Pharmaceutical Tablet Size Chart

You might have come across tablets with different sizes, big small with different shapes. As simple as it may looks but tablet sizes vary widely and definitely for a good reason. These sizes of tablets are not just randomly decided but they are engineered carefully depending on the drug dosage, release mechanism and patient preference.

In the following read we will explain all the highlights you need to know about the tablet size.

1.What is standard pharmaceutical tablet?

Standard round shape tablets-picture courtesy: Holland tableting science

A standard pharmaceutical tablet can be defined as a compressed solid dosage form containing a calculated amount of active pharmaceutical ingredient with the addition of excipients. A standard pharmaceutical tablet is the most commonly used method of drug administration due to its stability cost effectiveness and convenience.

A standard pharmaceutical tablet is usually round, oval or oblong, with size ranging from 5mm to 22mm in diameter or length. It could be a plain tablet, coated tablet or a scored tablet. The tablet can be formulated for immediate release, delayed release or extended release of drug formulation.

2.Understanding basic dimensions in pharmaceutical tablet size chart.

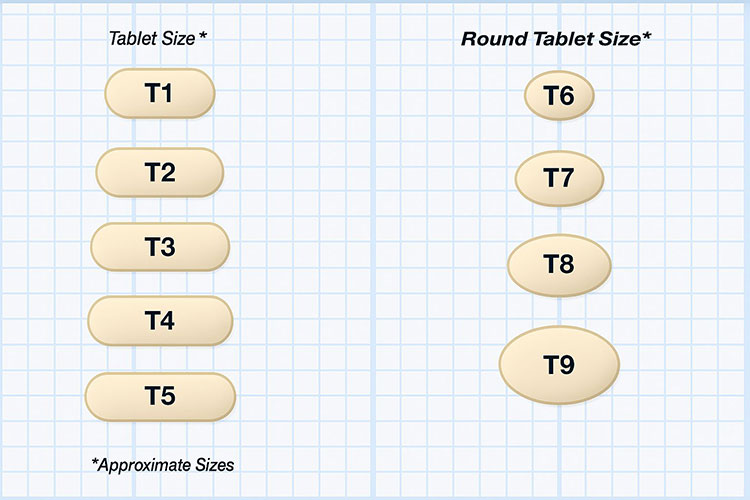

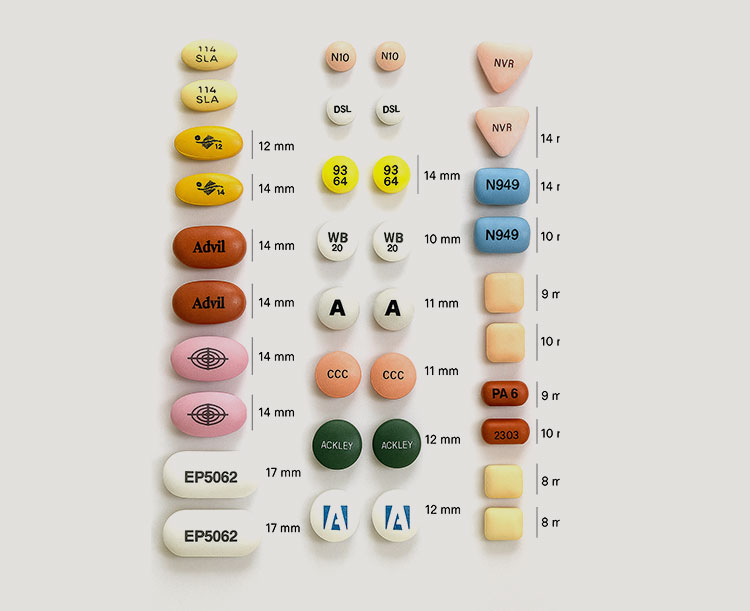

Variety in sizes and shapes of tablets ranging from 8mm to 17mm

A pharmaceutical tablet size chart is a standard guide of tablet sizes used in pharmaceutical manufacturing. This pharmaceutical tablet size chart has various shapes and sizes of tablets which are used in the pharmaceutical manufacturing.

This size chart helps the manufacturer, formulator or dispensers to choose an appropriate tablet size and shape according to the dosage, swallow ability, production tools and regulatory requirements.

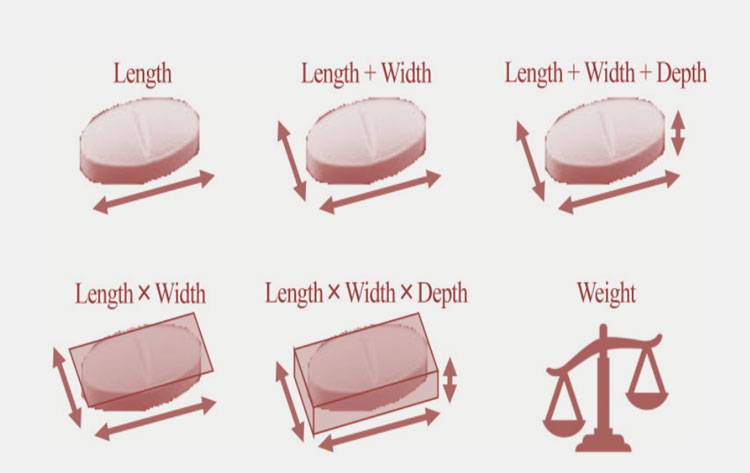

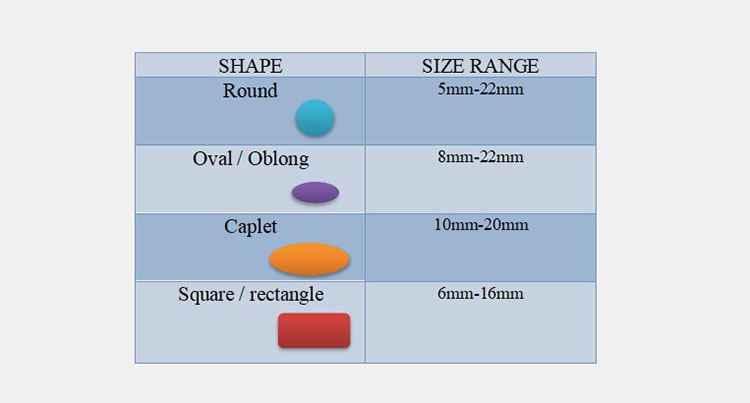

Following chart shows the basic dimensions which are considered in tablet with different shapes and included in tablet size chart:

| Dimensions | Description | Typical range |

| Diameter

It is measured for round tablets |

The distance measured in straight line across the tablet. | 5mm-13mm |

| Length

It is measured for oval or oblong tablets |

It is the long side of oval or oblong tablet. | 8mm-22mm |

| Width

It is measured for oval and oblong tablets |

It is the short side of tablet. | 4mm-10mm |

| Thickness

It is the height of the tablet |

It is the measure of how thick a tablet is from top to bottom. | 2mm-8mm |

| Cup depth

It is measured in case of concave tablets |

It is the depth of curvature on the tablet face. | The cup depth varies on the shape of tablet and it affects the engraving. |

| Weight | It is the given mass of tablet. | Weight very commonly ranges from 500-1500mg |

| Tooling code | They are the letter codes on the dies used to identify the dies. | Usually J,K,L,M,N,P,Q,R,S |

The following image shows the dimensions of tablet which are considered during design and formulation of a drug.

Picture courtesy: NLM

In case of a round shape tablet, the measured dimensions include diameter and thickness. The length and width both are considered as diameter in case of round tablet. In case of oval, oblong tablet or a caplet the measured dimensions are length, width and thickness.

3.Why does tablet size chart matters in pharmaceuticals?

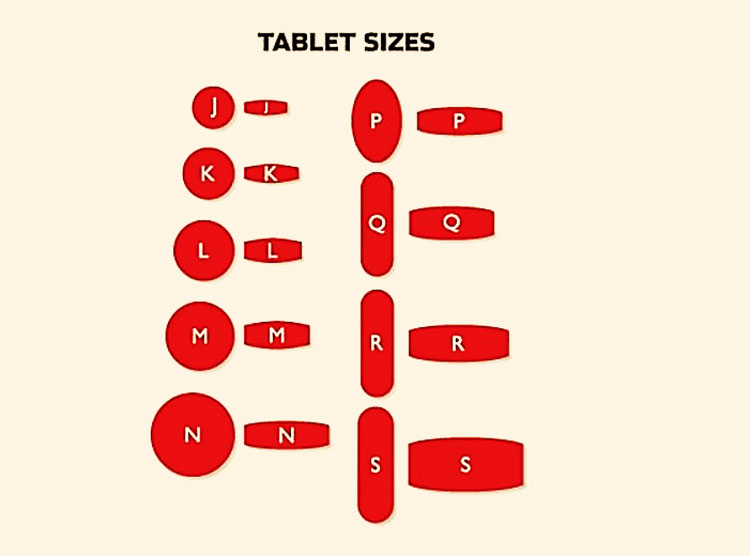

Top view and side profile reference for different tablet size codes

The tablet size chart provides a standard reference for the selection and designing of tablets that are safe, effective and patient friendly. It is used as a critical tool used in formulations, production and quality assurance process.

There are codes assigned to tablets in tablet tooling and tablet size charts, for every shape and size there is a code, usually they are J, K, L, M, N, P, Q, R, S. These alphabets are not just codes, they help the in standardize the following:

| Code | Typical shape | Use |

| J , K | Small, round | It is usually for the pediatrics or low dose formulations. |

| L, M | Medium, large round | They are designed for moderate doses and adults chewable formulations. |

| N | Larger round | This the suitable code for effervescent tablets or multivitamins. |

| P,Q | Oval | These are easier to swallow. |

| R,S | Oblong / Caplet | They are usually for extended release formulations or formulations with large doses. |

The pharmaceutical tablet size chart has tooling codes through which it is ensured that correct punch and dies size are selected for tablet compression machines. It ensures the regulatory compliance of FDA is followed, tablet size not more than 22mm is recommended by FDA.

The size chart ensures that the volume of tablet match with the amount of active ingredient of the tablet and excipients. The size chart shows that tablets greater than 17mm in size are difficult to swallow, so we can choose a suitable size on the basis of age group and certain patient conditions like dysphagia.

There are different types of punches like B, D, BB, DB tooling. We can choose a suitable punch code avoiding any unnecessary custom tooling. The packaging of tablet in right size of blister packs, bottles or sachets is ensured.

4.Overview of standard pharmaceutical tablet sizes.

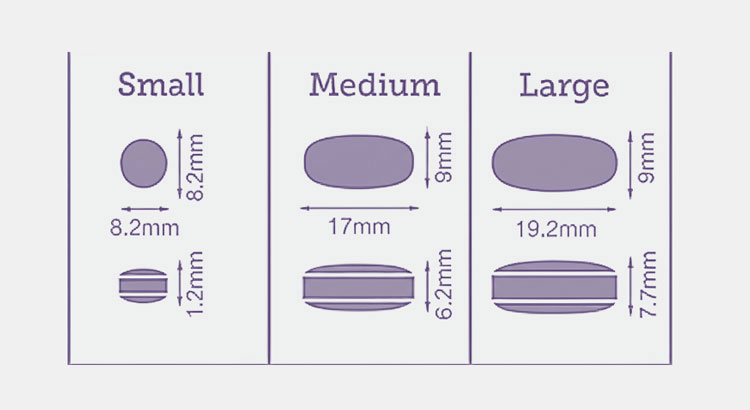

Random dimensions of a tablet in small, medium and large size

There is a large variety in commonly available size of the tablet. The size ranges from 1mm to 22mm. They are divided into three categories based on their dimension, which include small, medium and large.

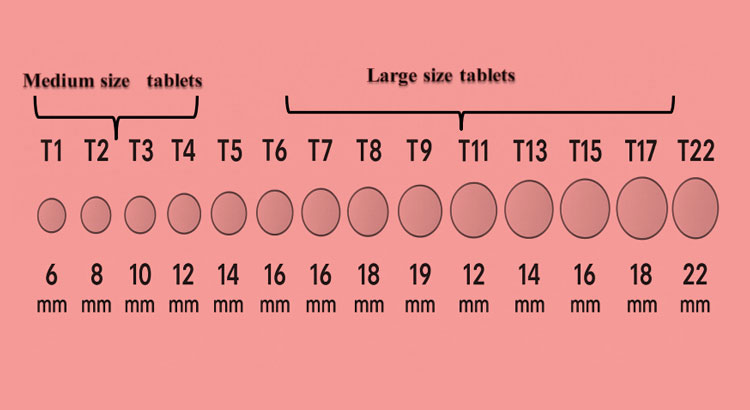

Image showing gradual increase in sizes of round tablets, T1=6mm to T22=22mm

Small sized tablets: they are usually ≤ 6mm.

Standard medium size tablets: The tablets greater than 6mm are usually classified as medium size tablets. The common range is 9-12mm.

Large sized tablets: The tablets 13-17mm are classified as large size tablets, but tablets greater than 17mm which can be up to 22m are very large tablets, this size is for effervescent tablets or chewable.

Size ranges of tablets on the basis of their shapes:

If we consider a few examples from our daily life, we can see a standard paracetamol tablet weighing 500mg is a 12-14mm round or oval tablet. A low dose aspirin tablet weighing 81mg is 5-6mm round tablet. Metformin which usually a larger dose tablets with weight range 500-1000mg is 1-mm-21mm oblong or caplet.

Multivitamins is usually 15-22mm oblong or caplets with different doses.

5.Pharmaceutical tablet size chart on the basis of punch codes.

Different punches and dies used in tablet formation

Punch codes in tablet manufacturing refers to the standard tablet tooling system which is used in the rotary tablet press during the production of tablet. The usual tooling system used is B, D, BB, DB and BBS punches. The pharmaceutical tablet size chart based on the tablet punch code system is highly relevant in the compression of tablet and tablet design.

The following tablet gives and overview of pharmaceutical tablet size chart on the basis of punch codes:

| Punch code | Tooling type | Die diameter | Max Tablet size | Weight range | |

| B | Standard B type tooling | 30.15mm | Round shape | Other shapes | 100-500mg |

| 3mm-16mm | 19mm | ||||

| BB | Smaller than B type tooling | 24.0mm | 13mm | 14mm | 50-300mg |

| D | Standard D type tooling | 38.10mm | 10mm-25mm | 25mm | 500- >1500mg |

| DB | Deeper than B type tooling | 30.15mm | 19mm | 19mm | 300-800mg |

| BBS | Slimmer BB type tooling | 21mm | 12mm | 13mm | 50-200mg |

Different sizes of tablet achieved through different type of tooling

6.Pharmaceutical tablet size chart on the basis of dosage forms.

Different types of tablets-picture courtesy: FPA

The following table shows the pharmaceutical tablet size chart on the basis of different types of tablets dosage form available.

| Dosage form | Tablet size | Average weight | Common shape |

| Immediate release | 6-12mm | 100—600mg | They are usually round or oval |

| Extended release | 13-22mm | 600-1200mg | They are usually oblong or caplet |

| Enteric coated | 8-18mm | 150-800mg | They are usually oval or oblong |

| Chewable tablets | 10-20mm | 500-2000mg | They are round, square or flat |

| Effervescent tablets | 15-25mm | 1500-4000mg | They come as large round and flat tablets. |

| Sublingual tablets | 4-8mm | 0.5-10mg | These are small and round |

| Layered tablets | 10-22mm | 600-1500mg | They are round or oblong |

This pharmaceutical tablet size chart is important because it allows the manufacturer to prepare and match the tablet according to its function. It helps in improving the patient compliance and appropriate drug release is controlled. It also helps in the decision of right tooling and packaging of the tablet.

7.Why there is no universal pharmaceutical tablet size chart?

Different types of tablets-picture courtesy: pharma excipients

It might sound frustrating to not have a universal size chart for the tablet, but there are reasons that justify the cause. The pharmaceutical tablet is manufactured for a wide range of dosage forms, patients and manufacturing needs. The size of the tablet is related to the weight of tablet. A low weight tablet will be of small size while a high weight tablet will be of larger.

The variation in the potencies and bulk densities of the API has a major impact on the weight and size of tablet. The different type of dosage forms, extended release or immediate release has different types of coatings which leads to difference in the weight and size of tablet.

The companies manufacture different types of shapes and sizes of the tablets depending upon the needs of their target audience, brand identity or patent protection. Therefore, two tablets with same dosage can still be completely different.

In pharmaceutical manufacturing, the weight and shape of the tablet is used as reference. Therefore, the manufacturers are mainly relying on the general tooling standards like B, D, BD, BB punches and tablet size is customized as required.

8.FDA guidelines for pharmaceutical tablet size.

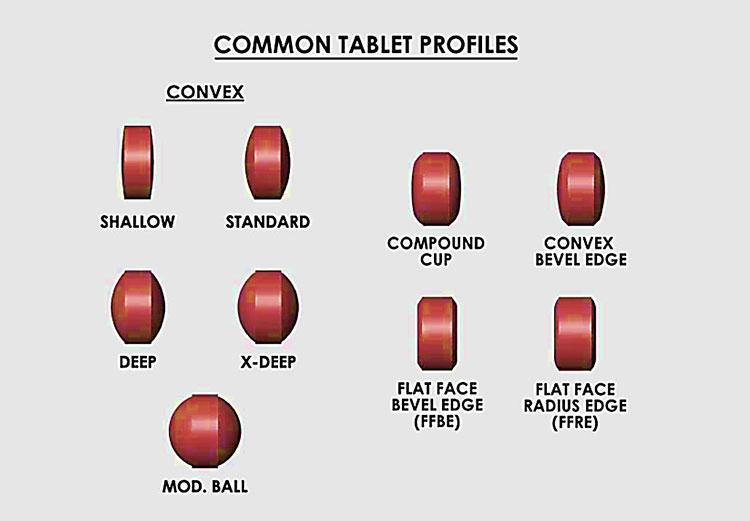

Few different tablets profile- Picture courtesy: natoli engineering

These are the few FDA guidelines that must be followed during the manufacturing of tablets with different sizes, so that they align with the reference listed drug (RLD) as closely as possible:

The largest dimension of the tablet must not exceed 22mm. tablets larger than 22mm can be a problem for patients to swallow. In case the RLD is larger than 22mm than the generic drug is also required to match the RLD.

If the RLD is less than 17mm in its largest dimension, then the generic tablet should not be more than 20% larger than RLD in a single dimension and should not exceed 17mm.f the RLD is equal to larger than 17mm in its largest dimension, then the generic tablet should not be larger than 17mm in any dimension.

Tablets which are equal or less than 8mm are given more flexibility in the size.

Conclusion:

In nut shell, this is how pharmaceutical tablet size chart can help us understand a wide range of tablets sizes, shapes and dimensions. In this way we classify a wide range of tablets on the basis of their diameter, shape, tooling system and dosage strength. As there is not a fixed limited universal size chart for the tablets due to the diversity in tablet dosage forms, the standard classifications like small, medium or large tablets and the punch codes system provide a framework to the manufacturers and health care professionals for a better experience with the tablets. You can get all the more interesting information and purchasing guidelines by visiting our AIPAK website.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours