Your Ideal Automatic Labeling Machine

- Wide Labeling Range

- High Accuracy High Speed

- Stable Performance Easy Operation

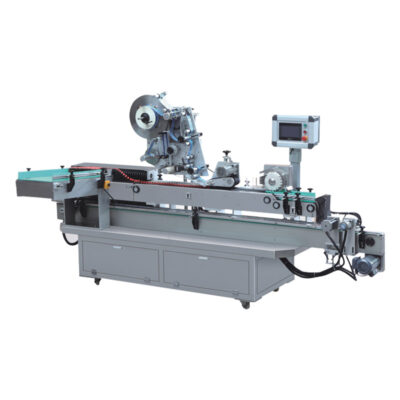

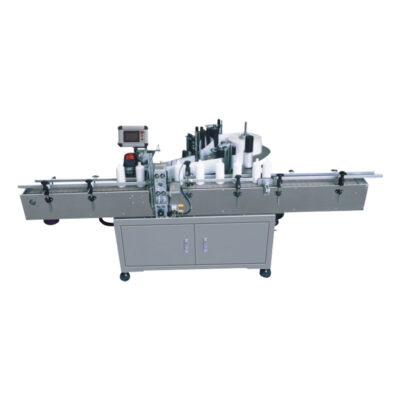

AIPAK Automatic Labeling Machine

AIPAK offers various multifunctional automatic labeling machines, suitable for labeling all kinds of bottles such as PET bottles, plastic bottles, glass bottles and metal bottles. All automatic labeling machines are widely used in pharmaceutical, electronic, metal, cosmetic, beverages, food, plastics,daily chemical and other industries, greatly improving productivity and labeling quality. All AIPAK automatic labeling machines are controlled by touch screen control panel,which is easier and convenient to adjust the parameter. The labeling process is automatic operation, simple operation, fast production speed, uniform, beautiful and neat labeling position. Optional color belt printer and inkjet printer, labeling at the same time to achieve printing production batch number, production date and other information. Realize the integration of labeling and inkjet printing, reduce the packaging process and improve the production efficiency.

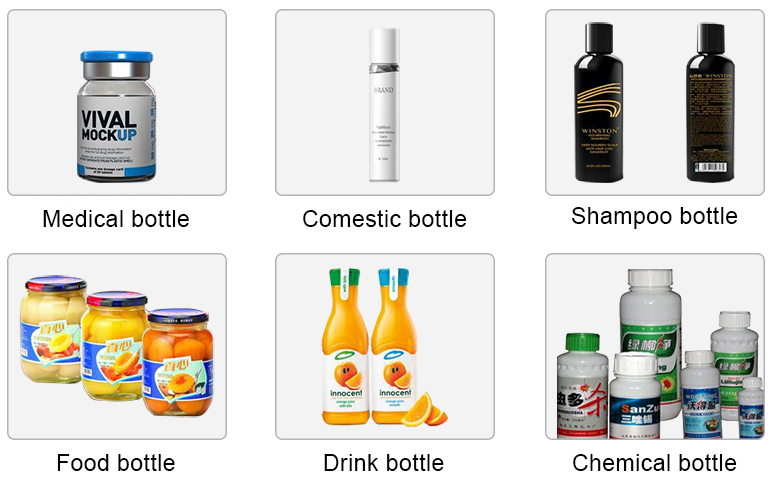

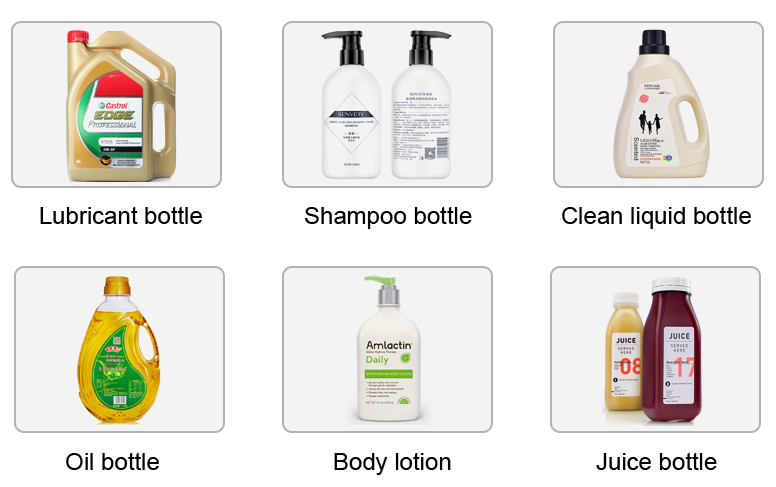

Applications Of AIPAK Automatic Labeling Machine

The Buyer's Guide

Automatic Labeling Machines:The Complete Importing Guide in 2024

Automatic Labeling Machine is as important as the product because it will help you to pack in such a precise. You might have been facing difficulties labeling different type of products?

Do not worry about labeling the products Automatic Labeling Machine is a simple but powerful solution that can be used to label multi type products.

Automatic Labeling Machine is used with different production lines to label on a product give details about product and its use & in this complete guide I am going to give you overlook about uses of labeling machine, the way it works and other useful features.

1.Explain Automatic labeling machine?

AIPAK Automatic Labeling Machine

A labeling machine is a powerful solution to display and explain about the product. There are different type of labeling that can be done while using this machine including side way labeling, top to bottom labeling, corner labeling and wrap labeling.

An automatic labeling machine can save your time & money as well in terms of labor to display the product details for giving the awareness about the product to the customers because it can move the products from one place to the other easily.

Automatic Labeling Machine can be used with any type of production line to make your production more reluctant and powerful. A good production line defines all about its product including the manufacturing details, batch number, product manufacturing date & expiry date as well.

Labeling of the product can help you to increase the trust of your customers.

2.What is the main purpose of Automatic labeling machine?

Different kind of labeling machines are used for different kind of products for labeling purpose but some labeling machines are almost used for labeling almost every type of product.

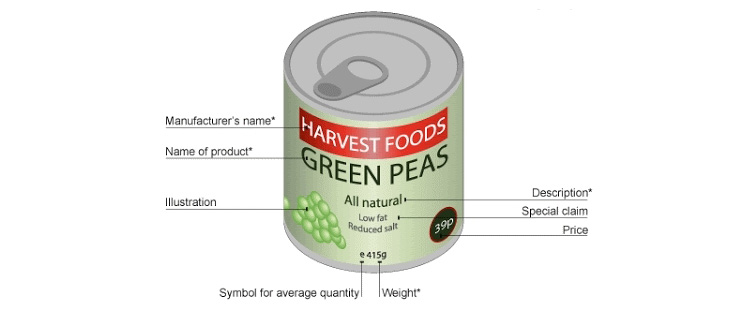

The main and one function of a labeling machine is to show the details about the product type and all the related stuff about the product in the form of a label to give a look and awareness to the customers about the product.

Label on a product is done in the form of an adhesive print or a simple print on the product. The main purpose of an Automatic Labeling Machine is to explain or give some glimpse of information about the product.

If a product is well labeled then more customers will reach your product in a friendly manner when they read about the product it will be easy for them to buy the required product of their choice.

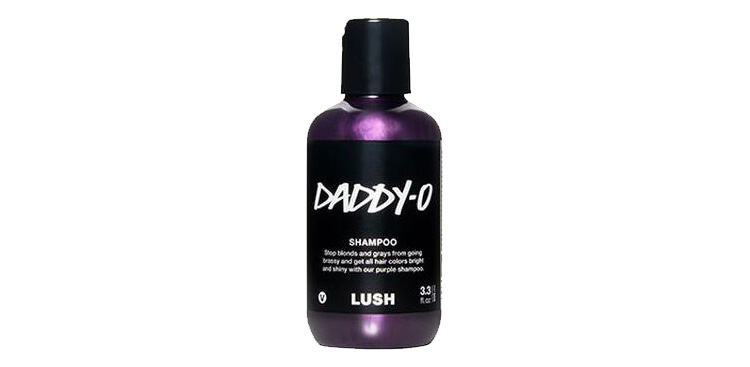

Label on shampoo bottle

To complete the production line a labeling machine is very essential for a production unit to give every type of labeling on different type of products.

Labeling machine is almost used with every type of production line rather it is liquid filling, tablet or capsule packing or whatever the production line holds. Label on a product will made a clear image about your product for example when you went to the grocery shop or somewhere else the first thing attract you about the product is product labeling.

If a product is labeled well it will attract the customers and they will become conscious to read more about the product and its production type via labeling.

The main impact or purpose of labeling machine is to give a unique informative look to your product to grasp new & more customers with the help of an informative detail note on the product.

3.What are the different types of Automatic Labeling Machine?

AIPAK automatic labeling machine

Various types of labeling machines are available in the market to perform labeling task in a specific way and on a specific product.

Let me explain to you about all the labeling machine types one by one.

Hand Operated Labeling Machine

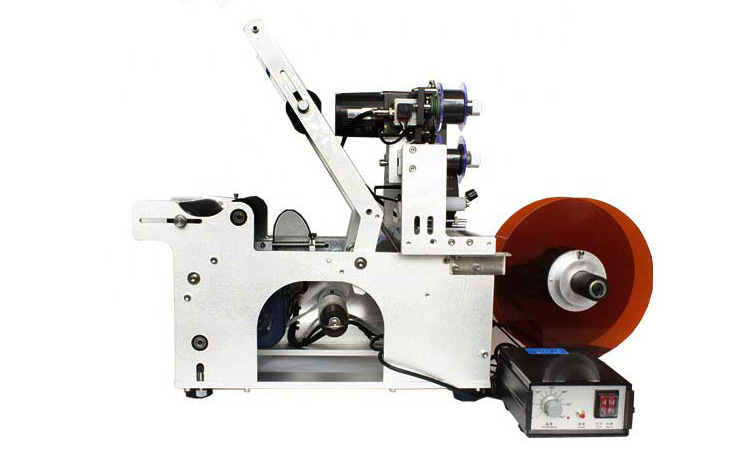

Manual/Hand operated labeling machine

This labeling machine is a small size device that is used to label different type of products with the help of manual handling by a labor/person.

It is a portable device that you can take everywhere and do the labeling on different type of products like rectangular based products including boxes, and other plastic packed products.

Adhesive type of label is generated with this small labeling machine by using a gum material inside of it and paper is used to print different type of information on it and then label it on the product.

The cost of this machine is very low as compared to the other machines as it is limited to some products when it comes to labeling them in terms of giving you limited labeling this machine can also save your money as well.

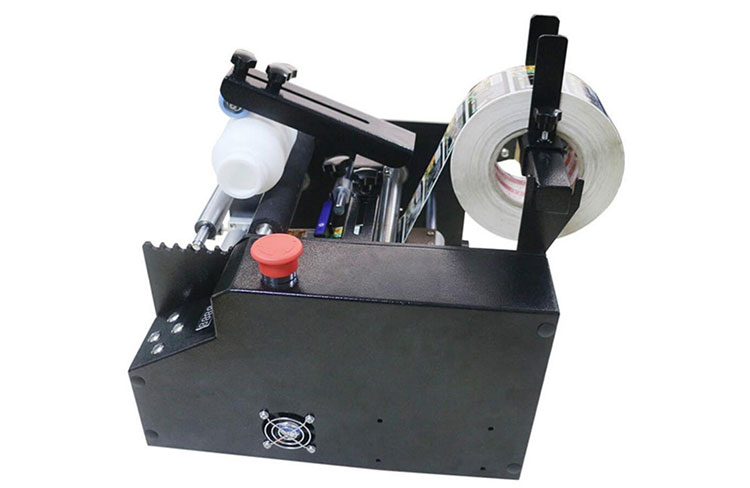

Manual Labeling Machine

Manual Labeling Machine

A manual labeling machine often came with different functionalities and use to label different type of products. A normal type of labeling machine can label different size of plastic bottles and steel cans from 1 to 5 diameter bottles.

It works manually to label different size of products while giving you the output of one thousand labels in a minute with high accuracy and adhesiveness on the labels to make them stick with the product during the travel.

Manually any person with some basic knowledge can operate and work with this labeling machine because it requires less time to set up the labeling on the product and requires very small space to be settled.

Different labeled bottles-Photo Credits: Online Labels UK

Manual labeling machine is used to label the products in a round way some other manual labeling machines are also there to label one side or two sided labeling on the product according to their working principle and functionality they work on labeling different type of products.

In manual labeling you have to interact with the machine because most of the work is done manually inside of this machine like providing the required label paper to the roller to label it and then fill the ink tanker after checking it.

Semi-Automatic Labeling Machine

Semi-Automatic labeling machine

Semi-Automatic labeling machine is somehow one or two step ahead from the manual labeling it comes in different size according the labeling functionality.

Different container size can be used in the semi auto labeling machine and it gives different type of labeling as well including two side labeling and top bottom labeling.

Some of its working parts required human effort to complete the labeling process where as some of the parts work automatically via sensor system to complete the labeling process.

So this labeling equipment gives you more flexibility in terms of labeling different size of containers. Semi-Automatic Labeling Machine is present in various different types to label multi and specific type of products so you can choose one according to your demand and production line.

Semi-automatic labeling machine

Most of the production lines use this labeling machine as it fulfills their requirements according to their needs and production unit. It is more costly than the other manual labeling machines providing automatic labeling up to some level.

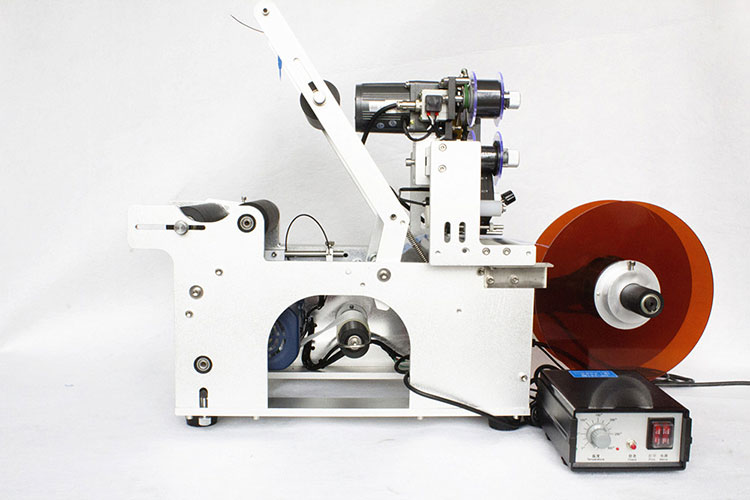

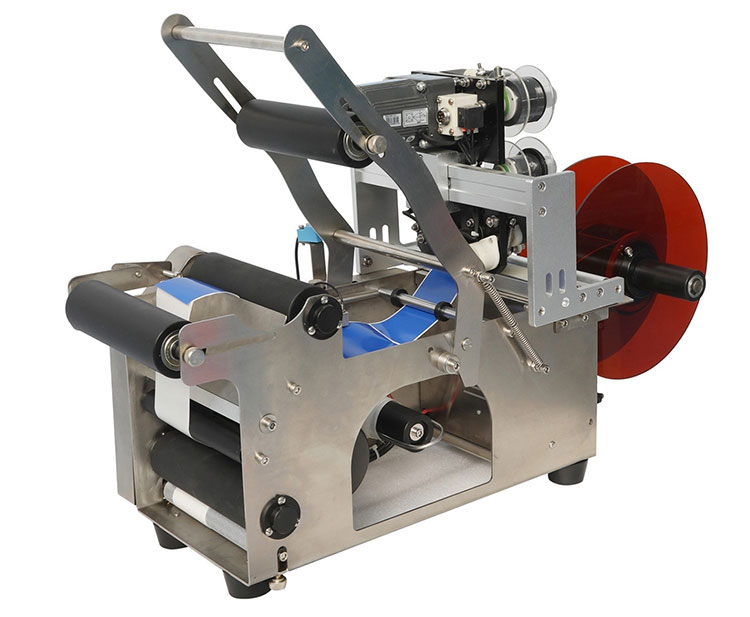

Automatic Labeling Machine

A fully automatic labeling machine is used with almost every type of production line to make labels on the products. Automatic labeling machine is no doubt an expensive equipment to buy but it gives you speedy and quick labeling working alongside with your production unit.

Inline or automatic labeling machine is very reliable in terms of providing you consistency and precise in packing along with labeling on the products. Multi type of production line uses this machine for labeling purpose.

It is easy for you to handle bulk amount of products with much ease and precision to show labels on them and then send them for further packing. Different types of automatic labeling machines are available according to the production line that can label multi type and size of products within your production unit.

Different label types-Photo Credits: Bottle our brand

Maintenance and working of a fully automatic machine will provide you ease as it works automatically to label the product so, you will not require any extra labor for your production line to work with the labeling machine.

All the tasks will be performed automatically without any necessary human effort and fully automatic machine can handle all the process of labeling the different products by its own.

You can adjust the font size & choose the color of text to print on the labels and some other type of selections can also be made in fully automatic labeling machine regarding the appearance of your label on the product.

4.What are the different advantages of Automatic labeling machine?

Labeling idea-Photo Credits: Freepik

A fully automatic labeling machine can provide you plenty of benefits in terms of quality labeling and safety of your product during the labeling process.

These are the advantages that you can get from the labeling machine.

- Product will look attractive with a good label on it.

- Details about the product will make it easy for the customers to understand about the product.

- Installing automatic labeling machine with your production line will make it easy for you to pack the product before and after the labeling.

- Labeling on a product will increase its market value.

- Help you to gain the customers trust by showing the right description about the product via labeling machine.

- Automatic labeling machine will save your material from getting wasted because during the manual labeling product may get wasted.

- More product can be labeled with in the less time frame as compared to manual labeling.

- A fully automatic labeling machine will help you to save the labor cost as it can work on its own without any human effort.

- Greater output production can be gained with accurate labeling.

- Easy to change the modular functions according to your production line.

- Multi type of labeling can be done with the automatic labeling machine and with changeable appearances including font color & size.

- Product description, batch number, manufacturing date, expiry date and various other types of labeling can be done with the labeling machine.

- Comparison between different types of products will be easy for you when you work with the automatic labeling machine.

- A good label with accurate description about the product will help you to attract more customers with good intention.

- Standard labeling of the product according to the law will help you to reach the market values and demand of customers.

5.What are the disadvantages of Automatic labeling machine?

Label on glass bottles-Photo Credits: Online Labels

Some of the disadvantages of the labeling machine that can be ignored while keeping in mind the many advantages.

- During the labeling the label may not get stuck to the specific product and quality of the label is not much satisfied along with other production line unit.

- The method of labeling will completely depend on the type of product so, you will not be able to choose the label design according to your wish.

- Selection of the labeling machine can be done according to your production line and then you will be able to get the required label on the product.

- Some minor problems may encounter you during the labeling like the leakage of ink, label not getting stick to the product this is because of maintenance of the machine.

6.Explain how Automatic Label Machine Works?

Every labeling machine works in a different way according to its label functionality and type of labeling on the product so, let me explain to you the basic and general working of the automatic labeling machine.

- Step-1

Different types of label-Photo Credits: Evermine

In the first step in an automatic labeling machine a conveyor belt move the product from production unit towards the labeling line and this is done with the constant speed of the conveyor belts to move the product from one place to the other.

Conveyor unit and the feeding unit made the same movement so, that label on the product can be done perfectly.

- Step-2

Label on small size bottle-Photo Credits: Stick & you

Labeling on the paper may be done before the product arrives at the labeling unit or may be the paper first stuck with the paper and then the further labeling is done this process of labeling on the paper or after the paper attached to the product is completely depend on the type of labeling machine.

When the wheel rotates the label and conveyor unit move the product towards the labeling unit the labeling unit checks the distance between the products and then measure the speed of conveyor belt & wheel roller to make the label in a perfect manner.

- Step-3

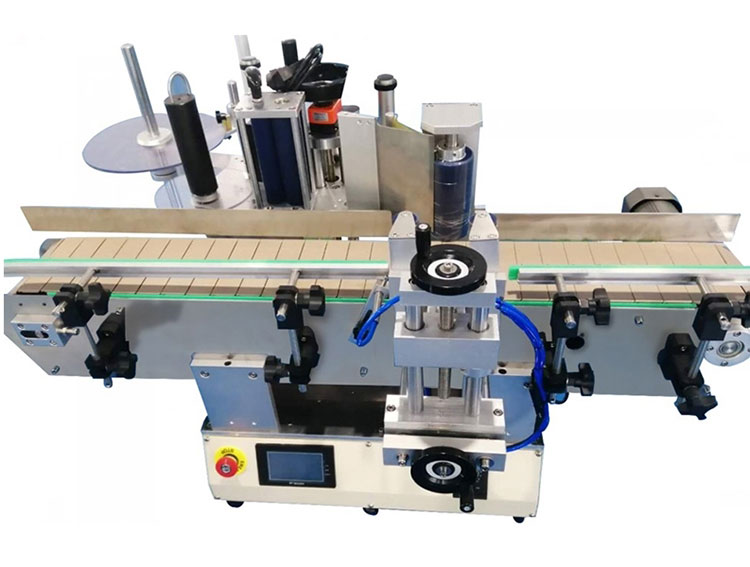

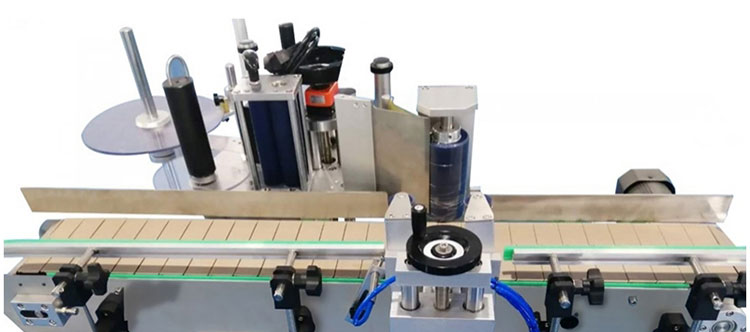

Horizontal labeling machine

Product when came into the labeling unit then movement of conveyor unit & feeding system is synchronized and then the label is cut to the required size according to product type.

Then reel moves the label on the product and make the label according to the given command using the control system via PLC system.

After the reel rolls it paste the label on the defined surface of the product and this is how the label is done on the product with the right movement of two different parts of the automatic labeling machine.

- Step-4

AIPAK high speed labeling machine

When labeling is done on the product then the ejection of the product is done with the help of ejection unit.

In this unit the ejection is done very carefully so, that the label not get any damage or miss printing not happen because of any wrong step.

This is the last and final step for your product to get labeled and you can if the labeling is done accurately or not? So, working according to the manual with automatic labeling machine will help you to label your product perfectly and precisely.

7.Explain the Main Working Components of the Automatic Labeling Machine?

Working of any machine mainly depends on its moving parts which helps the movement of the machine and help you to proceed with the required production so, the labeling machine also depends on its working parts to complete the labeling process.

Let’s discuss the different working parts of the Automatic Labeling Machine.

Label Holder

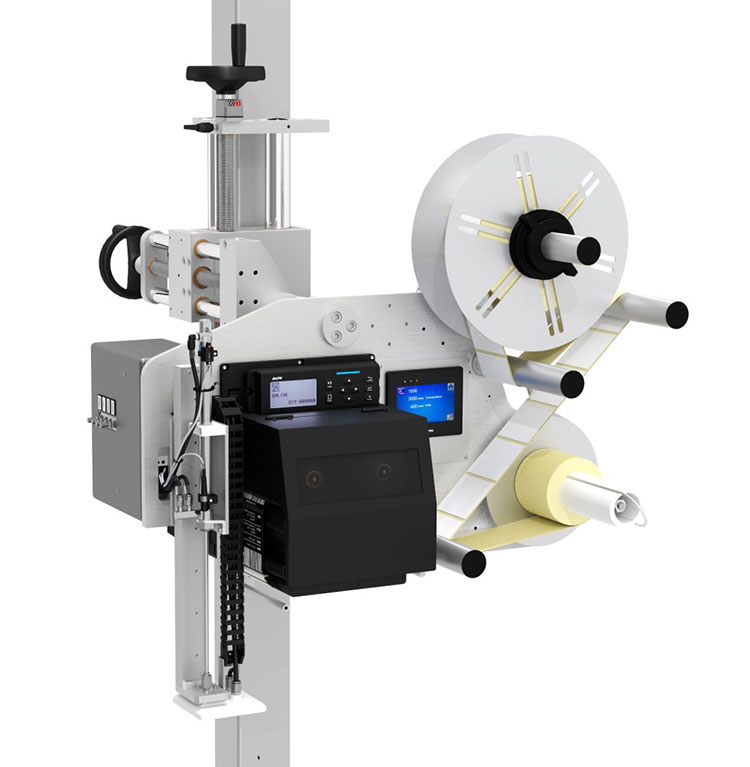

Printer & label unit-Photo Credits: Kwangdah

Before the label comes into the labeling unit it is present in a container/tray called the label container or label holder.

Mostly these containers are stainless steel based to stay away from any kind of chemical reaction between the labeling paper and holding tray.

To feed the labels to the labeling unit this part of the machine mostly present at the top of the automatic labeling machine to access the labels easily.

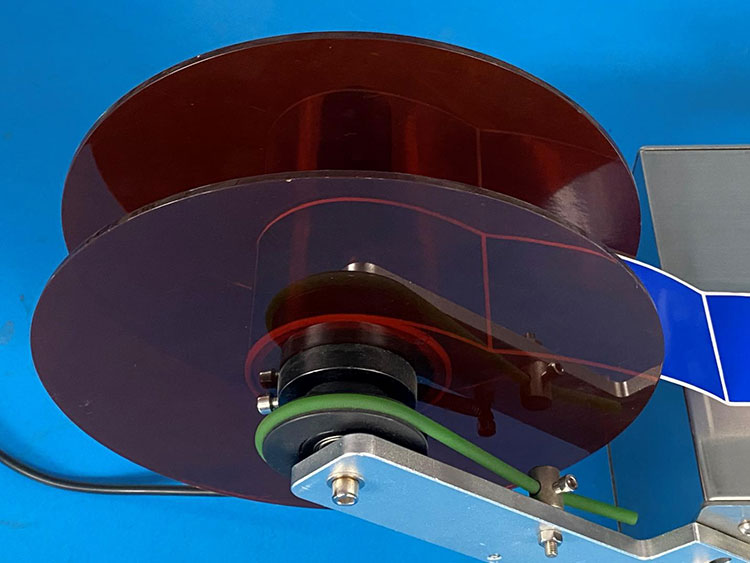

Moving Wheel & Roller

Automatic labeling machine

A moving wheel work to move the products coming from the production line towards the labeling machine with the help of conveyor belts.

Roller holds the label to move it forward towards the labeling unit every type of label movement and cutting is done with the help of these rollers to move the labeling material forward or backward.

Power Motor

Label on bottle-Photo Credits: Label & co

A motor in automatic labeling machine is considered as one of the main unit of the machine that helps to move the other parts of the machine by gaining electrical energy and convert it into the mechanical one.

Motor performs the power function according to the model of the automatic label machine and every different type of machine provides different type of power along with different work rate.

Label Unit

Labeling unit

Every type of label process is controlled in this part of the automatic labeling machine. First when the label is cut according to the prior size of the product then it is sent forward via rollers that rolls the label towards product labeling.

Label type and appearance of the label is done according to the product type this unit helps to label the products by checking the right distance between the box, container or bottle and the labeling unit. Sensor system present in the automatic labeling machine checks the product is settled on the desired location for labeling.

Labeling pen/head also present in the labeling unit to complete the labeling process.

Control Unit

PLC control unit-Photo Credits: DirectIndustry

A touch screen or may be the hard form buttons are installed on the top or may be on the side of the automatic labeling machine to control the working of the machine according to the desired production type.

You will not require any extra person to operate the machine all you need to do is adjust the controls of the labeling machine according to the type of product to get the labeling done.

You do not need to interact with all the parts of the machine manually as the control system will show you the warning sign that the specific part of your labeling machine needs to be repair or has been stop working so, that will the plus point for you to overcome the problem without any problem.

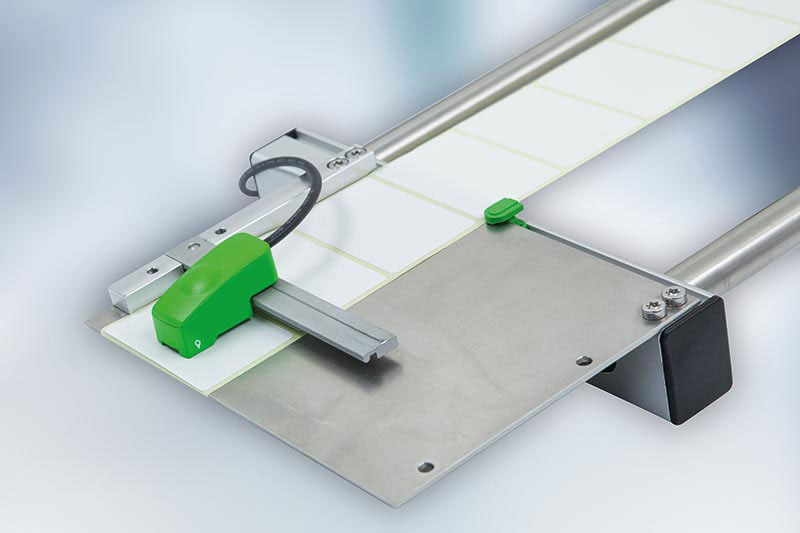

Sensor System

Sensor in label machine-Photo Credits: Cab Production

Whenever the product is moved towards the labeling unit via conveyor belts the sensor system present in the automatic labeling machine checks rather the product is settled or not for labeling and then give the signal to the rollers to move the label towards the product.

When the labeling is done on the product it checks the label is present on the product during the ejection. In this way the complete labeling on the product is done when each part of the automatic labeling machine performs its functionality without a delay.

8.Why it is Important to Label the Products?

Labeling of the product is an essential part of the marketing if a product is labeled well and every type of required information is provided via labeling then it will attract more customers.

There are some following key points that a label can give to your product if you are wishing to sell your label at its best.

Clear Idea

Label on water bottle

Label on the product will make clear image to the customers about the product that how much it will cost and what type of ingredients are used for the manufacturing of the specific product and this can be done with help of automatic labeling machine.

Attractive Look

Always choose the best color combinations for your label to attract more people & also keep in mind that what type of font style and size will be appropriate for your product.

There will be more than 10 same type of products decorated in the shelves so, you need to choose the unique and attractive look for a label to reach more customers.

Better Branding

Label on bottles-Photo Credits: Vector stock

Branding of the product can be done with the quality labeling always use the authentic and related description about the product try to use the logo of your brand at the top of label.

There are many other important points that an automatic labeling machine can provide you to reach new customers and new market trends.

9.What Type of Products can be Labeled with Automatic Labeling Machine?

Label design-Photo Credits: Quora

Every type of market product can be labeled with the Automatic labeling machine. As the machine often come in different shapes with different functionality so, it is quite hard to get multi type of labeling by using only one machine.

There are many types of products that can be labeled with the labeling machine from soft form to hard form and from box to the container.

Automatic labeling machine can done two basic type of labeling Description labeling and Informative labeling. And both of the labeling can be done on the same product if a product is present in the desired shape and size.

AIPAK Automatic labeling machine

Here are the different type of products that can labeled like bottles used in different fields with different manufacturing material and of different size as well, plastic bags to hold the product inside and labeling on the outside, boxes and containers to pack the products and then labeled.

Bottles, vials, containers, plastic bags, and other type of products can be labeled with the automatic labeling machine. Every type of bottle like plastic or metal type can be labeled with the labeling machine having different size and shape as well.

So, overall every type of product can be labeled with the machine considering the working specification and functionality of the machine.

Food items having a labeled plastic wrapper around them also use automatic labeling machine to first label the wrappers and then pack the product inside of that labeled wrapper.

10.What Type of Labeling can be Done with Automatic Labeling Machine?

Every automatic labeling machine has its own labeling methodology depending upon its size and model. And there are several types of labeling that can be done with the help of labeling machine.

These are the following types of labeling that you can do by using the automatic labeling machine.

- Shrink Labeling

Shrink sleeve label-Photo Credits: Inovar Packing

This labeling type is done with the use of heat. A thin form of plastic film material is used in this labeling process when the product comes into the labeling unit this plastic material is wrapped around the product with the pre written label and then heat is provided on the label wrapper to get shrink & stick with the product.

Shrink label is done with the use of a polymer and the durability of this labeling on the polymer is very high as compared to the other labeling types.

- Thermal Labeling

Thermal label-Photo Credits: IndiaMart

This labeling is almost same as the shrink labeling because it uses the heating process as well to stick the label with the product. There is no ink used in the printing of label in this labeling because a label is already done and when the heat is applied the label color changes.

Ribbons are used to stick the label on the product without labeling the extra wrapper around the product. This labeling remains very long as compared to the others.

- Pressure Labeling

Pressure-sensitive label-Photo Credits: Resource label

In automatic labeling machine pressure labeling is used for the sensitive type of products for labeling because if the heat labeling is applied on the sensitive products they may get torn apart or label will not stuck with the material body.

It is very rare labeling that an automatic labeling machines use. Many types of painting and appearances can be selected while working with this label and it mostly used for the bottles or different types and jars.

- Molding Label

Molding label-Photo Credits: DEK

This labeling type is the most used labeling in the automatic labeling machines. Most of the labeling machines use this labeling to mold the label paper to the product.

Plastic and other wrapping paper can be used in this labeling process because they are easy to be molded along the sides of the product. The most example of this labeling type is the detergent bottles that hold different type of detergents for our laundry use.

- Dry Labeling

Label on bottles-Photo Credits: Pinterest

This type of labeling is used in different type of bottles and food bags that uses the coupon code to scratch the specific area and then use the coupon code.

Many of the food industries use this common labeling to label inside the caps of the bottles for coupon code and for other products as well. Peeling process is used in this labeling when the user scratches the area and the other label is present beneath the dry label.

These are some common labeling types that can be done with the help of Automatic Labeling machine.

11.Explain Different Applications of Automatic Labeling Machine?

Almost every field that sells different type of products use Automatic Labeling Machine up to some extent while they are giving information about the product or description about the product or may be other type of details related to the product.

These are some various applications in which an automatic labeling machine is used.

Pharmaceutical Industry

Different labels on different pharma vials/bottles-Photo Credits: Vector Stock

Automatic labeling machine is mostly used in this industry for labeling different types of medical items including injection bottles, syrup bottles, capsules boxes and other types of medical products.

Pharmaceutical industry also use labeling machine to label capsules & tablet bottles. Most of the vials we see are filled with dry capsules & tablets these vials are labeled with automatic labeling machine.

It is necessary to label medical items in pharmaceutical industry so, that your customers can easily understand about your product and use it according to the written description.

Different types of injection bottles including glass bottles, glass vials & containers or plastic vials or bottles they can be labeled with the labeling machine.

Food Industry

Labeling on food product-Photo Credits: FMP

Most of the food items that we see on the grocery stores or in super market they all have a unique print on them which is called labeling. Several types of food items including candies, juices, cold drinks, and every food item is labeled with some information on it.

Labeling on the product tells your customer that what type of customer you are selling and what is the use of this product and with some description in which you explain about the use of product.

Automatic labeling machine also label the product price, date of issuance and expiry date as well so, that you can satisfy your customer with every type of knowledge about the product.

There are some of the food industries that uses the automatic label machine along with their production line.

Label on cold drink bottle

- Cold drink manufacturers.

- Candy & bubble manufacturers.

- Juice manufacturers.

- Floor manufacturers.

Chemical Industry

Label on detergent bottles-Photo Credits: Fiverr

Several types of chemicals that are used in manufacturing of different type of products use labeling machine to specify about the chemical type in the product. Use of laundry products including detergents in which combination of different chemicals are made then labeled with the automatic labeling machine.

It is important to label the product when you are working with the chemical industry to give awareness and tell the use of the product to your customer so, it will be very beneficial for your production line as well as for your customers.

Beauty & Cosmetics Industry

Label on beauty products-Photo Credits: Allure

In cosmetic industry automatic labeling machine plays a very important role of labeling the products because if a product is not labeled then your customer will not understand the purpose of your product.

Many types of skin care products including lotions, baby lotions, creams, face wash, and other products are labeled to show the right use of the product.

Shampoo, body cream, body lotions, makeup items and many more cosmetic and beauty items uses the labeling machine.

Electrical & Mechanical Industry

Label used in electric & mechanical equipment-Photo Credits: Siyavula

All the home appliances that we use in our daily life came inside a packed box with well labeled information and price tag as well to show about the use and other necessary things about the product.

Different type of small & large size machines are also labeled with the company name and logo on them it is done with the help of labeling machine that performs the labeling task according to the material of the product.

Stationary Industry

Label style on different stationary items-Photo Credits: Loads of Labels

Stationary items used in colleges, schools and universities are labeled with the help of labeling machine for the branding of their company. For example led pencils, ball pens and other writing items are labeled with the company name and some type of information is also labeled on them.

Paper that we use also has label at the top may be in a corner or in the center with a light view that is also done with the labeling machine.

These are the various applications in which automatic labeling machine used to label different type of products.

12.What is the Difference Between Labeling & Printing Machine?

Semi-auto labeling machine

There is a huge difference between labeling and printing machine as both of the machines work to give a print on a specific material but labeling machine works in a different way.

| Labeling Machine | Printing Machine |

| Different type of label is generated to make a label on the product. | Use to print the specific information without labeling it. |

| When the printing is done on the paper it is labeled as well on the product. | Only printing is done on the specific paper. |

| Useful in almost every field to label the products. | Used to draw the information on the paper without further processing. |

| Adhesive material is used to stick the label on the product. | Direct printing on the product can be done. |

| More durable to give a smart look to a label with different color combinations. | Durability of the print depends upon the type of product. |

13.How you can Maintain the Automatic Labeling Machine?

There are many ways to maintain the automatic labeling machine so, that your machine remains in good shape and keep giving you the output in a best way.

Cleaning & Lubrication

Labeling rollers

When the label on the product is done after that try to clean the machine by taking a small piece of cloth or some other cleaning equipment and try to clean any type of outer material stuck into the parts of the labeling machine.

Cleaning of the machine will keep the movement of working parts smooth and error free. Your machine will remain in good shape and keep delivering you quality output.

Try to clean your machine regularly after the labeling process if it is hard for you to clean the automatic labeling machine then try to clean it at least two times in a week for better experience.

Before starting the working with the label machine try to lubricate all its moving parts so, that they can move fluently and desirably according to their working principle to keep the labeling intact.

Oiling inside labeling machine parts-Photo Credits: Oil inc

Lubrication will increase the life of your inner moving parts of the machine and will make your labeling less error free. Try to use oil & grease for the moving parts including the arms & inner bearings of the machine.

Check your labeling machine before and after the working and repair the damage parts on time to enjoy the smooth working of it.

14.What you should consider while purchasing the labeling machine?

There are some key features or points that you need to remember when you are considering to buy an automatic labeling machine.

Quality Standardizations

ISO & CGMP logo-Photo Credits: Fiverr

This key feature will tell about the model, design and manufacturing material that is used to build the machine and what type of practices are made on your machine in what type of environment.

Your machinery must fulfill GMP, cGMP and ISO standards during the manufacturing phase so, that you can easily understand about the machinery automation level and under what type of environment you can use the labeling machine.

Area & Production line

Label style & design-Photo Credits: Curvearo

Choose your machine according to your area and space that how much area you have to install the labeling unit under what circumstances. For example if you buy big & large size machine and you have a small area then it will be inappropriate to install the labeling unit in that area.

Always select the labeling machine according to your production line like labeling the bottles & boxes will be complete different process so, always choose the labeling machine according to your product type.

Label Type

Different label types-Photo Credits: Vector Stock

Label type is selected according to the product type that you want to label and in this way labeling on the product is done precisely. Some people use shrink labeling for different type of bottles whereas some people use thermal labeling to label bottles.

If your product is not that big and comes in a small size so, choose small size label to perfectly adjust the label to wrap around the product.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951