How to Fit a Full Powder Filling Line in a Compact Facility?

Starting a new manufacturing business is hard, especially when you have limited space and need professional equipment. You might worry that industrial machines simply won't fit in your small factory.

We solved this exact problem for an Australian startup by creating a custom layout and modifying our powder filling machines to fit under low doors while handling a wide range of bottle sizes.**

Powder filling machine in a clean room facility

Space constraints are a common headache for new businesses. You find a perfect location, but the ceiling is too low, or the layout is awkward. This stops many companies from buying the automatic lines they need to grow. But it does not have to be a deal-breaker. If you work with a partner who understands engineering, there is usually a way to make it work.

1.How Do We Ensure the Right Equipment Fit for Your Needs?

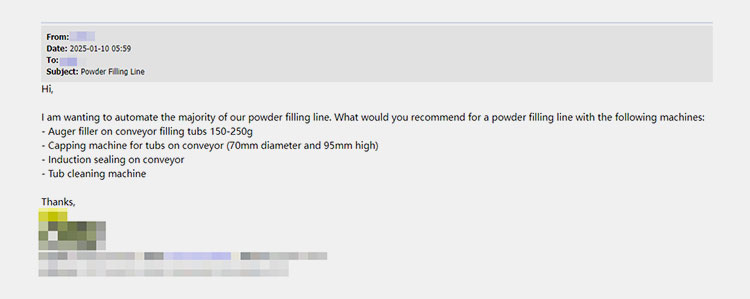

Powder filling inquiry from customer

In early 2025, we received an inquiry from a health supplement company in Australia looking for a powder filling line.

Details from customer

We immediately asked for details on bottles, caps, powder type, and target speed to ensure we could actually build what they needed.

Engineer checking technical specifications

When I first saw the email from this Australian client, I knew we had to move fast but stay accurate. I did not just send a generic price list. Instead, I replied on the same day. I asked for specific details. I needed to know the bottle sizes, the cap types, the density of the powder, and how many bottles they wanted to produce per hour.

This step is vital. Many suppliers skip this. They just want to sell a machine. But at AIPAK, we know that powder varies. Some powder is sticky. Some is free-flowing. The machine must match the material. The client told me later that this level of detail made them trust us. They saw we were professionals who cared about the result, not just the sale. We cleared up all the technical needs in the first few emails. This prevented any confusion later on. It laid a strong foundation for the project.

2.What If Your Factory Space Is Extremely Limited?

The client hesitated because they were a startup with a very small factory and low door frames.

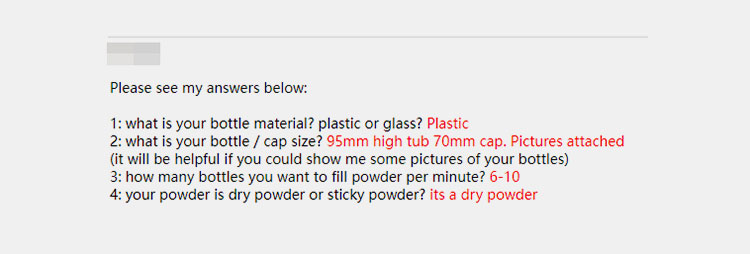

We requested their floor plan and drew a complete machine layout to prove that our equipment would fit perfectly in their specific space.

2D CAD layout of a packaging line

The client was honest with me. They said, "We want to work with you, but we don't think these big machines will fit." Their facility was not a huge industrial warehouse. It was a compact startup space. This is a critical moment in B2B manufacturing. I could have just guessed, but that is dangerous.

I asked the client to send me the architectural drawings of their room. I handed these to our engineering team. We looked at the dimensions of our powder filling machine, the conveyor belts, and the capping station. We created a custom layout map. We placed every machine in the drawing to scale.

We showed the client exactly how the line would flow. We showed where the operators would stand. We showed the clearance for the doors. When I sent this layout back to the client, their worry disappeared. They could see it with their own eyes. This visual proof was the turning point. It gave them the confidence to say yes.

3.How Can Machinery Adapt to Low Door Heights and Mobility Needs?

The client’s facility doors were only just over 2 meters high, which is shorter than many standard industrial hoppers.

We customized the powder filler with a manual lifting column to lower the height below 2 meters and added castors for easy movement.

Customized powder filler with lifting column

Standard machines are often tall. They rely on gravity and large hoppers. But this client had a strict limit. Their door height was just over 2 meters. A standard machine would get stuck at the entrance. We had to innovate. We did not ask the client to rebuild their factory. We changed the machine.

Here is how we customized the solution for practicality:

| Feature | Customization Detail | Benefit to Client |

| Height Control | Manual lifting column on the filler | The machine height can be adjusted to under 2m to fit through doors |

| Cleaning | Detachable machine head | Operators can take the head off easily to wash it without ladders |

| Mobility | Heavy-duty castors on all units | The client can roll the machines aside when not in use to save space |

| Dust Control | Anti-leak and vacuum design | Keeps the small room clean and meets GMP standards without expensive HVAC |

Leak-proof and dust-proof design

I emphasized these points to the client. I told them that a machine is only good if it is practical. If you cannot move it or clean it, it is useless. The manual lift allows them to lower the machine for transport and raise it for production. The castors mean they are not tied to one spot. This flexibility is exactly what a startup needs.

4.How to Handle Multiple Bottle Sizes Without Changing Molds?

The client had a huge range of bottle sizes, from small 60mm jars to large 200mm containers.

We built a versatile capping machine with adjustable height and rail width so they can switch sizes without buying new parts.

Adjustable capping machine for different bottle sizes

Startups often have many products. They test the market. This client had bottles with diameters from 60mm to 200mm. The heights ranged from 50mm to 200mm. The caps were 50mm to 120mm. In a standard setup, you might need different "star wheels" or molds for every size. That is expensive. It also takes a long time to change.

I proposed a different approach. We customized a capping machine that does not use fixed molds. Instead, it uses a linear belt system. The operator can use a hand wheel to widen the guide rails. They can crank a handle to raise the capping head.

This means they can switch from a small vitamin bottle to a large protein powder tub in minutes. They do not need to use tools. They do not need to store spare parts. This saves them money on tooling costs. It also keeps their production agile. For a small team, saving setup time is the same as saving money. This machine grows with them.

5.Why Is Pre-Shipment Testing with Real Samples Crucial?

Before shipping, we asked the client to send us 100 samples of their largest and smallest bottles.

We used these samples to set all the machine parameters in our factory, ensuring the equipment was "plug and play" upon arrival.

Technician testing bottles on the conveyor line

I never like to guess when it comes to final settings. Once the machines were built, I asked the client to ship us their actual bottles and caps. I asked for 100 of the big ones and 100 of the small ones.

Why do we do this? Because a drawing is not the same as a physical object. Sometimes a bottle has a slight curve. Sometimes a cap is slippery. When we received the samples, our engineers ran the full line. We filled them with dummy powder. We capped them. We labeled them.

We recorded all the settings. We marked the positions on the guide rails. We adjusted the torque on the capper. When we packed the machine for Australia, it was already tuned. The client did not have to hire an expensive local engineer to figure it out. They just had to plug it in and load the recipe we created. This is part of our service. We take the risk out of the installation.

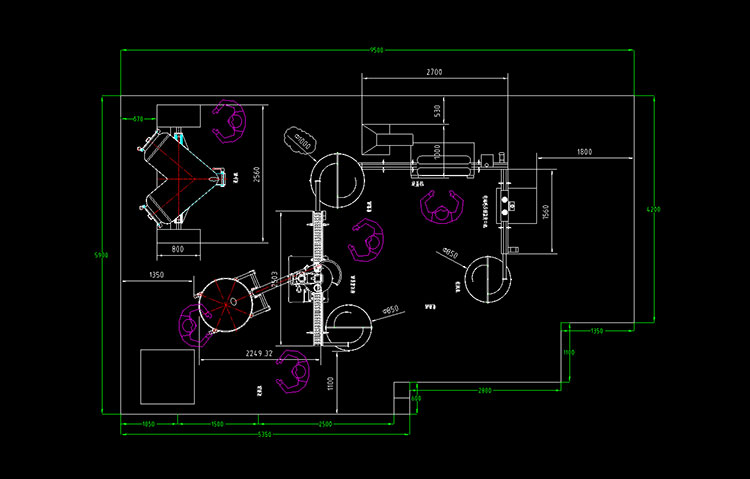

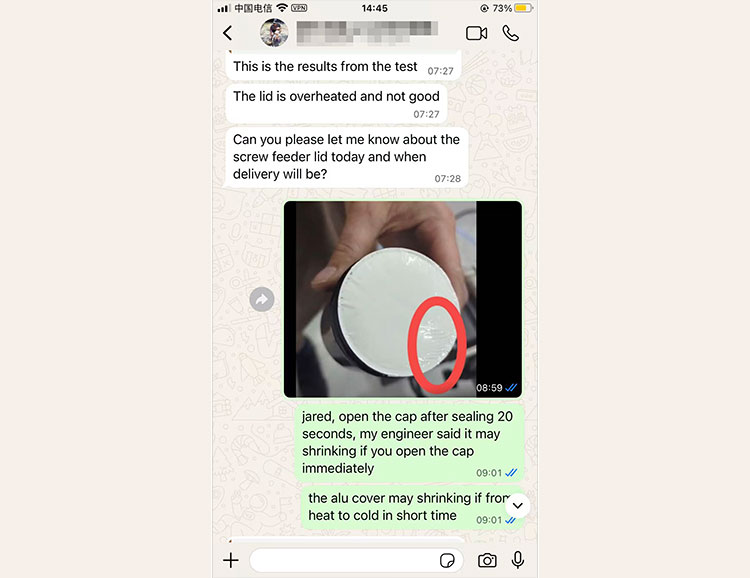

6.How Do We Solve Common Induction Sealing Issues Like Wrinkled Foil?

After the machine arrived, the client noticed wrinkles in the aluminum foil seal and worried about overheating.

Our engineer advised adjusting the cooling time and temperature, explaining that thermal expansion causes wrinkles if the cap is opened too soon.

Induction sealing machine process

Even with the best testing, questions arise during actual production. The client contacted me shortly after they started running. They were using the induction sealer. They found that the aluminum foil looked wrinkled after sealing. They were worried. They thought the machine was getting too hot and burning the liner.

I spoke to our senior engineer immediately. He looked at the parameters. He explained the physics to me, and I explained it to the client. It was not just about heat. It was about "thermal expansion and contraction."

Wrinkled Foil issue solving when production running on customer site

When the foil is heated, it expands. If you open the cap immediately to check it, the foil cools down fast and shrinks. This sudden change creates wrinkles. We advised the client to do two things. First, lower the temperature slightly or speed up the conveyor. Second, do not open the cap right after the machine. Let it cool for a few seconds. The client followed this advice. The wrinkles disappeared. The seal was perfect. This quick support solved a panic moment and got them back to production instantly.

Conclusion

By customizing dimensions, ensuring flexibility, and providing real-time support, we helped an Australian startup fit a professional production line into a small space.

Don't forget to share this post!

Maximizing Efficiency in a Compact Powder Filling Facility

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine