Tablet Capping And Lamination: 8 Causes And Prevention

Tablet manufacturing is not simply limited to compression and compaction. There is a precise and advance blend of pharmaceutical technology, engineering and quality control. This procedure is advance, complex and sensitive at the same time. The seemingly easy process of compressing powder into tablets can be affected with major defects arising from minor inconsistencies.

Starting from mixing, blending and granulation to compression and coating, every step is critical. Minor negligence during the whole operation which can be a mechanical error or a dosage error can cause any kind of defected tablet like cracked, capped or layered, instead of a proper smooth dosage form.

This is where tablet capping and lamination happens. They directly threaten the regulatory compliance, tablet integrity and patient compliance. This blog is going to give you a complete inside of what are causes of tablet capping and lamination happens and how they can be prevented, so let’s dig in!

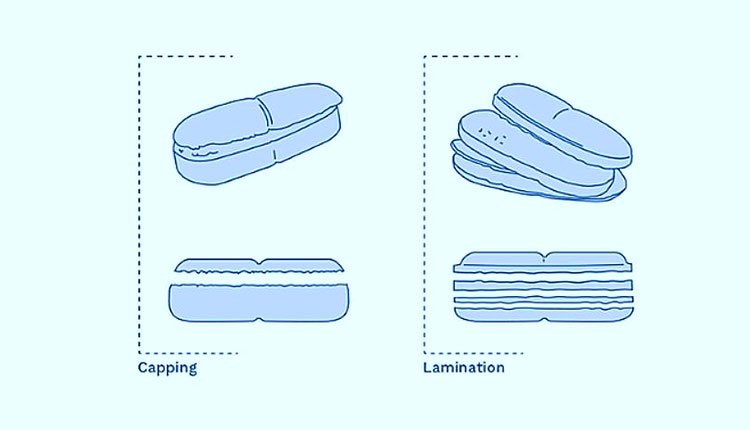

1.What is tablet capping and lamination?

Capping:

Tablet capping is the phenomenon when domed shaped top or bottom of tablet detaches from the body of the tablet, the phenomenon is known as capping. This is a compression stage defect. It happens when the air is entrapped in between powder particles during compression of powder into tablet, causing micro cracks in the compaction. These cracks expand and lead to separation of tablet cap from the body. Thus, this defect is termed as capping.

Lamination:

Lamination is the phenomenon in which the tablet is visibly separated into horizontal layers. It can occur anywhere other than top surface of the tablet. It occurs in the main body of tablet. Lamination can be a single layer separation or multilayer separation of the tablet. It is a compression stage defect. It also occurs during storage periods.

Lamination is the precursor, or may be considered as an early sign of the defect which ultimately leads to capping.

2.Understanding types of capping and lamination:

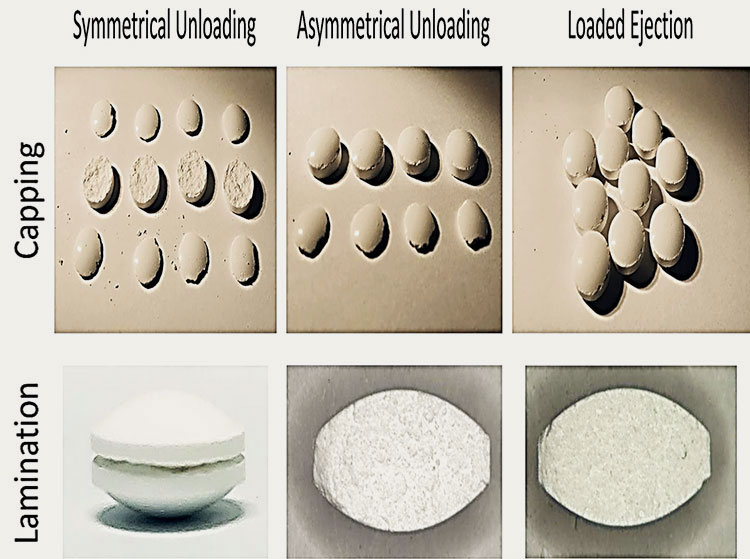

Capping and Lamination- picture courtesy: Quadro blog

Capping types:

Top capping:

The detachment of upper part of the tablet or the top crown is termed as top capping. This happens when the entrapped air escapes upward, pushing the top layer of tablet away. The other reason could be the weak bonding of granules between the top layer and body of the tablet.

Bottom capping:

Bottom capping is when the bottom crown of the tablet is separated or breaks off from the body of the tablet. It happens when the granules are filled poorly at the bottom die or if there is week bonding of granules during compression near the lower punch of the die.

Lamination types:

Horizontal layer splitting:

This is the classic type 1 lamination. It revolves around layers separation along the horizontal planes of tablet. This is caused by entrapment of air particles, poor particle bonding and weak cohesive forces among granules. The tablet is separated into two or more layers. It is mainly observed when there is very fast compression force or the granule flow is inconsistent.

Compression induced lamination:

This type 2 lamination occurs when there is excessive use of compression force. The excessive compression force over densify the granules which cause internal stress leading to lamination. Due to poor elastic recovery the tablet splits into layers as soon as the trapped energy is released.

Tensile strength lamination: (limited to convex tablets) :

This type of lamination is limited to biconvex or deeply convex tablets. There is a buildup of tensile stress at the center of tablet during compression and ejection. The tensile stress exceeds the cohesive strength of the convex tablet which leads to internal separation due to pulling apart effect.

3.8 causes and prevention of capping and lamination:

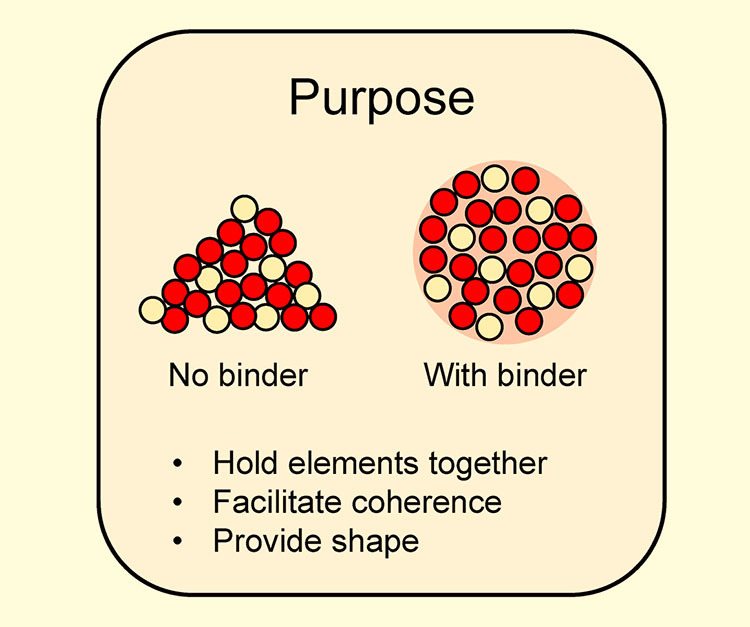

Inadequate Binder Quantity:

Picture courtesy: ecoNugenics

Binder is an integral part of tablet manufacturing. Binders are added to increase the adhesiveness among the particles. This adhesiveness is the reason of granules sticking together and keeps the granules compact during and after compression. If the binder is not adequately added in the tablet manufacturing, it will cause mechanical failure in the tablet like capping and lamination.

How It Cause Capping?

When there is not adequate binder in the tablet formulation, the top and bottom curved areas, which are the crown of tablet, are not strongly bonded to the tablet body. This leaves behind tablets with weak points, especially in the crown region. When the mechanical stress is applied on the tablet during ejection, these weak crown areas cannot withstand the mechanical stress and it leads to separation of top or bottom part of the tablet.

This is how capping happens with inadequate binders. The tablet may appear fine during the whole compression process but it may have cracks in the crown region during ejection or handling.

How It Cause Lamination?

Just as in case of capping, inadequate binders lead to poor bonding of the particles which resides throughout the tablet. Ultimately, when the internal stress increases during or after compression it cause the tablet to split in multiple horizontal layers, especially if there is poor granules flow.

Prevention:

This is how binder holds the particles together-picture courtesy: science direct

It is recommended to optimize the concentration of binder from the start of the procedure, during wet or dry granulation. The use of strong binders like PVP (Poly vinyl pyrrolidone) or MCC (micro crystalline cellulose) is recommended, they maintain a good binding effect in the tablet. After adding, proper distribution of the binder should also be ensured.

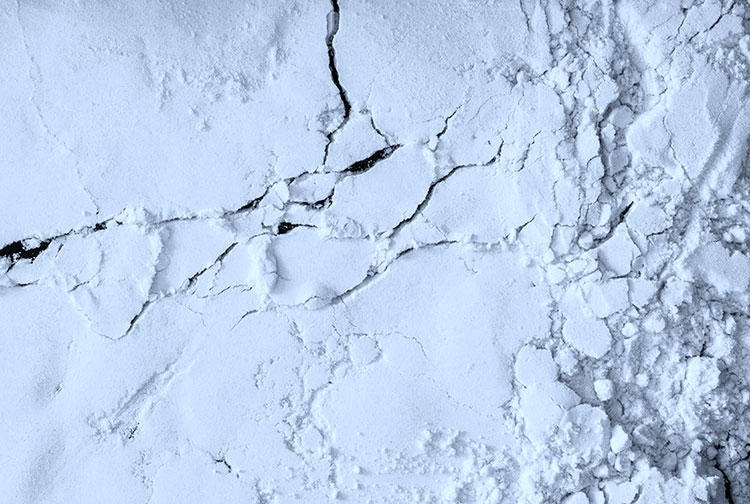

Air Entrapment During Compression:

During the tablet compression, especially when it is done at a high speed and there are granules with poor flow properties, there are chances of air entrapment. The air is entrapped in the powder bed inside the die cavity. This entrapped air, if not expelled before the compression process; it can create internal pressure in the tablet which weakens the tablet structure.

This entrapped air exerts outward pressure on the tablet, which will either separate the crown of the tablet (capping) or split the tablet into horizontal layers (lamination. Ideally, the tablets have to decompress slowly to release the trapped air but if the decompression occurs at a fast rate it can cause the trapped air to expand which will than split the tablet either in capping or lamination.

Prevention:

Cracked powder bed due to air entrapment

Powders with poor flow properties entrap more air in the die, which expand during compression and push the layers apart leading to lamination and capping. It is recommended to enhance the granule size distribution and improve powder flow ability. The uses of glidants like colloidal silica improve the flow properties and hence less air pockets in the tablet.

The use of vacuum de aeration system in large scale tablet production helps in squeezing out the air. The optimization of dwell time also allows the air to escape during compression.

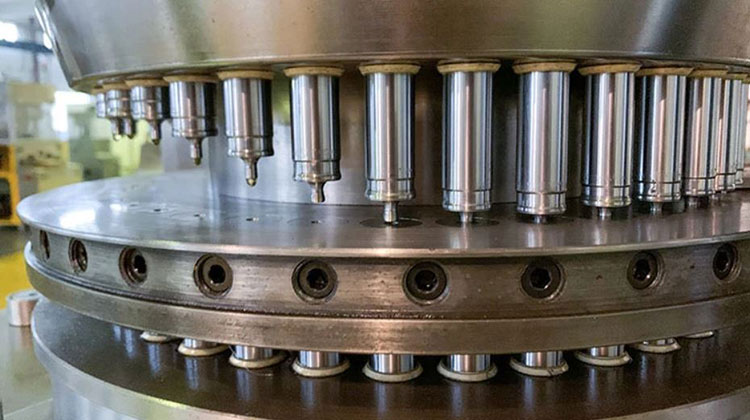

Worn Or Poorly Fitted Punches:

Well maintained die punch assembly of tableting machine-picture courtesy:

The punches and dies are the main tool in tablet compression. If they are damaged or worn off, they will definitely cause a major impact on tablet quality.

Poor edges due to worn off tooling:

If there are poor edges due to worn off tooling, it will have weak sealing of the crown, leading to capping during or after ejection. Similarly, damaged tooling applies an uneven pressure during compression which causes internal stress that separates layer upon ejection.

Uneven die fill:

If the die has not uniformly filling, it will have a weak compaction, mainly at the crown region of the tablet which will easily lift off or crack from the main body causing capping. Uneven die fill also cause variation in the density that make the tablet prone to splitting into layers causing lamination.

Prevention:

Picture courtesy: pharma sources

Regular maintenance of the equipment is recommended to rule out chipping, deformation or any wear off. It is better to efficiently replace any damage tooling to ensure a uniform compression of the tablet. The alignment of dies and punches should be well maintained so that there is no uneven pressure or mechanical stress on the tablet which cause capping or lamination.

Over Dry Granules:

Good granules-picture courtesy: metal powders

The drying of granules is a critical process and it should be balanced. The over drying of the granules can make them very brittle, hard and non-cohesive. These over dry granules don’t even contain the moisture which is necessary for inter particle bonding in granules and tablet. This over dryness reduces the ability of granules to bind properly and decrease their plasticity.

These over dry granules with low plasticity and decreased cohesion cannot strongly bond together causing mechanical failure. They cause micro cracks in the compaction. These micro cracks expand and end with splitting of the tablet either in capping form or lamination.

Prevention:

LOD apparatus for powders-picture courtesy: pharma guideline

Over dried granules can be prevented by optimizing the drying time and temperature. There are controlled drying methods like fluidized bed dryer which can retains the minimal moisture required for good compression.

There are procedures like LOD (loss on drying) or moisture analyzers which ensure there are ideal moisture levels in the granules. Binders like PVP enhance the adhesion and compensate low moisture in dry formulations.

High Compression Speed:

Fine powder compressed into fine tablets-picture courtesy: fabtech technologies

If the compression force is too high it leads to stress buildup in the tablet which causes capping and lamination after ejection. If the compression force is too low, the particles do not strongly bond with each other which lead to production of weaker tablets that fall apart easily.

Turret speed:

The turret speed has to be adjusted at an optimum rate. If the turret speed is faster than required, it will shorten the dwell time which can prevent the proper bonding of particles and weak bonds make tablets which are weak and prone to defects.

Inadequate ejection force :

It is recommended to maintain an optimum and constant speed during tablet compressing. Forceful and abrupt ejection of tablet causes the tablet crown to break to detach, especially when interparticle bond is already weak. It also creates a mechanical stress within the tablet, which will make the tablet separate in layers causing lamination.

Prevention:

Image showing effect of loading on capping and lamination of tablet-picture courtesy: science direct

The main preventive measure is to start with optimizing and reducing the turret speed, so that there is enough dwell time for particles to bond properly. There is sometime addition of a pre compression stage in the tablet formulation, this helps in removing any entrapped air so capping and lamination can be avoided.

The use of efficient binders ensures that there is good bonding of particles even at high speed. The in process testing of tablet hardness, thickness and weight can detects early defects and signals adjustment of compression speed. The use of well lubricated granules maintains consistency in die fill at moderate speed.

Improper Lubrication:

Addition of lubricant

The lubrication of equipment is equally important as the lubrication of granules. The granules behavior of how they flow into dies, compress under force and both together is the result of lubrication. The excessive use of lubricant like too much magnesium stearate creates a hydrophobic layer over the particles which weaken the cohesive forces in between the particles.

Over lubrication also cause layer splitting of the tablet because it does not allow the proper fusion of the particles. When the granules are poorly lubricated, they have greater tendency to entrap air particles that will ultimately cause capping or lamination by pushing the layers after ejection.

These poorly lubricated granules causes sticking to the die punch assembly causing dragging effect during ejection which increase stress in the tablet. This stress cause capping.

Prevention:

The quantity of ingredients to be added should be critically monitored

It is common understanding that we can prevent improper lubrication by accurately measuring the amount and concentration of the lubricant. It must be noted that using the right kind of lubricant is equally important. 0.25-2% magnesium stearate is mostly recommended. The lubricant should be according to the types of granules.

The lubrication before granulation ensures a proper blending without over mixing of the whole batch. Dry coating is another advanced method of lubrication. In this method, each granule is coated with dry lubricant using dry coater which helps in increasing the flow ability and tablet ejection.

Granule Size Distribution Issues:

Different granule sizes-picture courtesy: bulk inside

Granule size distribution explains uniformity and variation in the size of granules used in your tablet formation. Ideally, there should be a narrow size range of granules. Recommendation is neither too fine nor too many large chunk of granules. The uneven granule size leads to air entrapment, poor bonding and uneven compression, all these factors are the root cause of capping and lamination.

Over granulation gives hard and non-cohesive granules which are prone to splitting. These fine particles are more liable to air entrapment during the compression. This trapped air expands upon ejection of tablet and cause layering or capping by pushing away the layers of tablet. The tablet apparently looks rightly compressed. But it has internal stress due to lack of proper bonding of particles.

After ejection, as the particles bounce back to original form they cause micro separation of layers leading to visible lamination.

Prevention:

Very fine powder particles-picture courtesy: thrive freeze dry

The first step to prevent granule size distribution issue is to start by the use of proper milling and sieving techniques. The sieving of granules through well calibrated sieves eliminates irregular and oversized particles. The use of laser particle size analyzer monitors the consistency and uniformity of the granules size.

The binder adjustment in wet granulation and controlling the speed of roller pressure and screen size can avoid excessive fine particles.

Environmental Factors:

Electrostatic charge in the hair-picture courtesy: Britannica

These are the external elements which can have a direct effect on the tablet during manufacturing:

Humidity:

During tablet manufacturing, it is recommended to maintain optimum humidity and moisture content. If the humidity is very low it will make the air dry which pulls the moisture from powder and granules.

Electrostatic charge buildup:

The electrostatic charge is usually built up in dry environmental conditions. In the manufacturing of table, the friction is created between the powder and machine parts. This is more common with extra fine particles. The charge particles will repel each other and will not allow uniform settling.

This is more common with the upper dies region. This will lead to weakness in the top crown which can split from tablet body after compression or during ejection of tablet. These static charges also make the granule particles clingy to the equipment. It causes internal weak zones in the tablet which will end up with lamination.

Prevention:

The electrostatic charge can be control by controlling and maintaining the humidity of the environment. The ideal humidity conditions recommended are 40-60%. The use of anti-static feeders, hoppers and contact surfaces prevent any charge buildup. This is the reason that all the equipment for tablet manufacturing should be grounded so that there is no charge buildup.

There are anti-static agents like PEG or sodium lauryl sulfate; although they are added in trace amounts but they also prevent static charge buildup in tablets. The use of anti-static agent is only permitted if they don’t have any effect on the tablet safety and performance.

Conclusion:

Tablet capping and lamination are not just random mechanical flaws. These defects are the indicator of a deep imbalance in the formulation, processing or environment of the tablet manufacturing. There are different mechanical and formulation related reasons for these defects but what matters is that any cause of these defects can affect the tablet integrity, dosage accuracy, patient safety and regulatory standards. This blog makes you well aware with the causes and preventive measures of capping and lamination. Optimized granulation, precise compression, controlled humidity and efficient lubrication and binders strategies can help the manufacturer over comes these defects on capping and lamination. For more information and details visit our AIPAK website.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine