Top 10 Global Ampoule Filling Machine Manufacturers: The Definite Guide In 2024

Ampoule filling is full of challenges, but there are many excellent ampoule filling machine manufacturers worldwide for your request. These excellent ampoule filling machine manufacturers can provide you with high output, high quality, safe and hygienic ampoule filling machines. This top 10 global ampoule filling machine manufacturers have listed all the global top ampoule filling machine manufacturers and their outstanding products. Hope you enjoy it to the fullest!

Top 10 manufacturers of ampoule filling machines in the world

The ampoule filling machine is a machine widely used in the pharmaceutical and chemical industries to fill and seal the ampoule filling liquid. This machine generally uses a piston metering pump for quantitative filling. It can automatically stop filling when there is no bottle. Among them, coal gas, liquefied natural gas, and liquefied petroleum gas can be used as gas.

Here is the top list of manufacturers:

| RANK | MANUFACTURES OF AMPOULE FILLING MACHINE | HEADQUARTERS |

| 1 | SYNTEGON | Germany |

| 2 | Marchesini Group | Italy |

| 3 | IMA Group | USA |

| 4 | AIPAK | China |

| 5 | ROMMELAG | Germany |

| 6 | OPTIMA | Germany |

| 7 | ROTA Verpackungstechnik | Germany |

| 8 | Cozzoli Machine Company | USA |

| 9 | BAUSCH Advanced Technology Group | USA |

| 10 | Kambert | India |

1. Syntegon

SYNTEGON Background:

SYNTEGON is a multinational engineering and technology company headquartered in Gerlingen, Germany. Syntegon has decades of experience in processing and packaging engineering, research, and development. Their technical solutions are high-quality, efficient, and reliable. The ampoule filling machine that they designed is visually appealing, cost-efficient, and extremely flexible. At Syntegon, they have a passion for both: ampoule filling and sealing machines for low to high-output production to ensure gentle, hygienic, and accurate processing.

Key Products

ARF 1000

ALF 4000

ALF 5000

Recommend Reason

- Syntegon Technology is your reliable partner for ampoule filling machines in the global food and pharmaceutical industries.

- Whether you are an aspiring start-up or a global market leader, they offer intelligent and sustainable ampoule filling machines and solutions for everyone.

- Individual machines, systems, or services – as a full-service provider, they take responsibility right up to fully integrated ampoule end-to-end solutions.

- They offer solutions for the production, processing, filling, inspection, and packaging of liquid and solid active ingredients in all common ampoule filling materials.

2. Marchesini Group

Marchesini Group Background:

Marchesini Group was established in Pianoro in 1974 by virtue of the shrewd intuition of Massimo Marchesini, over the years the company has grown from a small, local business into a major industrial enterprise. They design and produce a wide range of packaging and filling machines and lines for the pharmaceutical industry, designed to promptly respond to any kind of request, from standard to extraordinary. This machine family includes filling and sealing machines for open or closed ampoules which can produce between 6,000 and 24,000 pieces per hour, guaranteeing perfect repeatability of filling and sealing operations coupled with perfect sterility of the latter.

Key Products

RSF Series

WR Series

DEPYR

Recommend Reason

- The ampoule filling and sealing machines are suitable for aseptic dosing of liquid products and sealing of open or closed ampoules.

- As an option, the ampoule filling and sealing machines can be used for filling and rubber stoppering of vials.

- They include filling and sealing machines for open or closed ampoules which can produce between 6,000 and 24,000 pieces per hour, guaranteeing perfect repeatability of filling and sealing operations coupled with perfect sterility of the latter.

- They design and produce a wide range of packaging and filling machines and lines for the pharmaceutical industry, designed to promptly respond to any kind of request, from standard to extraordinary.

3. IMA Group

IMA Group Background:

IMA Group, established in 1961, is a world leader in the design and manufacture of automatic machines for the processing and packaging of pharmaceuticals, cosmetics, food, tea, coffee, and much more. IMA is a global leader in the design and manufacturing of automatic machinery used in the processing and packaging of pharmaceutical products, especially ampoule filling machines. Thanks to its high technological profile and the ability to offer tailor-made ampoule filling machines and solutions, IMA can satisfy the most sophisticated requests of the different reference markets.

Key Products

VEGA 400

STERIFILL

ISOLATION TECHNOLOGY

Recommend Reason

- IMA's ampoule filling machines can be tailored to match each customer's specific needs and deliver maximum production flexibility and efficiency at each performance level, from entry-level through to highly automatedhigh speed lines.

- IMA is a global leader in the design and manufacturing of automatic machinery used in the processing and packaging of pharmaceuticals products.

- IMA, with the aim of maximizing customer satisfaction and internal and external processes effectiveness, has undertaken since the beginning the way for the implementation of a documented Quality System.

- Designed for QC Labs, pharma production and pharmacies, the IMA Life sterility test isolators are equipped with unidirectional air flow system and guarantee a constant positive pressure gradient between the chambers and the external lab environment.

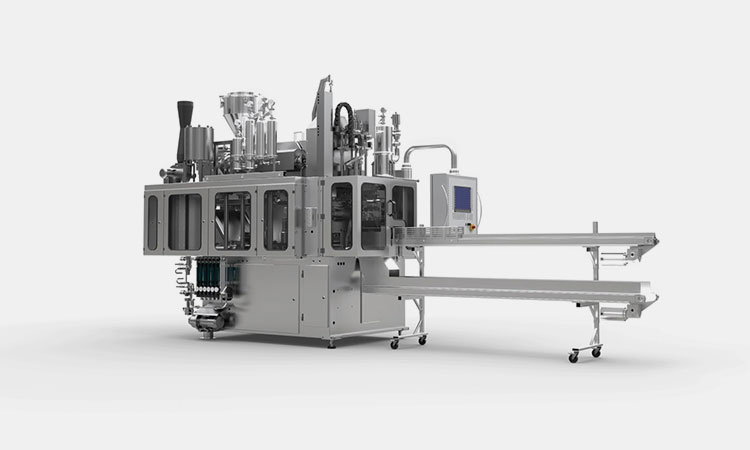

4. AIPAK

AIPAK Background:

AIPAK is a world-famous food nutrition equipment and packaging machinery supplier. It was established in 2008, with 15 years of manufacturing experience. They are able to provide top-class machines, especially packaging and filling machines. AIPAK provides different kinds of ampoule filling machines and the whole filling lines. AIPAK Ampoule filling line can be also called ampoule bottle washing, sterilization, filling, and sealing line, consisting of an AKCA vertical ultrasonic bottle washer, AKDH hot air circulation sterilization tunnel, and AKA type ampoule filling and sealing machine.

Key Products

AKA series ampoule filling and sealing machine

AKBL series ampoule filling line

AKDH series hot air circulation sterilization tunnel

Recommend Reason

- AIPAK ampoule filling machine can automatically complete the whole production process from bottle feeding, preheating, drying and sterilization, cooling to bottle bottle discharging.

- AIPAK ampoule filling machine has reached the advanced level at home and abroad, with reasonable structure, high automation, stable and reliable operation, high production efficiency and mechatronics.

- All AIPAK ampoule filling machines are designed and manufactured that meets the requirements of the new GMP.

5. ROMMELAG

ROMMELAG Background:

ROMMELAG was established in 1952 and is at home in Germany and Switzerland. Their solutions and technologies are in demand in over 80 countries around the world. They are the inventor of the Blow-Fill-Seal-Technology (BFS) as well as flexible containment systems based on plastics. Their ideas and complete solutions guarantee that pharmaceuticals, in particular, can be filled safely and sustainably. They provide the ideal extensions for your ampoule filling machines to ensure maximum safety and efficiency.

Key Products

bp 312M

bp 321M

bp 324M

Recommend Reason

- They produce every part of the ampoule filling machines with Swiss precision and German engineering for the highest quality, reliability and a long service life.

- Every ampoule filling machine meets the strict requirements of the global pharmaceutical industry: From Abrasp and Anvisa to EMA and FDA.

- Theyhave been continuously optimizing since the first bottle-pack prototype in 1960.

- Theyare now the global market leader, offering highly efficient aseptic filling machines, a wealth of experience and a unique range of services.

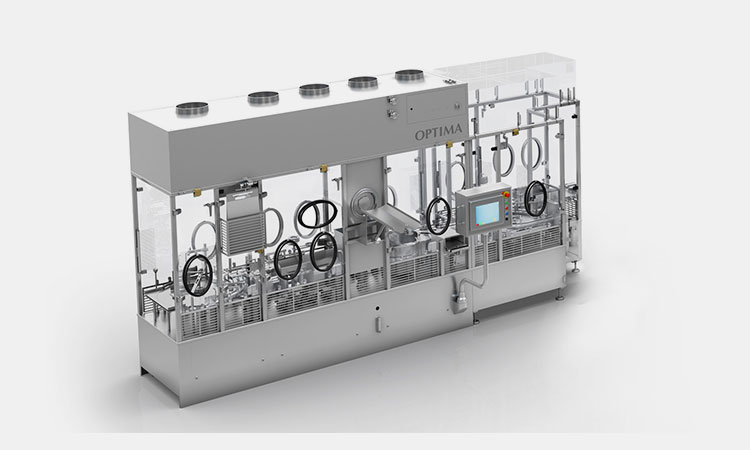

6. OPTIMA

Optima Background:

Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven, and life science products - from single standard machines to complete complex turnkey systems. Optima Pharma offers an innovative machine portfolio for the filling and packaging of sterile liquids and powders in disposable ampoules, syringes, vials, infusion bottles and cartridges, isolators, and freeze-drying systems also complements the portfolio perfectly.

Key Products

OPTIMA SV/H

OPTIMA UJ

OPTIMA VFVM

Recommend Reason

- Pharmaceutical filling systems from Optima Pharma ensure flexibility, reliability, security and profitability in your production.

- Vials, bottles, syringes, carpules, ampoules in nest or in bulk form and well plates for liquid and highly viscous pharmaceutical products are processed.

- The extensive spectrum of machines is perfectly complemented by innovative isolators from METALL+PLASTIC and freeze drying systems. This ensures that complex turn-key lines are made simple.

- Optima Pharma is the best partner for economic development and pinpoint implementation. Especially for complex turnkey projects.

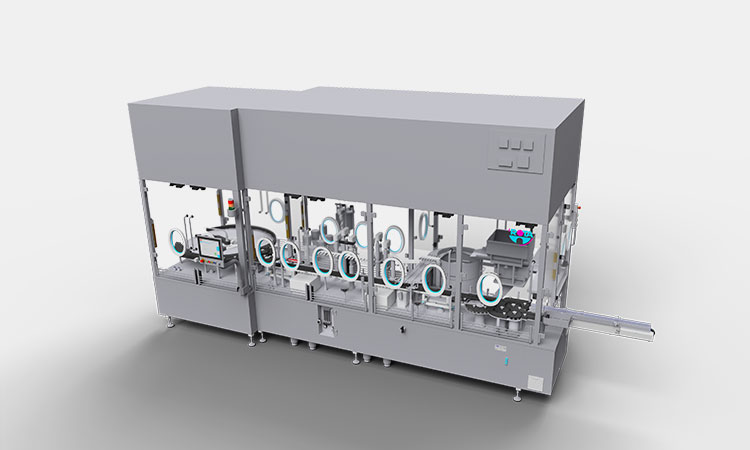

7. ROTA Verpackungstechnik

ROTA Verpackungstechnik Background:

ROTA Verpackungstechnik is a renowned manufacturer of machines and systems for aseptic primary packaging of parenteral drugs for the pharmaceutical and biotech industries. As a family-run medium-sized company, ROTA has always been able to meet changing market requirements and customer needs flexibly and with personal commitment thanks to its extensive experience. As a partner, ROTA acts far-sighted and responsible. The machines and lines form a comprehensive modular machine portfolio of the latest technology for ampoules, vials, syringes, and nested objects.

Key Products

ROTA FLL301

Recommend Reason

- ROTA offers the suitable filling concept for any liquids with high reproducibility and maximum precision.

- ROTA seal-less rotary piston pumps guarantee high filling accuracy in continuous operation, without readjustment.

- Easy handling facilitates cleaning and sterilization of the ampoule filling system, whether manually or in automatic CIP/SIP processes.

- Peristaltic pumps are characterized by their flexibility and "single-use" concept.

- ROTA is the pioneer in this field with its ampoule filling and closing machines.

8. Cozzoli Machine Company

Cozzoli Machine Company Background:

Cozzoli Machine Company has provided technologically advanced machinery for the bottling and packaging industry for over a century. Cozzoli Machine Company supplies and services a full line of precision custom packaging machinery and systems for cleaning, sterilizing, filling, and closing applications. Their products are sold to the pharmaceutical, cosmetic, biotech, food, chemical, and beverage industries all around the world.

Key Products

FPS

F329HE

Recommend Reason

- Cozzoli Machine Company supplies and services a full line of precision custom packaging machinery and systems for cleaning, sterilizing, filling and closing applications.

- Cozzoli ampoule filling and sealing machines accommodate a range of products from aqueous solutions to powders and even pellet applications.

- These high-speed ampoule filling and sealing machines are versatile, compact, and self-contained.

- The FPS series is a compact ampoule filling and sealing monoblock machine; featuring an unscrambler, flushing and filling stations and is known for its simplicity, operational reliability and minimal maintenance factors.

9. BAUSCH Advanced Technology Group

BAUSCH Advanced Technology Group Background:

BAUSCH Advanced Technology Group designs, manufactures, and services controlled and aseptic fill-finish packaging equipment for the pharmaceutical and related industries. With 55 years of experience, they integrate advanced modular components to deliver a custom packaging platform to meet specific customer needs. Their ampoule filling and closing machines offer flexible solutions for packaging liquid pharmaceutical products into open or pre-sealed ampoules.

Key Products

Type 504-506

Type 502/503

Type 401-40x

Recommend Reason

- Their ampoule filling and closing machines offer flexible solutions for packaging liquid pharmaceutical products into open or pre-sealed ampoules.

- All the ampoule filling machines can be used stand-alone or integrated into a production line.

- They develop the right solution to meet all your primary packaging objectives.

- They tailor-build their ampoule filling and closing machines to customer specifications and employ advanced technologies for high-quality performance.

10. Kambert

Kambert Background:

Kambert with years of experience in delivering pharmaceutical engineering solutions today emerges to approach the market with a clear objective of providing the most competitive products. They continuously thrive to make the best research possible with their in-house facilities to be a world-class manufacturer with core technologically driven products that brings a change in the globe of engineering experts. Kambert offers two models KAF-06 & KAF-08 for ampoule filling and sealing machines with an accurate individual spacing of the ampoule tips to match the stations as well as perfect vertical fixing while at rest.

Key Products

KAF-06

Recommend Reason

- Kambert offers two models as KAF-06 & KAF-08 for Ampoule Filling & Sealing Machine. The basic design principle and the type of operation offers optimum reliability for conveying the ampoule for the filling (servo based) & sealing process and out-feed.

- With a strong motivated team, they are ground committed to servecustomers with superior services that ensure them to be at ease at their work place, every time they are using their ampoule filling machines.

- Kambertis ready to serve you with ampoule filling machines and other ancillary equipments.

Conclusion

Ampoule filling machine is a challenge for all manufacturers. However, the top 10 global ampoule filling machine manufacturers that we introduced above are all excellent ampoule filling machine and solutions experts. If you are interested in any of the above manufacturers and related products, or if you have more to add, welcome to browse our website https://www.icapsulepack.com/ or contact our customer service. Thanks for reading!

Don't forget to share this post!

Ampoule Filling Machine Related Posts

Ampoule Filling Machine Related Products

Ampoule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us what you want to fill or your budget, we'll reply to you ASAP within 24 hours!