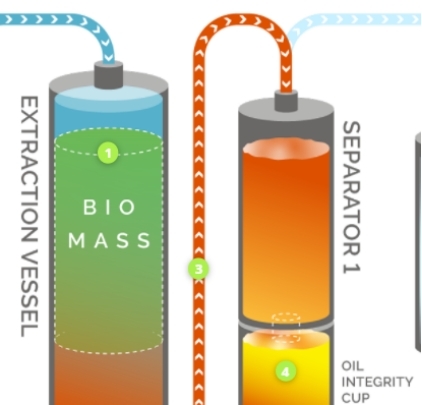

- Extraction Vessel

Based on the model of the essential oil extraction machine the container for raw materials is available as a combined or separate unit. Extracting vessel is made entirely of stainless steel which is being filled with raw material with the help of a basket. There are many extraction vessels collectively combined to a functional system. So, the process of extraction can be carried out continuously despite batch production.

- Separator

In separator loaded CO2 with extract are separated by mean of change in pressure and temperature. In this condition, the extract gets separated from CO2 and collected at the bottom of the separator. In separator solvent properties of CO2 facilitate the fractionation of extract components into various separators.

CO2 then expands and transforms into a gaseous form and removes all remaining components.

- Back Pressure Regulator

A back pressure regulator (BPR) allows a defined pressure upstream of itself their own inlet. When the pressure at the inlet reached the setpoint, the BPR valve opens in order to release the excessive pressure. In simpler words, a back pressure regulator holds pressure built during production vessels, for instance, separators, extractors, so it releases as it exceeds the setpoint.

A back pressure regulator

11.What industrial sector requires an essential oil extraction machine?

Essential oils have diversified applications in various industrial sectors in the manufacturing of therapeutic agents or as excipients. Additionally, they are frequently used in making food and beverages units.

Mentioned below are the following applications of essential oil.

1- Cosmetics

Essential oils are used as prime ingredients in the manufacturing of cosmetics due to their anti-bacterial, anti-inflammatory as well as antiviral properties. So, they serve as a preservative in the making of the organic cosmetic manufacturing unit.

Moreover, essential oils are of great interest in perfume, soap, and detergent industries because of their economical point of view. Due to these properties, the essential oils from specific plants are in high demand such as lavender, salvia, citrus, or rose are considered as a novel entity in perfumery for boosting the quality of the final product.

Various Application of Essential oils extraction machine- Picture Courtesy- GMS

2- Medicine and Pharmaceutics

Generally, essential oils have wide pharmaceutical and medicinal applications for their potential therapeutic activities. For instance, peppermint, clove, star anise, tea tree, or eucalyptus.

Did you know these oils are used when you cough?

Because eucalyptus has bronchodilatory properties, it opens your breathing airways allows easy breathing. Similarly, tea-tree sage or clove has antimicrobial properties. If you feel congestion peppermint oil drops help to relieve the respiratory congestion. Clove oil is used when you have mild to moderate dentistry problems.

The most troublesome skin issue is to treat acne, for this purpose tea tree oil extract is in growing demand among pharmaceutical and cosmetic industries.

Furthermore, in pharmaceutical preparations, essential oils are used to promote taste and aroma. Many topical preparations of contained essential oils in a diluted form are used in massage therapy, inhaling, used in steaming and atomizers, or applied as creams or ointments.

Their oral applications are involved in encapsulation or programmed release protocols. They may be consumed in the form of tea or in soft gel capsules to achieve an accurate dosage.

3- Food & Beverages

The essential oils are broadly used in a variety of food and beverages manufacturing areas with an expanding pace in the global market.

The researcher also recommended that the incorporation of essential oils coating, microencapsulating or combination with other preservatives is useful in reducing microbial growth certifying the protection and quality of poultry and meat foodstuffs.

4- Bio-Pesticides

Essential oils offer antiparasitic, anti-bacterial, anti-viral, fungicidal, and insecticidal properties. Because some of the essential oils are extracted from those plants which may produce toxicants and regulating the growth of insects greatly involved in pest management in crop production.

5- Agro-Food

A supercritical CO2 essential oil extraction machine broadly represented with a super-growing and a useful technology. To isolate and purify orange juice this technique is preferred. Because as you know, you can not use boiling procedure to purify the orange juice as boiling may harm the taste and benefits associated with it. Also, it is proved that you cannot subject the planetary sources to extreme temperatures, therefore, plants do not experience any harmful factors that degrade their active constituents as it does with other extracting procedures.

Similarly, for nutraceuticals applications many scientific studies recommended to use this equipment for variety of products such as spices, alkaloidal compounds, various antioxidants, vanilla and much more.

6- Sterile Products

In the field of sterile product manufacturing, utilization of supercritical CO2 essential oil extraction machine is of prime importance and has demonstrated uncountable benefits. This is well-recognized instrument to provide a product that has no traces of residues, delivers a pure final extract that ensures product is free of pathogen and traceability.

If you any residue is left on the extract it can easily be evaporated because CO2 is become gaseous in room temperature. That’s why extract attained from CO2 extraction machine is appealing to pharmaceutical, food and beverages departments. As it assures you that extract is devoid of residual solvents and purer than other solvent based extraction systems.

12.What is the working principle of an essential oil extraction machine?

The basic working principle of an essential oil extraction machine is based on utilization on temperature and pressure to attain a purified and isolated heat-sensitive content such as aromatic compounds. A co2 is well-known as a ‘tunable-solvent’. It has significant role in obtaining multitude end product by modulating temperature and pressure. Due to this property different fractions of plant component can be isolated depending upon their weights. The collection of light weight essential oils from heavier lipids are easier with the use of CO2 essential oil extraction machine.

Let’s have a look on the working principle of CO2 essential oil extraction machine.

#1- Filling of Biomass

As you know that extraction is the process of isolating essential oils from planetary sources. During this process you will always solvent systems such as ethanol, butane, supercritical CO2, or water. So, in this step you need to fil the extraction vessel with biomass.

#2- Pressurize the Vessel with CO2

After loading the biomass, you can pressurize each respective vessel with CO2 from a supply chamber.

#3- Run in a Closed Loop

In an extraction vessel various components are ejected/pulled out from the biomass into the solution.

In separator 1, CO2 is boiled out of solution.

This evaporated CO2 is captured and condensed into a liquid form which is stored in accumulator.

#4- Periodically Collection of Extracted Sample

When CO2 starts accumulating into an accumulator, you can open the valve of oil integrity cup. By doing this, you can collect the extraction samples periodically. You should not remove the integrity cup.

#5- Depressurize

After completion the run time, the system is now depressurized via released of CO2 across the separator 2.

#6- Collection of Extract

Collection of extracts can be done from oil integrity cup.

13.How to install an essential oil extraction machine?

Installation of essential oil extraction machines is carried out by individuals with proper training and expertise in machine installations to avoid any potential loss during operations. Company representatives may help in the first time assembling and installation procedures. The essential oil extraction machine is customized to the consumer's need and based on the requested size, each component may be provided in single or separate wooden crates. The following points should be part of any installation SOP’s.

Installation of Supercritical CO2 essential oil extraction machine- Picture Courtesy- careddi

- Use of fork lifter or any other proper equipment with approved specifications is recommended to move the wooden crates. Do not use cables to bring the machine to the installation site.

- Care should be taken to open the wooden crates with hammers and steel bars. Avoid hitting the machine while opening the crates in some models’ condensers and oil and water separating units are made up of glass. A list of components is provided with the essential oil extraction machine. Immediately report to the manufacturer in case of any damage to the machine or missing parts.

- The installation site of the machine should be properly grounded for electrical connections.

Installation of Supercritical CO2 essential oil extraction machine

14.What are the benefits of essential oil extraction machines?

As you know, by using a supercritical CO2 essential oil extraction machine, you may have total control over the manufacturing process. As it cannot harm you and environment because CO2 is entirely recycled making it more environment friendly process as compared to other extracting procedures and equipment.

Interestingly, FDA has labelled supercritical CO2 essential oil extraction machine as CO2 safe for entire industrial sectors that involved with extraction procedures. A CO2 may act as cleaning agent that prevents microbial growth, molds, mildews that are eliminated during the procedure.

They yield from supercritical CO2 essential oil extraction machine is absolutely higher than other methods of extraction. Additionally, the determination of quality of products and yield can easily be diversified via modulating the physical properties.

#1- Extraordinary Healthcare values- High Nutritional Content

The low-temperature method always is of great importance as it potentially protects the entire spectrum of active and beneficial constituents. For instance, mineral, vitamins, antioxidants, and fatty acids in plants that brilliantly facilitates the perfect therapeutic functions.

#2- Original Aromatic Constituents

Compared with other methods of product isolation, extraction of essential oils via essential oil extraction machines can closely provide you original aromatic constituents with greater than 90% of original fragrances because upon the high temperature you can easily destroy the active and sensitive ingredients present in essential oil.

#3- Small Investment and High Production

Essential oil extraction machines cost very low as well as little production expenditure which is suitable to run large-scale industrial manufacturing services.

#4- Broad Range Extraction

An essential oil extraction machine is useful to extract many important constituents known as immiscible substances in a cost-effective range.

#5- High-Quality Product

Essential oil extraction machines result in extractions of cleaner and pure oil as it expels unwanted solvent residues from oil. The oil yield by an essential oil extraction machine is more reproducible and, you’ll high-quality product closed to nature.

#6- Automatic Control

Essential oil extraction machines facilitate an automatic control system, one person can easily operate the machine to get a high yield of essential oil.

Automatic Control system of the Essential oil extraction machine- Picture Courtesy- Arone

#7- A Stainless Steel Equipment

Essential oil extraction machines are mainly constructed using stainless steel which is an efficient and corrosive free material that provide long-lasting equipment stability.

Essential oil extraction machines- Picture Courtesy- GMS

15.What are the disadvantages of essential oil extraction machines?

#1- High Operating Pressure

The primary disadvantage associated with supercritical CO2 essential oil extraction machine is high pressure modulation requirement to maintain the solvent in sustainable form. Essential oil extraction machines are a highly expensive way to obtained essential oil on a larger scale. As result, it causes a higher capital and operating cost.

#2- Longer Time Duration

The essential oil extraction process is a time taking procedure that requires intensive energy to recover solvents, especially in solvent extraction machines.

#3- High Power Consumption

It requires high-power expenditure to establish the extraction process of essential oil extraction.

#4- High Maintenance Cost

A supercritical- CO2 essential oil extraction machine requires high maintenance for entire components associated with machine. Therefore, high cost incurred.

16.What safety measures are required to operate essential oil extraction machines?

Essential oil extraction machine is continuously being assembled and dismantled for the input of materials or cleaning purposes therefore, the machine is provided with safety features to reduce any operational hazards during any process. These include pressure gauges, silicon tubing between boiler and material basket, safety valves, and electrical earthing. However, the following safety measures should be practiced reducing accidents during the process.

- Individuals with proper training (hours) will operate essential oil extraction machines since special precautions are required when handling steam and boiler.

- Operators will use proper protective gear such as heat-resistant gloves helmets safety goggles and safety shoes during operations.

- Do not remove any parts during the process and before one hour of complete shutdown.

- After each assembling and dismantling of the essential oil extraction machine, proper checkpoints will be ticked. These include connections and fittings, refer to the manual for further details.

- In case of any error during operations, the power supply to the boiler will be immediately cut off and pressure released using a safety valve before moving towards other components.

17.How to clean and maintain the essential oil extraction machine?

A properly maintained essential oil extraction machine will give the best and effective output for a long period production and performance. Maintenance should be carried out as per scheduled time to reduce the cost incurred due to malfunction of instruments. Following key points should be followed when carrying out maintenance of the machine.

Supercritical CO2 Essential Oil Extraction Machine

- Focus on the Key Components of the Extractor

Key components of essential oil extraction machine may include extraction vessel and separating vessels, pipes, connections, chiller, and compressing pump. So, it is necessary to become familiar with these components and understand their working performance. This knowledge will help you to choose the unique parts and you will be well aware of cleaning them during use. Moreover, during troubleshooting this knowledge will allow you to overcome any problem if arise. Personnel equipped with proper training and knowledge will conduct the cleaning and maintenance of essential oil extraction machines.

The common cleaning process include:

- Flushing of separating vessel and connecting lines with ethanol. Check if residue present in separating vessel and in downstream filter. Proper flushing will minimize the incidence of clogging and poor separation during process. This protocol should be strictly followed if you’re running multiple samples of different strain using same equipment that may cause cross-contamination.

The common maintenance points include

- WEEKLY:

Maintain a CO2 compressor, oil levels and running oil pressure at every week. Always examine changes in the level of noise and vibration of machine during each run. The electrical earthing of the equipment should be conducted on regular basis (refer to the manual).

- MONTHLY

Pump connection should be checked and examine the belt tension every month. Rubber tubing and connections should be checked every month and replaced if required.

- BI-ANNUALY

At every six months oil filter should be replaced. Diaphragm should be changed at every 18 months to minimize the downtime.

- Keep a Maintenance Log

Once you decide what need to be performed and when it performs should be

properly maintained for each extraction system that will allow you to acknowledge the routine maintenance. The scheduled maintenance is carried out based on the utilization of the equipment. Maintenance of the functional machine is carried out after half an hour switching OFF of the main electric supply. Keep in mind that the boiler should be emptied first before carrying out regular maintenance.

Make sure every run has its assigned logging record for reference.

- Have Spare Parts

It is of great importance to keep every spare parts of machine available indoor such as valves, belts, filters, and oils, that may require over time. This will allow quick repairing and lowers the downtime. So, keep the stock log of the following parts and replenish when required.

18.Do essential oil extraction machines comply with international quality standards?

An international quality standard generally focused on the entire relevant requirement, specifications, services, and safety parameters of essential oil extractions machines.

Therefore, when you are going to purchase an essential oil extraction machine you must consider some basic concepts.

These parameters must be highlighted and should not be ignored to ensure good quality practices assigned by international bodies for this equipment. These factors are of prime importance when it comes to pharmaceutical preparation, food, and beverages.

Supercritical CO2 Essential Oil Extraction Machine

Mentioned below are the following product certification that the essential oil extraction machine complies with. So, you need to confirm whether the following machine has passed the certification of relevant bodies.

1- CE Certification of Quality Standards

CE-certified essential oil extraction machine ensures that the manufacturing of this machine meets the entire assigned parameters associated with health, safety, and security. Furthermore, all components and services of essential oil extraction machines are well-documented.

2-cGMP Standards

cGMP is the leading regulatory standard that is mandatory for every pharmaceutical and food industry.

An essential oil extraction machine has safe and Current Good Manufacturing Practice that conforms with the quality standard required for human consumption.

3- ISO Certifications

Essential oil extraction machine is an ISO verified instrument that follows the required management and manufacturing values for quality assurance and standardization.

4- Food and Drug Administration

An FDA is a US government agency related to health and human services. The purpose of FDA certification is to ensure the protection of consumers via regulating and controlling food consumption and related equipment. So, it is necessary to confirm the FDA certification before buying this machine.

19.What are the buying guidelines before purchasing essential oil extraction machines?

You must look for many things when purchasing an essential oil extraction machine.

Price, reliability, working, and safety are the topmost criteria that come swiftly to mind. To run any business, procurement management and purchasing the machine the key goal should be to get a good deal that firmly meets with the system of manufacturing unit/company.

So, to get a positive experience and efficient decision kindly read the following factors that will help you in assessing a suitable extraction system.

- Be Clear on Capacity Requirement

If you want to establish an extraction plant capable of processing hundreds of pounds of biomass each week, then you need to opt for such a system that can meet up your needs. Such as small- extraction units requiring longer time, energy, and cost to run bulk volume goals.

Therefore, you need to be clear about your working needs before deciding on an extraction unit. It may also help you to ascertain the revenue opportunity.

- Evade Outrageous Claims

A savvy buyer must know the significance of investing time in realizing and understanding the entire process or product before purchasing it. You are well aware of marketing strategies in an extraction environment that are flooded with outrageous claims.

So, it is well acknowledged to consider the science of extraction and categories of equipment or manufacturer. Perhaps it will make you purchase a piece of quality equipment free of errors or wasting energy.

- Knowing the Safety and End Goals

Before purchasing an essential oil extraction machine, you must consider the safety and end goals. For instance, what you’re producing or the targeted compound and recoverable material? Knowing safety and end goals will allow you to identify the selection of appropriate extraction equipment based on profit margin, cost-effectiveness, and time efficiency.

- Licensing, Shipment Charges, and Setup Facility

The required licensing and regulation related to essential oil extraction machines may vary among different nations, states, and cities.

Additionally, you must look for manufacturer packages for the installation and shipment process. A good manufacturer company provides these services to gain customer satisfaction and comfort them. Furthermore, before purchasing an extraction unit, you must consider your lab facilities and set up to ensure the extracting machine will be able to get into it properly.

Because it is rather difficult or impossible to move five-foot wider equipment in a smaller hallway or assemble a ten-foot longer system in an eight-foot-high room that can be a daunting job. Therefore, it is necessary to know your room dimensions before going to get an extraction unit to save your retrofitting cost.

Keeping above mentioned tips when making a purchase of an essential oil extraction machine will better prepare you to make a sensible decision that can establish a goal for your company’s success.

Supercritical CO2 Extraction Machine Related Products

Supercritical CO2 Extraction Machine Related Posts

Supercritical CO2 Extraction Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours