Soft Gelatin Capsule Manufacturing: A Complete FAQ Guide In 2025

You must have noticed soft shinny liquid filled capsules in your medicine cabinet. These pretty little things are not as simple as they appear. There lies a whole scientific process of soft gelatin capsule manufacturing which provide us these shinny capsules holding the liquid magic which is turned into various pharmaceutical benefits upon swallowing. This is literally something where innovation combines with pharmaceutical techniques.

They can encapsulate a large number of formulations from delicate oils to tricky drugs. The soft gelatin capsule manufacturing is an attention to detail procedure. Every step involved is critical and calculated to obtain the right product. Let’s dwell into following to learn about the detail and technicalities of soft gelatin manufacturing.

1.What is soft gelatin capsule manufacturing?

A container full of soft gelatin capsules-picture courtesy: daisily

The process of manufacturing soft, gelatin based one piece body; completely sealed capsule shell is termed as soft gelatin capsule manufacturing. This manufacturing also includes the filling of liquid or semi-solid substance in the gelatin capsule shells and sealing them completely right away.

Gelatin is the main ingredient beside other supporting agents in these soft gel capsules. The fill material in these gelatin shells can be any solution, suspension or emulsion with a suitable vehicle.

2.Why soft gelatin capsule manufacturing is required?

Picture courtesy: freepik

Soft gelatin capsule manufacturing is required for a multiple reasons which are not really achievable with tablets or hard capsules. A few of the reasons are explained below:

Encapsulation of liquid or oily dosage forms:

There are many formulations and active ingredients which are insoluble in water or oil based which makes them very difficult to intake directly. Soft gelatin capsule manufacturing comes to rescue with such dense formulations especially. Soft gelatin capsules provide encapsulation for such dosage forms and more effective delivery.

Improved bioavailability:

The soft gelatin capsules allow the encapsulation of water insoluble or poorly soluble active ingredients and deliver them in emulsions or solution forms which directly increase their bioavailability.

Accurate and uniform dosing:

The soft gelatin capsule manufacturing ensures each capsule has a well calculated and accurate dosage filled. This reduces the variability in dosage which is very common with liquid dosage forms. Also, there is no wasting of dose by sticking with the container and accurate and complete dosage is administered easily.

Protection of sensitive ingredients:

These soft gelatin capsules are hermetically sealed. It is ensured in the soft gelatin capsule manufacture that they are well sealed restricting any air, oxygen or moisture through the shell. This way they protect the sensitive ingredients from any kind of environment oxygen or moisture. The stability of ingredients is also increased.

Better identification with colors as per active ingredients:

The variation in colors and shapes of the soft gelatin capsules is not only for aesthetic purpose. The different colors of capsules help in identification of the medication and keep a track of dosage, especially in case of geriatrics that usually have a difficulty keeping a track of medications.

The difference in colors is usually according to their purpose and active ingredient involved that makes the medicine identification easier.

Marketing appeal along with patient compliance:

The soft gel capsule manufacturing is a win-win for both, consumer and the manufacturer. The vibrant colors and attractive shapes as per patient preference make them more appealing in the market. While on other hand, the ease of swallowing dense liquids, oils or formulations with pungent taste or smell increase the patient compliance irrespective of age.

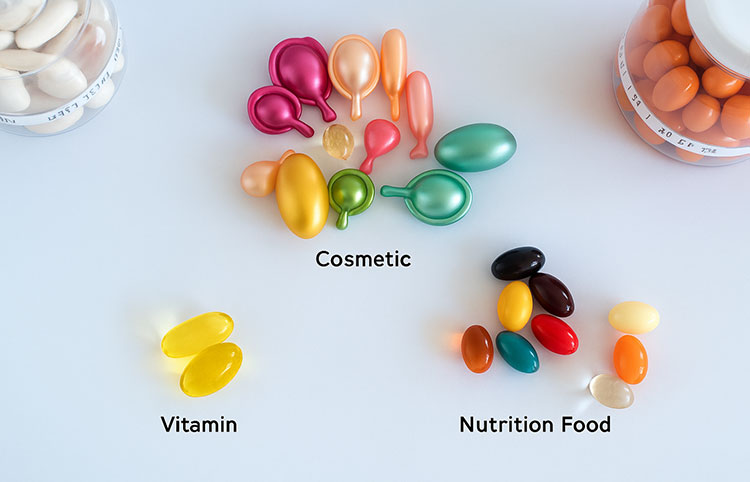

3.What are the applications of soft gelatin capsule manufacturing?

The soft gelatin capsule manufacturing is versatile and goes beyond the typical usage that comes to your mind, i.e., pharmaceutical industry. The other applications along with pharmaceutical are explained below:

Pharmaceutical industry:

Pharmaceutical soft gelatin capsule

There are a large number of dosage forms that require soft gelatin capsules for their effective administration and their handling becomes easier. There are hormonal medicines like progesterone, testosterone which comes in soft gelatin capsules. There are antibiotics and antifungals in liquid form. The drugs with poor water solubility and requiring rapid absorption are preferred.

Nutraceuticals and dietary supplements industry:

Nutraceutical fish capsules-picture courtesy: nutria ninja

There are very commonly available nutraceuticals and dietary supplements as soft gelatin capsule. These supplements are usually oil based, soft gelatin capsule manufacturing make them easy to intake. There are soft gelatin capsules for multiple fat soluble vitamins like vitamin A, D, C, E etc. There are supplements and nutritional oils like fish oil, krill oil or flaxseed oil which are easily administered through soft gelatin capsule.

Cosmetic and beauty industry:

Cosmetic capsules have become a part of your vanity

There are many edible beauty formulations, like anti-aging collagen formulation which are commonly available in soft gelatin capsules. There are skin and hair supplements like biotin, hyaluronic acid or retinoid which comes in soft gelatin capsules. The soft gelatin capsules increase the bio availability of such products and deliver the beauty from within the product.

Veterinary medicine:

Soft gelatin capsules for animals

There are palatable soft gelatin capsules which make the administration easier to the animals. There are also nutritional supplements of the animals especially the pet animals which come in soft gelatin capsule form. The veterinary medicinal dose is usually larger, but it is made easier with soft gelatin capsule manufacturing.

Herbal medication:

Soft gelatin capsules in herbal formulations

The soft gelatin capsule manufacturing is widely used in encapsulation of herbal extracts, which would be difficult to compress into tablets or use in dry powder form. These soft gelatin capsules protect the stability of these products and also mask their usually strong and pungent smell and taste. Soft gelatin capsules for turmeric extract, ginger oil, black seed oil, palmetto extract, and ashwagadha are a few example of herbal use of these capsules.

4.What are the ingredients required in soft gelatin capsule manufacturing?

We can say that there are two parts of the soft gelatin capsule manufacturing. One is the outer shell and then there is the fill material which is filled inside the capsule shell. Let’s dig into the soft gelatin capsule to know about its ingredients.

The complete breakdown of the ingredients required is given below:

| The outer soft gelatin capsule shell | |

| Gelatin

This is the primary structural ingredient of the soft gelatin capsule manufacturing. It is derived from animal collagen. Its main purpose is to provide elasticity, strength and flexibility to the soft gelatin capsule shell. |

|

| Plasticizers

Glycerin and sorbitol are commonly used plasticizers in the soft gelatin capsule manufacturing. They are added to avoid brittleness in the capsule. They make the capsule soft and pliable. The softness of capsule depends upon the ratio of gelatin to plasticizer. |

|

| Water

The procedure for soft gelatin capsule manufacturing starts with mixing of gelatin with water to make a mixture of gelatin. The viscosity and workability of gelatin mass is dependent upon water. |

|

| Colorants

Natural colors are used, but sometimes synthetic colorants can also be used. The colorants are required for the identification, branding and sometimes for light protection. |

|

| Opacifier

Opacifiers are added to make the capsule non transparent. The commonly used opacifier is titanium dioxide. They protect the sensitive fill material from external light. |

|

| Flavoring agents (optional)

Flavoring agents are optional and occasionally added to mask the smell and strong flavor of fill material. They are sometimes added in soft gelatin capsules prepared for kids or sometimes the nutrient supplement capsules can have flavoring agent according to that nutrient. This enhances the patient compliance of the capsules especially in chewable soft gelatin capsules. |

|

The inner fill material:

The inner fill material is not a part of the ingredients require for the soft gelatin capsule manufacturing. Rather they are just the dosage form or formulation which is filled inside the soft gelatin capsule shell formed. They are:

Active pharmaceutical ingredient:

It is the main active ingredient which identifies the type of soft gelatin capsule; it could be nutraceuticals, herbal, pharmaceutical or other.

Solvent or carrier:

They are carrier oils for the active ingredient to for properly suspending the active ingredient into the formulations. They are usually vegetable oil, polyethylene glycol or triglycerides.

Surfactants:

They are added to enhance the stability and solubility of emulsion based formulations.

Preservatives:

They prevent any kind of microbial growth in the soft gelatin capsule formulation.

5.What are the critical steps involved in the soft gelatin capsule manufacturing?

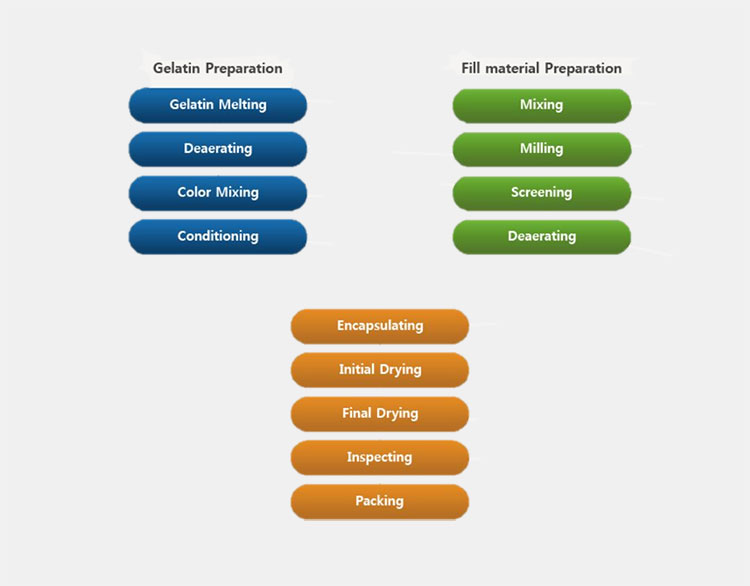

Soft gelatin capsule manufacturing comprises of two simultaneous processes. The preparation of soft gelatin capsule shell mass and the fill material mass is prepared through the respective processes. Finally, soft gelatin encapsulator completes the soft gelatin capsule manufacturing with both of these materials prepared.

Following image show both of these processes:

Let’s look through the detail of steps involved in soft gelatin capsule manufacturing:

Gelatin mass preparation:

Gelatin melting and mixing with other ingredients-picture courtesy: pharma excipients

Gelatin preparation is a critical step as the quality and viscosity of the gelatin sheets forms directly affects the thickness, strength and performance of the capsule shell. First of all gelatin is mixed with water and gently heated at a temperature of 60-70̊C. It is heated until gelatin dissolves and makes a thick viscous solution.

The plasticizers are added after the melting of gelatin. It could be only one plasticizer or a mixture of two different plasticizers. The colorants and opacifiers are also added to this mixture. This homogenized mixture is treated under a vacuum to remove any air bubbles, this process is called deaeration. It ensures there are no air bubbles in the final capsule shell.

This mixture is required to be kept neither warm, neither hot boiled nor cold. The gentle stirring is done to avoid any solidification before use.

Fill material preparation:

The fill material which is the drug formulation is prepared. The active pharmaceutical ingredient is dissolved in suitable carrier oil with the addition of preservative if required. It is ensured that this mixture is uniform and stable to avoid any defect while filling and maintain a consistent dosing.

Encapsulation:

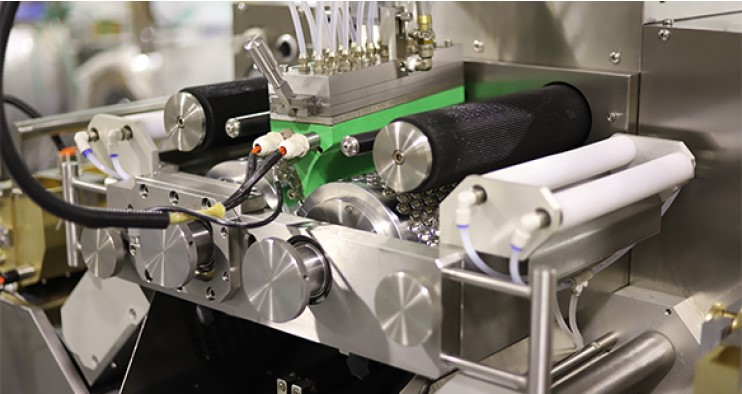

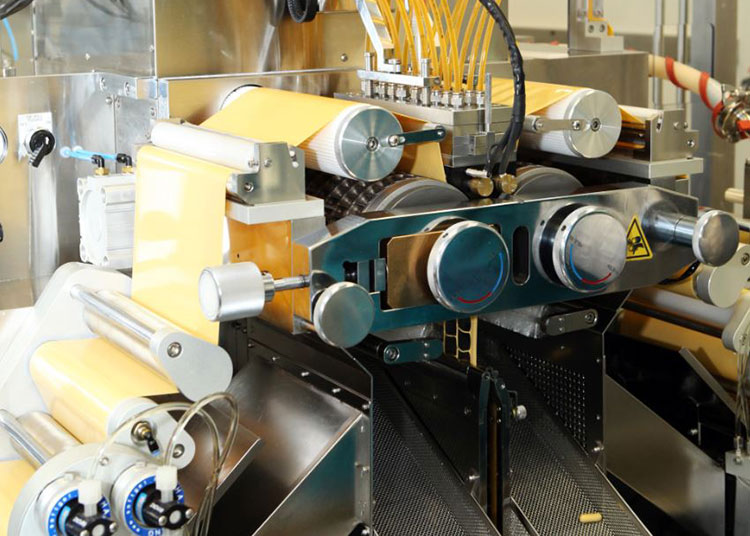

The encapsulation procedure going on through encapsulation machine-picture courtesy: acic machinery

Now this is the core step in the soft gelatin capsule manufacturing. It is a very advanced and unique manufacturing where the capsule shell material and fill material are simultaneously fed to the machine and encapsulation is done while the capsule is being formed and sealed. All this happens in a one continuous process. This whole process is carried out in machine called encapsulator or soft gelatin encapsulation machine.

The most efficient and commonly used method for encapsulation at large scale is rotary die process, which is explained below:

Rotary Die Process:

This is the process where gelatin shell material and fill material collectively form soft gelatin capsule in one operation. The machine used in this method is rotary die encapsulation machine. It has following steps:

Gelatin ribbon formation:

The gelatin mixture is converted to sheets or ribbon by feeding to spreaders or large ribbon forming drums. The gelatin ribbons forms are 0.5 -1.0 mm thick. These ribbons forms are continuously moving downward in the encapsulation zone.

Synchronized filling material:

At the same time, the fill material is also being fed into the machine. It is fed through a precise and controlled nozzle which is placed in between the two gelatin ribbon passing down.

Rotary die operation:

These two gelatin ribbons or two sheets are passed through the rotating dies. These dies are oppositely rotating and engraved with the required shape of capsule, could be oval, oblong, sphere or any other customized shape. As the gelatin ribbons pass through the dies the fill material is also being injected in between the two layers from the nozzle.

Sealing and shaping:

The pressure, timing and counter rotation of the rotary dies cut, fill, shape and seal the capsule within seconds and all in one go. The sealing and cutting of gelatin ribbons after filling give you the final soft gelatin capsule.

This procedure requires maintaining temperature and humidity to prevent drying or sticking of gelatin. The speed of machine and precise alignment ensures that the capsules have a symmetrical shape and properly sealed.

Plate Process:

In this process, the soft gelatin capsules are formed by applying vacuum over a sheet of warm gelatin, which is placed over molds of the required capsule shape. The fill material is poured over this. After that, another sheet of molds are placed and pressed over this gelatin layer. Pressure is applied to mold and seal the gelatin capsules formed and filled.

It is relatively a slow process and very less used. It is mostly used at very small scales because it has some limitations. It lacks the uniformity of dosage and production losses are also high.

Drying:

Freshly formed capsules coming into drying trays-picture courtesy: collagen peptide and gelatin

The freshly formed soft gelatin capsules pass out from the machine and undergo the process of drying because they are soft and sticky. Some advances automatic machines have integrated tumbler dryer which cause the initial drying.

These soft gelatin capsules after passing through the tumbler dryer are placed in specific drying trays which are placed in a drying room with controlled environment to remove any kind of excess moisturizer from it. This is the final drying phase of capsules. This process can take from 24-72 hours.

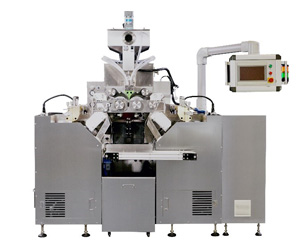

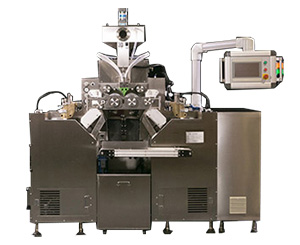

6.What is the equipment used in the soft gelatin capsule manufacturing?

The basic equipment and machinery required for the soft gelatin capsule manufacturing are given below:

| Machine used | Features |

| Gelatin melting tank

AIPAK gelatin melting tank |

These are large stainless steel tanks. They have agitators or to ensure a uniform mixing of the product inside. Gelatin is melted and mixed with other ingredients in this tank.

They have heating jacket to maintain a consistent temperature and viscosity of the gelatin mixture. |

| Preparation tank

AIPAK Preparation tank |

These tanks prepare the final material preparation. These mixers prepare a uniform solution of the fill material, i.e., API with other suspending agents.

They have additional vacuum deaeration in them to ensure there is no air in the solution. |

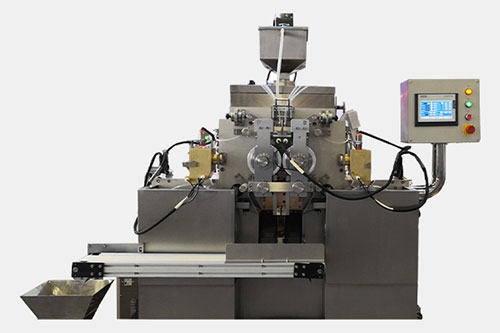

| Soft gelatin capsule manufacturing machine

AIPAK Softgel encapsulation machine |

This is the core machine, it ensure the production of soft gelatin capsules in a single continuous process.

The gelatin mixture and fill mixture prepared is combined here into a softgel capsule form. The gelatin ribbons are converted to soft gelatin capsules by the rotary die operation of this machine. The fill material is being filled into capsule through injection wedge. This soft gel encapsulation machine has rotary dies, injection wedge, and gelatin ribbon spreader and lubrication system which collectively give the final filled soft gelatin capsule. |

| Tumble dryer ( initial drying)

AIPAK tumble dryer |

As the name suggest, they dry and remove moisture from the freshly prepared capsules.

In these dryers, the capsules rotate gently inside the perforated drum under the influence of airflow which dries them and sticking is prevented. |

| Drying trays / tunnels ( final drying)

Capsule drying trays |

The final process of drying is completed in drying tunnels. The capsules are placed in drying trays and kept into drying tunnels.

These tunnels have temperature of 20-22̊C and humidity ranges from 20-30%. |

7.What types of substances are ideal for encapsulation in soft gelatin capsule manufacturing?

Suspension encapsulated soft gelatin capsules

Soft gelatin capsules are used for encapsulating liquid or semi-solid substances. The oily and poorly water soluble substances are especially encapsulated with soft gelatin capsules. The aqueous solutions are less suited with soft gelatin capsules because gelatin is sensitive to water.

The hygroscopic, volatile and highly acidic compounds are also not suitable with soft gelatin capsule manufacturing. Here are the few examples of soft gelatin capsule manufacturing.

Emulsions and suspensions:

Cosmetic used emulsion based soft gelatin capsules

Soft gelatin capsule manufacturing allows the pharmaceutical and other manufacturers to encapsulate suspension of fine particles or any self-emulsifying agent SEDDS (self-emulsifying drug delivery system) for complex formulations. There is immunosuppressant or anticancer drugs available in this form.

Hormones and lipids:

Primrose oil hormonal soft gelatin capsule for women-picture courtesy: teami blends

There are many examples of low dose but potent formulations that require a stable environment for good absorption. Hormonal formulations and lipid based API is very common example for these formulations. Progesterone, testosterone, primrose oil and thyroid hormone related drugs are very commonly available in soft gelatin capsules.

Oil soluble drugs and nutrients:

Soft gelatin capsule for omega-3 fatty acid formulation

There are the most commonly seen and known formulations for soft gelatin capsule manufacturing. This is because they dissolve well in oil based or fatty carriers. Vitamin A, D,E, omega-3 capsules, fish oil, cod liver oil, coenzyme-Q10 are very commonly available soft gelatin capsules.

Herbal and nutraceuticals extracts:

Herbal soft gelatin capsule-picture courtesy: physical solutions

The usually herbal active ingredients are lipophilic. The soft gelatin capsule shell provides them with protection and enhanced bioavailability. Garlic oil, clove oil, palmetto extract are some common example for herbal soft gelatin capsules.

Lipophilic or poorly water soluble drugs:

Lipophilic layer in water

The lipophilic drug substances have very low bio availability with oral administration. The soft capsule gel enhances the bioavailability of such formulations with delivery oils or surfactants. They could be nutrient supplements or pharmaceutical drugs.

8.Does the soft gelatin capsule manufacturing allow customization?

Different shapes and colors of soft gelatin capsules

It’ll be a quick yes to this question. A high degree of customization is allowed in soft gelatin capsule manufacturing. This is one of the main reasons of its advantages and preference in the functional and marketing purpose. Here is how customization is done in the soft gelatin capsule manufacturing:

Color customization:

Different colors of cosmetic use soft gelatin capsules-picture courtesy: style caster

The soft gelatin capsules are manufactured and easily available in a wide range of colors. The colors or natural dyes used are FDA approved. The color provides easy identification, as it could be according to the dosage form, strength or type of the formulation.

Size and shape:

There are various shapes of soft gelatin capsules like oblong, oval, and spherical or heart or fish shaped available in various sizes depending upon the dose and market requirements. The unique shapes and variety in sizes is suited for children and veterinary use. Small sizes make the swallowing easy for children especially.

Printing and labeling:

Laser printed soft gelatin capsule-picture courtesy: scantech laser

There are capsules which are printed with logos, dosage information or brand names. This printing is done using edible ink because the printing is done directly on the capsules. The labeling enhances the identity of brand and medicine errors are reduced.

Shell properties:

Unique twist off soft gelatin capsule shell

The soft gelatin capsule manufacturing is so versatile that along with different shapes and sizes there are varieties in gelatin shell available. The gelatin shell could be transparent, opaque and flavored. All these varieties depend upon the formulation demands.

Fill customization:

Types of soft gelatin capsule according to fill material

As we have explained earlier, the fill material could also be of different types. It could be suspension, emulsion, solutions or oil blends. The versatility of fill material supported in soft gelatin capsules allows precision in bioavailability, release rate and compatibility with active ingredient.

9.What are the common range of soft gelatin capsule sizes and shapes supported in soft gelatin capsule manufacturing?

The following table highlights a few examples of size ranges of the soft gelatin capsule manufacturing, along with the shapes available:

| Soft gelatin capsule Shape | Soft gelatin capsule size code | Soft gelatin capsule capacity and size |

| OVAL

|

Ranges from 2 oval to 40 oval | Capacity: 0.092ml-2.454ml

Size: 1.5mm-24.0mm |

| OBLONG

|

Ranges from 3 oblong to 22 oblong | Capacity: 0.142ml-1.3555ml

Size: 2.3mm-24.0mm |

| ROUND

|

Ranges from 2 round to 110 round | Capacity: 0.074ml-6.160ml

Size: 0.75mm-20.0mm |

Other special shapes:

Animal and other special shapes and sizes of soft gelatin capsules-picture courtesy: style caster

Other than the basic shapes, there are also special shapes like fish, heart or animal shapes for children formulations. These special shapes also include tube shape or twist off shapes that are preferred in cosmetic industry. The twist open capsules allow the opening while using by the cosmetic consumer.

10.What are the common problems and troubleshooting in soft gelatin capsule manufacturing?

The soft gelatin capsule manufacturing is an interesting but very critical procedure. If maintenance of the machine equipment and handling of ingredients is not done right, it can lead to a lot of problems with the final product and defected capsules.

Leaking or unsealed capsule is a very commonly seen problem. It happens due to un aligned dies and improper gelatin mixture. It is fixed by adjusting the gelatin temperature and ribbon thickness and alignment of dies is fixed.

If the fill material is not deaerated properly it can cause air bubbles in the capsules. The agitation speed needs to be adjusted in this case and the speed of nozzle delivering the fill material needs to be adjusted. The deaeration of the fill material should be done properly under vacuum.

Some defected soft gelatin capsules-picture courtesy: sensum

The capsule fill pumps are required to be calibrated carefully so that there is no weight variation in the capsules. The other causes of weight variation include irregular thickness of the gelatin ribbon and air bubbles in the fill material.

The sticking of the capsules to the die or dryer occurs due to increased gelatin temperature and it can be avoided by using lubricants in the molds and reduce the speed of machine. In case of deformed capsules, the plasticizer to gelatin ratio needs to be optimized and avoid over heating during the drying of final capsules.

The last but not the least problem which needs to mention here is the contamination or microbial growth in the soft gelatin capsule manufacturing. It can be avoided by keeping a controlled environment, the hygiene should be ensured in the gelatin preparation area and even if some of the equipment is enclosed, make sure to sanitize it completely

Conclusion:

Soft gelatin capsules are oral dosage forms and they are achieved by soft gelatin capsule manufacturing. This manufacturing of soft gelatin capsule provides us with these versatile capsules. The soft gelatin capsule manufacturing has not only been helpful for the patients but for the manufacturers as well. The ease of administration and large varieties of capsule types increase the demand of soft gelatin capsule manufacturing which is totally an economical benefit for the manufacturer. As we summarizes this FAQ guide we hope you have understand the technicalities in the soft gelatin capsule manufacturing and all the work that goes behind those little shinny and colorful capsule beans. For more details visit our AIPAK website!

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine