Eye Drop Filling And Capping Machine:The Complete Buying Guide In 2025

Eye drop is the common use for our modern life. You may get the eye drop for people of different age and pets of different kind. The various kinds of eye drop cannot leave a professional machine for the product packaging work. Do you want to have a deep knowing about eye drop filling and capping machine?

How dose eye drop filling and capping machine work? What machine can eye drop filling and capping machine corporate with? How to maintain and clean your eye drop filling and capping machine? What are the common problem and relative solution of eye drop filling and capping machine? Here please come to the reading!

1.What Is Eye Drop Filling And Capping Machine?

Eye Drop Filling And Capping Machine-Sourced:groninger-group

Eye drop filling and capping machine is the machine which is used for the filling and sealing of small bottles or vials for eye drop use. This equipment is efficient in making the sterile and aseptic filling of solution for the safety of customers. You may also apply your eye drop filling and capping machine in the packing of ear drop and so such products.

Eye drop filling and capping machine can make the precise and efficient filling and capping of your eye drop. It can make several work in a time and make the automatic operation for your eye drop filling work. You may also corporate your eye drop filling and capping machine with other products for the more efficient work here.

2.What Industry Can Eye Drop Filling And Capping Machine Be Applied?

What industry can eye drop filling and capping machine be applied? Here are the industries the eye drop filling and capping machine usually applied.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:aptar

Eye drop filling and capping machine is widely used in pharmaceutical industry. Besides various eye drop products, you may also get the eye drop filling and capping machine applied for the tincture, syrup and other various pharmaceutical products. You may find the various liquid medicine solution packed by this machine.

Food industry

Food Industry-Sourced:ameft

Food industry has various liquid which requires the efficient and careful packaging work. And you may find the wide applying of eye drop filling and capping machine for the filling and capping of fruit juice, sauce, seasoning products and so on. The food can have the safety and cleaning proved here.

Cosmetic industry

Cosmetic Industry-Sourced:nytimes

Cosmetic industry applies eye drop filling and capping machine for the filling of various personal care products. Eye drop filling and capping machine can pack shampoo, conditioner, lotion and toothpaste. This machine can make sure the the hygiene of your products.

Chemical industry

Chemical Industry-Sourced:solimix

There is a wide range of products in chemical industry and you may find the applying of eye drop filling and capping machine for the packing of cleaning agents, lubricants and other chemical products. For many chemical products, there is the need of pack liquid solution by eye drop filling and capping machine.

3.What Are The Advantages Of Eye Drop Filling And Capping Machine?

What are the advantages of eye drop filling and capping machine? And here are the reasons you have to get it.

High productivity

High Productivity-Sourced:simplilearn

Eye drop filling and capping machine makes the high productivity which makes thousands of bottle filling and capping in short time. High productivity is the save of your energy and cost. The higher efficiency and productivity is the prove for your business making money.

Enhanced precision

Eye drop is the product which takes great concern on accurate dosage. Eye drop filling and capping machine can make the accurate filling and capping of your eye drop products. The accurate filling amount shows the high quality of your eye drop products and reduce the risk of product trouble.

Quality prove

Quality Prove-Sourced:topclassactions

Eye drop filling and capping machine can prove the quality of your eye drop products with accurate filling amount, sterile filling work and tight capping work. You may have the quality of your eye drop products proved here in eye drop filling and capping machine.

High sterility

With least intervention of human, you may have the less labor cost and better hygiene prove. The reduced human intervention refers to products hygiene prove. Your eye drop filling and capping machine makes the strict control of hygiene and sterility with the outstanding cleaning system in it.

4.What Types Of Container Can Eye Drop Filling And Capping Machine Handle?

What types of container can eye drop filling and capping machine handle? Here are the different types of containers for your eye drop products.

Material

Material-Sourced:taisei-g

For eye drop bottle of different material like plastic or glass, eye drop filling and capping machine can all handle. For different plastic material like PET or HDPE, eye drop filling machine and capping machine can all handle. You may change the parts of your machine for the avoiding of damage or instability of your products.

Shape

Shape-Sourced:behance

Eye drop filling and capping machine can of course handle various shapes of bottle. The round eye drop bottle is the most common one and you may also find bottle with different shape from square, oral and so on. You should also change the relative parts like custom-fitted guide or pucks for the better product producing.

Size

Size-Sourced:tradeindia

For different eye drop bottle size, you may adjust the parameter for diameter and height for the smooth manufacturing process. You should also adjust the guide rail and nozzle height for the smooth manufacturing of your eye drop size of different size. And the adjusting can also prevent the splashing or dripping in the filling process.

5.What Are The Main Types Of Eye Drop Filling And Capping Machine?

What are the main types of eye drop filling and clapping machine? Here are the main types of it. Welcome to check it.

Semi-automatic eye drop filling and capping machine

Semi-automatic eye drop filling and capping machine is usually applied for the small scale eye drop manufacturing business. There is the human intervention in the manufacturing process of putting eye drop bottle and taking out eye drop bottle. And for the filling and capping work, semi-automatic eye drop filling and capping machine is automatic.

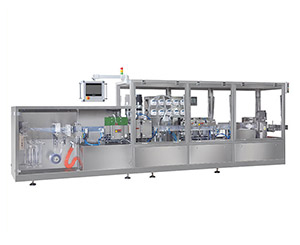

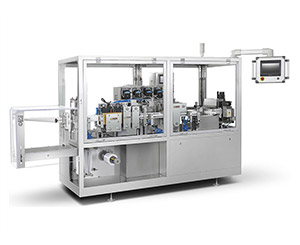

Automatic eye drop filling and capping machine

AIPAK Automatic Eye Drop Filling And Capping Machine

Automatic eye drop filling and capping machine saved your energy in putting in bottle and taking out bottle. Your fully automatic eye drop filling and capping machine can make the one-stand work in eye drop filling and capping. It is the ideal selection for the large production as it improves efficiency in a comprehensive way.

6.What Are The Main Parts Of Eye Drop Filling And Capping Machine?

What are the main parts of eye drop filling and capping machine? Here comes to get the main parts.

Control panel

AIPAK Control Panel

Control panel is the part which connects you and your eye drop filling and capping machine. You may send your direction and parameter adjusting in control panel for the machine manufacturing work adjusting and so on. It is usually a touch screen which help make the convenient connecting of you and your machine.

Electric system

Electric system is the place where you may have the power give to your eye drop filling and capping machine. Without it, there is no motive of your eye drop filling and capping machine and no move for the eye drop filling and capping machine.

Unscrambling system

AIPAK Unscrambling System

Unscrambling system is the part which can help arrange the bulk bottle in line. It makes the preparation for the next filling step. Unscrambling system makes the prove of the arranged and neat producing line.

Conveyor system

AIPAK Conveyor System

Conveyor system makes the connection of the various parts of your eye drop filling and capping machine. The well designed road of your conveyor system help make the efficient and safe conveying of your products for the next step. It makes sure the suitable link and container moving.

Automatic sensor

Automatic sensor is the part which check the right place of your eye drop bottle before you have the filling system filled them in. The automatic sensor makes sure the right place of your eye drop bottle and reduce the waste of your eye drop materials. It can thus improve the efficiency and reduce cost.

Filling system

AIPAK Filling System

Filling system in eye drop filling and capping machine makes the accurate filling of your eye drop solution in your eye drop container. Feeding nozzle of filling system is the important filling part which can prove the precise and careful filling.

Capping system

Capping System

Capping system can make the reliable and strict capping of your various eye drops. Capping system can make sure the no leaking of your eye drop solution and make sure the vacuum condition of your container. There are well being hood gadgets, cap setting gadgets, cap in-feed containers and such parts as the important parts of capping system.

Bottle rejection system

Bottle rejection system can make the careful inspecting of your eye drop products. For any defects of them, bottle rejection system will make the quick reaction to reject the container. After bottle rejection system, you may get your well qualified eye drop products out your eye drop filling and capping machine.

7.How Dose Eye Drop Filling And Capping MachineWork?

How does eye drop filling and capping machine work? Here are the manufacturing process of your eye drop filling and capping machine.

Manufacturing Process Of Eye Drop Filling And Capping Machine

Prepare

You should first make the preparation of your eye drop material sending, eye drop container sending, parameter setting and so on. In preparing, eye drop filling and capping machine will pre-orient the container position for the later better and more precise filling.

Unscrambling

After the sending of your empty bottle, you can then have the all bottles arranged in the beginning parts. The beginning parts of your eye drop filling and capping machine makes the neat sending of the various bottles. The conveyor belt makes the excellent work in transporting them.

Filling

After the preparing, you may then begin the filling work for your eye drop filling and capping machine. Your eye drop bottle can then be filled with eye drop solution. The precise work of eye drop filling and capping machine can make the precise and efficient filling. The micro-professor proves the accuracy of your air drop products.

Capping

After the filling of eye drop, you can then have your capping of the various eye drop bottles. You may have your eye drop sealed and closed with high efficiency. The capping process should be quick and correct for the prove of sterility of your products.

Quality control

Quality control is also the important step for your eye drop filling and capping machine. Your eye drop products will have the comprehensive check from sealing, accuracy, quality, hygiene and so on. Quality control is usually the last step of your eye drop filling and capping machine.

8.What MachinesCan Eye Drop Filling And Capping Machine Corporate With?

To improve the efficiency of your eye drop filling and capping machine, here are the machines you may corporate with your eye drop filling and capping machine.

Labeling machine

AIPAK Labeling Machine

Labeling machine sticks the label on the well-capped bottle for the brand signing. This is the way for the showing of products brand, main components and so on. The linking of labeling machine and eye drop filling and capping machine can save you great time.

Cartoning machine

AIPAK Cartoning Machine

For your well made eye drop products, you should put them in carton for the transporting and sale in market. Cartoning machine can make a series of work like folding carton, filling product in carton, sealing carton and so on. The final linking of cartoning machine with your eye drop filling and capping machine makes the last manufacturing step of the whole process.

9.What May Affect Your Eye Drop Quality From Your Eye Drop Filling And Capping Machine?

What may affect your eye drop quality from your eye drop filling and capping machine? You should check the below factors with great attention.

Machine condition

Machine Condition-Sourced:reliableplant

For different production scale and different product type, there is different need for machine condition. The machine with high automatic level reduces your need of labor intervention and makes the more efficient and precise filling work for your eye drop products. The higher efficient machine can deal with products with large production scale.

Liquid feature

How about your eye drop liquid? Different liquid feature affect eye drop product quality greatly. The different liquid viscosity, foaming and many features can all affect the quality of your eye drop products. The different liquid feature makes different affect for your eye drop filling and capping machine work.

Regulatory compliance

Regulatory Compliance-Sourced:ipleaders

For different place and location, there is different need about eye drop product quality and so on. Regulatory compliance affect your eye drop products manufacturing in a comprehensive way. You should conform to the local regulatory compliance for your eye drop products manufacturing.

Sterility manufacturing environment

Sterility Manufacturing Environment-Sourced:jgl

Sterility and hygiene affect your eye drop quality greatly. Your eye drop products should definitely be clean and safe. The manufacturing environment can make great affect for your products cleaning and hygiene. You should make deep cleaning for your machine and make careful manufacturing.

10.How To Maintain And Clean Your Eye Drop Filling And Capping Machine?

How to maintain and clean your eye drop filling and capping machine? You may make careful maintaining and cleaning for your products quality prove.

Regular inspecting

Regular Inspecting-Sourced:fieldinsight

You should make regular inspecting for your eye drop filling and capping machine. You would better make the preventative maintenance schedule for your eye drop filling and capping machine. Daily check, weekly check, monthly check and so on should be strictly performed for the maintaining of your eye drop filling and capping machine.

Lubricate the main parts

Lubricate The Main Parts-Sourced:thecarguys

You should also make lubrication for your eye drop filling and capping machine. Regular and suitable lubricating is great for the preventing of wear and tear and can make your eye drop filling and capping machine the more stable operation. You would choose the suitable cleaning agent and lubricating oil.

Operate machine in standard

Operate Machine In Standard-Sourced:vecteezy

You should operate machine in standard and this is the important step for you maintaining of your eye drop filling and capping machine. The right eye drop filling and capping machine operation is the best machine maintaining. The keeping of machine in suitable environment is also the thing you should conform.

Make deep cleaning

Make Deep Cleaning-Sourced:sunriseindustrial

You should make deep cleaning for your eye drop filling and capping machine. Disassembling, rinsing, washing and final rinsing, you should not miss one step of it. If required, you should also make the deep sanitization for your eye drop filling and capping machine. Make sure the total drying before you make the reassemble of the various parts.

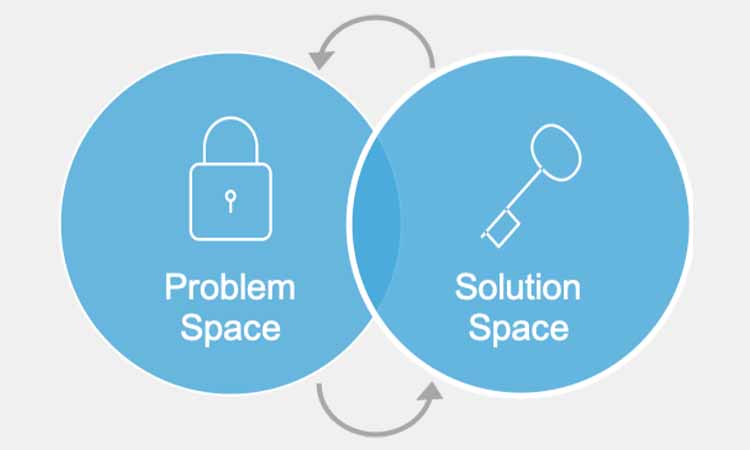

11.What Are The Common Problem And Relative Solution Of Eye Drop Filling And Capping Machine?

What are the common problem and relative solution of eye drop filling and capping machines? Here are the common problem and relative solution you should know.

Problem And Solution-Sourced:productfolio

| Problem | Solution |

| Inaccurate fill volumes | You should check the setting, products supply and nozzle. The right setting, consistent product supply and complete nozzle can avoid your inaccurate fill volumes. |

| Nozzles dripping | You should check nozzle seals, suck-back setting, pressure for the avoiding of nozzle dripping. The three steps can avoid most nozzle dripping. |

| Leaks | Products line or nozzle leak may cause spills and products waste. You should clean seals and gaskets and tighten loose fittings and connections. |

| Contamination | The lack or fail in machine cleaning may lead the contamination of your eye drop products. You should make the total cleaning of container, machine parts and whole machine parts for any contamination avoid. |

| Machine alarms | Your machine makes alarms for the violating of guards or code. You may check sensor, guard and relative manual for the advice and suggestions. |

| Clogs | Clogs may lead problem in accurate filling or even the problem of your machine. You should get any blockage and debris out of the system. The total cleaning of nozzle or products line is essential sometimes. |

| Electrical problems | Electrical system may lead the machine malfunction and shut down. You should make sure the linking of any wiring and connections. The checking of control panel and other electronic components can help you troubleshoot problems. |

| Fills are not level | Your liquid of eye drop may in wrong level for the machine slanting, wrong changeover space, changed fill time and filling nozzle blockages. |

| Excess foam in bottles | Excess foam in bottle may come from the rapid filling time or the wrong nozzle place. For the avoiding of excess foam in bottle, you may make adjust in these steps. |

12.What Are The Key Factor You Should Consider For Your Eye Drop Filling And Capping Machine Selection?

What are the key factor you should consider for your eye drop filling and capping machine selection? You should conform the below factors for your selection.

Production scale

You should assess your production scale for the selection of your eye drop filling and capping machine. According to your assessment, you may make the selection of the large scale production or small scale production.

Budget

Budget-Sourced:universalfunding

You should make the serious and deep consideration of your manufacturing cost for the getting of your budget to eye drop filling and capping machine. It may cost a lot for you to get the high qualified eye drop filling and capping machine. But it may make great profits for your high qualified products.

Accuracy and efficiency

Accuracy And Efficiency-Sourced:parascript

Accuracy and efficiency are the important standard for your assessing of your eye drop filling and capping products. It can make sure the products efficiency and completeness. It is the prove of your high qualified eye drop products manufacturing.

Hygienic standard

Your machine should conform to the strict hygienic standard and this is rather important for your eye drop products. You should make clear the various regulatory standard for the selection of your qualified eye drop filling and capping machine.

Reputation

Reputation-Sourced:mavagency

The great reputation of your eye drop filling and capping machine manufacturer is the important factor for your selection of eye drop filling and capping machine products. You should seek machines from the reliable eye drop filling and capping machine manufacturer.

13.What Are The Certification Requirements Of Eye Drop Filling And Capping Machine?

What are the certification requirements of eye drop filling and capping machine? Here are the regulatory you should know about eye drop filling and capping machine.

ISO standard

ISO Standard-Sourced:arenasolutions

You should make sure the conforming of your eye drop products of ISO 0991 and ISO 13485. This standard can make sure the quality and safety of your eye drop products. You should conform these standards for your manufacturing of your eye drop products.

CE certification

CE Certification-Sourced:sunfiretesting

For your eye drop products sales in European area and countries, you should make sure the getting of your CE certification. CE certification helps the conforming of the health and safety measures of your products. Your eye drop filling and capping machine should conform the standard for the smooth distribution.

FDA

FDA-Sourced:digicomply

The conforming of FDA standard refers to the conforming of quality protocols for your producing and packaging of your eye drop products. You may have the quality and safety proved in your eye drop filling and capping process.

GMP standard

GMP Standard-Sourced:ebbecke-verfahrenstechnik

GMP standard has the full name of good manufacturing process which ensures the smooth production of your eye drop products. It makes the strict regulation for products in various manufacturing process. It is the essential standard for your medicine products manufacturing.

Conclusion

Do you still have question or problem about eye drop filling and capping machine? You may have your most questions solved here in this post. And if you have any problem or question, you may feel relaxed to contact AIPAK now. Waiting for your any consult about eye drop filling and capping machine.

Don't forget to share this post!

Eye Drop Filling Machine Related Posts

Eye Drop Filling Machine Related Products

Eye Drop Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours