Nasal Spray Filling Machine: The Complete Buying Guide In 2025

Are you looking for a machine to fill nasal spray bottles? Or have you seen nasal sprays and wondered how accurately it is filled? In pharmaceutical industries, hundreds to thousands of nasal spray bottles are filled and sealed in precise and contaminated free environment. To meet these high-quality standards, a nasal spray filling machine is used. It gives you a fast result, with less down time.

Since nasal spray is administered internally; for curing allergy, or for pain relieving, however, a sterile management is required which is fulfilled by this filling machine, and also ensures an accurate filling without compromising quality.

If you are new to buying pharmaceutical machinery, selecting a nasal spray filling machine is difficult without proper knowledge. This guide will help you in finding a right information. Like its function, components, types, factors to consider when buying a filling machine and many others.

1.What do you mean by nasal spray filling machine?

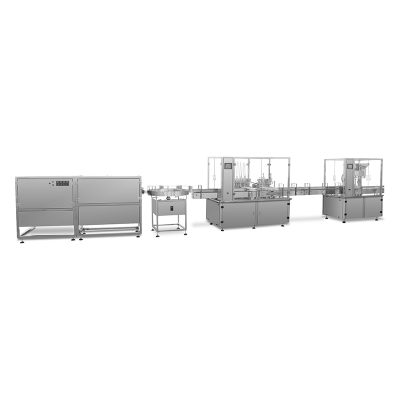

AIPAK nasal spray filling machine

Nasal spray filling machine is designed to fill spray necked bottles with nasal spray. It fills bottles up to desired level without compromising the quantity of liquid medication. Different operations are handled at a time such as filling, inserting spray nozzle and sealing, consistency is maintained throughout the process. This filling machine is applicable in other industries too where ensures product safety from contamination. But commonly use in filling allergic nasal spray and other intranasal sprays.

2.Enlist advantages of using nasal spray filling machine?

People are more inclined to buying good quality filling with no germ’s possibility. So, pharmaceutical industries grasp their hold on a filling machine that has better speed, efficiency and hygiene. This is the reason in modern world, industries are moving towards automated or modern rather than traditional filling machines. Let’s know the advantages of using nasal spray filling machine.

Increase production rate

Increase production rate

Nasal spray bottles don’t produce or fill one by one, with interval of time rather hundreds to thousands of bottles are handled at a time. You don’t have to feed few bottles but can feed in bulk quantity for sterile filling. This increases the production rate in less time to meet the demand without or less errors.

Precise and accurate dosage

Precise and accurate dosage

Do you know accurate dosing is important in medication? A slight change in filling can affect the efficiency of medication. Thus, there are dosing meter to check amount of nasal spray dispense in nasal spray bottle up to right level, reducing chances of overfilling and underfilling.

Reduce product waste

Reduce product waste

Since liquid solution is precisely dispense in automated filling machine, so this reduces product waste. In manual filling machine, product waste is the main concern due to spillage and filling problems. Do you know there are less faulted bottles in automated operations? By this, a raw material can be less wasted and improves profit.

Consistency

Maintaining consistency across the batch is mandatory. This not only builds consumer trust but also improves the brand image. Nasal spray bottles are equal in volume and also have clear nozzle insertion and sealing. Reliability is maintained by consistency and maintain product quality across the production.

Versatility

Versatility

There are different size and shape of nasal spray bottles. Are you also setting business of handling different bottles with diverse shape? Then, you can buy nasal spray filling machine. It is flexible with adjustable and interchangeable parts. You don’t have to buy different equipment for different nasal spray bottles. This reduces cost and save space.

Easy to use

Easy to use

This nasal spray filling machine can be easily operated. If you have not skilled labors- don’t worry. It has automated system where most of the tasks are easily managed by machine itself. But still there are touch screen, and other user-friendly interfaces. Operators can easily get the system and can change parameters according to product.

Contamination control

Where the nasal spray is administered? Of course, in nasal tract. A sterile liquid solution is necessary to hold back the allergy or other nasal problems. But how this can be achieved? A nasal spray bottles are filled using nasal spray filling machine that follows quality standard. There is closed and sterile environment where filling process is carried on without human interaction. However, there is less chances of contamination.

3.What is the application of nasal spray filling machine?

There are nasal spray type bottles in different field such as use in cosmetic, for vet, in pharmaceutics products etc. Ever give a thought, is there same machine in filling these bottles? You are right. Same filling machine is used to fill and insert a nozzle spray pump. Its application or uses is wide in many industries due to its precise and sterile result. Are you ready to know its application? Let’s start.

Pharmaceutical industry

Pharmaceutical industry

Nasal pray filling machine is most commonly used in pharmaceutical industry. Most of the medication comes in spray head bottles. Even most of the derma creams are also filled in these head bottles. Since you know that filling precision is mandatory for effectiveness of the medication, a slight deviation from preset filling volume can be a big deal for consumers and for product. Allergic sprays, migraine nasal sprays, intranasal vaccine etc. are filled through this filling machine.

Cosmetic industry

Cosmetic industry

In the world of beauty, most of the liquid solution are filled and sealed in spray head bottles. The accuracy and standard are still maintained here. Even some of the cosmeceutical products are administered through nasal route for fast action such as aromatherapy sprays, antiaging sprays etc. The cosmetic industry uses the filling machine for enhancing product reliability. This is exemplary technology in this arena where different size and shape of bottles are handled.

Detergent industry

Detergent industry

Another application of nasal spray filling machine is in detergent industry. Product includes sanitizer, liquid dishwash, hand wash and other detergent bottle press liquid. All the product are filled with accuracy and contamination free through this filling machine. Product quality and leak proof sealing are achieved by filling machine to make a brand image.

Veterinary industry

Veterinary industry

Do you know there are nasal sprays for vets? For treating disease, nasal sprays are recommended in form of vaccine, and as a vitamin. This is easy way of administration rather than injection that are difficult to deliver and has low absorption rate. For pets, accurate and sterile filling improve efficiency of medication.

4.Do you know what packaging options are handled by nasal spray filling machine?

You may have seen different pump or nozzle kind of bottles on market shelf, either made of plastic and glass. Have a question pop in your mind, do they handle by same filling machine? Well, nasal spray filling machine makes it easy for manufacturer to buy one kind of filling machine to handle diverse bottle sizes and shapes rather than selecting different machines for different bottles. Following below are the packaging handled by this filling machine.

| Packaging options | Explanation |

| Glass bottles

|

This filling machine handles glass bottle. Are you worried about its handling? Glass bottles are sensitive so they are gently handled and have cramps to hold them in way to prevent cracks. Consumers can see the product from outside due to its transparent and visible packaging. These amber bottles are ideal for sensitive liquid and medications to avoid interaction to environmental factors. |

| Plastic bottles

|

Nasal type spray bottles also come in plastic packaging. They are made from PP, PET and other materials. You can squeeze these bottles. These easy-to-handle bottles are demandable because they are cheap, cost effective and light weighted. Less energy is consumed while handling these light weighted bottles. These are ideal for children’s products and safe for traveling. |

5.Explain structure of nasal spray filling machine?

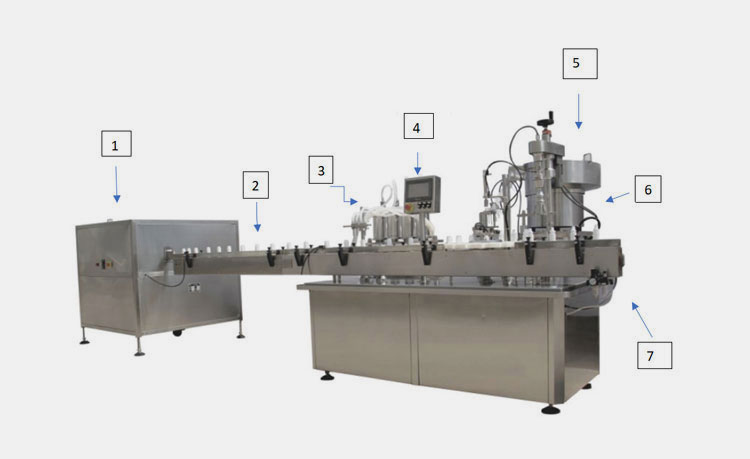

Structure of nasal spray filling machine

In above diagram, components of nasal spray filling machine are mentioned. Following below is the explanation of structure.

| S.no | Components | Explanation |

| 1 | Bottle unscrambler or feeder | In machine, bottles are not ready-madly present. These are loaded with help of feeder. Unaligned bottles are received by this component and then, give a sequence to them in conveyor. This is automatically loaded to ensure speed, increase production efficiency with no down time. |

| 2 | Conveyor belt | Conveyor belt moved material from one place to another place. Same, it also functions here. This acts as a chain in production line. Conveyor belt works smoothly, ensure smooth transport. One of the best features of it is that can be clean easily. |

| 3 | Filling nozzle | From the above diagram, you can see there are number of pipes. From there, liquid nasal spray solution is dispensed in bottles. Filling nozzles are inserted in bottles. Different filling system is used for consistent and precise dosing. The nozzles have a system that prevent form producing and spillage. |

| 4 | Control panel | From control panel, machine operations can be control. It has smart features of touch screen, programs of preset volume, speed, and other parameters can be adjusted. Any error or fault in machine can be monitor from control panel. |

| 5 | Spray pump cap feeder | Clear from its name, it is used to feed spray pump caps. As it uses vibration or rotatory system to deliver caps to capping head. Here caps are ready to be placed on bottles. |

| 6 | Capping station | In capping station, spray pumps are inserted into bottles. With help of torque, caps are tightened. Set the torque parameter, otherwise, extra torque will cause break or leakage of bottle. |

| 7 | Exit conveyor | After applying caps on bottles, conveyor moved the bottles out from machine for continuing the process and applying labels to capped bottles in other machines. |

6.What is the working principle of nasal spray filling machine?

Nasal spray filling machine accurately fills bottles. But it doesn’t fill directly. Though different steps are involved in the process. Here you go:

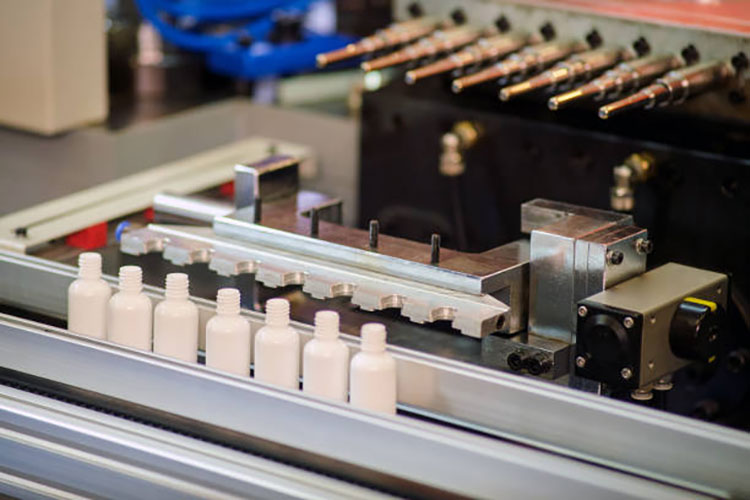

Bottle feeding

Bottle feeding

The first step in filling mechanism is feeding of bottles. There is conveyor belt that load bottles to filling station. This is smoothly carried on. In some of the machines, conveyor-built transfer and place the bottles in their desire holders so they align on their exact place.

Bottle positioning

Bottle positioning

After bottle feeding, next step is to place them under filling nozzle. There are sensors that detect the position of bottle. If bottle has distracted position, it rejects it by ring alarm about dispositioning. This helps to prevent spillage or production loss. However, the filling nozzle are inserted deep in bottles for filling. This will help in filling process.

Filling

Filling

Dosing system such as piston or peristatic pump accurately and precisely dispenses the nasal spray solution in each bottle up to right volume. If you are worried about foam formation-then no form formation occurs due to filling head insertion at bottom of bottle. Filling is done under aseptic environment.

Pump insertion

Pump insertion

In nasal spray bottles, there are pumps to which they are pressed to squeeze the liquid solution. So, how they are inserted? There are robotic arms or gripper that pick the pumps from hopper or vibrating bowl and place on bottles. Vertical insertion of pumps is done. There are sensors that detect the correct placement of them.

Cap insertion

Cap insertion

When pumps are inserted, caps are inserted. The filled and pumped bottles are moved to the capping station. Caps provide more protection to the nasal spray liquid by prevent from dripping or from wasting. Depends on the bottle designs, screw or crimping system are used. In crimping mechanism, an aluminum roller is crimped around the bottle while in screw system, torque is applied to tighten the pumps to proper position. Vision inspection system detects presence of caps. Faulty caps are diverted to rejection bin.

Discharge

Discharge

After caps inserting, they are finally moved from the machine and forward to other machine for further process like labeling, cartoning etc. The filled bottles are moved through conveyor belt.

7.Are there types of nasal spray filling machine in market?

Different types of this filling machine are available. Each depends on the filling mechanism and level of automation. Before doing a quick decision of buying a nasal spray filling machine, knowing different types of machine are important. Here you go.

On the basis of automation

Followings are types of nasal spray filling machine on the basis of level of automation.

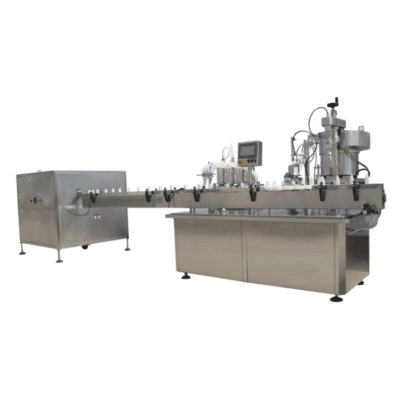

Semi-automated nasal spray filling machine

Semi-automated nasal spray filling machine

In this filling machine, filling is done automatically while other process such as capping is done manually. Bottles are loaded manually and filling is done automatically. For medium scale production, semi-automated machine is suitable. If you compare manual with this machine, it gives accurate result. If you are on path of advancement, buy this machine. In some of steps, human involvement is provided.

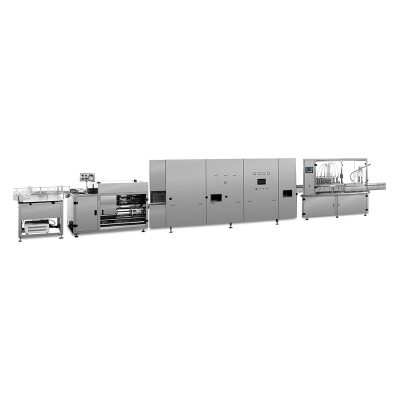

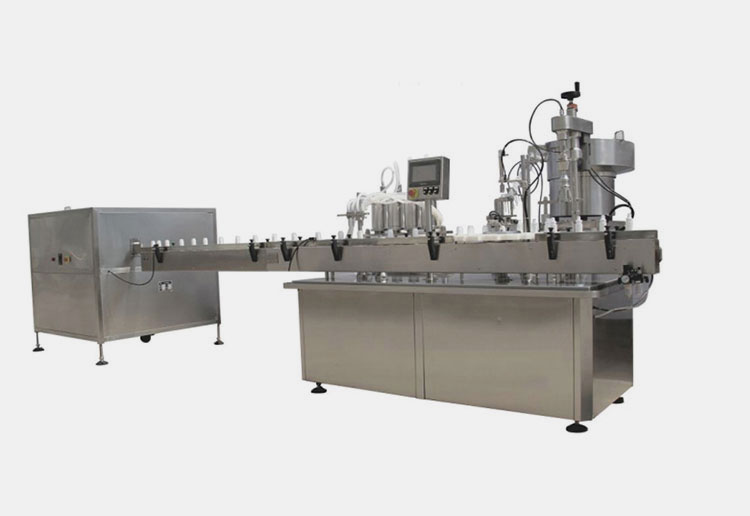

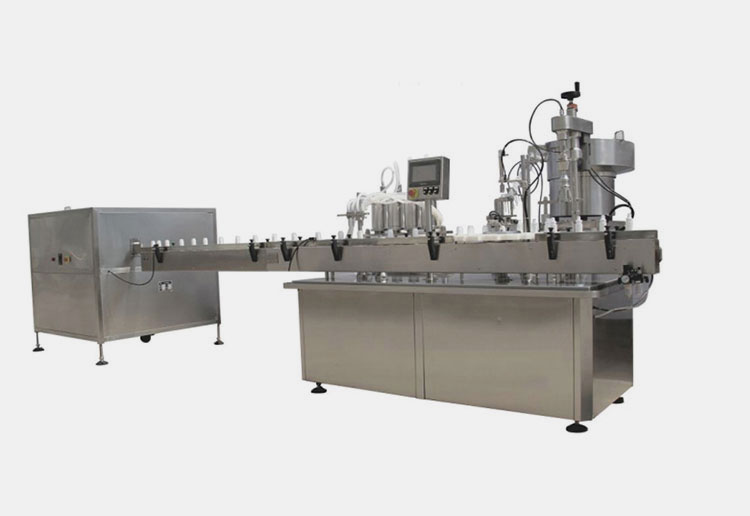

Fully automated nasal spray filling machine

AIPAK Fully automated nasal spray filling machine

From its name, you can guess its features and advancement level. All the tasks from bottle loading to filling, capping, all is done and managed by machine. There is little chances of error and inaccuracy. Safety features, sensors, auto rejection system, touch screen and others are compacted in fully automated filling machine. High scale production is possible due to this machine. This machine of AIPAK gives accurate results with high speed production, meet demands in less time with less downtime and quick changeover. As there is less human involvement, so possibility of error is less. In modern automated machines, there is robotic arms for pick and place operations.

On the basis of motion design

Followings below are the types of this filling machine on basis of motion design.

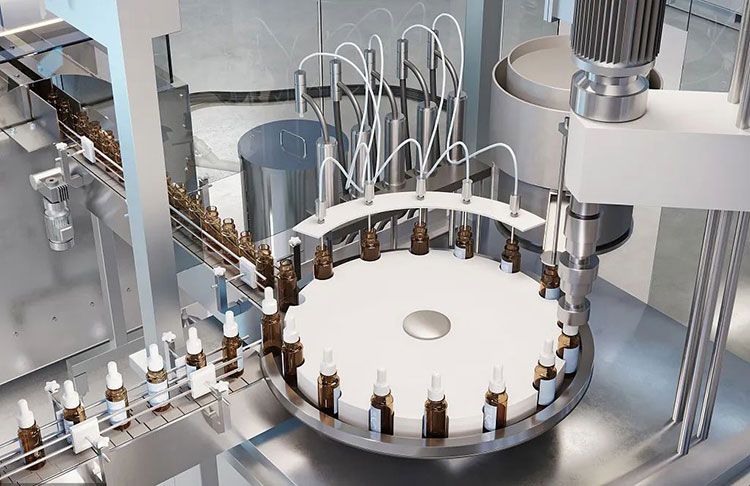

Rotary nasal spray filling machine

Rotary nasal spray filling machine-Picture courtesy: Picture courtesy: aarveepharma.com

This type of filling machine is suitable with low viscosity liquids. It uses vacuum based or peristatic pump mechanism to dispense liquid in bottles where vacuum is created to push liquid solution in bottles. Bottles move in linear path. It gives accurate and contamination free result as it ensures liquid comes only in contact with inner of containers. It is expensive due to its contact free operation.

Linear nasal spray filling machine

Linear nasal spray filling machine-Picture courtesy: vkpak.com

This filling machine uses a rotating motion where bottles are fed into machine in rotating wheel. It uses piston to deliver medium to high viscosity of liquids. Piston draws accurate volume of liquid in nasal spray bottles. As pistons are mechanically design, so you can easily clean inside of machine. For more accurate results, try to calibrate movement of piston.

Based on Bottle and Pump Type

Machines on basis of bottle and pump type are as given:

Crimp-On type machines

Crimp-On type machines-picture courtesy: schafergroup.com

This machine uses a crimp-on a sealing place to make it tight. A mechanical crimp-on system is used in which pump is attached to bottle neck to crimp a metal collar. By this, a consistent and tamper prof enclosing of nasal spray solution is done.

Screw-on type machines

Screw-on type machines-Picture courtesypppharmapac.com

A screw system is used by this filling machine to enclose the bottles. When pump is screwed on bottle neck, a torque is used till it is tightened. This ideal machine sealing is user friendly as you can easily open them. You can use the machine for different kinds of bottle.

Special custom designs

To know special custom design, lets read below.

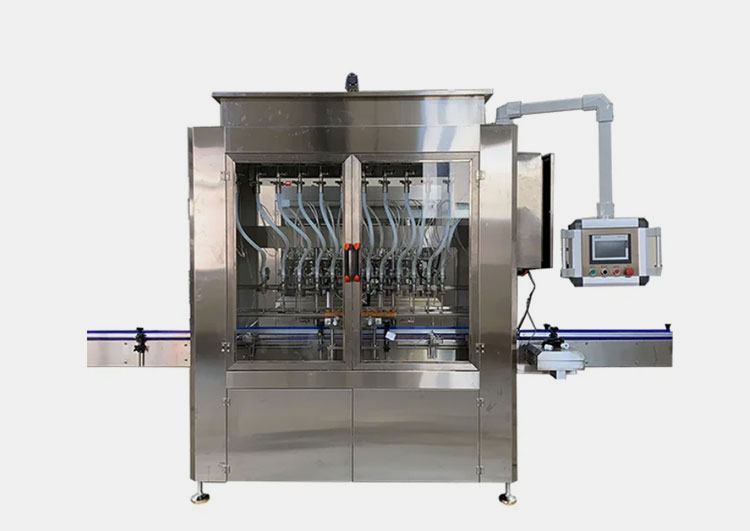

Multi-head high-speed machines

Multi-head high-speed machines-Picture courtesy: ruilimachine.com

The word ‘multi-head’ shows that this machine has multi-head, a filling nozzle. So, number of nasal spray bottles can be filled at a time. A high scale industry where needed a sped and large production capacity uses this machine. Several bottles can be handling in one cycle without compromising the quality, as it is automated.

Monoblock nasal spray filling machine

Monoblock nasal spray filling machine-Picture courtesy: harikrushna.com

In this monoblock filling machine, different tasks can be operated. From loading, filling, sealing to capping and screwing. The product is handled in one production line, no need to buy more machine and saving space. This filling machine ensures contaminated free product and ensures a synchronizes operation.

8.How to troubleshoot common problems in nasal spray filling machine?

Filling machine can have different problems due to different reasons. But you can troubleshoot these problems. Common problems involve mechanical fault, electrical issue and other reasons. Following below are the ways of troubleshooting problems.

Inconsistent filling

Inconsistent filling

| Cause | Troubleshooting |

| You might see that bottles have different filling level, some have large volume, others have small liquid volume. Filling nozzles clogging may disrupt liquid solution fluidity. If pump is of poor quality, same issues can be face. | There are ways to troubleshoot the problems. Let’s have a look:

Clean the nozzle after each batch to remove the stick liquid. Remove the pump if worn out and calibrate it time-to-time. |

Misalignment of spray pump

Misalignment of spray pump

| Cause | Troubleshooting |

| Spray pump caps are loaded in capping station. But sometimes, these spray pumps are misaligned due to fault in capping hopper, as vibration might not happen. Chute blocking can be also cause. | First thing you should do is to inspect the vibratory bowl. Check chute, to inspect is there any stuff that block the way of chute. But if all things are alright, check size of chute and spray pump. |

Spillage while filling

Spillage while filling

| Cause | Troubleshooting |

| While filling process is operating, and you find a dripping of liquid. It can be due to overspeed, problem in filling nozzle or head. Spillage contaminate the product and compromise quality. | To trouble spillage, check cracks or worn out of filling head. From control panel check for speed parameter and adjust it. |

9.What are the future prospects of nasal spray filling machine?

Future prospect of nasal spray filling machine depends on technological advancement and changing trend, global trend. This filling machine is moving towards more accuracy, sustainability, and automation. Here below are the future prospects.

AI integration

AI integration

This is the age of artificial intelligence. In every field, AI is integrated. Similarly, this filling machine is integrated with use of AI to give more accurate result, maintained hygiene, improves production capacity. Smart sensors detect any defect, checks fill-in-volume. In traditional filling machine, human labor was incorporated. But trendy AI algorism autocorrects.

Robotic assistance

Robotic assistance

Robotic technology is used in modern automated filling machine. As this filling machine handles different size and shape of bottles. For this, there are robotic arms that pick and drop bottles where required. Robotic innating improves speed and efficiency by speeding spray pumps insertion, adding caps by reducing human intervention.

Formats compatibility

Different packaging formats are handled by this machine. From plastic to glass bottles of different sizes and shapes are handled. This prospect allows users to use machine for different purpose and can expand its brand. You can change format from batch to batch. In short, single machine with numbers of formats compatibility.

Hygiene design

As in maintenance factors, you have read that you should clean machine to maintain hygiene. But in modern machines, cleaning is done automatically. There is self-draining system that clean internal components. Hence, human labor is not required for cleaning as still, it can be probe to germs.

10.What are the factors to consider when buying nasal spray filling machine?

Choosing right kind of filling machine is necessary for product. Manufacturers try to buy a machine that enhances sterility, accuracy and other features that make their product a top brand and first priority for the consumers. Inefficient machine results in product spillage, and even compromise the product quality. Let’s dive into the factors that you should consider when selecting a nasal spray filling machine.

Filling accuracy

Filling accuracy

Choose a machine that gives accurate results in filling. Select a machine that has system of auto filling and sensors that detect any mis-hype in filling as over filling and underfilling can result in product spillage, resulting in product loss. This adds a loss in industry profit. Piston and peristaltic pump in machine ensure accurate dosing. So, select a machine with these filling systems.

Variability/ compatibility

Another factor you should consider is select a machine that can handle different bottle types. Some of the bottles are small or large in size with oval, square or rectangular shape. This will benefit you in term of cost and will save a large space. Also make sure, it can be easily change over.

Product handling

Nasal spray filling machine is applicable in various industries, handle different products such as cosmetic, detergent and a pharmaceutical. Each product has different properties with different viscosities and needs different environmental conditions for handling. Buy a machine that is compatible with your product.

Product capacity

Product capacity

Do you know you should gauge your product target before buying a nasal spray filling machine? Yes, set a target of product you want to fill per hours or a day. Don’t rush to buy- it will result in over-budgeting or under-budgeting. If you have small scale production target, go for manual filling machine, medium-scale; buy a semi-automatic filling machine. On the other hand, for large scale production, choose automated filling machine.

Level of automation

Another factor to consider is level of automation. For your information, a manual filling machine has human intervention in operation. Secondly, in semi-automated machine, there is involvement of human and some of tasks handle by machine. Thirdly, in fully automated machine, all the operations are controlled by machine with less human intervention. Select a machine according to your budget since level of automation effects speed and efficiency.

Safety features

Safety features-Picture courtesy: supmeter.en.com

For safety of machine, product and operators, safety features are necessary. Select a machine that comes with safety features includes emergency button, anti-spill nozzle, automated shut off features, misaligned bottles detector etc. These help in reducing risks and product loss.

Machine material

Select a machine that is made from stainless steel components or parts. It should be corrosion free, ideal for sensitive ingredients of products as they can be probe to reaction to corroded parts.

Conclusion

To conclude buying guide, you must have an idea that nasal spray filling machine is used to fill nasal spray bottles from liquid solution; it isn’t only a pharmaceutical filling machine but you can widely use in cosmetic, detergent and other industries. Best in giving accurate result, consistent filling and most important, its stainless-steel components improve quality by providing hygiene product. Before buying a machine, know automation level of machine and note the production target. If you have any query and interested in buying machines, do contact AIPAK.

Don't forget to share this post!

Syrup Filling Machine Related Products

Syrup Filling Machine Related Posts

Syrup Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine