Milk Powder Filling Machine: The Complete FAQ Guide In 2025

Have you ever wondered how industries pack milk powder so neatly and quickly? What is the reliable way to fill and pack milk powder? You are at the right place, welcome to the fascinating world of milk powder filling machine. This comprehensive guide by AIPAK has been designed for you to understand the milk powder filling machine, which plays a crucial role in food industry. Besides food industry, you can also use this machine to package other powder products as well so, the diversity of usage of this machine is vast and can be used in other industries.

This FAQ guide will provide you the most commonly asked question about this machine from working steps, the types of milk powder filling machine in the market, its maintenance and even the factors that should be considered while buying this machine. At the end of this guide, you will have complete information about this machine that can help your business grow. So, let’s start!

1.What is a milk powder filling machine?

AIPAK milk powder filling machine

A milk powder filling machine is a type of filling tool which is designed to accurately and hygienically fill the milk powder into various containers such as cans, sachets and bottles etc. This machine is equipped with a weighing system that ensures the exact amount of powder dispensing. For the filling system, it has auger screw system that delivers the milk powder into the each packaging formats .Once filled, these containers are then processed to the other procedures such as capping, sealing, labeling and hence ready for further packaging steps.

2.What are the main benefits of using a milk powder filling machine?

You may have seen the milk powder filling machine in industries and factories or might read about the machines online, but have you ever wondered in how many ways you can get benefited by using this machine? Alright! Let me explain it the ways in which you can get advantages by using it.

High accuracy in filling:

Have you ever wondered how much accuracy is important while filling the powder into the containers? Think about it, if you are filling the containers by your hand, may be overfilling or under filling occur but milk powder filling machine has completely solve this problem. It has a precise filling tool that can accurately fill the measured amount of powder into the containers. In this way, no under filling or overfilling occur.

Increased production efficiency:

Increased production efficiency- picture courtesy: etsy.com

Do you want to produce large production in less time? If you have ever filled the containers with powder, then who will more than you that it is more tiring and time consuming procedure. But by using milk powder filling machine, hundreds and even thousands of containers are filled in a fraction of time. You will get faster production rate which means more products preparation, more supply and more growth for your business.

Consistent quality:

Are you wishing to pack the consistent filling in each pack? Your customers notice every pack and if one pack seems heavier and the other lighter then it leads to complaints and affect your brand reputation. But this problem has solved by the milk powder filling machine. It can fill each container with an exact quantity of powder which enhance the trust of your customers.

Hygiene and cleanliness:

Hygiene and cleanliness of the product

Are you worried about the hygiene and cleanliness of your filling system? The food powders maintenance of hygiene play an important role. Don’t you need to be worried? The milk powder filling machine is made up of stainless steel which does not corroded. Many filling machine has a dust collector which sucks the dust particles and hence, maintain the hygiene and cleanliness during filling procedure.

Flexibility for different packaging:

Flexibility for different packaging

Do you need flexibility to fill different types of containers? Are you want to fill sachets with milk powder one day and other day, you want to fill milk powder in tins and bottles? The advanced milk powder filling machine are designed to handle various formats of containers with different sizes and shapes. You don’t need a separate machine for fillings so, this can reduce your investments cost and space.

Compliance with standards:

I’m sure you must be concern about the food industry standards and regulations. The modern powder filling machine are designed to meet the internal safety standards, so, you should be confident that your process is compliant. This ensures that your customers will be satisfied and also your brand will rule in the market.

3.Are there different types of milk powder filling machines available?

If you are running a business then you must know that every production setup is not same so, manufacturer has designed different types of powder filling machines that can fulfill your need. So, let’s explain each of them and find which one is best for your business.

Based on filling mechanism:

Auger filler powder filling machine:

AIPAK Semi Automatic Auger Filler Machine For powder

This is the most common filling machine used for filling milk powder into the containers. It is suitable for free-flowing and non-free flowing powders. You can easily measure and weight the precise amount of powder and fill them into the desired containers. If you are looking for the versatility and high accuracy then you should invest in the auger filling machine.

Volumetric cup powder filling machine:

Volumetric cup powder filling machine-Picture courtesy: iapack.com

Have you ever heard about the volumetric cup filling machine? This machine works on the fixed volume rather than weight. It is less expensive and simple to operate but less precise as compared to the auger filling machine. If you are running low production business and not strictly follow weight accuracy, then you can choose volumetric cup filling machine.

Gravimetric/ weight based powder filling machine:

Gravimetric/ weight based powder filling machine-picture courtesy: makwell.com

Do you want to fill high regulated milk powder like infant powders? The gravimetric filling machine use weighing scale that can weight exact amount of powder and fill them into the containers. If you are preferring the powder quantity then this machine is perfect for your business.

Based on level of automation:

Fully automatic powder filling machine:

AIPAK fully automatic powder filling machine

The fully automatic powder filling machine can handle all task by its own. You just need to adjust the weight/ volume of the powder and place the desired containers for the filling into the machine. Then machine can weigh the measured amount of powder, filled it into the containers and then sealed the filled containers. This machine operates at high speed and can be used for large scale production and suitable for those, who has consistent businesses.

Semi-automatic powder filling machine:

Semi-automatic powder filling machine-picture courtesy: iapack.com

The semi-automatic powder filling machine needs the assistance of an operator. The machine can weight and filled the powder accurately into the containers. But operator should have to place the containers manually. Then for filling the powder, you should place each container under the filling nozzle and machine starts to fill the packages. This machine is suitable for small or medium batch production.

Based on production layout:

Inline milk powder filling machine:

Inline milk powder filling machine-picture courtesy: makwell.com

In this machine, the whole process occur in a straight line along the conveyor belt. The containers are placed at one end of the conveyor belt which moves straight to the filing nozzle. Under the filling nozzle, the containers are filled with milk powder and then goes to the next station for capping and sealing. It can handle various sized containers and perfect for linear production environment.

Rotary milk powder filling machine:

AIPAK rotary milk powder filling machine

In rotary powder filling machine, the setup is arranged in circular form. The containers are placed and filled with milk powder in circular form. Empty containers move to the filling nozzle where they are filled with measured amount of milk powder and then moves to the next station for capping and sealing. These all stations are arranged in circle and hence, the process is continuous and extremely fast. If you want to save floor space and high production then you should choose this machine.

4.Enlist the industries that can use milk powder filling machine by filling various powders other than milk powder?

Even though it is known as milk powder filing machine but it is not limited for filling of milk powder, there are other powder materials filled through these machines. You must be surprised the diverse usage of these machines in various industries. These are as follows:

Food and beverage industry:

You should noticed how many types of powder do you use in everyday life in food and beverages? It is not just a milk powder, the coffee powder, cocoa powder in various drinks and beverages, the seasoning powder gives the delicious taste to your products, baking powders, flour mixes and protein powders are very popular in gyms. These powders are also filled into the containers by using milk powder filling machine.

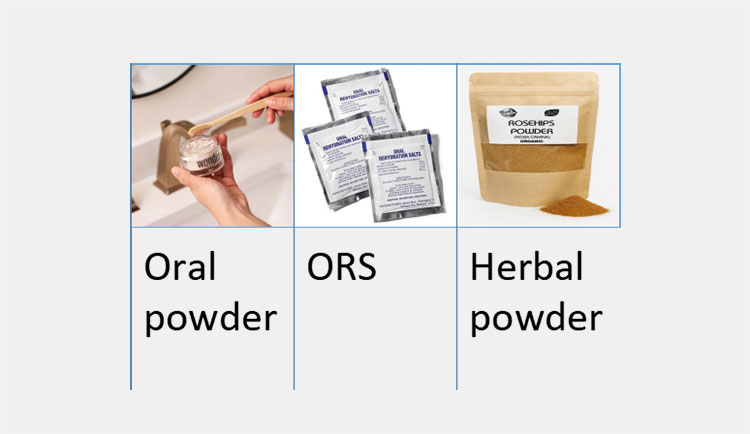

Pharmaceutical industry:

Some medicine powders like antibiotics and other oral products, you might use ORS when your body is deficient in salts and water, calcium or protein powders, the sachets or small jars filled with herbal powder for the treatment of various diseases. These powders are filled into the containers by using the milk powder filling machine.

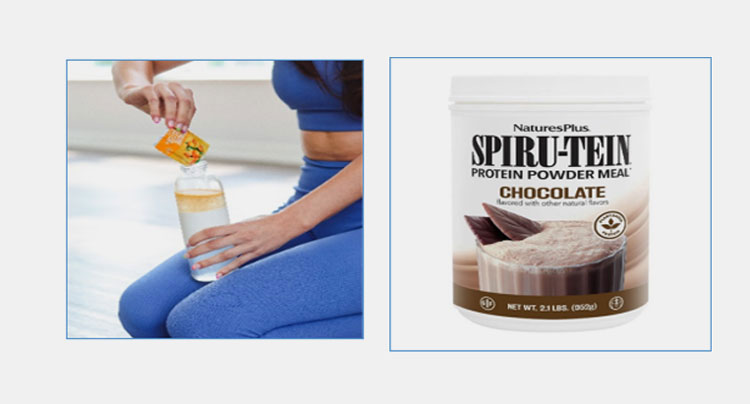

Nutraceutical & Health Products Industry:

The vitamin powder and protein powder

You may have noticed a lot of healthcare products in the market. Do you know what kind of products are these? The vitamin powders and dietary supplements can be packed by using the milk powder filling machine. Have you ever used protein or meal replacement powder? If yes, then you must have observed how neatly and beautifully packed these powders into the containers.

Chemical industry:

You can see the detergent powders or cleaning powders used for laundry and for other cleaning purposes. Have you ever wondered how the same packets are filled with a concise amount of powder? This is due to an advanced milk powder filling machine. You use detergent powder for washing dishes or for washing clothes. These are filled by the milk powder filling machine.

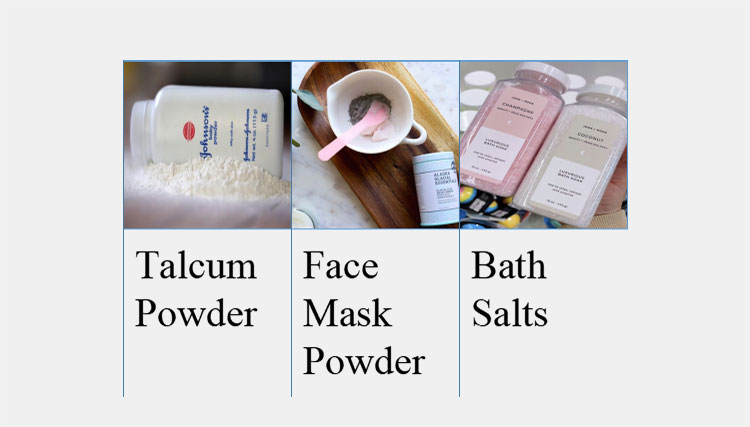

Cosmetic and personal care industry:

You often visit to the cosmetic shop and see a variety of beauty products that come in powder texture. Have you ever wondered which machine makes it easy to handle different texture of powder? Let’s explore these powder textures. You can see a large bottles of talcum powder on the shelves of cosmetic shops, face mask powder and clay, the bath salts and body and face scrubs are also found in powder form. These powders are filled into the desired containers by using the same machine.

5.What kinds of packages can a milk powder filling machine fill?

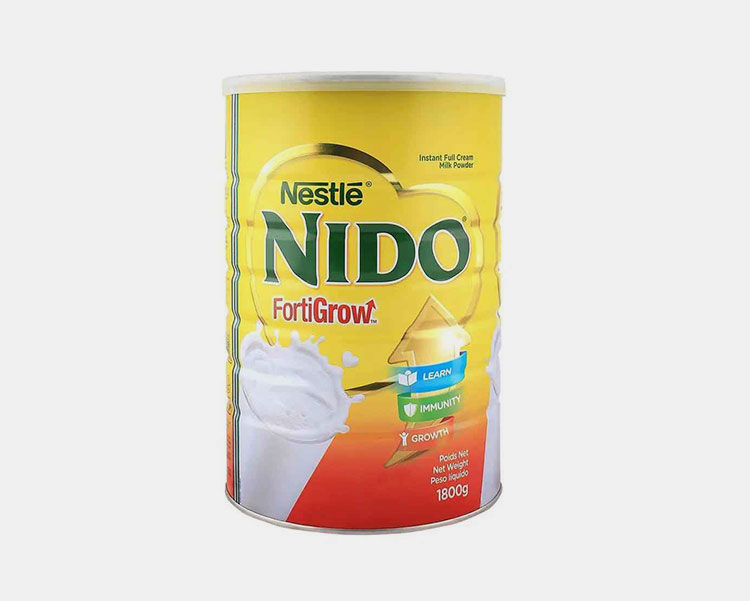

Tins, cans and jars( rigid containers):

Tin container filled with milk powder

Have you ever seen tins, cans and jars filled with a powder milk? Yes, off course, these containers are filled by the milk powder filling machine. The metal tins filled with infant formula milk, plastic jars with lightweight quality for supermarket and glass jars for premium look.

Pouches and sachets:

Pouch of milk powder

Have you ever bought a pouches and sachets for a single use or used while traveling? These pouches and sachets are filled with a milk powder by using the same machine. You will noticed every sachets is filled with a consistent powder.

Bottles ( plastic or glass):

Glass bottle of milk powder-picture courtesy: honorpack.com

This machine can handle different neck sized bottles for easy pouring of the powder. You may see milk powder in PET bottles as a lightweight and durable bottle and glass bottle filled with milk powder for the aesthetic look. It can enhance the customer desire to buy it.

6.What are the components of milk powder filling machine?

You may see just a box that laid in your industry or company but it has several components that are working together to precisely and neatly fill the powder into the containers. These are as follows:

| Components | Function |

| Hopper ( powder storage tank)

Hopper of milk powder filling machine |

Before filling the powder into the containers, did you know before that this powder is stored in the hopper? Hopper is a large bowl on the top of the machine where milk powder is stored. This hopper has lid that covers the hopper and milk powder are prevented from contamination and dust particles. |

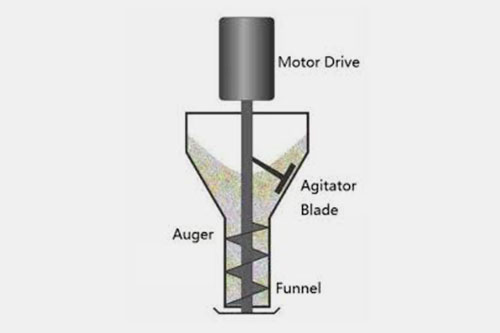

| Auger screw or filling system

Auger or filling system in milk powder filling machine |

Have you ever thought how the containers filled with precisely and accurately does? This is the job of auger filler that controls the amount and volume of milk powder. You can say, it is the heart of accuracy in this machine. |

| Weighing or measuring unit | You might be thinking now that how it knows the right amount of weight of the powder? This machine has measuring unit or sensors that detect the weight of each type of product. This machine ensures each containers is filled with exact the same amount and prevented the overfilling or under filling of the containers with milk powder. |

| Conveyor system

Conveyor system in milk powder filling machine |

There are various stations in the powder filling machine. The containers move and reach to different stations by using conveyor system. |

| Dust collection system

Dust collection system in milk powder filling machine |

Some machines have dust collection system that collects the powder particles. This ensures the maintenance of hygiene and keep the workspace clean. |

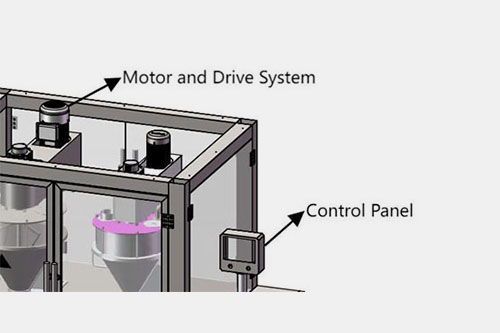

| Control panel

Control panel of milk powder filling system |

Through control panel, you can adjust the whole machine system like the weight of the milk powder, speeds with which the containers should be filled and different container sizes. You can control and run the whole machine system by using control panel. |

| Motor and drive mechanism

Motor and drive system in milk powder filling machine |

The auger screw and conveyor belt need the power but who is the in-charge of providing the power. It is the motor and drive system that provide the power to auger screw and conveyor belt to run smoothly. |

| Frame and casing | But who is responsible for holding all these valuable components? The stainless steel framework of the machine holds all the components in place which is food grade and can’t be corroded. This framework keep the machine durable and run for a long period. |

7.What are the working steps of milk powder filling machine?

Loading the milk powder into the hopper:

Loading the milk powder into the hopper

In the first step, you should load the milk powder into the hopper which is placed at the top of machine and is large bowl. In some machines, the hopper is integrated with an agitator that prevent the loose powder from clumping.

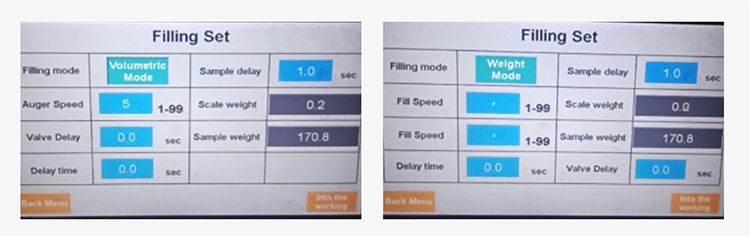

Setting the machine parameters:

Setting the machine parameters-picture courtesy: topspack.com

Then, you should set the filling volume parameters on the control panel. Because you might be thinking how the machine will know that how much to fill in a tin or in a pouch etc.? So, if you want to fill 500g or 1Kg per container then that should be set and machine will remember this unit for consistent batch production.

Feeding and positioning the container:

If you are operating a fully automatic milk powder filling machine, then conveyor belt will move the empty containers to the filling nozzles for filling each container with a milk powder. In contrast, the semi-automatic milk powder filling machine needs the help of an operator. The operator should place each container under the filling nozzle for filling purposes.

Measuring and dispensing the powder:

Now, the auger screw will show its magic. It rotates and release the exact amount of powder that you have set. The sensors will detect the weight of the powder and you will get the exact amount in each container or sachets.

Settling and leveling the powder:

Settling and leveling the powder-picture courtesy: fillingmachinepp.com

In some modern machine, the settling of powder in a container occur to avoid the air trap and for the nice look. The machine tap on the top or vibrate the container to set the milk powder properly and prevent the wastage of the powder.

Moving to sealing and capping:

The conveyor belt transfer and move the filled containers to the next station in some machines. As the sealing is essential because of to provide the freshness and cleanliness to the milk powder. The containers like tins, bottles etc. are caps and the sealed while the sachets are vertically and horizontally pressed and sealed.

Dust collection and cleaning:

Have you ever thought while filling that why and what happening during the filling procedure, where does the extra milk powder particles goes? The dust collecting system captures the extra milk powder particles and ensures the work place is neat and clean.

8.What other machines to be integrated with the milk powder filling machine to form a complete production line?

Bottle unscrambler:

AIPAK Automatic bottle unscramble

Bottle unscrambler machine plays a vital role in the formation of complete production line. This machine automatically orient and placed an empty bottles into the unscrambler hopper. The bottles are oriented in such way that the neck of the bottles are in upright direction. The sensors detect and ensures every correctly oriented bottles transferred to the conveyor belt for filling the milk powder.

Capping machine:

AIPAK capping machine

After the filling of milk powder into the containers like tins, jars and bottles, how should you protect the product? By integrating the capping machine, you can protect the milk powder without the exposure with an external environment. This machine can be adjustable and can handle variety of containers. It place caps on to the containers. This machine has alarm system and if anti-cap containers found, this machine automatically remove them.

Aluminum foil sealing machine:

AIPAK induction sealing machine

The induction sealing machine plays an important role in the milk powder filing line. This machine ensures the airtight seals to prevent the milk powder from contamination, spoilage and preserving the freshness of the product. The electromagnetic field heats the aluminum foil, and melt it to adhere to the neck of the bottle. In this way, the product is prevented from oxidation, spoilage and extend the shelf life of the product.

Labeling machine:

AIPAK labeling machine

The sealed containers are then needed to be labeled but this task can handed over to the labeling machine. The labeling machine put labels of ingredients, direction of use, visual aids, manufacturing and expiration date on the containers of the milk powder. You will get neat and consistent labels on each container.

9.What are the maintenance requirements for a milk powder filling machine?

Maintenance of milk powder filling machine

Have you ever asked yourself that how should you take care of milk powder filling machine to keep it running for many years? Well, you should to follow several steps for caring of it. These are as follows:

| Maintenance | Description |

| Regular cleaning | Are you using the machine for filling the milk powder into the containers? You should have to maintain the hygienic and clean environment. After each batch production, you should clean the hopper, auger filler, nozzles etc. with food grade cleaners. |

| Lubrication of moving parts

Lubrication of moving parts |

In order to avoid friction, wear of moving parts and unpleasant noise, you should apply the food grade lubricants to the chain, gear etc. this will ensure you the smooth functioning of auger filler and conveyor belt. |

| Routine inspection of critical components | Some parts like auger filler, weighing system, motors and belts should be inspected before running the machine. You should check for any wear and tear or other defaults because early inspection of machine parts are better than the later costly repairs. |

| Electrical and control panel checks | Do you want a smooth functioning of the filling machine without stoppage? You should inspect the wiring and other electrical system. You should also check and calibrate the control panel because this act as a heart in the machine. |

| Scheduled services by the professionals | Even if you are keeping the daily and monthly maintenance but do you know your machine also needs some professional technician for its service. So you should have the technician service the machine at regular interval. They will deep clean the machine and replace the machine parts if needed. |

10.What factors should be considered while buying a milk powder filling machine?

Production capacity:

Production capacity

Ask yourself, do you want a large batch production of milk powder containers or small batch? If large batch production, then you should buy fully

Automatic milk powder filling machine but if for small or medium batch production, then you should buy semi-automatic milk powder filling machine.

Hygiene and food safety priority:

You should invest in that machine which is made up of stainless steel because it is not corroded and hence, the food products will also be safe for your body. Also you should look for a machine that is easily cleanable and should have dust control system.

Dimensions and layout compatibility:

Dimensions and layout compatibility

While buying a milk powder filling machine, you should ask yourself, do you have enough space for the machine? Because some machines are compact while other needs enough space in the industries for the complete production line.

Your budget:

Choose a machine according to your budget

Is your budget allows you to invest in premium automation or is affordable option? Because the cost of the machine depends on the automation level of the machine, its accuracy, speed and the structure and the material used for its build up. Then, you should buy a machine.

Support and warranty of the machine:

You should keep it in mind that what kind of support the supplier is providing you. Are they providing you installation help, and after sale services? Are they providing you spare parts if needed? If yes, then you should invest in the machine.

Conclusion:

As you have seen throughout this FAQ guide that milk powder filling machine is far beyond a simple piece of machine. It can handle a variety of powder either you are in food industry, pharmaceutical, chemical, cosmetic industries etc. then you can invest in this amazing advanced filling machine. If you want to invest in milk powder filling machine or other machines to form a complete production line then AIPAK is the trusted brand because it can transform your production line and it is also providing you technical and after sale guidance. For more information, contact us!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine