Vial Filling and Capping Machine: The Complete Buying Guide in 2025

Are you a manufacturer searching for an equipment that’s reliable, works efficiently, and makes production smoother and faster? Then this guide will make you understand everything you need to know before buying the machine and will help you make the right choice.

Vial filling and capping machine helps you fill small bottles which are called vials with liquid or powder and then seal it properly. You don’t have to do it yourself; the machine will perform it efficiently with health and safety protocols while avoiding any error. This will save both your time and energy.

Buying a vial filling and capping machine can be complicated but this guide will help make you understand what you need to keep in mind before making an investment. Let’s explore the guide with us.

1.What is vial filling and capping machine?

Vial filling and capping machine-Picture courtesy: PHARMEC

Vial filling and capping machine helps you fill small glass bottles which are called vials with either liquid, powdered or lyophilized medicine and then seal it properly. The machine will carry out the whole process efficiently without any manual involvement keeping in view the health and safety protocols while avoiding any error. This will save both your time and energy.

2.What are the benefits of using vial filling and capping machine?

Vial filling and capping machine has numerous gains as compared to manual filling methods. The machine provides greater speed, reduce the risk of errors, better hygiene and optimize consistent product quality, making them a key asset for any production line.

Let’s explore the main advantages of using vial filling and capping machine:

High Speed Production

Medicine vial filling and capping machine

A vial filling and capping machine provides great speed and efficiency. Depending on the model, this machine can seal hundreds or even thousands of vials per hour. This is much faster than filling manually which takes more time and effort.

Since the machine operates at higher speed independently, there’s a lesser amount of workers required to hire, this also helps the production company reduce labor and training cost. The vial filling and capping machine works at uniform pace without breaks, helping the production run proficiently without interruptions.

Accuracy in Dose Volume

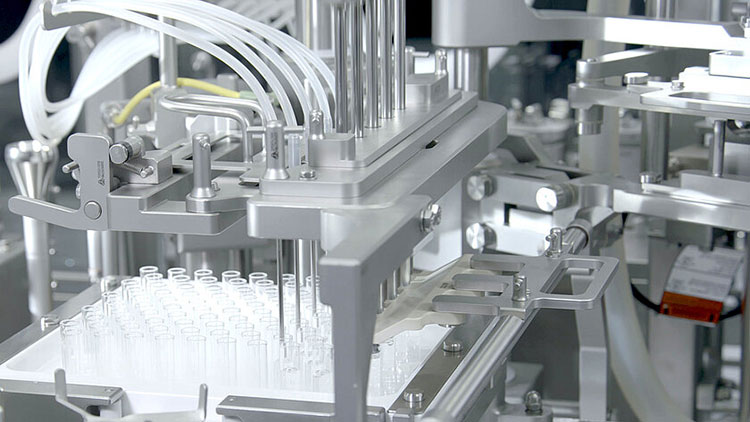

Vial filling by syringe- Picture courtesy: Fibonacci

In complex manufacturing process such as injectable drug manufacturing, ensuring precision in every fill is not just a matter of quality, it’s a matter of safety of human health. In manual filling, the production often struggles with accuracy in dosing. To avoid all this, vial filling and capping machine is equipped with highly effective dosing mechanisms like peristaltic pumps and piston based fillers, these tools help the vial filling and capping machine fill accurately.

Product Safety and Sterile Environment

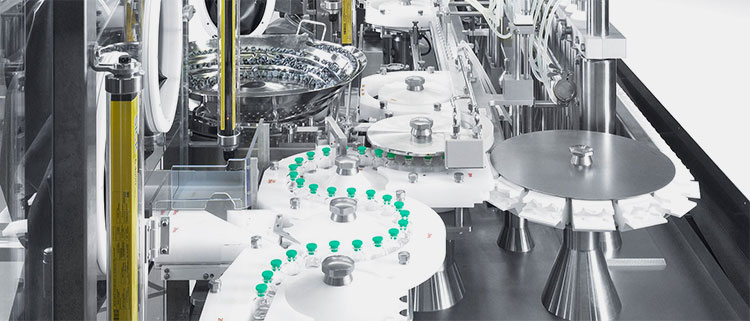

Vial filling and capping machine- Picture courtesy: Syntegon

Since the production process is performed by vial filling and capping machine, there is very little human interaction with the vial or the medicine, which minimizes the risk of germs and contamination. The machine ensures germ free and secure filling of medicine. This helps secure the product quality and ensures patient safety.

Minimized Product Waste

Vial filling and capping machine- Picture Courtesy: Steriline

The vial filling and capping machine is equipped with accurate filling mechanism, which prevent any kind of product spill or waste. The machine ensures to deliver the right amount of product in each vial precisely. By reducing product waste, the machine helps reduce cost while enhancing the overall production flow.

Scalable and Flexible Design

Robust design- Picture Courtesy: groninger

Modern vial filling and capping machines are manufactured in a modular and flexible design, which means their parts can easily be replaced or reconfigured. This feature allows the manufacturing company to upgrade the system or switching the production for instance, changing from liquid to powder formulation very easily. This makes it a key asset for manufacturers for smart and expand production.

3.Where vial filling and capping machine used?

Vial filling and capping machine is predominantly used in pharmaceutical and biotechnology industries, but they also have important applications in other sectors such as chemical industry, veterinary industry, cosmetic and personal care industry, food and nutraceuticals industry. Let’s explore it’s uses and applications in different sectors:

Pharmaceutical Industry

Pharmaceutical industry- Picture courtesy: Vibgyor

The vial filling and capping machine is primarily used in the pharmaceutical industry for filling and sealing medicines accurately and precisely like insulin, vaccines, antibiotics and others. The machine ensures safety, accuracy and perform according to the regulatory standards. The common applications of vial filling and capping machine in pharmaceutical industry includes injectable solutions, powdered medicine, ophthalmic products.

Biotechnology Industry

Biotechnology industry- Picture Courtesy: Syntegon

Vial filling and capping machine is commonly used in biotechnology industry. It is commonly used in handling fragile biologic solutions like enzymes, genetic material as well as antibodies. Biotechnology products are very sensitive and require extra precision and care. Common applications of the machine include mRNA vaccines, monoclonal antibodies which are used in cancer treatments, hormones, enzymes and gene therapy products.

Chemical Industry

Chemical filling s- Picture credits: PixelSquid

Vial filling and capping machine are commonly use in the chemical industry to ensure safety while handling corrosive and flammable chemicals. The chemicals are highly sensitive and require packing in precise amount and safe storage. In chemical sector, a vial filling and capping machine is essential for handling sensitive and hazardous material, accurate packing for lab use, precise dosing. Common applications of this machine in the chemical industry includes industrial solutions, diagnostic reagents, environmental safety testing kits.

Veterinary Industry

Veterinary Industry- Picture Credits: PetDesk

Veterinary Industry focuses on treatment and healthcare of animals. In veterinary medicine vial filling and capping machine is essential for production of accurate medication dosage, safe and sterile products. The machine helps in filling and sealing animal medications precisely, ensure accurate dosage, safe and sterile products. Some examples of veterinary products filled with this machine are vaccines, anti-parasitic drugs, nutritional supplements.

Nutraceuticals Industry

Nutraceuticals and dietary supplements

The nutraceuticals industry consists of products like vitamins, probiotics, herbal extracts that aims to boost immunity and improve health. In this industry vial filling and capping machine is used to fill and seal glass or plastic vial with health supplement which are either liquid, powdered or gel based. Some examples of products filled by the machine includes herbal extracts, vitamin supplement, collagen or beauty supplement and probiotic supplements.

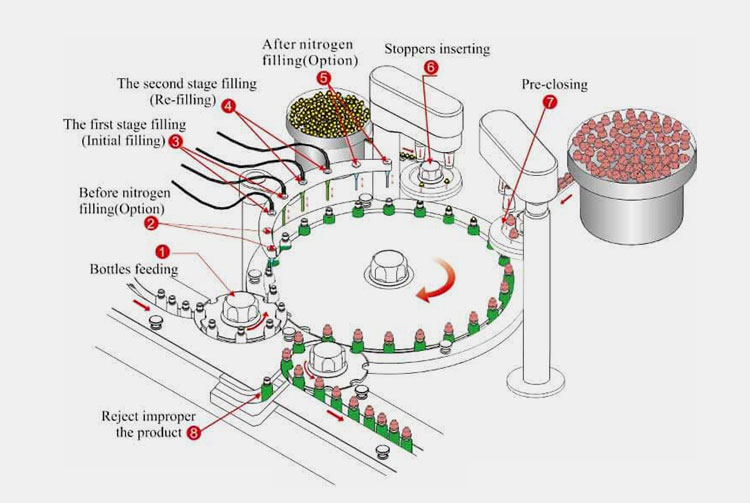

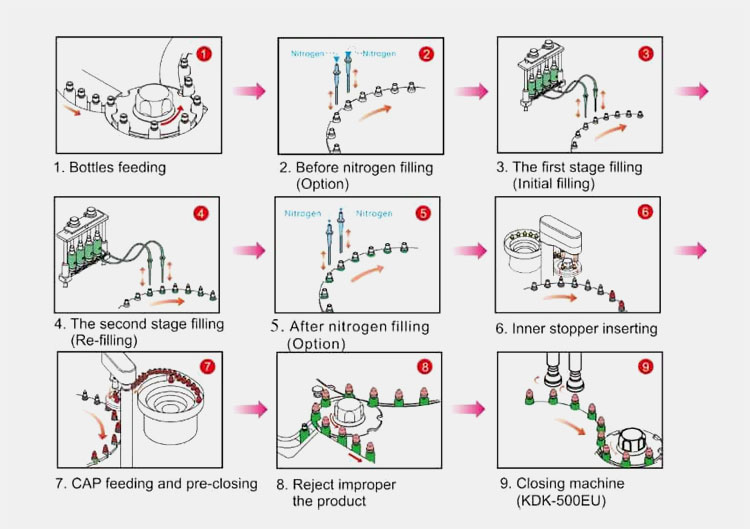

4.How vial filling and capping machine works?

Vial filling and capping machine is a cohesive system predominantly used in pharmaceutical and biotech industry for safe, efficient and sterile filling of liquid, powdered or lyophilized medicines into glass or plastic bottles called vial. The process is semi-manual or automatic depending on the different sort of vial filling and capping machine.

The working principle of the machine is based on the following steps, which is illustrated in the following flow chart for clarity:

Working of vial filling and capping machine

| STEP 1: Vial Feeding | Empty sterile vials are transported from the source to the machine conveyor system for further processing. |

| STEP 2: Nitrogen Purging (Pre-Fill) | Gaseous nitrogen GN2 is blown into empty sterile vials before liquid filling, this prevents oxidation and extends product shelf life. |

| STEP 3: Vial Input | Empty sterilized vials are placed on a moving belt also called a conveyor which transports them to the filling line. To ensure precise alignment under the filling nozzles the vials are adjusted correctly using a star wheel or rotary dial. |

| STEP 4: Vial Filling | At the filling station, a sequence of precise nozzles typically depending on 2 to 12 depending on the machine’s capacity, dispense a specific quantity into each vial with high accuracy. The number of nozzles can be customized according to the production needs.

This mechanism is ideal for sensitive productions such as insulin, which require high accuracy as well as sterility. The process starts with pumping liquid through a flexible tube or hose ensuring that the liquid will go directly into the glass minimizing the risk of contamination. |

| STEP 5: Nitrogen Purging (Post-Fill) | Gaseous nitrogen is blown second time after filling. This method clears out oxygen from the headspace. |

| STEP 6: Stoppering | In stoppering unit of vial filling and capping machine, the filled vials are moved to the stoppering station where rubber stoppers are precisely placed on each vial to seal and maintain product integrity. This process typically involves several steps:

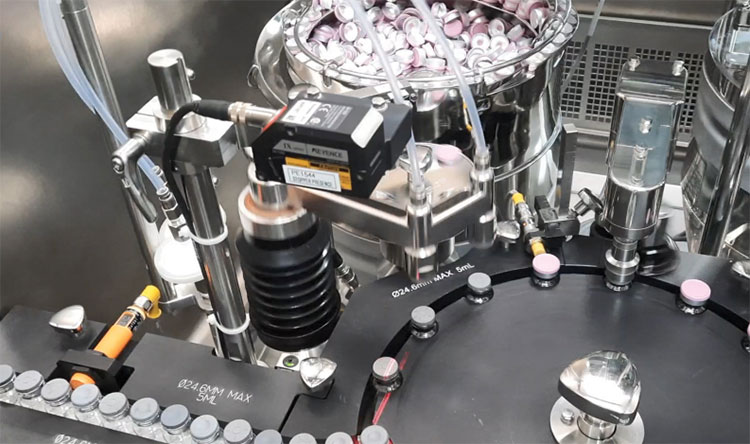

Stopper Feeding: Sterilized stoppers are placed in a chute system or vibratory bowl, which facilitates them to stoppering point one by one. Vial Alignment: Each filled vial is held firmly in place, by a star wheel or conveyor. To ensure accurate alignment under the stopper feed. Placing the Stopper: The rubber stopper is carefully picked using a vacuum based system and is placed onto the vial mouth to avoid the risk of contamination. Stopper Sealing: A spring loaded roller applies pressure on the stopper firmly to insert and seal the stopper onto the vial, ensuring an air tight seal. Continuous Operation: In many highly equipped machines, the stoppering is synchronized with vial movement. Allowing linear operation without breaks. |

| STEP 7: Capping

|

Capping is the most critical step in the vial filling process. After the vials are filled with product and sealed, a cap is securely applied on the stoppered vial to maintain the sterility of the product. The process involves several steps that are mentioned below:

Cap Placement: After the vial is filled with liquid and sealed, a cap usually made of aluminium are aligned precisely and positioned on vial’s neck. Compression: The capping mechanism squeezes the rubber stopper with cap and secures the cap skirt securely around the vial’s neck. This process produces an airtight seal on the medication to ensure its sterility and safety. |

| STEP 8: Rejection of Faulty Vials | After capping, the vials are moved for inspection. Vials with defective caps or improper sealing are removed to ensure control. |

| STEP 9: Rotary Closing Machine | Rotary vial closing is a high functioning mechanism which applies and crimp aluminium caps onto filled vials. This system ensures proper sealing and capping of filled vials to maintain sterility. |

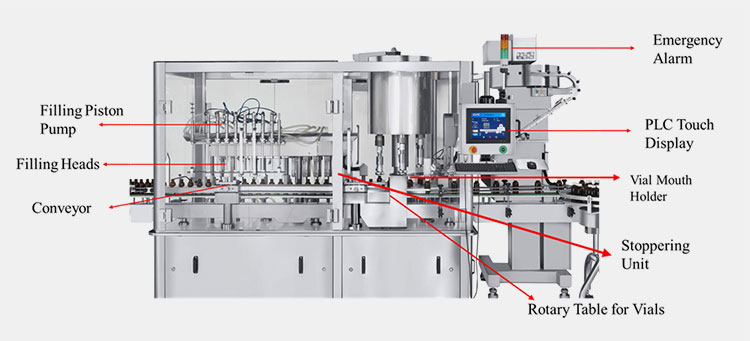

5.What are the main parts of vial filling and capping machine?

Vial Filling and capping machine

| Parts | Description |

| Filling Piston Pump | In vial filling and capping machine, a filling piston pump is a type of positive displacement pump which dispense accurate amount of formulation into the vials. |

| Filling Heads | Filling heads in vial filling and capping machine ensures consistent, sterile and accurate fill volume of dosage. Especially of sensitive medicines like insulin or vaccines. |

| Conveyor | A conveyor system in vial filling and capping machine transports the vials throughout the different stages of production within the vial filling and capping machine. |

| Emergency Alarm | An emergency alarm system integrated into vial filling and capping machine plays a key role as a critical safety mechanism to detect errors or malfunctions. |

| PLC Touch screen | A PLC touch screen also known as Human-Machine Interface (HMI) serves as an interactive display that allows the manufacturer to monitor the process and adjust settings instantly. |

| Vial Mouth Holder | The vial mouth holder is a mechanism in the vial filling and capping machine that grips the neck of the vial to maintain stability during automated movement of vials. |

| Stoppering Unit | The stoppering unit of vial filling and capping machine is responsible for placing rubber stoppers onto the vials to prevent unsterile conditions. |

| Rotary Table for Vial | A rotary table in vial filling and capping machine is a circular disc used to transport empty vials into the production line smoothly. |

| Vibratory Bowl | A vibratory bowl or cap feeder aligns the aluminium caps in accurate direction, so they are prepared to be placed on vials. |

| Cap chute | The purpose of cap chute mechanism in vial filling and capping machine is to transport vials from feeder to the capping head. |

| Crimping Head | The purpose of crimping head is to put pressure on aluminium cap to crimp it and secure it precisely. |

| Height adjustment mechanism | Height mechanism in vial filling and capping machine adjusts the capping height according to the vial size for accurate capping. |

| Cap Detector Sensor | A cap detector system in vial filling and capping machine is an electronic sensor that prevents faulty capping and ensures a proper cap is present on vials. |

| Cap Integrity Rejection Unit | This mechanism in vial filling and capping machine ensures that the capping is precise according to the quality control standards and rejects vials with defective caps. |

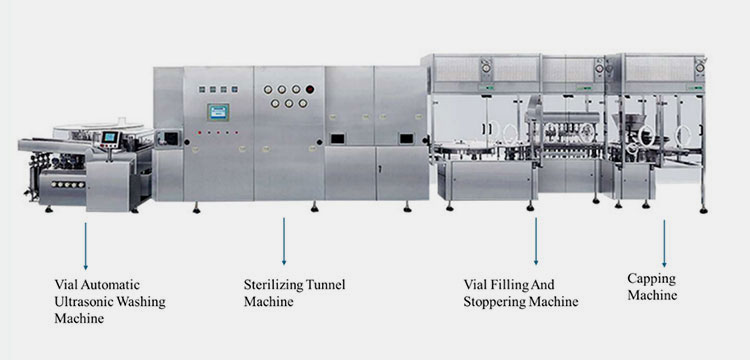

6.What is the complete production line of vial filling and capping machine?

AIPAK Engineering Vial Filling and Capping Machine

| Names | Description | Working Principle |

| Vial Automatic Ultrasonic Washing Machine | A vial automatic washing machine uses ultrasonic waves to deeply clean the machine before or after a production process. | The machine uses ultrasonic waves that are high in frequency, which creates rapid pressure bubbles. These bubbles implode producing shock waves that efficiently clean the inside and outside surfaces of vials. |

| Sterilizing Tunnel Machine | A sterilizing tunnel machine uses dry heat or UV light to sterile the surfaces ensuring aseptic conditions for the production process. | The working principle of sterilizing tunnel machine involves continuous cleaning of vials usually through dry heat treatment. In dry heat treatment the vials are exposed to hot temperatures between 170 °C to 400°C to decompose endotoxins. |

| Vial Filling and Stoppering Machine | A vial filling and stoppering machine carefully fill the accurate dosage of liquid or powdered medicine into the vials and place a rubber stopper onto them for proper capping. | Using peristaltic or piston pumps, the vial filling and capping machine dispense the liquid into vials precisely, following that, the stoppering unit puts rubber stopper onto the vials for proper sealing and capping. |

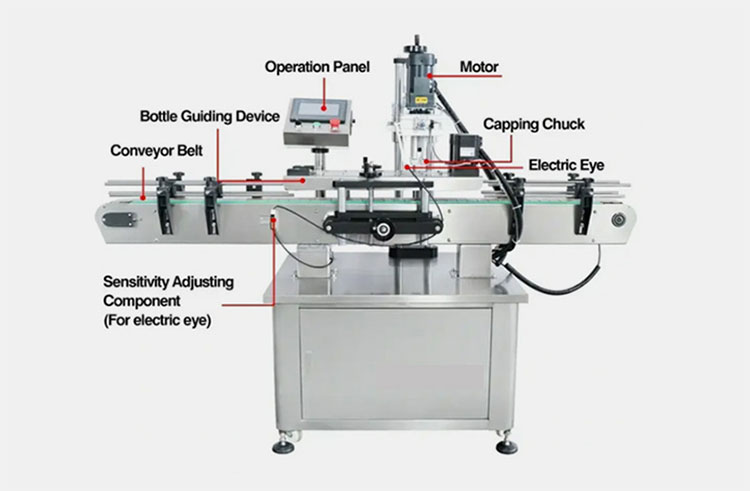

| Capping Machine | Capping machine is a mechanism in vial filling machine that applies aluminium caps on vials for security and sterility. | The machine positions the vials under the capping unit which applies a crimped aluminium cap with adjusted torque to ensure proper sealing. |

7.Can the vial filling and capping machine fill both powder and liquid formulations?

The vial filling and capping machines are flexible and are designed to handle a variety of formulations like liquid, powdered or freeze dried. The main purpose of the machine is to properly fill and seal these medications. Below are the common formulations that are treated with these machines:

| Liquid Formulations

|

Liquid formulations, such as insulin, vaccines, and injectable antibiotics, are most commonly filled into vials by these machines.

These formulations are in liquid form and are intended to administer directly into the body either into a vein, into a muscle or under the skin. Vial filling and capping machine play a significant role in guaranteeing the accuracy of fill dosage while maintaining sterility. |

Liquid formulation-Picture Courtesy: RAND |

| Powdered Formulations | Powdered formula medicines are in powdered form; they are required to be mixed with a liquid before use. These types of medications are dry to increase their shelf life and stability. These powders are filled into vials using the filling machine. These machines are designed to handle these formulations.

Since the medicine is in powdered form it is hard to fill these manually with the risk of dosage error. The vial filling and capping machine ensures accuracy while maintaining sterile environment. |

Powder formulation |

| Lyophilized Formulations (Freeze Dried)

|

Lyophilized formulations are special kind of medicines that starts as liquid medicine but later turned into powder by removing the water and freezing them.

This process increases the medicine’s shelf life, especial if it is fragile. The vial filling and capping machine ensures the safety and sterility of these sensitive medications by filling the correct dosage, support the freeze drying process by converting the liquid into powder form, and then sealing it properly. |

Lyophilized Vial- Picture courtesy: Berkshir |

8.What is difference between vial filling and capping machine and ampoule filling machine?

AIPAK Engineering Vial Filling And Capping Machine and Ampoule Filling and Sealing Machine

In pharmaceutical industry, selecting the right kind of machine for vial filling and capping is crucial because of the sensitivity of medicines. Vial filling and capping machine and ampoule filling and sealing machine are both designed to handle different kinds of container and sealing method. Understanding the key differences between both machines will help in getting to know what to choose according to the product type. The differences are listed below:

| Attribute | Vial Filling and Capping Machine | Ampoule Filling and Sealing Machine |

| Container Form | Vials are usually small bottles made of either glass or plastic. | Ampoules are small, sealed glass tubes, with a slender neck. These are meant for one time use only. |

| Filling Process | Vials are filled with liquid, powdered or lyophilized formulation using filling nozzles. | Ampoules are filled precisely often using a syringe-based system. |

| Sealing Process | After filling, the vials are sealed by a rubber stopper and covered with a crimped aluminium cover. | Ampoule is filled carefully by a small nozzle, after that the top of ampoule is sealed after melting with a flame. |

| Ensuring Sterility | Vial filling and capping machine is designed for sensitive and sterile operations, inside a laminar flow cabinet that circulate filtered air to prevent germs. | Ampoule filling and sealing is done in laminar flow, ampoules is quickly sealed right after filling to protect the medicine. |

| Stoppering | Before capping, a rubber stopper is placed to keep the vial sterile. | Unlike vials, ampoules don’t have a rubber stopper and are permanently sealed by melting the glass at neck of bottle. |

| Container Reuse Capability | In vial filling and capping machine, the vials are designed to be sealed and reopened. | In ampoule filling and sealing machine, the glass bottle is sealed permanently and must be broken to consume |

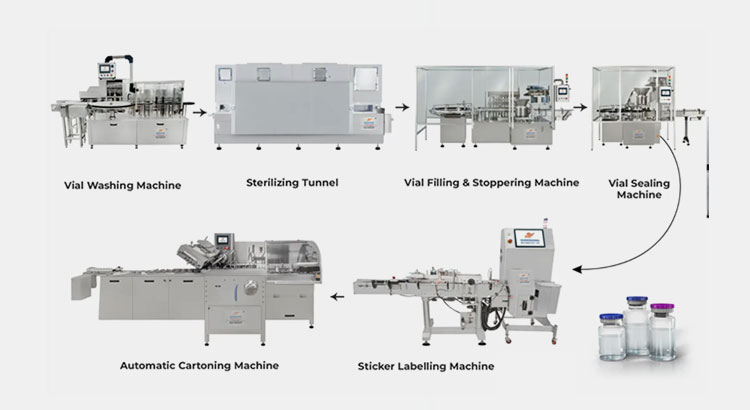

9.What other machines are part of the vial filling and capping process?

Units Integrated with Vial Filling and Capping Machine

The above diagram shows vial filling and capping machine line which is also integrated with other units to bring a complete work process. We have mentioned some of the machine already in specified topic. Whereas the other integrated units are explained below:

Vial Labeling Machine

AIPAK Vial Labeling Machine

This is unit you need to complete the finishing of vials by implementing the required labels over it. There are many different working principles of vial labeling machines that either utilizing self-adhesion method, direct printing or hot glue and other procedures. The ultimate purpose is to achieve professional and accurate application of labels over vial.

Automatic Cartoning Machine

AIPAK Vial Cartoning Machine

For the safety and flexible distribution of vials, the cartoning machine is integrated in production line. It helps in packaging of vials and also ensure they are packed inside the cartons featuring automatic insertion of informative leaflet. The cartoning machine works by picking up of flat empty cartons and make them fold around the edges and grippers ensure the positioning of vials along with leaflet. That’s it! Your product is now ready for distribution.

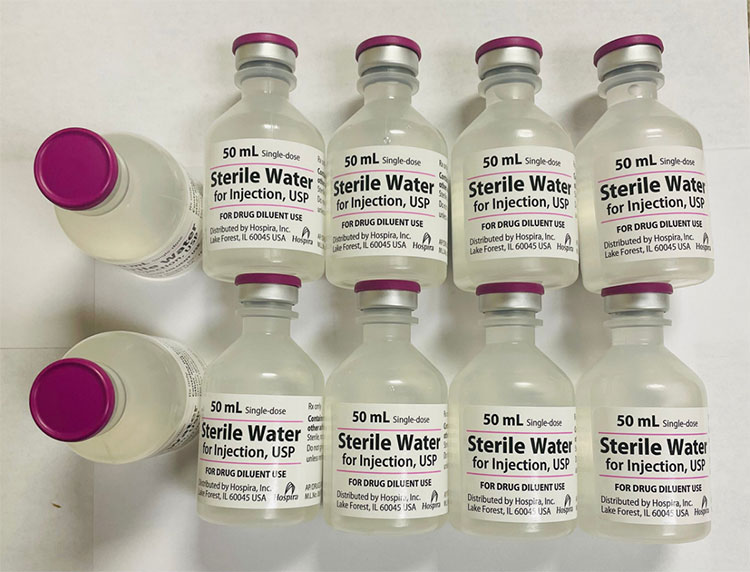

10.Is vial filling and capping machine offer sterile operation?

Sterile Water for Injecting Vials- Picture Courtesy: Farris Labs

Vial filling and capping machine are designed to ensure sterile handling during the production of injecting medicines. They are intended to function within highly sterile environments, usually under laminar airflow, to prevent germs and contamination during the precise steps such as stoppering and capping.

The vial filling and capping machine maintain aseptic conditions throughout the production process, which is highly required for pharmaceutical process. The machine is equipped with specialized elements such as small gap between filling and stoppering sections, finest stainless steel (AISI SS 316L) to ensure accuracy and sterility.

11.What type of formulation can be treated with vial filling and capping machine?

Covid Vaccine Vial

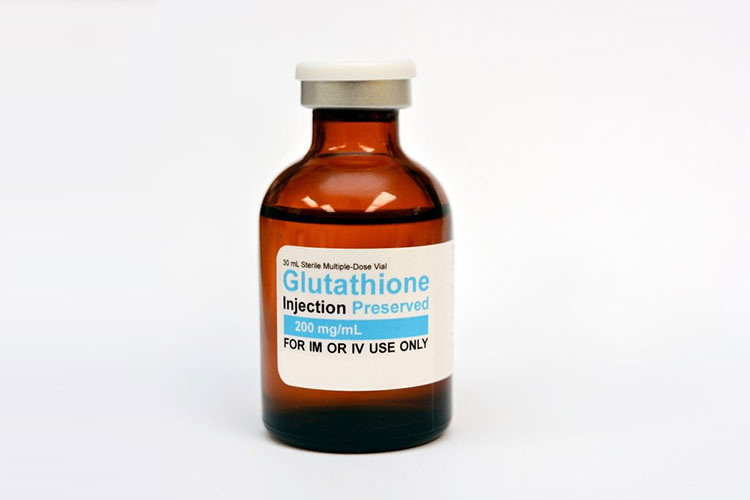

Vial filling and capping machines are designed to handle different kinds of formulations, predominantly focusing on injectable products. These machines are highly equipped in filling precise formulation into the vials while maintaining sterility and safety. The machine consist of peristaltic pumps are piston pumps to ensure sterility and prevent risk of contamination.

Some examples of these formulations are as follows:

Vaccines

Vaccine Vials

Vaccines are filled into glass vials as liquid or lyophilized formulation with the help of nozzles. Vial capping and filling machine ensure safety and sterility while filling these kinds of liquids.

Antibiotics

Antibiotic vials and Syringe

Antibiotic are filled as either liquid or as free-dried formulation into the vials. penicillin and cephalosporin are some of the examples of antibiotics filed in vials.

Pain Killers

Painkillers IV vial

Injectable painkillers like morphine or diclofenac are typically filled into the vials as sterile liquid formulation. Vial filling and capping machine tightly seals these kinds of medications to maintain sterility and safety.

Chemotherapy

Chemotherapy vial

Highly potent cytotoxic are typically filled as lyophilized formulation. These formulations require high sterile environment. The vial filling and capping machine ensures production within isolators or RABS (Restricted Area Barrier System) to comply on quality control regulations.

12.What are some of the common problems of vial filling and capping machine and how to fix them?

Vial filling and capping machine-Picture Courtesy: Compromec

The vial filling and capping machine is efficient and precise, but since it’s a machine, it can face a number of problems during operation. Below are some of the common problems and how to fix them.

| Problem | Description | Solution |

| Inaccurate Fill Volume

Vial Glass Bottles- Picture Credits: CARL ROTH

|

The most common problem that occurs in a vial filling and capping machine is inaccurate dosage fill. This is a serious safety risk. Due to this issue, the vial solution or powder can be overfilled or under filled, resulting in incorrect dosage volume. The main cause of this problem are worn-out or wrongly aligned filling nozzles, Air trapped in the filling system, Inaccurate pump calibration. | Fix the inaccurate calibration. Adjust the filling pump properly.

Eliminate the air bubbles trapped in the filling system. Replace the worn out nozzles with new ones. |

| Leakage from Nozzles

Different types of nozzles-Picture Courtesy: Filamatic

|

In this issue, after filling the vial, the solution keeps dripping and a few extra drops fall out, this means there is a leakage or dripping issue in the filling nozzles.

This can result in product wastage and could create a mess by overfilling the vials. All of this can be a result of worn-out nozzle or there might be too much pressure in the filing system which is pushing out extra solution. |

Usage of anti-drip nozzles which prevent nozzles from dripping extra solution.

Repair or replace the worn-out nozzle. Alter the filling pressure to the correct level.

|

| Loose Capping

Capping of Lyophilized drugs- Picture credits: Aptar |

After the vial is filled, it is not sealed properly due to improper placement of cap or rubber. This can result in loose capping which is a serious issue. Due to improper capping, germs can enter inside, contaminating the medicine and making it lose its effect. This may also result in failing the quality check, due to which whole batch would be wasted. Improper capping can be due to misaligned capping head, wrong torque settings, defective stoppers or vials not placed correctly. | Properly align the capping head.

Set the right torque level not too loose or too tight, just the right level. Place the vials correctly. Replace the defective. stoppers with effective ones. |

13.What things you should consider when purchasing a vial filling and capping machine?

Investing in a vial filling and capping machine can feel overwhelming especially when there are so many options available. To choose the right machine, you need to consider some important factors which are mentioned below:

| Factor | Details to consider |

| Product Type

Vial Formulation- Picture Credits: CPHI Online

|

This is the most important factor to consider. Choose the machine based on the kind of medicine you are filling. Either it’s liquid or powdered or freeze-dried medicine.

Liquid medication requires accurate pumps and anti-drip nozzles. These medications include insulin, vaccines, and antibiotics. Powder medicines need a machine with a powder dosing structure. Certain antibiotics and cancer drugs are included in powdered medicines. Freeze dried medicines require a special fill machine that can fill the liquid first, then freeze it remove water, and seal the vial after drying. |

| Fill Volume Accuracy

Sterilized and liquid filled Vials. |

When choosing the right vial filling and capping machine, you need to keep in mind the volume ranges of your product.

The right kind of machine should be able to fill different amounts special the amount your product contains. Some medicines are 1ml, some are 50ml or even 100ml. If your product has no specific fill volume, you need to choose a machine that has adjustment for change |

|

Production Output Capacity Chromatography Vials- Picture Credit: StonyLab |

If you need to produce a large amount of medicine rapidly, you need a high-speed machine or if you are producing small batches you need a machine with a slower production capacity.

The production speed of the machine symbolizes how fast the machine can work and produce medicine at a specific amount of time. You need to choose one that matches your batch volume. |

| Automation Level

Lyophilized Medicine- Picture Credits: TA Instruments |

While choosing the right kind of machine, you need to keep in mind how much work you want the machine to handle

There are manual, semi-automatic and automatic machines. In a manual machine, most of the work is done by labor like placing the vials or starting the filling process. A semi-automatic does some operations on its own but still needs manual supervision. A fully automatic machine performs the entire operation by itself without any manual involvement. |

| Easy Cleaning and Maintenance

Vial filling |

While purchasing a vial filling and capping machine, it is important to choose one that is easier to clean and maintain, especially when you are manufacturing medicines. If the machine is difficult to maintain or hard to clean, the germs or leftover product from last production could contaminate the next production.

Machines that are made with smooth stainless steel are easier to clean, some machines are equipped with specialized features like CIP which is clean in Place, or SIP sterile in place. These features clean the machine automatically. So, choose a machine that is not only efficient but also easy to clean. |

Conclusion

Choosing the right kind of vial filling and capping machine according to your production needs is crucial and overwhelming, especially with lots of options available. Whether it’s filling vials or subjecting the capping, the right kind of machine will ensure a sterile environment with maximum production speed. After going through this guide, we hope you will get a fundamental understanding of the different aspects of vial filling and capping machines. To learn more, make sure to visit AIPAK.

Don't forget to share this post!

Vial Filling Machine Related Posts

Vial Filling Machine Related Products

Vial Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine