8 Possible Defective Cause & Problems Solving During Soft Gelatin Capsule Manufacturing

Are you bothered by the troubles of soft gelatin capsule manufacturing? Are you looking for sterling piece of knowledge that can figure out your matter? You don’t need to go anywhere, here you will get the in-depth insights in possible defective cause & problems solving during soft gelatin capsule manufacturing!

You know it well that soft gelatin capsule manufacturing is regarded as one of the complex production process. This process demands for precision, consistency and control. Any variability from mandatory standards can cost you quality problems, manufacturing defects or regulatory incompetency. This article will help you in coping with common issues encountered during soft gelatin capsule manufacturing. Let’s read to comprehend!

1.What is soft gelatin capsule and soft gelatin capsule manufacturing?

Soft Gelatin Capsules

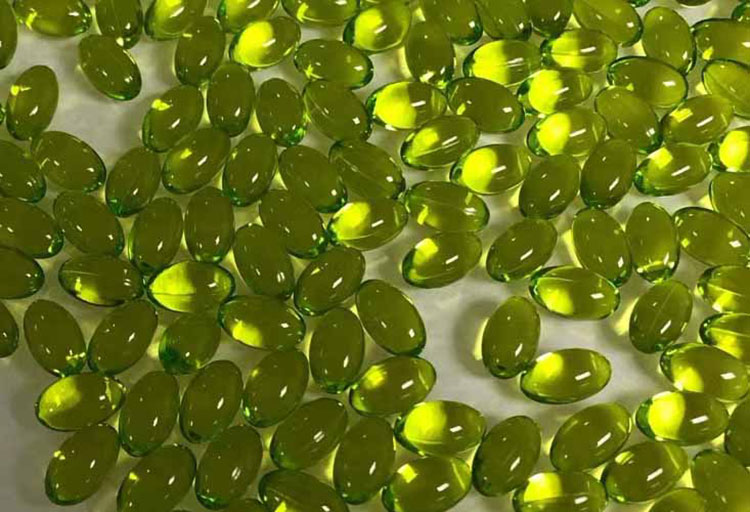

Soft gelatin capsule is also known as softgels, which is a single piece, tightly sealed dosage form. It is made by gelatin, plasticizer (glycerin or sorbitol) and purified water. It is considered ideal for delivering semi-solid, liquid or suspension form of active agents, either drugs or supplements. It is preferred due to good bioavailability, precise dosing and ease in swallowing characteristics.

Soft gelatin capsule manufacturing is the art of crafting softgels by using gelatin. It is a well-renowned pharmaceutical process, which is characterized by melting, mixing, molding and drying. This process involves enclosing of valuable drugs or health supplements in a soft and flexible gelatin capsule.

2.What steps are involved in soft gelatin capsule manufacturing?

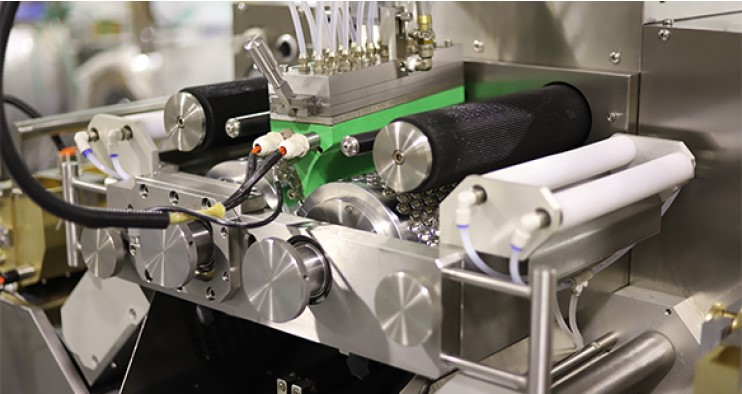

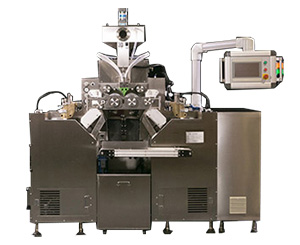

Soft Gelatin Capsule Manufacturing-Picture Courtesy: Vantage Nutrition

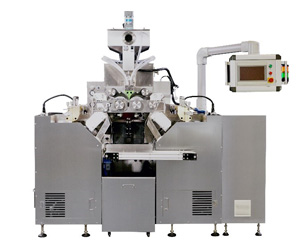

Creating soft gelatin capsule isn’t just about pressing a button. But it’s a perfectly designed process of producing active ingredient filled softgels with precision and uniformity. You employ soft gelatin encapsulation machine to craft these soft gelatin capsules. Let’s explore the journey behind soft gelatin capsule manufacturing!

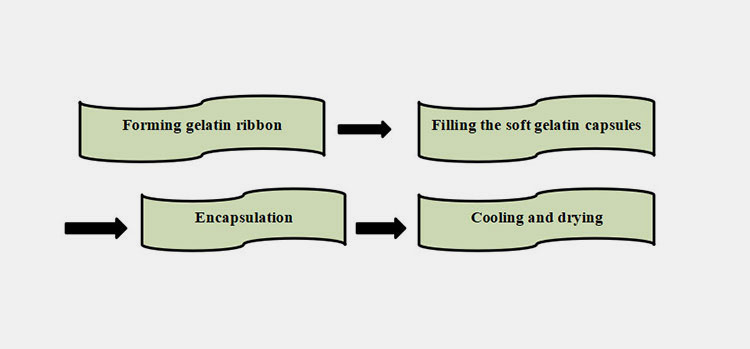

Forming gelatin ribbon:

You are going to form gelatin ribbon, for this purpose you require molten gelatin. You make a warm blend of gelatin, plasticizer and purified water by using gelatin melting tank. This formulated gelatin mixture helps you to form gelatin ribbon by using rotating rollers. Here you get the two thin gelatin ribbons!

Filling the soft gelatin capsules:

You are required to make the fill material by mixing active substance with other ingredients. You can see precise dosing system in soft gelatin encapsulation machine, which performs the process of filling. You can observe the fill material is injected between two gelatin ribbons by utilizing filling nozzle.

Encapsulation:

This filled gelatin ribbon is forwarded towards rotating die system. Here the soft gelatin capsule gets its new shape, either it could be oval, round or oblong. The capsule shut is sealed through applying pressure by the system. Every soft gelatin capsule gets cut from gelatin sheet and this whole process of encapsulation is performed in one go.

Cooling and drying:

After the process of encapsulation, soft gelatin capsules are required to get cool. The reason is that warm softgels are soft and delicate to get packaged. After cooling, you perform the drying process to eliminate the moisture content from capsules. For this purpose dryers are employed and environment is set to be controlled for a smooth drying process.

3.Can you describe 8 possible defective cause and problems solving during soft gelatin capsule manufacturing?

In the fascinating world of soft gelatin capsule manufacturing, every step needs to be performed flawlessly. Any minor mistake can lead to a disaster in making of soft gelatin capsule. You don’t need to be worried about such circumstances, as here you get absolute guide about defective cause and problems solving during soft gelatin capsule manufacturing. As this process is not just about creating softgels and filling it, it’s a blend of temperature, timing, precision and equipment performance. Let’s dive in!

Leaking capsules:

Leaking Capsules-Picture Courtesy: Alder Biochem

Leaking capsules are simply referred to the escape of fill material from the softgels either right after encapsulation or during the drying, storage or packaging. Fault in sealing process, gelatin formulation or drying process can promote this problem. Overfilling can also be the reason of leaking capsules.

Now this problem can be overcome by calibrating the process the gelatin formation, sealing of gelatin ribbons, filling process or drying process. You need to repair or replace the die rolls, dosing pumps or drying equipment.

Sticking or merged capsules:

Sticking Or Merged Capsules

You observe that softgels get stick to each other or to the processing equipment. This could happen due to insufficient drying process, improper gelatin formulation, high humidity and less lubrication of shells. These factors can make the shell soft and flaky which results in sticking or merged capsules.

First you need to ensure the sufficient drying, either process or equipment is calibrated or not. Placing softgels at ideal distance and lubricating them properly can solve this problem. You also need to check the ingredients of gelatin and do not add glycerin in excess amount. During drying, capsules are advised to place in controlled environment that contains optimal temperature and humidity.

Capsule flattening:

Deformity In Capsule’s Shape Is Capsule Flattening

You can experience the loss of capsule’s shape either its round, oblong or oval, this is called capsule flattening. This problem is seen because of negligence in making gelatin mixture, carrying out the drying process and maintaining controlled temperature. Usually capsules are placed nearly or not provided with optimal temperature and humidity, which affects the shape. Secondly gelatin mixture contains high amount of plasticizers that create soft shell of capsule, which deformed later.

You can cope up this problem by placing the softgels a little away from each other. You need to keep environment controlled for drying and temperature must be set in optimal range. You have to check the soft gelatin capsules either they are fully dried or not? Then subject them for further processing. Capsule gelatin must have less plasticizer and humidity also kept in range to prevent the chances of capsule softening.

Air bubbles inside capsules:

Air Bubbles Inside Capsules Can Affect Capsule Quality, Filling & Encapsulation

You can see air bubbles inside capsule during manufacturing process, which form internal voids that influence capsule quality, filling and encapsulation. You can observe the reasons behind this problem like insufficient degassing of fill material, inefficient vacuum system, inaccurate design of filling nozzle, high speed encapsulation or movement during filling process.

You can solve this trouble by calibrating vacuum system and filling nozzle. You need to carry out the encapsulation at low speed. You need to utilize the ways to degas the fill material and stabilize the filling process.

Dimpling or wrinkling of capsule surface:

Dimpling Or Wrinkling Capsules Hint About Poor Formulation, Drying Or Environmental Control

You can define dimpling as small depressions on capsule surface, while wrinkling refers to smooth surface creases or folds. You can encounter such faults during production, which indicates problem in drying, formulation or environmental control. This might happen when capsule shell is under dried or over dried, gelatin formulation is not accurate or change in environmental factors occurred.

You can correct this issue by optimizing drying tunnel airflow and temperature. You need to check gelatin ingredients, fill material and the resultant capsule shell before proceeding forward. Environment must also set controlled so that it would not affect the quality of product.

Discoloration or spots:

Discoloration Or Spots On Soft Gelatin Capsules-Picture Courtesy: Vitafoods Insight

When you talk about discoloration, it means capsule has uneven color, or complete fading of color. Similarly spots appear like white, dark, oily or irregular marks. Such issues are developed due to lacking in formulation or drying. Any chemical reaction can also be a reason for such defects.

You can rectify this problem by evenly blending the all ingredients of gelatin. Temperature must be kept optimal during drying. You need to check the nature of fill material as some oil, excipients or APIs can react. Other factors like exposure to light, humidity or any chemical must strictly avoided.

Gelatin ribbon tearing during encapsulation:

Faulty Gelatin Can Cost You Gelatin Ribbon Tearing During Encapsulation

Gelatin ribbon tearing is regarded as crucial problem that might occur during encapsulation. You can see the ribbon tears apart or shreds before or during exposure with the filling nozzle or die rolls. The reasons behind this trouble could be poor formulation of gelatin, overheating of gelatin ribbon, misalignment of filling injectors or die rolls, air bubbles in capsule or quick speed encapsulation.

You could get rid of this problem by using appropriate amount of plasticizer in gelatin mixture. You also need to ensure ribbon gelatin cooling before contact to processing equipment. You have to remove air from capsule by using vacuum system efficiently. You should remember that encapsulation must always be carried out on ideal speed.

Low yield or high rejection rate:

Low Yield Or High Rejection Rate Reflects About Multiple Issues In Production

Low manufacturing yield or excessive rejection rate happens when a countable part of soft gelatin capsule does not meet quality, physical or regulatory standards. The reason for this problem could be many like, poor gelatin formulation, incorrect fill volume, misalignment of equipment, inconsistent drying process, and uncontrolled environment.

You could fix this problem by carrying out proper gelatin formulation and ensure precise filling process. All machines need to be inspected and calibrated. Drying process should be performed with carefulness and utilization of all drying equipment. At the end, you must keep the environment favorable for production of high quality soft gelatin capsules to get good yield and least rejection rate.

Conclusion:

It is comprehended that by the help of accurate gelatin formulation, well-efficient equipment, strict process control and GMP-compliant practices, you can reshape the softgel chaos into polished and high-yield success. Are you still finding some more authentic knowledge about soft gelatin capsules manufacturing? AIPAK can provide you best information with harmony. You can contact us at any time!

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine