High Shear Mixer Granulator For Chicken Essence:The Complete Buying Guide In 2025

Do you like chicken essence? Chicken essence is the irreplaceable seasoning for our kitchen. It made from fresh chicken extracts which is nutritional and great taste. How does the liquid become the protein with smaller size and better peptides? Here you may get the secret about high shear mixer granulating for chicken essence.

What are the main type of high shear mixer granulator? What is the manufacturing process of high shear mixer granulator for chicken essence? What are the components of high shear mixer granulator? How does high shear mixer granulator work? Here comes for the most comprehensive answers of high shear mixer granultator for chicken essence!

1.What Is High Shear Mixer Granultator For Chicken Essence?

AIPAK High Shear Mixer Granulator

High shear mixer granulator for chicken essence is a flexible machine which can be used shearing, mixing, granulating, emulsifying, dissolving and so on for chicken essence manufacturing. The main function of high shear mixer granulator for chicken essence is to granulation. For chicken essence powder with different size and shape, high shear mixer granulator makes great job for the producing of seasning products.

You may make both dry granulation and wet granulation here of high shear mixer granulator for chicken essence. And you may also adjust the size of your chicken essence according to your request on seasoning products. High shear mixer granulator for chicken essence can always make the high qualified chicken essence products.

2.What Industry You May Apply Your High Shear Mixer Granulator For Chicken Essence?

High shear mixer granulator for chicken essence can also be applied for other products and industries.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:contractpharma

Pharmaceutical industry has the wide application of high shear mixer granulator for chicken essence. It can be applied for the mixing, granulating, wetting and blending of various materials. For the various suspension and granular products, it has the great use. For both liquid and solid, it can make great degrading and mixing.

Chemical industry

Chemical Industry-Sourced:alpapowder

High shear mixer granulator for chicken essence is highly efficient in mixing various types of materials. For the material with different texture and size, you may get your appropriate mixing here. For the standard mixing condition, there will be no change for your chemical material feature.

Food industry

Food Industry-Sourced:hanningfield

For food which is hard to mix together, it is essential to apply high shear mixer granulator for chicken essence for its applying. It is helpful in manufacturing emulsion, sauces, seasoning and so on. For food which relies on gummy properties for the desirable characteristic, high shear mixer granulator is essential.

Cosmetic industry

Cosmetic Industry-Sourced:bulkinside

Cosmetic industry contains the products like lipstick, toothpaste, cream and so on. For cosmetic products, the disperse and stable mixing and granulating is essential. High shear mixer granulator for chicken essence can also avoid the waste, pollution and prove the high quality of your cosmetic products.

3.Why You Should Apply High Shear Mixer Granulator For Chicken Essence?

Why you should apply high shear mixer granulator for chicken essence? Here are the advantages you may get from your high shear mixer granulator for chicken essence.

Great homogeneity

Great Homogeneity-Sourced:cinchempro

High shear mixer granulator can make the even and stable mixing for your various products. The final components of your products will be even and stable. The various components of your material will disperse evenly. You may then get your desirable mixing work from high shear mixer granulator for chicken essence.

Little waste

You may have your time and energy on mixing and granulating saved with high shear mixer granulator for chicken essence. For labor work of mixing and granulating, it may make the unqualified products which cost more time. With the machine, you can have your time and cost saved here.

Environment protect

For mixing and granulating, the mixing may make pollution for environment or world. You should pay attention to air pollution in the mixing process. High shear mixer granulator for chicken essence makes the great reduction of air pollution and reduces the risk of people getting hurt by harmful products.

High efficiency

High Efficiency-Sourced:motorsatwork

High shear mixer granulator makes the high efficiency in mixing and granulating. This machine makes the complex blending and mixing process easily. This machine is thus irreplaceable for your industrial business.

4.What Are TheGranulating Way For Chicken Essence?

The granulating way for chicken essence varied. Here are the common granulating way for chicken essence.

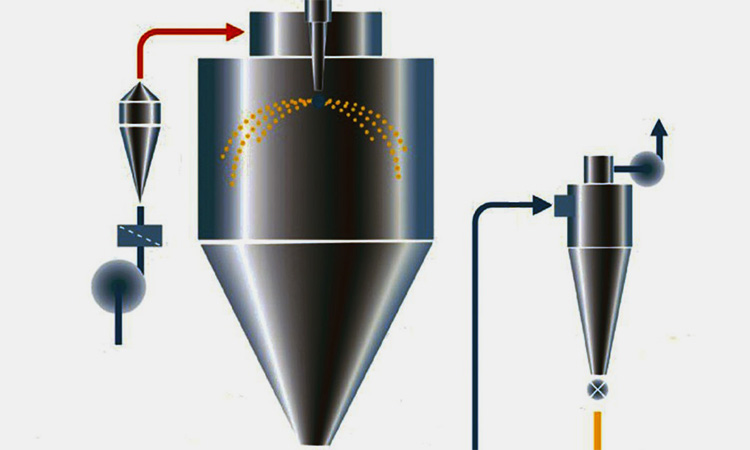

Spray drying

Spray Drying-Sourced:kerone

For the liquid chicken essence, you should put them in the hot drying chamber and while the moisture are evaporated instantly, there will left fine granule and powder. This process is called spray drying. It is efficient and precise in manufacturing the great chicken essence products. But spray drying may reduce some flavor of your chicken essence products,

Fluidized bed granulation

Fluidized Bed Granulation-Sourced:thyssenkrupp-uhde

Fluidized bed granulation makes the chicken essence granulation from fluid bed dryer. The hot air in fluid bed dryer makes the consistent drying and moving for the manufacturing of chicken essence granules. It can handle chicken essence with larger size and produces the even and flow particles.

Freeze drying

Chicken essence will be frozen and then be dried under vacuum. After the evaporation, there will leave the chicken essence with dry and porous structure. Freeze drying makes the best maintaining of chicken essence taste and flavor. But the high request on technique and high cost of freeze drying makes it has restricted applying.

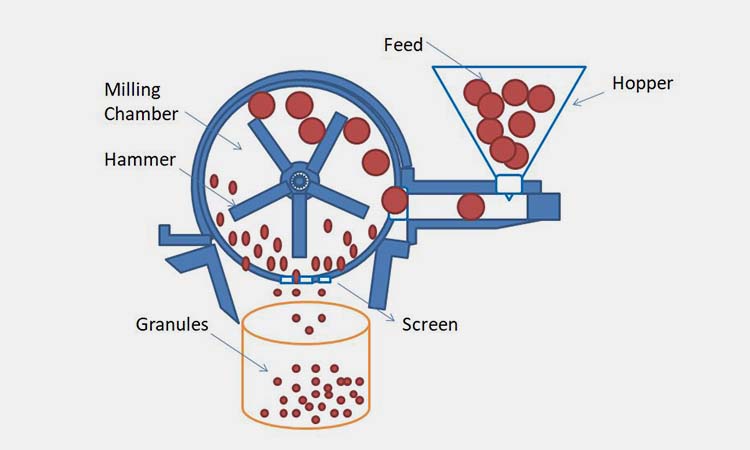

Vacuum drying and milling

Hammer Mill-Sourced:pharmaguddu

Vacuum drying and milling refers to the drying under reduced pressure and heat and then mill them in granules. You may apply granulator or hammer mill for the vacuum drying and milling work. This machine is suitable for the batch manufacturing process and sensitive material.

5.What Are The Main Type Of High Shear Mixer GranulatorFor Chicken Essence?

High shear mixer granulator for chicken essence has different types. And here are the main types of high shear mixer granulator for chicken essence.

Batch high shear mixer granulator

Batch High Shear Mixer Granulator-Sourced:fbddryer

Batch high shear mixer granulator can take care of the large bunch of material. For the request of large scale and high speed, it makes the great dealing. There are also different size and type of your batch high shear mixer granulator. Besides the basic mixing and granulating, you may also get degrading, homogenizing and so on here.

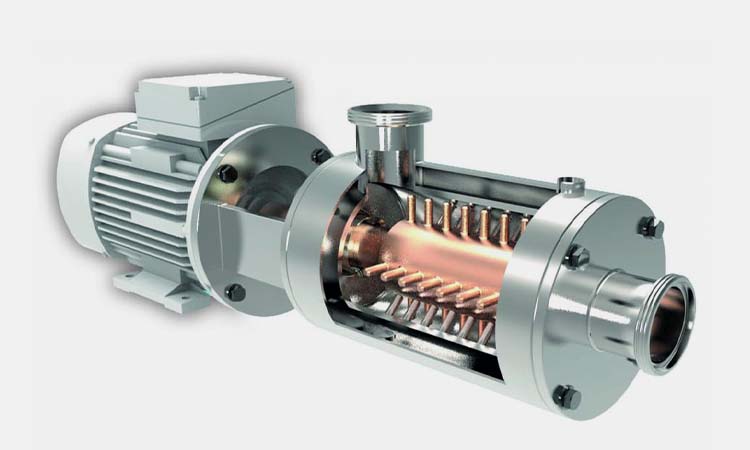

Inline high shear mixer granulator

Inline High Shear Mixer Granulator-Sourced:ace-chn

Inline high shear mixer granulator is also reliable and efficient in mixing and shearing work. It makes the flexible work in mixing various powder and liquid. This equipment is flexible and can make the consistent mixing for your business. It can also be applied for the mixing, degrading and dispersing solids.

Lab high shear mixer granulator

Lab High Shear Mixer Granulator-Sourced:prismpharmamachinery

Lab high shear mixer granulator is suitable for the manufacturing of small scale work and lab investing. It is economical and efficient and can provide the outstanding work for your material. Lab high shear mixer granulator has also different size and type for your different work.

6.What Is The Manufacturing Process Of High Shear Mixer Granulator For Chicken Essence?

The manufacturing process of high shear mixer granulator for chicken essence isn’t complex. And here you may check the manufacturing process.

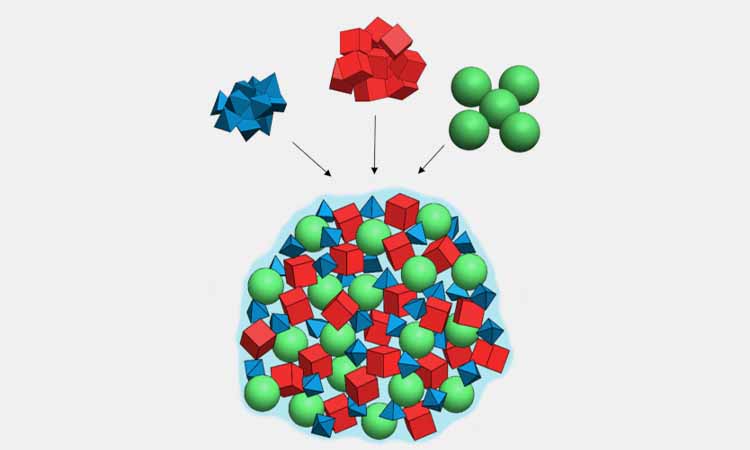

Material preparing

Material Preparing-Sourced:organicspices

Material preparing is the first step of your high shear mixer granulator for chicken essence. You should make sure the high quality and cleaning of your material which is the base for your later mixing and granulating work. Your material should be prepared according to your chicken essence formulation.

Mixing and granulating

Mixing and granulating-Sourced:virosiusputra

After the filling of raw material in high shear mixer granulator, it is then time for mixing and granulating. High shear mixer granulator makes the mixing and granulating for your chicken essence. You may adjust the rotating speed and frequency for the reliable mixing and granulating.

Binding adding

In the mixing and granulating of high shear mixer granulator, you would better to add binder solution for the agglomerates of your raw powder material. You may apply nozzle for the even and uniform spraying of binder solution for your material. The even and consistent binder adding can make the even adding and avoid the agglomerate.

Loading and drying

The last step pf high shear mixer granulator is loading and drying. While your granules are formed from machine, it will be transferred to the milling room and crushed to the smaller and even size. As it applies binding solution in the process, you would make drying for your products for the later reliable and great storing.

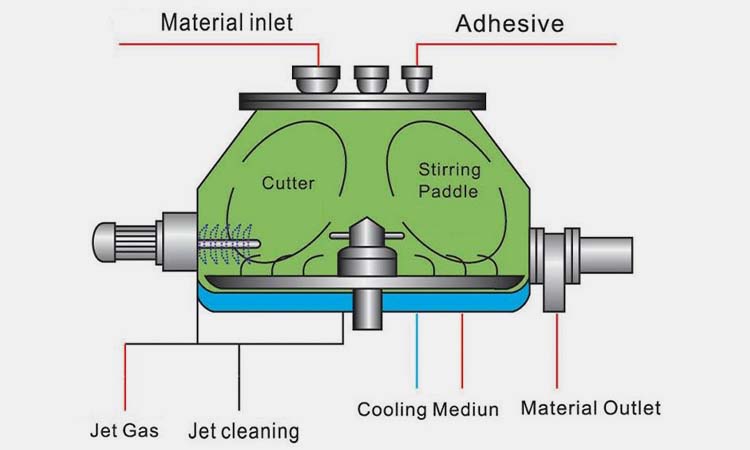

7.What Are The Components Of High Shear Mixer GranulatorFor Chicken Essence?

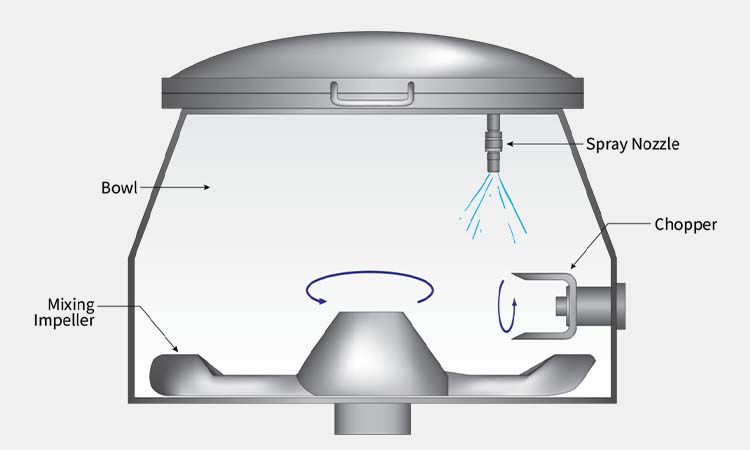

High shear mixer granulator for chicken essence is not a complex machine. And here are the main components of high shear mixer granulator for chicken essence.

Mixing impeller

Mixing Impeller-Sourced:fluidairinc

Mixing impeller is the component which makes the major mixing work for your chicken essence. There are different mixing impeller and different impeller type. Here you may find axial flow and radial flow for the high shear mixer granulator for chicken essence. It makes the efficient and great mixing job here.

Mixing bowl

Mixing Bowl-Sourced:romaco

Mixing bowl is the container where mixing happens. You may change its size and type according to your business need. The mixing bowl is mostly cylindrical which is suitable for the batch blending and mixing. It is sleek and qualified for your chicken essence manufacturing.

Multiple chopper

Multiple Chopper-Sourced:syntegon

Multiple chopper is a container which equipped with multiple blade for the degrading, emulsifying and dispersing material. You may also adjust the number of blade for the efficient and suitable chopping of your material. This part can make the fine powder which can be degraded from large lump.

Discharge unit

Discharge Unit-Sourced:lkpharmamachinery

Discharge unit is the part which can discharge your material from the high shear mixer granulator. It is usually on the low part of your cylinder which is suitable for the discharging of your material. You may corporate it with other equipment for the consistent and hygienic powder transporting.

Motor

Motor is the place which is irreplaceable for the manufacturing of your high shear mixer granulator. Without it, there will be no motive for the manufacturing process. You may also choose the size and type of your motor for the efficiency of your high shear mixer granulator.

Spray nozzle

Spray Nozzle-Sourced:freundglobal

As mentioned above, spray nozzle is applied for high shear mixer granulator for chicken essence manufacturing. It helps the binder applying on your chicken essence. Sprat nozzle can spray liquid on machine rather then material for the even and uniform spraying work.

Control system

AIPAK Control System

Control system is the place which can link you and your high shear mixer granulator. It is usually made of LED screen and touch screen. From it, high shear mixer granulator can perform your instruction for the different mixing and granulating work.

8.How Does High Shear Mixer Granulator For Chicken Essence Work?

How does high shear mixer granulator for chicken essence work? Do you know the working process of your high shear mixer granulator for chicken essence?

How Does High Shear Mixer Granulator Work?

Powder mixing

With powder flow into high shear mixer granulator, it then gets into the mixing bowl. The blades of high shear mixer granulator will make the even and uniform mixing and blending for your various raw material.

Binder adding

After mixing, there comes to the next step of granulating. High shear mixer granulator will add binder automatically for the granulating process. This process happens also in the cylindrical cabinet. Binder makes the tight connects of different powder materials.

Powder wetting

Powder wetting can make the soften for your powder material for the better and easier mixing and granulating process. This process applies spray nozzle for the even and uniform wetting.

Powder granule forming

The next step of high shear mixer granulator is to form and densify the powder granules. The well formed powder and granules need to be dried for the stable and robust feature. This step is one of the most important step for your high shear mixer granulator manufacturing work.

Powder crushing

The last step of high shear mixer granulator is to crush your powder and granule for the more even and uniform particle size and so on. The crushing part of high shear mixer granulator can make the great crushing job here.

9.How To Select The High Shear Mixer Granulator For Your High Qualified Chicken Essence?

In current market, there are high shear mixer granulator of different brand and types. The reliable machine can benefit you in a comprehensive way. And here is the guide for you to select the high shear mixer granulator for you.

Stainless steel material

Stainless Steel Material-Sourced:senieer

High shear mixer granulator should apply stainless steel material. This is the prove of your high qualified and stable high shear mixer granulator and also the prove for the safety and hygiene for your material applied.

Fine polishing

For the great cleaning of your high shear mixer granulator and the safety of the material in machine, you should make the fine polishing for your high shear mixer granulator which has no dead corner or welding slag.

Nice sealing

Nice Sealing-Sourced:fluidairinc

You should test the sealing of the high shear mixer granulator for the quality of bearing. The nice sealing can prove the airtight and hygienic manufacturing for your material. For food and products with high standard on sanitary, nice sealing of machine is essential.

10.What Problem You Should Care For The Choosing Of High Shear Mixer Granulator For Chicken Essence?

For high shear mixer granulator for chicken essence, you should care the below problems for the better quality of your products and smoother machine performance.

Chicken essence shape

Chicken Essence Shape-Sourced:haojifood

The neat and uniform chicken essence shape is the show of high qualified chicken essence products. In your selection of high shear mixer granulator, you should pay attention to the the uniform and spherical shape the machine can make for your products.

Chicken essence solubility

Chicken Essence Solubility-Sourced:tastingtable

Solubility makes affect for your chicken essence applying. For the ideal applying of chicken essence, you should make the most suitable solution for your chicken essence. Chicken essence solubility also show the special feature of your products. The high shear mixer granulator which can make the suitable solubility for your chicken essence is the great machine.

Chicken essence formulation and composition

How about the formulation and composition of your chicken essence. For different formulation and composition, you should also make the careful selecting of high shear mixer granulator. Thus, you should consider it in your selecting of machine for the high qualified and great taste chicken essence.

11.What May Affect The Work Of High Shear Mixer Granulator For Chicken Essence?

In the manufacturing of high shear mixer granulator for chicken essence, there may exist some problem. Here are the factors which may affect the work of high shear mixer granulator for chicken essence.

Formulation variables

Different formulation makes different chemical feature and different affect for your mixing and granulating process. The shearing and crushing of your chicken essence agglomerate makes affect for your final particle quality. Formulation variables should thus be considered seriously.

Physical properties

Physical Properties-Sourced:aces

Physical properties are also the key feature you should consider for your high shear mixer granulator for chicken essence. There are different particle size which can affect the work of high shear mixer granulator. The larger size takes more time and smaller size takes less time.

Binder material

There are different binder type and you may choose the binder according to the different chemical feature and different chicken essence request. The suitable binder can make great agglomerate and the unsuitable one makes the bad agglomerate which may lead the bad performance of your particles.

12.What Machines You May Corporate With High Shear Mixer Granulator For Chicken Essence Production?

For the high efficient manufacturing, you may corporate with other machine with high shear mixer granulator for chicken essence production.

Vibratory sifter

AIPAK Vibratory Sifter

Vibratory sifter is the machine which is applied to make the sifting and sorting of various kind of powder materials. It can separate, scalp and grading the material of different type and kind. For your manufacturing of chicken essence, you should first make the reliable sifter machine for your even and uniform products for further manufacturing.

Binder Preparation System

Binder Preparation System-Sourced:pinnacle-ssequip

Binder preparation system makes the great preparing for the binder. Binder is applied for chicken essence manufacturing process as above mentioned. Binder is made from primary binding material, additives and so on. Binder preparation system makes the preparing for your further chicken essence manufacturing work.

Vacuum Loader

Vacuum Loader-Sourced:ptonline

The material you prepared for chicken essence manufacturing is so fine that you may apply the special equipment for the material transporting and loading. Vacuum loader is the equipment which collect the fine material to the next equipment or container. It proves the hygiene of your products.

Fluid Bed Dryer

AIPAK Fluid Bed Dryer

Fluid bed dryer is the machine which is widely applied for food industry, pharmaceutical industry, chemical industry and so on. You may apply it for the drying, granulating and coating for your powder and granule products.

Oscillating Granulator

ALLPACK Oscillating Granulator

Oscillating granulator is the kind of machine which is applied for wet granulating. It can granulate the wet powder into the suitable particle size. For large lump products, sensitive products and fine powder, it can make the great job in manufacturing great powder and particle products.

Low-Shear Blender

Low-shear Blender-Sourced:continuous-mixing

Low-shear blender can make the less power to your powder material which reduces the risk of attrition, abrasing or heating. It makes the great blending and mixing with little hurt for your products feature.

CIP System

CIP System-Sourced:barisonindustry

You should equip CIP system for the whole chicken essence manufacturing process. CIP system has the full name of clean-in-place system. Without disassembling the whole process, you may apply the CIP system for the reliable and total cleaning of the various machines in your chicken essence manufacturing process.

Conclusion

How much you know about high shear mixer granulator for chicken essence now? As the most important machine for the manufacturing of chicken essence, you should have a comprehensive understanding of it for the benefit of your business. If you want to know more about high shear mixer granulator, come on and contact AIPAK now.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine