Automatic Liquid Filling Machine:The Complete Buying Guide in 2025

It is a must to have a Automatic Liquid Filling Machine according to the fast production requirements of the these days pharmaceutical business.

The challenge is huge if it does not match your production needs. Comparing with the other available choices in the market like manual methods of filling are out dated. It is not only faster it is also efficient. Automatic Liquid Filling Machine has not been the need of the many pharmaceutical business.

In today’s i will explain why you need Automatic Liquid Filling Machine and what you need to know when you want to buy Automatic Liquid Filling Machine. This article will be covering each and every small details of Automatic Liquid Filling Machine. Let’s dig in more.

1.What is Automatic Liquid Filling Machine?

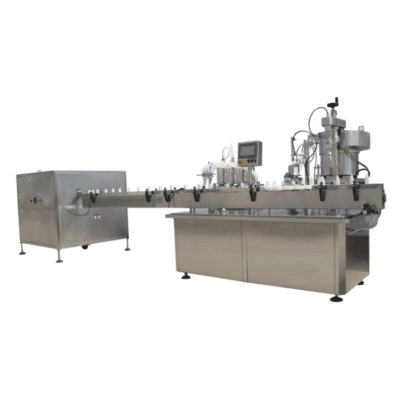

AIPAK automatic syrup filling machine

The Automatic Liquid Filling Machine is equipment which is specially used in the pharmaceutical industries for packaging process of the products made by the liquid.

The Automatic Liquid Filling Machine is the most needed equipment in packaging the liquid products.

The quality of the product matters the most which makes it efficient in working.

Moreover, in terms of quantity again it needs to be a the good quality Automatic Liquid Filling Machine for working to increase the quantity rate.

All types of fluid can be filled by the Automatic Liquid Filling Machine like the granules powder, creamy fluid and dense fluid.

The packages in which packaging is done are liquid bottles, small pots, the buckets, small pouches and many other types.

So, the Automatic Liquid Filling Machine is a very useful product in the industries. It makes the work easier for the producer.

2.What are the uses of Automatic Liquid Filling Machine?

The Automatic Liquid Filling Machine is commonly used in Pharmaceutical Industries. In the Pharmaceutical Industries the machine is used for the packaging and filling process.

The packaging is done accurately by the Automatic Liquid Filling Machine without any fault.

The process of filling is done in various steps. The steps are as follows:

- Filling of Vials

The process which is used to fill the bottles with the required liquid by the Automatic Liquid Filling Machine.

The Vial Filling is the filing of liquid medicines in the bottles.

- Capping Filling

This is the feature of Automatic Liquid Filling Machine which helps the medicines not to overflow from the bottles. The capping of bottles is done in this process.

The bottles are capped very tightly to avoid overspill of the medicine in the liquid form.

Capping Filling

- Filling with Accuracy

The Automatic Liquid Filling Machine is very good in accuracy. The equipment works accurately in filling the liquids in the bottles.

- Lessens Wastages

The Automatic Liquid Filling Machine also prevents the wastage of the material. It minimizes the wastage in the production.

So, this helps in increasing production.

- Labeling of Products

The labeling of the product is also done by the Automatic Liquid Filling Machine. The full information about the product is given on the label of the product.

So, the Pharma industries use Automatic Liquid Filling Machine as a labeling machine also.

- Hygiene Standards

The Automatic Liquid Filling Machine also follows the hygiene standards during filling of the liquid in the bottles.

In this machine the manual work is very less so the product is fully safe and hygienic to use.

- Production Efficiency

The Automatic Liquid Filling Machine is highly efficient in the production. It works very fast and improves the production rate.

So, efficiency matters when there is a higher rate of production.

3.What Advantages Automatic Liquid Filling Machine offer to you?

The Automatic Liquid Filling Machine is very advantageous in the Pharmaceutical Industries.

The equipment makes the work very easy. It gives you many advantages such as:

- Consistency

The Automatic Liquid Filling Machine is very consistent in filling the liquids in the bottle. It works with more efficiency than doing the filling manually.

The equipment does not stop in the filling.

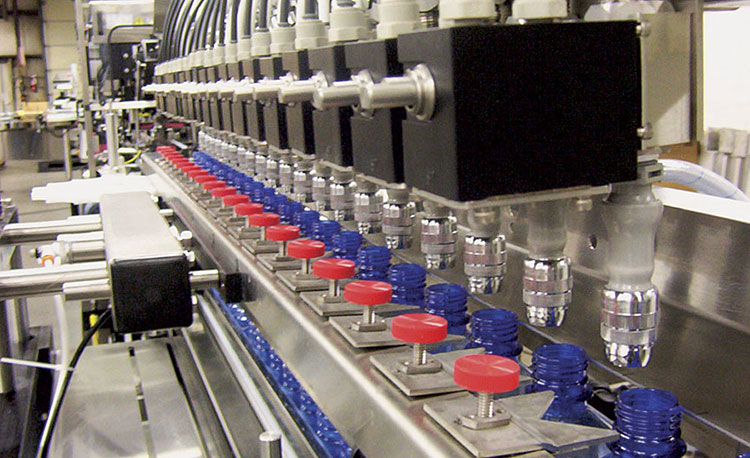

Automatic Liquid Filling Machine Credit: shemeshautomation.com

- Reliability Filling

Reliability and trust are the main factors of the Automatic Liquid Filling Machine. The equipment is reliable in filling the liquid medicines in the bottles.

It gives you satisfaction in the reliability of the product.

- Fast Speed of Filling

The great advantage of the Automatic Liquid Filling Machine is that the equipment fills the medicine in the bottles at a very fast rate.

Manually it is difficult to match the speed of equipment while filling.

The machine almost fills 1000 or more than that value in the seconds. So, the faster helps the increase in the production which gives great benefit in terms of profit to the user.

Fast Filling Machine Credit: machine-information-systems.com

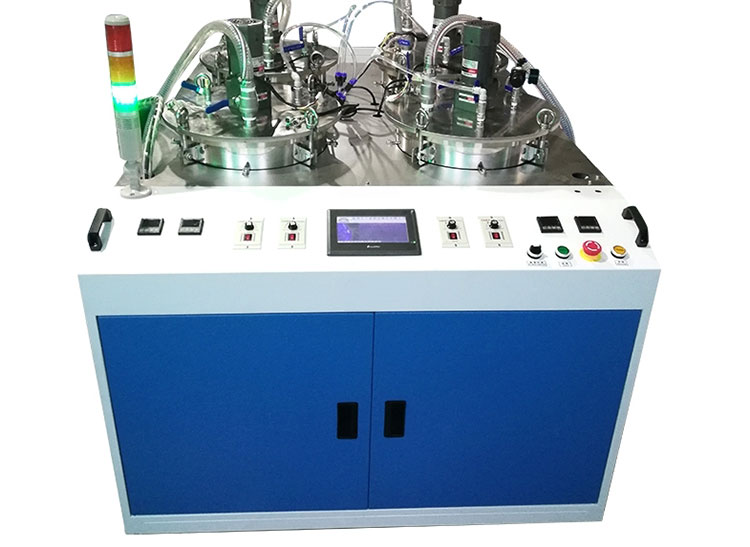

- Easy to Use

The Automatic Liquid Filling Machine is very easy to use. The equipment is very simple while operating it.

No difficulties occur in handling the machine. The functions of the machine are simple.

User has to give only some instructions to the machine by using the touch screen given on the equipment. And all other work is done by the machine itself.

- Versatile

The Automatic Liquid Filling Machine is very versatile in working or filling the medicine in the bottles.

The equipment is multi-functional. It gives the ease to the customer not to purchase other machines like for labeling.

So, this is one of the most important benefits of the Automatic Liquid Filling Machine that saves time and money for the user.

- Potential Growth

The Automatic Liquid Filling Machine is increasing the future potential growth. This is the main advantage where the user has to focus on the potential growth in future.

The machine increases its growth as the time passes.

So, the equipment is very beneficial in every aspect.

4.What are the Disadvantages of Liquid Filing Machines?

There are also some drawbacks of the Automatic Liquid Filling Machines. These are as follows:

- Can’t Fill Solid Products

The Automatic Liquid Filling Machine is not able to fill solid products in the bottles.

The machine only works in the packaging of the liquid products in the bottles.

So, this is the first drawback of the Automatic Liquid Filling Machine. The user has to buy other equipment for packing of solid material.

- Expensive

Another drawback of the Automatic Liquid Filling Machine is very expensive to buy. The equipment can not be bought by all the industrialists. Only the big industries can buy it.

- High Consumption Rate

The last drawback of the Machine is that it consumes more power. So, the consumption rate of machines is very high.

5.What are the main Components of the Automatic Liquid Filling Machine?

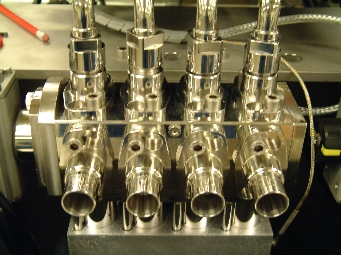

Components of Automatic Liquid Filling Machine

The Automatic Liquid Filling Machine has some main components. These components make it easier to work.

The components of the Automatic Liquid Filling Machine are as follows:

- Collection Tray of Cork

This is the first component of Automatic Liquid Filling Machine. At this component the material is filled for packaging.

- Unit of Corking

This is the second component of the Automatic Liquid Filling Machine. The component is helpful in placing the already filled vessels.

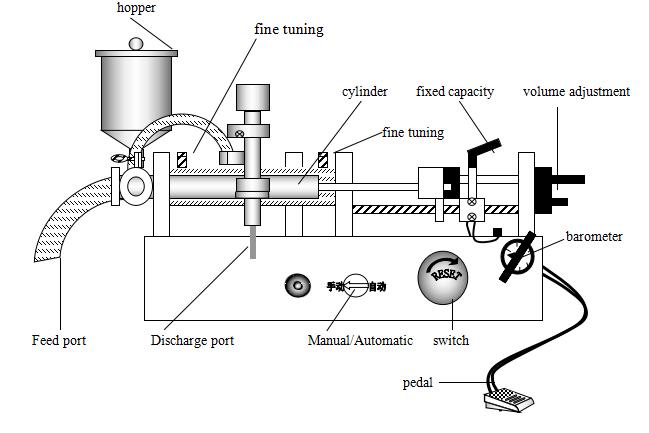

- Button Panel

The next component of the Liquid Machine is the button panel. By this component the user gives command to the wok.

- Bottle Holding Tray

Another component of the Automatic Liquid Filling Machine is the bottle holding tray. The work of this component is to hold the bottles in the filling process.

- Start Pedal

Moving to the next component, this component helps to start the equipment for working or filling the medicines in the bottles.

- Wheels

The Automatic Liquid Filling Machine has the pivot wheels which helps the equipment in moving freely.

- Collection of Liquid Tank

The function of this component of Automatic Liquid Filling Machine is that it clutches the liquid in the filling process of the medicines.

- Bottle Holding Trays

The Automatic Liquid Filling Machine has the bottle holding that holds the bottles tightly in the filling of the medicine.

- Filler Tap of the Machine

This is the component of the Automatic Liquid Filling Machine which helps in the feeding of the medicines in the bottles.

- Inlet Solenoid Valve of the Machine

The component helps the machine in controlling the liquid flow going into the filler taps.

- Tray Start Levers of the Machine

Another component of Automatic Liquid Filling Machine is the tray start levers. Which helps the machine in holding the trays and not to move away from its location.

Parts of the Machine

- Electrical Panel of The Machine

The Electric Panel is the most important component of the Automatic Liquid Filling Machine. The function of this component is to control the flow of current in the working of the equipment.

- Corking Unit Rati of the Machine

This is the component that works on the principle of rotation of the corking unit in the filling of the bottles of the liquid Medicine.

- Cylinders

Cylinders are also the component of the Automatic Liquid Filling Machine. The function of these cylinders is to hold the bottle during the filling process to keep it in the position.

6.How does a Automatic Liquid Filling Machine Works?

In this section you will know the working of the Automatic Liquid Filling Machine.

The working of the Automatic Liquid Filling Machine is done in the three different stages:

- Ordinary Filling

- Vacuum Filling

- Pressure Filling

- Ordinary Filling

This is the first stage of the working of Automatic Liquid Filling Machine.

In ordinary filling the fillers work mainly on the principle of the gravitation. According to the weight of the bottle you can fill the liquid in it. And the fillers hold the bottle during the filling process.

Moreover, there is some need in the maintenance of the thickness and the gas orientation of the fluids in it.

The examples of the ordinary filling are:

- Bottles of Milk

- Bottles of Grape Wine

Milk Bottle Credit: vectorstock.com

- Vacuum Filling

Vacuum Filling Machine Credit: indiamart.com

The second stage of the working of the Automatic Liquid Filling Machine is the Vacuum Filling.

In this stage there is a great need for the high pressure of the atmosphere. This should be greater than the pressure present in the bottles.

This is the stage where you can fill the thick liquid medicines into the bottle.

And the thick liquid medicines need efficient and smart working which is done by the vacuum filling.

The examples of this Filling are:

- Oil

- Syrup

Syrup Credit: pharmaapproach.com

- Pressure Filling

This is the last stage of the working of Automatic Liquid Filling Machine.

In this stage there is the requirement of a pressure that is higher than the atmosphere.

The Pressure Filling is done into two classes:

- High Pressure

This filing is done on the high pressure of the liquid which differs with the bottle.

- Equal Pressure

This type of filling is done when the pressure of the liquid and the bottle is the same. In this filling the liquid is being transferred to the bottle by the weight of the liquid itself.

7.Explain the Different Types of Automatic Liquid Filling Machines?

There are different types of Automatic Liquid Filling Machine. They all differ according to the features and their ability of working.

The types of Automatic Liquid Filling Machines are as follows:

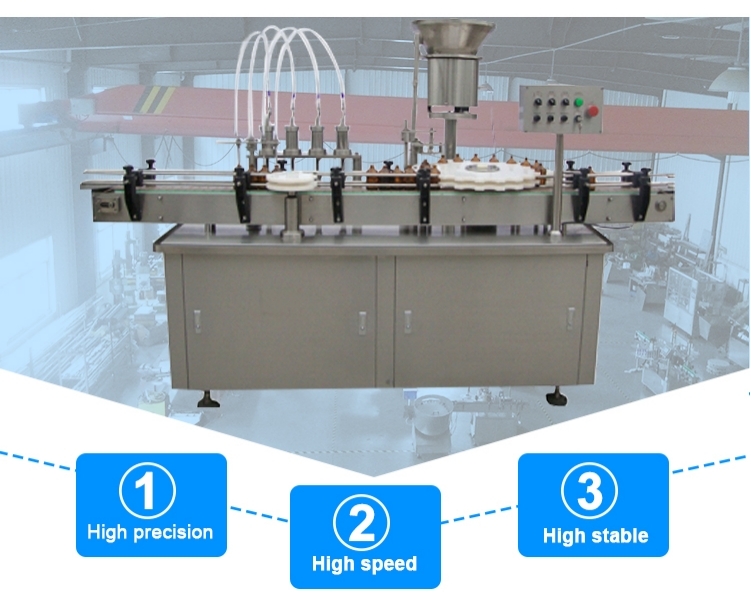

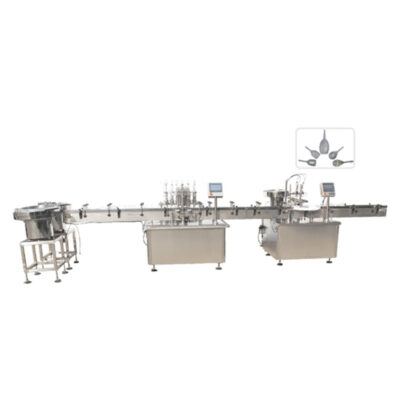

- Fully Automatic

This is the type of Automatic Liquid Filling Machine which works fully automatically.

This machine has a special characteristic which lessens the requirement of labor.

This type of machine also works on the arrangement of the bottles during filling and fills them mechanically.

The machine also controls the pace of the machine automatically. Capping is also done in the automatic Automatic Liquid Filling Machine.

The equipment also labels the products itself automatically.

So, these are the various features which make the machine automatic.

Automatic Automatic Liquid Filling Machine

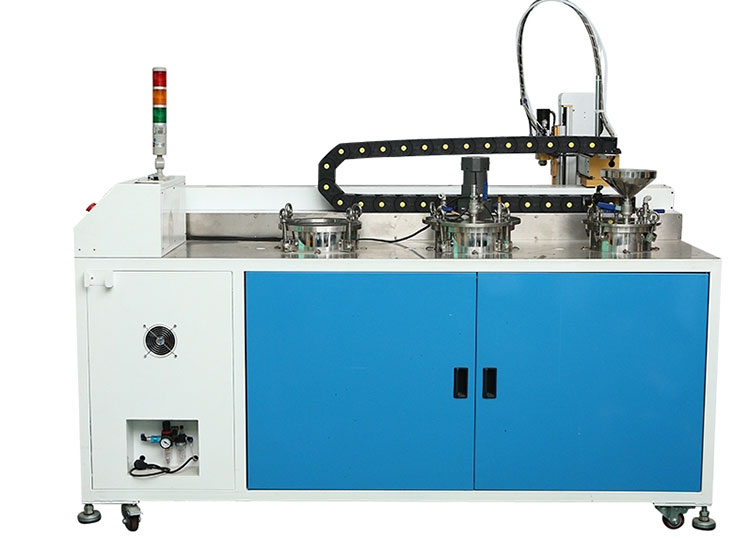

- Semi-Automatic

This type of machine needs some labor work for working or filling the Liquid in the bottles. In these machines labor itself arranges the bottles to fill the liquids in it.

Labelling is also done manually in it.

Semi-Automatic Filling Machine Credit: karmelle.com

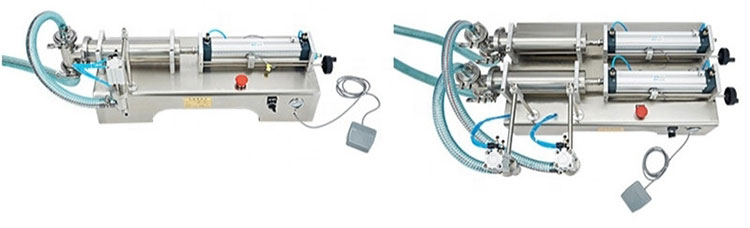

- Twin Head

The twin head Automatic Liquid Filling Machines are the type of machines which have two nozzles for filling of the products in the bottles.

In this machine it requires very little manual work.

The machine is mainly used in the industries like pharmaceutical and cosmetics. These machines mainly fill the bottles of milk and oil.

These types of machines may be fully automatic or Semi-automatic according to the need of the user.

Two Head Filling Machine

- Four Head

The four head filling machines are the machines which fill the vessels with great accuracy.

This machine also enables control the feed which is given to the machine with constant speed.

- Six head

This type of Automatic Liquid Filling Machines has the six nozzles of filling.

The equipment is multi-functional with the ability of holding the sticky products of the liquids.

These machines are fully automatic in most of the cases.

This machine also increases the efficiency of the product.

- Light Head

This type of Automatic Liquid Filling Machines is commonly used for the filling of non-sticky products.

The machines of such type are mainly used in the industries such as companies of water bottling.

- Electronic

The type of Automatic Liquid Filling Machines that work fully on electricity are electronic filling machines.

These machines are fully automatic.

This equipment is mainly used in pharma industries for filling the liquids in the bottles.

The machine works at great speed. The accuracy is perfect according to the design of the equipment.

8.Which Factors you Should Consider when buying an automatic Liquid Filling Machine?

In this section you will know about the factors you should consider when buying a Automatic Liquid Filling Machine.

The factors you should consider are as follows:

- Viscosity of the Product

The very first step you should know is the product viscosity.

The viscosity helps the liquid to move easily in the machine. It helps the highly viscous material to move easily in it.

So, the viscosity of the product matters always.

Viscous Material Credit: levapack.com

- Piston Filling

This type of machine mainly utilizes the cylinder and the piston for the correct filling of the bottles.

The Machine has an extra capacity to handle all the lumps present in the liquid.

So, this is the much-improved version of the machine.

- Container

The Liquid Filling also has the type which looks like a container.

The container is used for filling the bottles. The container type machines also used for the packaging process.

So, you should look forward to a container of your own choice for working. Consider that the container is good for filling the bottles. Check the quality of the machine.

Also check the material of the machine. Is the material high quality or of low quality?

Rememeber these factors when buying this type of machine.

- Rate of Filling

This is the very important thing you should consider when buying the Automatic Liquid Filling Machine.

The rate of filling the bottles should be great. It’s your choice of buying the equipment. If you want to buy the manual machine then you have to do all the work manually.

But on the other hand, if you want to buy a semi-automatic filling machine, then half of the work will be done manually like placing the bottles.

Moreover, if your choice is to buy a fully automatic filling machine. Then all your work will be done automatically. Although it is a little bit expensive, but it is efficient in working and the production rate is much higher.

9. How does Semi-automatic Liquid Filling Line compare to Fully Automatic Liquid Filling Line?

The semi-automatic liquid filling line differs from the fully automatic liquid filling line, majorly in terms of structure, function, and mechanism.

Automatic Filling Machine

Semi-automatic Liquid Filling Line

Semi-automatic liquid filling lines are convenient to operate as compared to manual Automatic Liquid Filling Machines. These types of machines are quite suitable for small and medium-scale production companies. Although their production is maximum in volume.

Operating a semi-automatic liquid filling line is somewhat time taking. As many tasks are done performed manually by the labor.

· Structure

Semi-automatic liquid filling lines have some essential parts in their design they are syringes, nozzle, and filler. These parts are very useful for carrying out its operation and maintenance especially when it drops to zero.

· Filling Liquid Products

These lines are designed to fill up the liquid products and are found in any industry be it agriculture, pharmaceutical, detergents, dairy products, and whatnot.

Somewhat viscous liquid can also be packed easily with semi-automatic liquid filling lines. Viscous liquids might include adhesives and other materials carrying small food particles in the liquid.

· Functioning

Although various semi-automatic filling lines operate differently. However, it is worth mentioning that these filling lines contain a filling range of 5ml to 1000 ml. Moreover, it can fill up to eight hundred containers with liquid products within one hour only.

The mechanism of the semi-automatic liquid filling line could not be completed without an active role of manpower.

The manpower will carefully plan procedures and plans to function alongside the setup of the machine to accomplish the tasks and achieve desirable results.

Semi-Automatic Filling Machine

Automatic Liquid Filling Line

Automatic liquid filling lines are more suitable for production companies that have a large-scale business and carry out huge production. It is easy to operate but quite tricky to maintain if things get worse.

An automatic filling line will make the whole process automatic and is quick to operate. It can be operated without much effort put in by the labor.

· Structure

Variable speed conveyor system is a must-have in automatic filling lines. Fully automatic filling lines make it possible for the manufacturers to align the filling line according to their requirements by setting up the specific value of volume, and the kind of container in which the liquid is filled.

By increasing the number of heads to the fully automatic filling lines, the rate of filling will also increase.

· Functioning

Automatic filling lines can fill the liquid ranging from 5ml to 10 L in the desired container. Such filling lines can fill up to 120 containers within a minute.

· Mechanism

Here is a mechanism of liquid filling line operating system.

1. Role of Conveyer

The one operating the filling lines will place the container on the conveyor. The conveyer will automatically make the containers reach the filling point in the filling lines.

2. Role of Filler

The filler will block the container that needs to be filled so that it can’t move, to prevent the spiling of liquid material, provided that the maintenance man will adjust the filler manually.

3. Movement of Container

The liquid is then pushed to the dosing system. Where the dosing is precisely performed with either the volumetric or liquid filling systems.

Sometimes the external pumps and other times the compressed air will move the container. The conveyer belt will help the container reaching the endpoint of the automatic filling line.

4. Washing Cycle

At the end of the automatic filling line system there occurs an automated washing cycle. It helps clean the bottle or containers from outside giving it a neat and finished look of the final product.

10. What is the Output of the Automatic Liquid Filling Machine?

AIPAK Automatic Liquid Filling Machine

The output of the Automatic Liquid Filling Machine has everything to do with the speed of the machine. The demand of the purchasing organizations when fulfilled with efficient and effective outcomes proves very cost-effective to them.

There are other various factors on which the filling of bottles in one minute is dependent. Such factors are the size of the container, viscosity of the liquid material, provided that the speed of the machine is the foremost important. The number of heads attached also determined the output of the Automatic Liquid Filling Machine.

· Result Measurement

The final output from the Automatic Liquid Filling Machine can be calculated by simply measuring the number of bottles that are filled by the machine per minute.

Other Favorable Outputs

Various other favorable outputs obtained from the Automatic Liquid Filling Machines are the following.

· Consistency and Quality

Any inconsistency as an output of a Automatic Liquid Filling Machine is not an option. Manual measuring techniques are just a waste of time, they do not provide any reliable measurements. The bottle that is fully and well packed will make an impact on the consumer as well.

Each bottle has the same level, volume, and weight as the liquid material.

· Simple and Quick

Easy filling of the liquid material without much wastage provides an edge to the business. Many inside operations are going on like pump seeds, indexing times, and fill times.

· Upgradation

Upgradation of the existing Automatic Liquid Filling Machines by just adding a greater number of heads is another aspect of the upscaling of business. So, it is one of the beneficial outputs of the Automatic Liquid Filling Machine for the business.

· Saving Time and Energy

Using Automatic Liquid Filling Machines instead of the workforce is quite convenient. As the work performed will be quick and saves time and energy at a greater scale. Consider your work done in a shorter span with minimum labor but with the help of a Automatic Liquid Filling Machine for better output.

11. Can your Automatic Liquid Filling Machine be modified if your needs change?

Modified Automatic Liquid Filling Machine

The answer to this depends on the type of machine you are using. Some of those machines grant you an option to change those parts that are easily detachable like section heads. However, it may not be the case with other machines.

It is perhaps one of the toughest decisions to purchase a new filling machine that serves your business needs. To take the best possible decision, consider various attributes like container size, style, shape, and also the characteristics of the liquid material.

So, choose wisely!

· Availability of Variety of Machines

Nowadays the marketplaces are saturated with various types of machines designed for filling any one specific substance. It is highly advisable to consider the properties, characteristics, and types of your machine as well as the material for filling before a purchase decision. Different substances are filled with entirely different filing machines.

· Consultation

The answer to the question that whether a particular machine could modify according to the changing needs can be best addressed by the experienced manufacturer. Taking advice and consulting some relevant, knowledgeable, skilled person will save you a huge sum of money.

12. Which Type of Filling System Should Your Machine Use?

Filling of Bottles Credit: pcimag.com

When it comes to choosing the appropriate type of filling system, liquid-level or volumetric machines are more commonly preferred.

Here we will shed some light on which filling system is good to go and for what purposes among these two.

It is perhaps one of the most common questions popping in the minds of many. So, for this, you need to consider the final product coming out of the production line at pharmaceutical industries.

Note the following points.

Volumetric Filling System

If the purpose is to fill the exact volume of medicine in each bottle, then it is better to opt for a volumetric filling system. Volumetric filling systems are installed in those machines that are meant to fill the same volume in every bottle provided that the fill level may not be the same.

· Efficacy

Overall, the volumetric filling system when present in Automatic Liquid Filling Machines enables to record more precision of the amount filled with accuracy. In addition to this, it can be used very conveniently for viscous liquids as well. moreover, it has an option to set the level of liquid to be filled in the bottles. So, that every bottle in the row will be filled to that particular level.

· Fittings

However, there is a need to purchase fillers ranging in various sizes. It is because the containers in which the liquid is being filled vary in size.

Liquid Level Filling System

Liquid level filling systems are meant to fill up the bottles to a specific level inside no matter whether the volume of liquid-filled in every bottle is the same or not.

· Efficacy

This system provides aesthetic fills to the liquid in bottles. It is because unlike in the former system, where you need to buy various fillers in different sizes. Here, it adjusts the level of liquid that needs to be filled according to the size of the container.

üPriority

It is recommended to prioritize opting for a liquid-level filling system. As the size of the container varies greatly. If there are ten thousand bottles to be purchased each of 22oz, then every bottle out of those ten thousand will not be of 22 oz. Thus, the same level of liquid-filled in every bottle gives a very raw look to the consumers as well. They may then be less likely to buy that product.

Especially when the liquid is to fill in the glass container, a liquid filling system is highly recommended to opt for. It will prevent the liquids in the bottles to be overfilled, half-filled, or whatnot.

13. Should Your Automatic Liquid Filling Machine Be Capable of Inline or Rotary Filling?

Whenever anyone decides for investing in the new Automatic Liquid Filling Machine, the first question that comes to the mind of the purchaser is that there are various options available in the marketplace. You must choose the best fit among the advanced technology available.

Rotary Filling Credit: pacificap.com

Inline Filling Machine

As the name indicates, the inline filling will enable the filling of liquid in bottles placed in a line. One of the main advantages of using inline filling is that they are very cost-effective and can be easily adjusted according to the needs and situation.

· Structure

You can even add from four to twenty heads, all depending upon the needs. However, most small and medium-sized companies tend to opt for the inline filling machine. It is because of its efficiency.

· Function

They are quite convenient to operate as they come in very less parts. The speed of line that is filling the liquid in the bottle in the bottle is maintained at sixty or eighty per minute. The larger the nozzle size the higher will be the nozzle size.

· Repairing

If in case, the machine has stopped working then it can be repaired more conveniently than the rotary filling machines. The machine that has been set back to work in no time after the stoppage of production will result in a minor loss of other products in processing as well. the maintenance of this machine is easy to carry out.

Rotary Filling Machine

If the goal is to initiate production on a larger scale, then rotary filling machines are good to go. They enable you to change their heads ranging from 25 and goes beyond a hundred. Parts present inside the rotary machine are quite expensive.

· Facilitates Larger Scale Production

A rotary machine is generally suitable for those companies whose production rate is very high. So, that even if some material or product is wasted then there are lesser regrets. The higher the number of products in the machine the higher is the ratio of wastage. Parts present inside the rotary machine are quite expensive.

· Function

It is noteworthy that the kind of production volume and efficiency gained by the rotary filling is matchless. It works at a constant rate with high velocity. High velocity and constant speed prevent the liquid material from spilling outside.

The 8 heads present in the rotary filling machine can fill up to 120 bottles per minute.

Preference

Both inline and rotary filling machine have their benefits, depending upon the scale at which they will be operating. For smaller-scale industries, the inline filling is good to go. However, for huge production, one must go for rotary foiling.

14. What Exactly can you Fill with Automatic Liquid Filling Machine?

Automatic Liquid Filling Machines are designed for filling the liquid products in the bottles. Those liquid products can be of any viscosity, as various machines are available in the marketplace for handling different kinds of liquids.

· Dispensing Liquid products

Liquid products like carbonated drinks, distilled water, liquid syrups and medicines, perfumes, beverages, and whatnot, can be poured into the desired container in a very sleek manner. Automatic Liquid Filling Machines poured in the exact amount of liquid substance into the containers like cans, bottles, and cups.

15.What Material is Automatic Automatic Liquid Filling Machine-made of?

Auomatic Automatic Liquid Filling Machine

Automatic Automatic Liquid Filling Machines of different materials are available in the marketplace. However, the mentioned materials are very commonly used.

· German technology

Most commonly the machine structure is usually made by utilizing German technology. The machine comes with a double-ended mechanical seal. Its emulsification speed goes to 4500 rpm and the shear fineness up to 0.25 micrometer.

· Stainless Steel Material

Most of the machines have built technology of dust sucking along with a boiler body. The body of the boiler is welded on three layers that make it quite hard as the layers are of stainless steel.

· Mirror Polished

The pipeline and the body of the tank are mirror polished. Mirror polish keeps the rust away from the Automatic Liquid Filling Machine.

Note that all the above-mentioned materials used in the finishing of the automatic Automatic Liquid Filling Machine conform to the standards of GMP.

16. What are the Different Container that Automatic Liquid Filling Machine Fill?

AIPAK Automatic Liquid Filling Machine

The type of container that the Automatic Liquid Filling Machine fills is equally important just like the selection of the Automatic Liquid Filling Machine itself.

However, before digging deeper into the attributes of the containers there is a need to consider some characteristics of the liquid material as well.

· Importance of Determining Container’s Attributes

The kind of container that is filled will talk about the filling techniques needed to adopt. So, choosing the right container is of high importance.

Below mentioned characters and attributes are important to consider because they will determine the output of the Automatic Liquid Filling Machine. The machine will show the best performance when it is coupled with the right container.

Take, for example, a Automatic Liquid Filling Machine that may not work properly when the lid of the container is of unusual shape.

· Material of the Container

The Automatic Liquid Filling Machine can fill any container whether it is of glass, plastic, or any other metal.

· The Shape of the Container

The container can vary in size and shape as well. every container whether tall, short, square, round, bottlenecked, etc. can be filled with the Automatic Liquid Filling Machine.

Although there are certain machines designated for filling up a certain type of container. However, there are some of the machines available in the marketplace that are very much adjustable to the needs of the consumer, and they are designed to be versatile to fill any container.

Conclusion

Automatic Liquid Filling Machines incur a high cost on installation, but the results are worth it. The machine can perform strenuous tasks with minimum utilization of manpower and in a very short time conceivable. Every user out there wants maximum effectiveness and efficiency as an output of the Automatic Liquid Filling Machine. It is worth mentioning that it can only be achieved if the purchase decision-maker thoughtfully ponders upon the business requirements and then choose the machine that best fits the business needs.

E-liquid Filling Machine Related Products

E-liquid Filling Machine Related Posts

E-liquid Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine