Detergent Powder Filling Machine: The Complete FAQ Guide In 2025

Have you ever thought, when you toss a detergent powder in washing machine, how accurately it was filled? All packets or sachets of detergent powder is filled with accurate volume. There is a game changer machine behind it- Detergent powder filling machine. The automation, precision, accurate powder weighting and many more features can you get with detergent powder filling machine.

Are you looking for types in this filling machine? Don’t you worry- detergent powder filling machine is available in different types and you can invest in them according to your budget. In these advanced filling machine, you will equip with different features such as fast changeover, auto-adjustable filling nozzle etc.

If you are owning a detergent brand and want to upgrade filling line or want to know how these machine work, structure, latest technology etc., you are welcome to this FAQ guide of AIPAK. Let’s have a look.

1.What is detergent powder?

Detergent powder

Detergent powder is dry cleaning product that is used to clean and remove dirt, stain and debris from cloths and other fabrics. Different ingredients such as brighten agent, surfactants, enzymes and other supporting agents are mixed together in its formulation. Due to its cleaning power, easy-to-use, and cost-effectiveness, it is widely used in household and commercial fields.

2.What do you mean by detergent powder filling machine?

AIPAK detergent powder filling machine

Detergent powder filling machine is designed to fill different containers, pouches or sachets from detergent powder. It can accommodate different detergent powder from fine powder to granules. The precision and accuracy are unmatchable- fast speed and rapid change over between batches are the main features of this filling machine. These qualities enhance productivity, efficiency, uniform weight and hygiene handling of this powder. This machine comes in latest technology with AI technology that can be fruitful to production line.

3.What benefits does a detergent powder filling machine add to your business?

Investment in right filling machine is necessary. Reason? Because the production capacity and brand image of detergent powder all depends on the filling machine. This is where a detergent powder filling machine does the whole process neatly and precisely. Following below are the benefits this filling machine can add to your business.

Consistent filling

Consistent filling-picture courtesy: makwell.com

In automated filling system, detergent powder can accurately fill in containers with same weight of each pouch, sachets or cans. There is less chances of powder loss. While product loss is aligned with manually filling of detergent powder. It improves customers satisfaction and quality control.

Increase product efficiency

Increase product efficiency-Picture courtesy: zonesuntech.com

Are you looking for a machine with less or no down time? Detergent powder filling machine fulfills your dream to enhance production efficiency of your business. Due to automation process, it can fill hundreds or thousands of packets with minimal down time. It can meet large-scale demand in less time.

Adaptability

Adaptability

Do you know this machine can handle different materials? One of the best features is that it is adaptable. It can suit to your different need; different materials, packaging styles. This machine adds advantage to the business with handling of different product.

Reduce labor cost

Reduce labor cost-Picture courtesy: Bridgit bench

Another benefit it adds to your business is reduces labor cost. Most of task it operates are automated. There are fewer manual tasks with less chances of human error. So, there are less need of operators and this reduces labor lost.

Scalability

Are you a small-scale manufacturer but thinking to buy another filling machine to upgrade the business? Detergent powder filling machine equates with your business expansion need. You can increase the production capacity without jump to new filling machine or to change the system. You can easily upgrade the machine by integrate it with other machines.

Product safety

Product safety-Picture courtesy: etsy.com

Product safety is the main concern of manufacturers. They cannot compromise in product quality as it can degrade their product quality and image. Detergent powder filling machine fits in here. It provides supportable stainless-steel parts and enclosed environment that protect the detergent powder from humidity and dust, as it needs to be dry. It maintains hygienic standard of detergent powder.

4.Do you know applications of detergent powder filling machine?

This powder filling machine is known for its accuracy and precision. Hence, different industries which you will learn about them below also use this machine. These industries carry on their task with this machine because here powder handling with hygienic compliance standard is necessary. Hence, its application extends beyond household detergent industry. Let’s know about them.

Household industry

Household industry

Detergent powder filling machine is commonly used in household industry. In household cleaning products, a stable volume and weight is necessary. If one pack has less volume and other has high and both carry same cost, it can break customer trust. So, this filling machine is used to fill different laundry agents, dishwasher powder or other powdered cleaning agent in packets or sachets with accurate volume.

Pharmaceutical industry

Pharmaceutical industry-Picture courtesy: cphionline.com

As you know that pharmaceutical products also come in powder form. So, to fill them in consistent quantity, detergent powder filling machine uses in pharmaceutical industry. It uses its high precision filling system to fill powder medication or supplements. It ensures strict hygiene and accurate filling.

Cosmetic industry

Cosmetic industry

This filling machine is also applicable in cosmetic industry. Cosmetic products also come in powder form such as compact powder, facial cleaners etc. Detergent powder filling machine is used to fill them in their desired containers.

Chemical industry

Chemical industry-Picture courtesy: vettertec.com

Chemicals also come in powder form in market. Their filling process is carried out by this machine. As these chemicals require corrosive free, explosion proof and contamination free environment, thus, these features are present in this machine. Hence, it is best suited with chemicals, and used in chemical industry.

Food industry

Food industry-Picture courtesy: rookiewellness.com

Your food also come in powder form such as coffee powder, dry milk, baking powder, protein powder, salt or any spices. A detergent powder filling machine is applicable in this industry because precision and accurate dosing is also needed in food products. And also, it complies with food standard practices.

Agriculture industry

Agriculture industry-Picture courtesy: katyayaniorganics.com

Another industry where this filling machine shows uniqueness of dosing system. Agriculture products such as fertilizer, pesticides etc. are filled in desired containers according to cost of product.

5.How to ensure accurate volume and weight by detergent powder filling machine?

If you are fed up from product spillage and inaccurate volume across the containers that affect brand reliability, then don’t worry. Detergent powder filling machine ensures accurate volume and weight. Inaccurate filling can result in product lost. So, following practices should you follow to ensure accurate volume and weight.

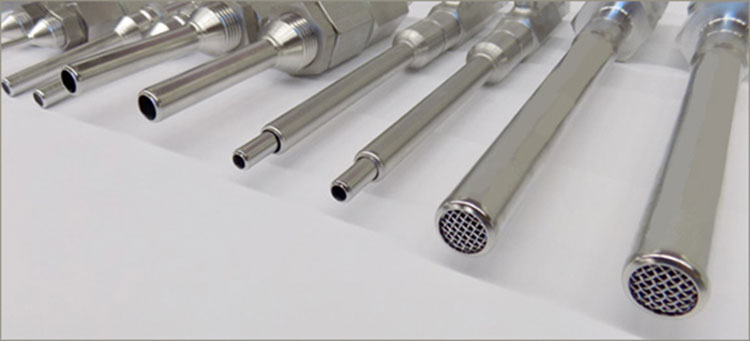

Proper feeding design

Proper feeding design-picture courtesy: deloro.com

Feeding design plays a crucial role in powder dispensing as it impacts flow of detergent powder. You should design feeder in such way that supports steady flow of powder. And yes, most importantly, there should be agitator to avoid powder clumps

Advance filling mechanism

It has advanced filling system such as volumetric and gravimetric filling. These are ideal for products where accurate weighting and volume is important. Volumetric filling measure volume and gravimetric filing system measures weight of detergent powder. Due to these mechanisms, it is highly demandable for precision and consistent quantity.

Sensors and controlled system

Along with above filling mechanism, there are sensors that detect volume and weight of detergent powder. Time-to-time, it checks volume and weight of powder’s packets and pouches. In case of improper filling, it would detect them.

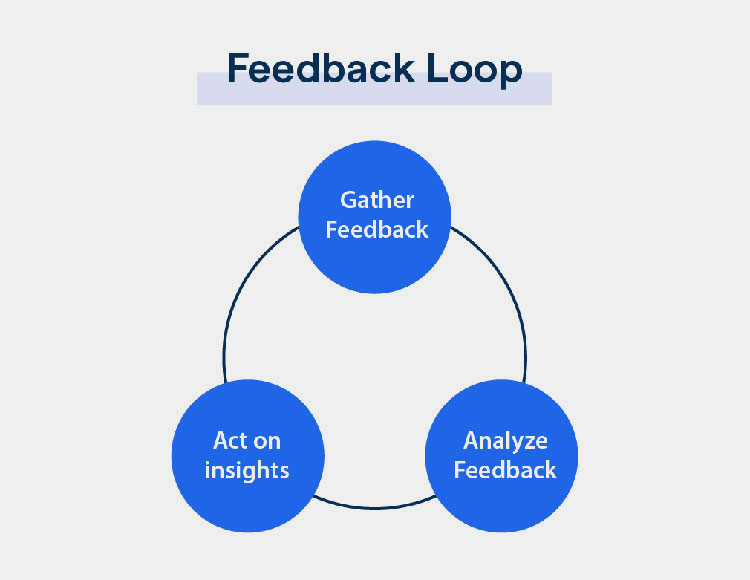

Real-time feedback loops

Real-time feedback loops-Picture courtesy: botpenguin.com

There are very rare cases of down time in detergent powder filling process. Know the reason? After each pack filling, weight and volume is measures. If these deviate from preset target, it will automatically adjust it for the coming filling containers. So, it does not disturb the production line.

Know powder characteristics

Know powder characteristics-Picture courtesy: wepack.com

Powder can be varied in size, density and flowability. So, knowing physical characteristics of detergent powder is necessary because inconsistent powder qualities can result in inaccurate filling. Use high quality homogenizer to avoid variation in particle size.

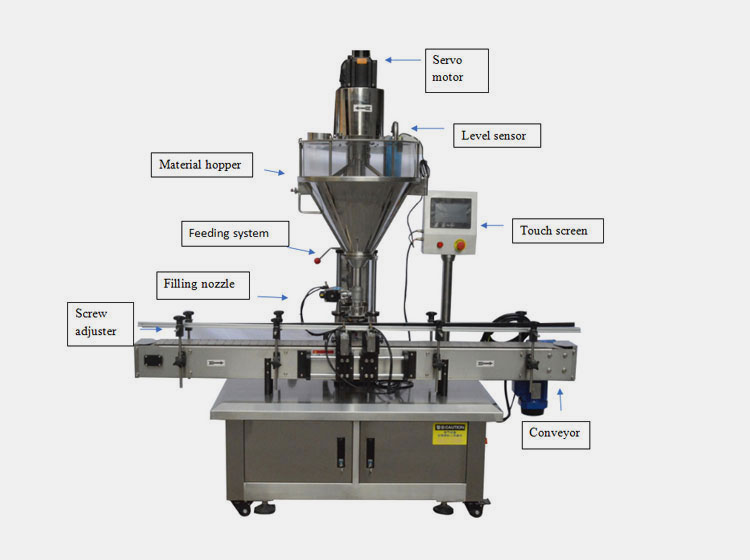

6.What is the structure of detergent powder filling machine?

Following below is the structure of detergent powder filling machine.

AIPAK detergent powder filling machine

| Components | Explanation |

| Servo motor | This is designed to control auger movement during dispensing of detergent powder. It ensures accurate and precise filling without facing problem. This motor can handle different detergent powder with smooth operation. |

| Material hopper | This is the component where filling process initiate. In material hopper, detergent powder is loaded for filling. Some hopper has agitator to avoid clumps of powder, and it is designed in such way to ensure smooth and direct flow. |

| Feeding system | With help of feeding system, auger screw, the loaded powder is moved from hopper to filling station. |

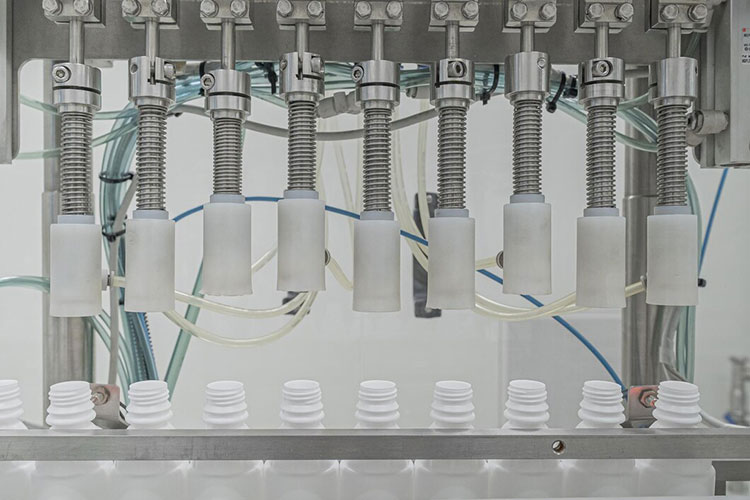

| Filling nozzle | In filling nozzle, detergent powder is dispensed into plastic bags, bottles or sachets. It is designed in such to minimize spillage and is controlled by touch screen to operate filling accurately. |

| Screw adjuster | By adjusting this component, powder flow can be controlled. Fill volume and weight can be controlled by screw adjuster. |

| Level sensor | Level sensor is installed beside hopper. This detects level of detergent powder in hopper. If level increase or decrease from certain point, it will alarm. This helps in avoid downtime in production process. |

| Touch screen | Touch screen is the central control system. You can say it is the brain of detergent powder filling machine. Parameters such as speed, filling volume, packaging options and others are managed through this screen. Any fault in it can compromise the process. |

| Conveyor | This is the transport channel. It helps to set containers right under filling nozzle and also adjust them in sequence when loaded. It can also be adjusted in term of speed and machine layouts. |

7.What is the working principle of detergent powder filling machine?

Detergent powder filling machine ensures precision and hygienic standard in filling process. This process is not one step process but it involves different steps. Let’s know the working principle of this filling machine.

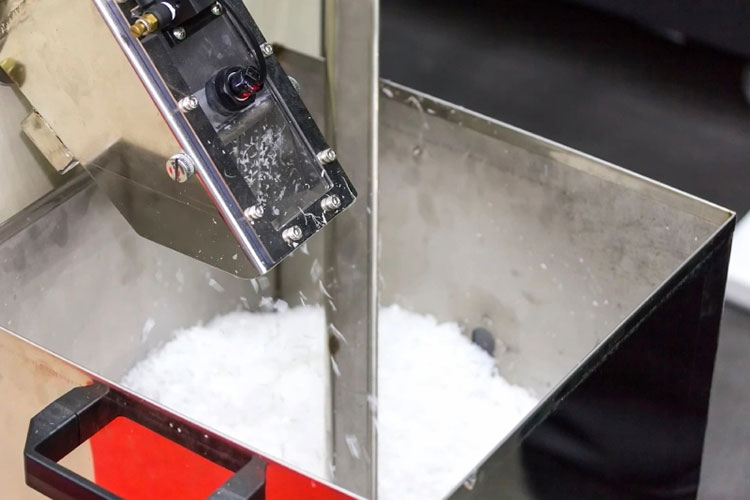

Powder loading

Powder loading

The filling process begins with loading of detergent powder in hopper. This is made of stainless-steel chamber that store powder and prevent it from moisture, microbes and humidity. This storage bin ensures a smooth flow of powder for further process.

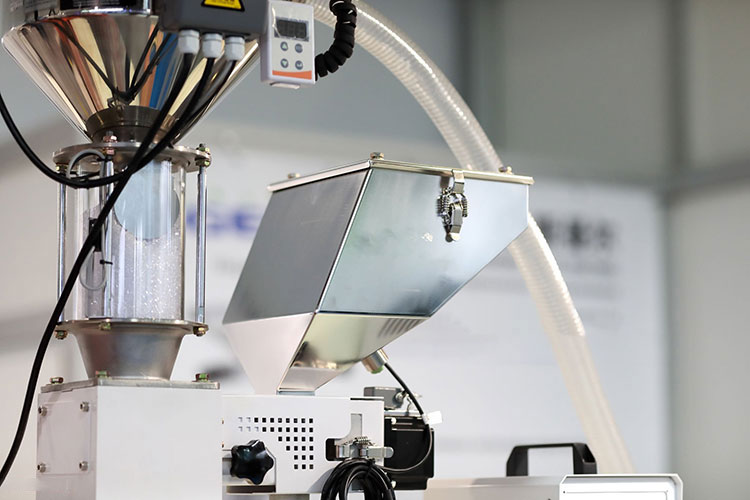

Feeding mechanism

Feeding mechanism

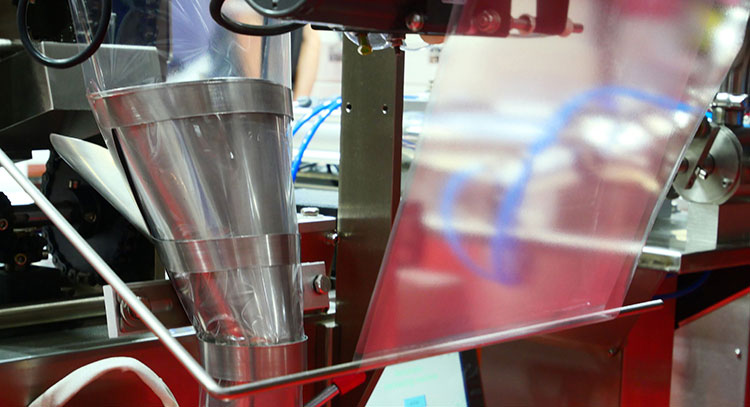

After loading of powder in hopper, the next step is to move the powder from hopper to feeding system. This system controls powder flow from hopper to filling unit. The flow is adjusted with help of sensor. There can be auger screw or vibrator tray that ensures free-flowing of detergent powder to the measurement system.

Powder metering

Powder metering

Containers are not filled simultaneously. For this, there are system such as volumetric system and weighting system. Before filling, powder is measured, how much powder should be dispensed in each packaging options. This ensures consistent quantity throughout the batch.

Containers positioning

Containers positioning

Before powder dispensing, conveyor loaded pouches, bottles or sachets are positioned under filling nozzle. There are sensors that detect position. If not on the right place, it will pass signal to avoid spillage.

Filling

Filling

Once container is positioned, the next process is of filling. Detergent powder is filling in desired containers through filling nozzle. There are less chances of overfilling and underfilling as target is adjusted in machine. This step needs attention as slight error can cause big issue.

Discharge

Discharge

The filled containers are discharge through conveyor for further processes such as sealing, labeling and cartoning. This filling machine ensures to repeat the cycle again with no cut-down.

8.What are the available types of detergent powder filling machine?

There are various types of detergent powder filling machine. Each is designed for specific packaging format, production need. Here below are the division of detergent powder filling machine.

Followings are the types of this filling machine on the basis of automation level.

Semi-automated detergent powder filling machine

AIPAK Semi-automated detergent powder filling machine

This type of filling machine is ideal for medium size production line. You can get some level of automated task from this machine. In this machine, bottles, jars or sachets are manually placed but detergent powder is dispensed in these packaging automatically. The volume and weight are preset so powder is accurately and precisely dispensed. If you are scaling up your business, this is the best option.

Fully automated detergent powder filling machine

AIPAK Fully automated detergent powder filling machine

The entire process of filling is handled by this machine itself, from detergent powder loading to discharge. There is less human intervention and is integrated with sensors, dust control system and even in latest automated filling machine, there is AI integration. It is ideal for large scale production where accuracy, and high speed to meet large production line is the ultimate goal.

There is different filling mechanism. On the basis of filling mechanism, following below are types of detergent powder filling machines.

Auger detergent powder filling machine

AIPAK Semi-automatic auger powder filling machine

This type of detergent powder filling machine is suitable with fine powder. Do you know what system it uses to dispense powder? It uses auger system to dispense detergent powder in containers; can be bottle, doypack or sachets. Pre-metered volume is filled to ensure precise and standard quality filling with specific volume. You can use it in industries where precision matters a lot.

Volumetric cup detergent powder filling machine

Volumetric cup detergent powder filling machine-Picture courtesy: all-fill.com

From its name, you can guess its function. This filling machine uses pre-set cups to measure volume before filling. It is suitable for free-flowing powder and use where volume matters more than precision. If you compare this machine with above auger machine, then it is not as accurate as it. This machine is cost effective, fast and best for large scale production where production speed needs to be high.

Weighting detergent powder filling machine

Weighting detergent powder filling machine-Picture courtesy: afrimart.com

Weighting detergent powder filling machine delivers accurate weight. For this, there is electronic weight system to check weight of detergent powder. Before dispensing powder into containers, it is weighted. It gives best and accurate result in term of weight. This machine is ideal for industries where weight must be strictly maintained.

9.What is the packaging optioning a detergent powder filling machine handled?

A detergent powder filling machine can handle wide variety of packaging options. You cannot fill powder in only one packaging style; but can in diverse, depends on industry requirement and type of machine. Here below are the major packaging options it can handle.

| Packaging options | Explanation |

| Plastic bags

|

Detergent powder come in plastic bags that are made up of plastic material such as aluminum foil and PP. These come in various sizes, from small to medium. These eco-friendly bags protect this powder from moisture and air through its different layers. |

| Plastic bottles

|

Detergent powder filling machine handles plastic bottles for filling detergent powder. These are durable, enhance shelf life of powder by protecting from moisture or humidity. Come with flip-top and can be pour easily. |

| Stand-up-pouches

|

Detergent powder also comes in stand-up-pouches or doypacks. These can be stand on your shelf. Doypacks can effectively prevent detergent powder from environment factors to extend its shelf life. |

10.How to maintain detergent powder filling machine?

Maintenance of machine is necessary to ensures smooth and efficient production and operation. By following proper maintenance practices can reduce worn out of machine parts and increases shelf life of machine. Let’s explore practices you should follow.

Calibrate weighing system

Accurate filling is the core objective of detergent filling machine. But dispensing target volume with weight should not be compromised. Check weighting sensors or cell timely. During batch filling, you should test weight of some of the containers to remove any mishap.

Inspect fasteners and worn-out parts

Inspect fasteners and worn-out parts-Picture courtesy: lightmetalage.com

You should check out for fasteners; screws etc. Reason? Loosen fasteners can leads to inaccuracy due to unbalance and detachment of parts during filling. Tightened auger screws and belts. Inspect worn-parts as it can cause leakage and disturb filling process. Change worn-out parts as soon as possible to reduce risk of downtime.

Regular cleaning

Regular cleaning-Picture courtesy: filamatic.com

There is risk of clogging nozzle or other parts of machine. So, clean them after each batch to ensure contamination free filling of detergent powder.

Check control system

Check control system

Control system of detergent filling machine should be check properly. Because all the operations of machine are controlled by control panel. So, check for damaged wiring and connections. You should update your machine system to align with latest features.

11.What are the common problems and solutions of detergent powder filling machine?

Detergent powder filling machine can face problems in its operation. These problems can create inaccurate filling and compromise quality standard of powder. Following are the common problems and solutions of detergent powder filling machine.

Powder spillage

Powder spillage

| Common problem | Solution |

| Powder can lose due to leakage. When containers are not under nozzles, misalign, it results in powder waste and potential germs growth. | To solve this problem, tighten the nozzle and align nozzles. If possible, adjust anti-nozzles. |

Powder clumps making

Powder clumps making

| Common problem | Solution |

| When desire packaging options are filled from detergent powder, you may experience irregular powder flow. It can be due to clumps of detergent powder. This can result in inaccurate filling. | In order to ensure consistent flow of powder, there should be agitator in hopper to dissolve clumps. You should calibrate filling and feeding system with time. |

Jamming in machine

Jamming in machine-Picture courtesy: suntermachine.com

| Common problem | Solution |

| Reason behind jamming is detergent powder may stick to machine parts. It results in jamming, results in machine’s stop. | All you should do is to clean hopper. Check for other debris accumulation on machines’ parts and clean it immediately. |

Sensors malfunction

Sensors malfunction

| Common problem | Solution |

| There are sensors to detect containers when they are loaded by conveyor to detect their position. But sometimes, they are not working correctly, cannot detect plastic bags, or bottles under filling nozzle, leads to product wastage and spillage. | To solve the problem, check for breakdown of sensor wires. Test for sensors. If they are damages, replace it immediately. |

12.Can you tell what are the latest technology in detergent powder filling machine?

This detergent powder filling machine is made better by incorporation of latest technology. It not only makes the operation speed up but made it easy for manufacturers to have less labor cost. Here they are:

AI based system

AI based system

In 2025 modern machines, they are installed with AI based algorithm. Due to this technology, machines run itself with no error and human labor and do its operation immediately. Detergent filling machine adjusts filling and weight or volume of detergent powder and reduce material waste.

Dust control system

Dust control system

In modern version of this machine, there is dust control system. Means? It has dust extraction unit that extract dust produced by detergent powder in order to minimize contamination growth inside operation chamber.

Servo-motor system

Servo motor system

In modern detergent powder filling machine, there is servo-motor system that controls rotation and speed of auger. It results in accurate filling, and adjust speed according to physical feature of detergent powder and packaging options.

Smart sensors and robotic arms

Smart sensors and robotic arms

There are smart sensors that maintain health of filling machine. It detects moisture level, or heat. Due to these sensors, operators can check the machine via their PC and smart phones. For accuracy and working speed, there are robotic arms to load containers and to discharge them. In short, there is pick and place system in latest detergent powder filling machine.

Conclusion

To conclude this guide, you must have learned that detergent powder filling machine is used to accurately fill detergent powder. This machine is adaptable, can handle different packaging formats. It is not only applicable in house hold industry but you can also install it those industries where powder is handled. Different types of this machine are available, from semi-automated to volumetric cups and weighting filling machine. If you are looking for high quality machinery, you can visit our site. Thanks!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine