Foil Sealing Machine: The Ultimate Buying Guide In 2024

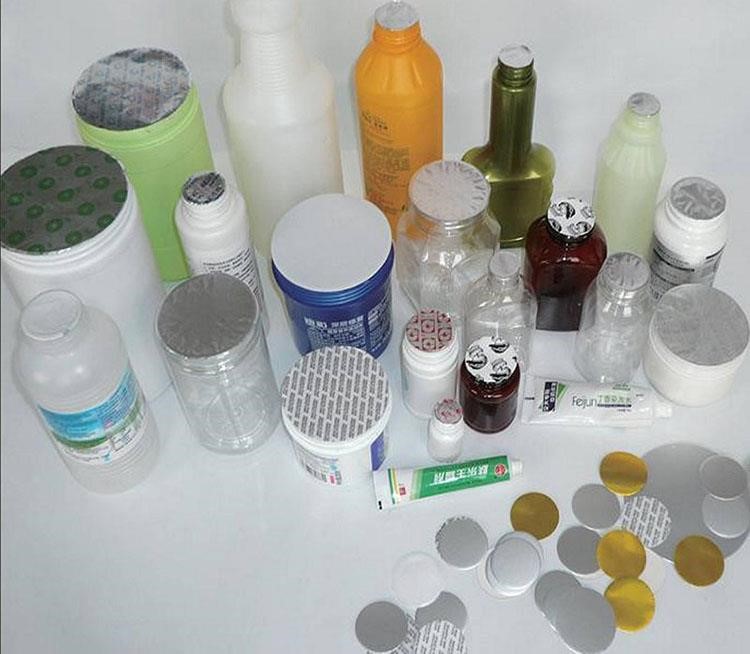

When you open cap of a bottle of milk, juice or petroleum products you will find a thin aluminum foil covering that can be removed by a slight tug of a finger. Have you ever wondered the purpose of that foil or how it was placed there in the first place?

The process is called as foil sealing of bottles and it is conducted by the use of foil sealing machine. Today foil sealing machine is widely used in food and dairy, petroleum and chemical, pharmaceutical and nutraceutical industry for sealing bottles/containers using thin aluminum foil around the neck with the application of high frequency magnetic field.

Use of foil sealing increases the stability of the packaged material, preventing contamination and spillage and ensuring freshness over a long period of time. If you open a bottle of orange juice or pills and you find an intact aluminum foil, rest assured the material inside is as new as it was on the day it was filled.

Flip Wilson clearly understands the idea when he says “you can’t expect to hit a jackpot if you don’t put few nickels in the machine”.Likewise, if you have decided to buy a foil sealing machine you have come to the right place. Bringing to you “Foil Sealing Machine The Ultimate Guide In 2021”.

At the end of the blog you will be able to recognize your requirements, fully updated in current market trends, expert in troubleshooting and technical specifications and ready for operations.

Become an expert in foil sealing machine. Let’s go!

1.What is the foil sealing machine?

Foil sealing machine- Picture Courtesy- Shjoylong Co., Ltd

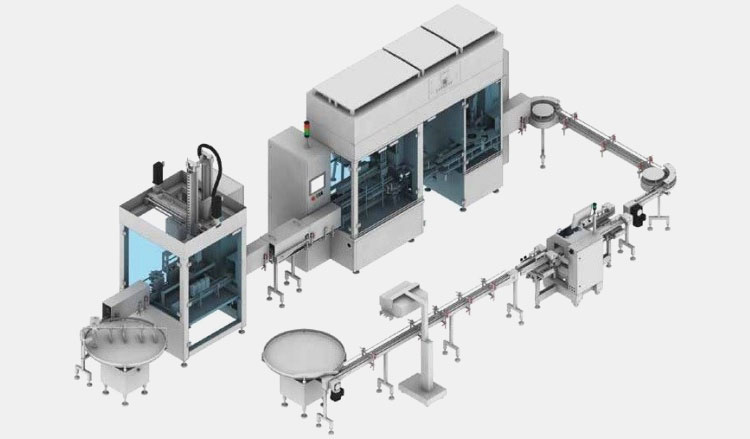

Foil sealing machine is a unique piece of instrument that gives you an advantage of sealing the neck of the bottles with thin air tight aluminum foil without touching the bottles in the first place. This protects the content from biological or chemical degradation processes as well as it prevents the leakage or spillage of the product. Foil sealing machine was invented by an engineer named Jack Palmer in order to prevent milk spillage from plastic bottles during shipment. Palmers’ invention became popular and now foil sealing machine is used in various food, chemical, dairy and pharmaceutical industries. Based on different versions, this machine can be attached or detached to other filling, packaging and labelling units to form a complete filling and packaging line. This machine is easy to maintain, with no problem in availability of accessories and parts. Furthermore, you can customize this machine based on your requirement and need and budget.

Complete packaging line- Picture Courtesy- Optima

2.What is the working principle foil sealing machine?

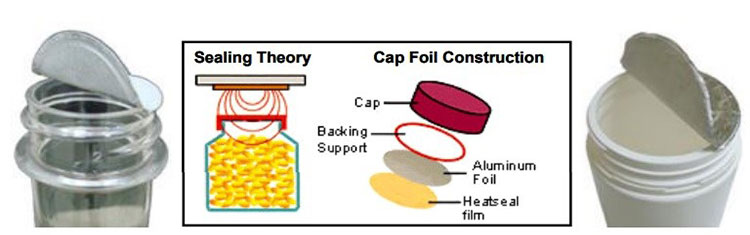

Principle of foil sealing- Picture Courtesy- Sealersales

“To understand a program, you must become both the machine and the program” Alan Perlis.

In order to generate a maximum output from foil sealing machine you should know this basic question of all, how does the foil sealing machine work? The foil sealing machine employs a simple mechanism i.e. use of electromagnetism to produce heat. Machine converts electric energy to a high frequency magnetic field. At right intensity and duration of the electromagnetic field exposure the aluminum foil gets heated which melts adhesive material (heat seal film) under the foil performing a contact less, hermetical (air-tight) seal.

3.Is foil sealing machine available in different types; manual, semi-automatic or automatic?

Your needs say it all, if you are a home user or a manufacturing industry there are different choices available for you in the market that can cater your requirements. Based on your work load you can opt for either a manual hand held foil sealer, a semi-automatic or a fully automatic foil sealing machine. All these machines though different in make and automation have one thing in common, they provide excellent foil seal. These machines are briefly discussed below.

- Manual hand held foil sealing machine

You can use manual hand held foil sealing machine to manage small to medium work load with accuracy and efficiency. A simple easy to use unit, this machine can also be used as back up device to perform sealing operations. Machine can be operated with thumb press button. Hand-held foil sealing machine is also equipped with fail safe features to prevent overheating.

Manual hand held sealing machine- Picture Courtesy- Wikipedia

1.Semi-automatic foil sealing machine

This is a superior version of manual sealing machine and is basically employed in research and development and production department. The main body is made up of stainless steel that gives a sturdy built. Semi-automatic machine is equipped with a conveyer belt on which bottles are placed manually at regular intervals. After placement of bottles on the conveyer heat sealing is performed, bottles are then collected from the other side of the conveyer. You can seal about 20-220 bottles in a minute based on bottle size and shape.

Semi-automatic foil sealing machine

1.Automatic foil sealing machine

Automatic foil sealing machine comes with an additional feature of filling bottles along with sealing with aluminum foil. You don’t need to buy a separate unit for filling containers with your product, automatic filling and foil sealing machine can do that for you. It is basically an upgraded version of semi-automatic sealing machine, equipped with advanced electronics and fail-safe features. This unit can be attached to other units to make complete line of packaging, sealing and labelling bottles that enable you to conduct the entire procedure with single push of a button.

Fully automatic foil sealing machine- Picture Courtesy- Deepora Food Machinery

4.What purposes does foil sealing machine serve?

You will find different uses of foil sealing machine in different types of industry. Some of them are given below: For instance

Food and dairy products: Seal foil prevents spillage of food and dairy products. Other than this, it also prevents degradation of filled product because of air tight seal which prevents microbial contamination and preserves freshness for a longer period of time.

Petroleum and Chemical Industry: The major use of aluminum foil is to prevent adulteration and of course spillage in a petroleum industry. When you opened a can of mobile oil and found a seal on the mouth of the bottle you should know that the product is not tampered with. In chemical industry the seal prevents the degradation of chemicals specially those which are prone to oxidation and hydrolysis and also prevents accidental spillage of toxic substances.

Pharmaceuticals and Nutraceuticals: Pharmaceutical and nutraceutical products are more prone to degradation due to environmental or microbial contamination. An intact foil seal reduces the direct impact of storage conditions and increases the shelf life of the product.

5.What are the technical parameters of foil sealing machine?

You should look for these before selecting any foil sealing machine. Since foil sealing machine are available in different versions you will find different technical parameter for different models. Standard unit require either a power supply of 120 V or 240 V. Given below are some technical parameter of foil sealing machine.

Bottles per minute: Foil sealing machine is capable of sealing 160 bottles per minute at nominal speed. At maximum speed the output increases up to 220 bottles per minute.

Fully automatic foil sealing machine- Picture Courtesy- Plastech control system

Seal time: It takes approximately 2.0 - 3.0 seconds of coil exposure to seal the neck of the bottle with aluminum foil. However sealing time is widely based on the version of machine and the type of bottles used.

Pneumatic unit: Standard unit does not come with a pneumatic unit. However if you have customized your machine the pneumatic unit supplied to you will generate 6 bar pressure.

Noise Control: State of the art design and built quality has enabled the machine to work with very little or virtually no noise. In normal circumstances the noise produced by the machine is less than 75 dBA.

6.What are the major parts of foil sealing machine?

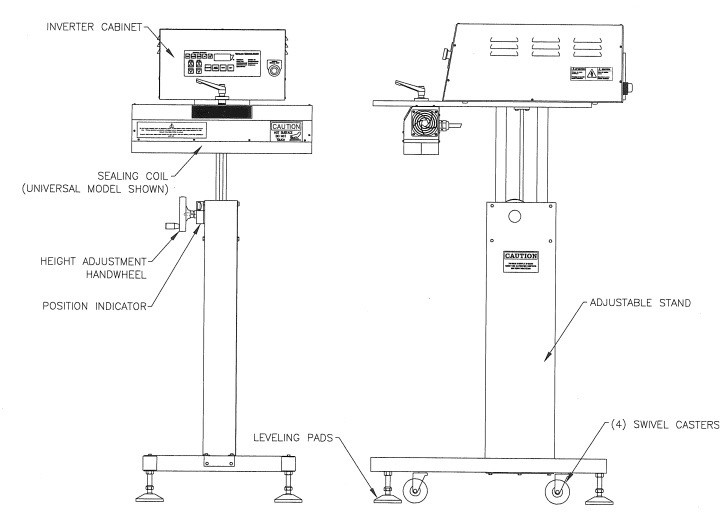

Foil sealing machine is available in a variety of range from manual to fully automatic units therefore, each unit is slightly different from the other in terms of parts and accessories. For your clarity we will be discussing the basic parts of a semi-automatic foil sealing unit. These include a) sealing coil b) stand or support c) inverter d) conveyer system

1.Sealing Coil

You may find different versions of sealing coils that can work on different applications. The sealing coil is the unit that generates an electromagnetic field and seals the bottles mouth with thin aluminum foil. The sealing coil is mounted on a stand or support, the mounting is similar for all sealing coils, each consists of a load capacitor, winding and a housing to hold them.

Sealing coil- Picture Courtesy- Industry Plaza

2.Coil support and stand

Coil support is basically a stainless steel frame that holds the sealing coil. The support is mounted on the conveyer system where the sealing takes place. A better option for the buyer is to opt for the stand instead of coil support to minimize the time required for installation and setup. Stand is a stainless steel frame that enables you to hold sealing coil and inverter at the same time.

A stand for mounting sealing coil- Picture Courtesy- Pillar Technologies

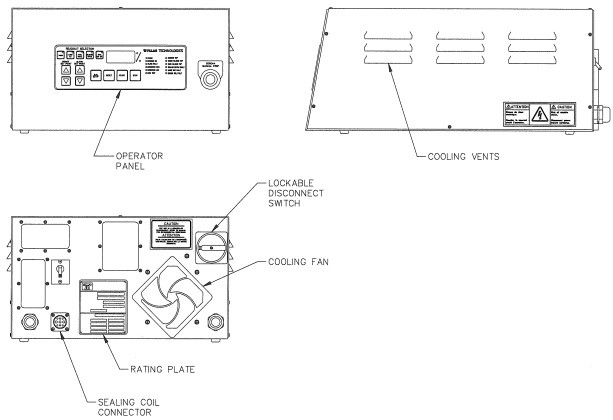

3.Inverter

Inverter basically controls the amount of electric current that reaches the sealing coil thereby, indirectly controlling the heat generated from the coil. A control panel is attached to the inverter that regulates the heat generated by the machine. Inverter is air-cooled and is also equipped with a fan therefore, on all side of the machine there should be adequate space to facilitate air flow. It also contains a safety disconnect with lockout function and a cord grip is provide at the back to hold power cable.

Illustration of inverter- Picture Courtesy- Pillar Technologies

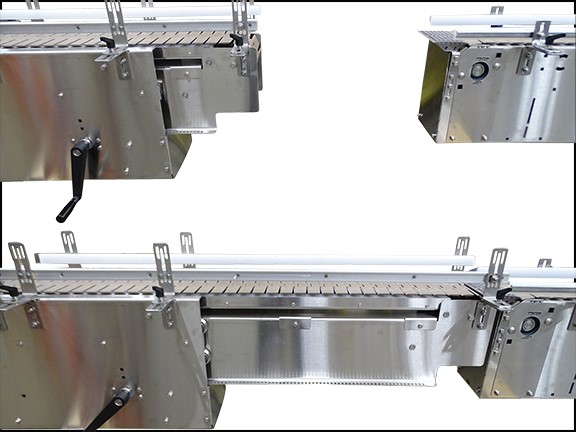

4.Conveyer system

You can also order a conveyer system with the foil sealing machine. The conveyer is approximately 1.5 meters in length and 100 mm in width. It is connected to 120 or 240 V three phase motor. A controller is also attached to the customized version that governs the conveyer speed from 0-60 feet per minute.

7.What are pre-start up points of the foil sealing machine?

Before operating the machine you should make necessary checks. These are as follows

- Check if the sealing coil is aligned and correctly mounted

- Check the connections. All electrical connections in and out of the inverter and coil should be properly in place.

- Make sure that all safety locks are in place and doors closed.

- If the machine is equipped with pneumatic unit check the air supply before switching on the machine.

- If the maintenance has been conducted or the machine was dismantled for cleaning purposes make sure the machine is properly aligned before operations.

8.How to operate foil sealing machine?

- Connect the main power supply and switch on the inverter. An inverter ON light will switch on indicating the power is being provided to the sealing coil.

- Set the power point, the amount of power delivered to the coil will be displayed on the LED. This will control the amount of heat generated for foil sealing

- Place the bottles with caps and foil on the conveyer.

- Press START button this will deliver the entered power to the coil.

- Start the conveyer. Make sure the conveyer speed is optimum to ensure proper seal.

- Retrieve the bottles and allow them to cool down for few minutes. Check the intact seal. The foil should completely seal the mouth of the bottle and there should be no signs of melting. Adjust the parameter if the seal is not proper or melted.

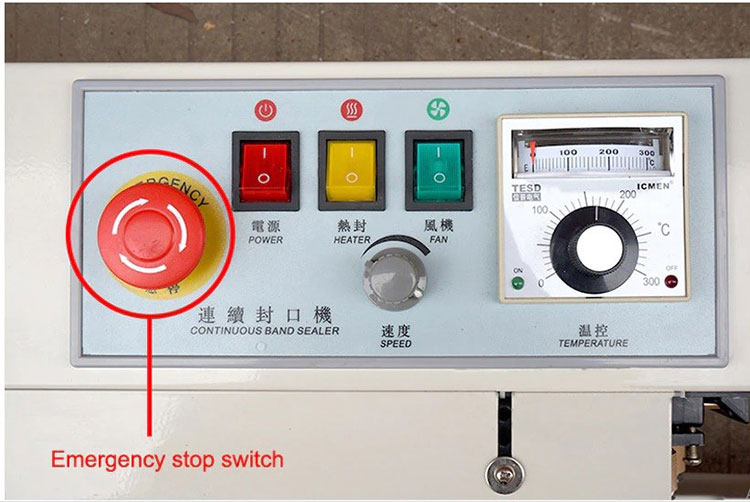

9.Can you stop foil sealing machine in case of any emergency situation?

Foil sealing features is equipped with a number of fail-safe features including an emergency stop button. You can press the emergency button that will bring the entire operations to a complete halt. It is advisable to use the emergency stop button in case of an emergency. The emergency stop button stresses the machine and should never be used for routine stopping of unit. Once stopped machine will not start, refer the manual how to reset and restart the machine.

Illustration of inverter- Picture Courtesy- Ali Express

10.What are the built in fail-safe features of foil sealing machine?

“If you are looking for perfect safety, you will do well to sit on a fence and watch the birds: but if really wish to learn, you must mount a machine and become acquainted with its tricks by actual trial”. Wilbur Wright

Now our goal is to get you acquainted with the machine without compromising your or your product’s reputation.

Your foil sealing machine should have following features to ensure optimum operation flow without any hindrance and high quality product delivered to the consumer. Though these features are not necessary but based on quality standards is a must see in any foil sealing machine.

- Bottle stalled detection

Governed by highly sophisticated three sensors the purpose is to detect movement of bottles on the conveyer system. One sensor detects the entrance, other one monitors bottle exiting and the last one measures the speed of conveyer. If bottles stall occurs on the conveyer unit the sensor detects and an alarm goes off and the machine automatically stops. Even a slight delay will trigger the alarm

- Missing foil detection

Your machine is smart enough to let you know if something is off chart. For instance if the container passes through the coil without having a liner, the operator will be alerted about the defected bottle. The missing foil bottle is than automatically removed from the conveyer using bottle rejection system.

- Loose cap detection

Loose cap detection gets activated when the cap is not properly fitted on the bottle or the bottle is without cap. The sensor than triggers the alarm and defected bottle is removed from the conveyer belt.

- Automatic bottle stop

When the machine is powered off or the coil is not ready the sensor prevents the motion of the bottle under the coil. In this way the risk of unsealed bottles getting through is eliminated. The motion restriction is brought about by activation of gates which are closed when the power to the coil is cut off. Once the coil achieves the required heating output the gates opens and the bottles start moving.

11.What are safety, transport, storage and installation requirement of foil sealing machine?

Automation is good, so long as you know exactly where to put the machine”. End user taking care of their equipment will ensure a longer and effective output delivered from their machine. Before operating a foil sealing machine you should be well versed in safety features, instrument as well as personnel, storage, transport and installation requirements. These are mentioned below

General Safety Requirements

- Foil sealing machine comes with built-in safety features however, not all dangers can be removed with machine built. Therefore, personnel working on this machine should be well versed with operational manual and trained before operating this machine.

- Caution is advisable when working around your machine during operations. Take special care with conveyer and bottles while working with the machine to avoid injury. For your safety you should never by-pass safety systems of the equipment when machine is switched on.

- You should never wear jewelry, watches or any metallic objects while using this machine. Foil sealing machine generates heats by creating an electromagnetic field, any metallic object that comes within the field will get heated. Serious injuries can occur if metallic objects are worn near the machine.

- For your safety place all safety features mentioned in the manual before operating the machine.

- Do not operate or maintain the machine under the influence of drug or alcohol.

- Operators working on the machine should know the correct way to stop the machine. Emergency stop buttons should be used in case of emergencies. Avoid unnecessary use of emergency stop button as it causes continuous change overs and will reduce the working life of the machine.

- Use of sign boards are recommended when using the machine or doing maintenance.

- Main power line should be disconnected when machine is installed or under maintenance. Never put tools on the main body of the machine specially the conveyer, you should always use a working bench.

- Report any unusual noise or smoke or excessive heat.

Transport Requirements

Foil sealing machine is transported from the factory to the buyer in wooden crates. The wooden crates are marked with lifting points, weight and orientation. Once delivered inspect the crates for any sign of damage incurred during transportation. Report any damage immediately to the manufacturer before installing the machine, failure to do so may result in loss of claim. The individual units may weigh up to 8000Kg, you should never move the units using direct human power. Always use forklift or recommended cables that can withstand the machine weight. Lifting points are marked on the crates use these to move the machine.

Storage Requirements

Each machine at the manufacturing plant passes stringent quality control checks before being delivered to the costumer. Each part is tested and inspected before leaving the plant. If the machine is delivered and cannot be installed immediately below points should be followed.

- It should be stored in a dry area free of environmental contaminations.

- The machine should be stored in an area devoid of activity to limit damage due to moving.

- The machine should not be taken out of the original wooden crates and stored in the manufacturer suppled containers.

Installation Requirements

If you want your machine to perform well and do not cause you unnecessary troubles you will need to take care of it in a similar way. Performance of any machine is based on how it is handle in the first place thus installation sites play an important role in hassle free working of industrial units. Following necessary requirements for installation site is recommended by the manufacturer.

- Foil sealing machine should be installed on a levelled floor or platform that can bear the weight of the machine. Special foundations are required if the weight of the machine exceeds the capacity of the platform.

- After installation the machine should be adjusted in a way that the entire weight is distributed evenly on all legs.

- All electrical connections should meet the requirement of the local authorities. There can be difference in voltage requirement of the machine, adjust the voltage according to the machine requirements. Never operate the machine on conditions for which it was never built.

- All connections should be properly earthed, the power cable and fuses should be of correct sizes according to specifications mentioned in the identification plate.

12.What are failure solutions of foil sealing machine?

Inverter

If inverter doesn’t start

- Check interlock mechanism: Deactivate any interlock mechanism.

- Check alarm indicator: Set the alarm setting lower than the power setting.

- Check transformer fuse.

- Over heating: The cooling duration is not enough. Lower the ambient temperature.

High surge of Voltage

Indicates that a high output of voltage has been delivered to the inverter. The inverter will shut down for self-protection.

- Check the connections between inverter and the coil

- Adjust the transformer setting for the coil being used.

Low surge of Voltage

Indicates that an output of voltage has been lowered to the inverter. The inverter will shut down

- A short circuit has occurred.

- Too many bottles under the coil: remove excessive bottles.

- Consider checking the supply.

Current fault

- Check the connections between the transformer and the sealing coil.

- Too many bottles under the coil: remove excessive bottles.

Optical sensor

- Check sensor operation from the setup mode.

- Check for proper connections.

- Align the sensor with respect to the bottles.

13.How to perform maintenance of foil sealing machine?

1.For a possible long life and prevention of premature malfunctioning of foil sealing machine, it is essential that work surroundings of machine should be free of dust and water vapors. It is important to place machine in environment that is not exposed to high humidity, harsh chemicals and huge amount of dust particles. These precautions also prevent deterioration of machine parts.

2.In order to avoid machine damage and gradual rusting of parts, it is crucial that control panel and other wirings should not be exposed to liquid materials such as water. Use soft cloth and mild detergent to clean the control panel.

3.The fan filter on the right side of the supply should be cleaned with air pressure or vacuumed on scheduled basis.

4.Proper lubrication of machine components like driving components should be done as to decrease friction.

5.High rotation in sealing coil and cabinet can produce electric shock so untrained personnel should not be allowed to unlock the cover of coil head and also safety cover on cabinet should be kept at all times when machine is in operation for averting electric shock incidents.

14.How to order foil sealing machine parts?

If your purchased machine has standard options then each part is describe in the manual section with the illustration. But if it is made up of custom parts then these parts are not illustrated in manual. Please refer to the material provided with custom parts. The illustrations and list are mentioned in the manual, for the purpose of identification of part which is to be replaced and also for easily recognizing proper parts needed for specific operation, maintenance and setting of machine.

Part Table Usage

Colorful illustrations are included in the handbook of machine so that desired part should be easily identified.

- See the illustration of desired part in manual, then note down item name.

- Follow part table and get item number, from this item number get company part number, its description and quantity.

Requisition of Parts

Possible alterations can occur with the passage of time in part number and quantity of machine part. So it is essential to properly follow these instructions when procuring the machine part. If some information is not available then this can be the reason of unnecessary holdup in delivery of order. Fill the procurement form with information detailed below.

- Identify the Model Number and Serial Number of unit which is printed on Rating Plate

- Note down Part number and published date of manual given at the front cover of the manual. This part number is also provided on footer of every page of handbook.

- Also mention on requisition form number of part required, the page number of manual on which it is detailed and also description of this part.

Shipping Information for Returning of Machine Components

Manufacturing companies have several facilities for carrying out repair and replacement of machine parts. So customer should contact company for special instruction about shipping.

- Contact manufacturing company Customer Service center and ask for Return Material Authorization (RMA) number. Also, ask for specific instructions that should be carried out when shipping machine part and shipping address.

- For shipping of machine part, it is instructed to use, if possible, packaging material in which parts were originally delivered. If this is not possible, then parts or components must be transported in the fiberboard box or suitable packing material that can sustain weight of the items and keep the parts firmly in place to reduce damage during transport.

15.Does the foil sealing machine comes with warranty and parts replacement?

1.Usually one year warranty is provided on parts of foil sealing machine. If the quality problem arises in machine then it is responsibility of manufacturing company to provide free of cost repair and substitution of machine parts.

2.Local venders and foil sealing machine manufacturing company should be asked for the warranty card on the procurement of machine. If defect occur in machine part in 12 months of purchasing date or in 2,000 hours of machine work then these parts are warranted.

3.Free substitution and delivery of defective machine part is covered by the warranty. Also, guarantee encompasses the replacement and transport of sub assembly which become nonoperational due to inadequate quality and manufacturing fault.

4.Companies maintain that customers should have valid claim substantiated by fact that defect has happened within time period specified by the warranty. These claims should mention unit/type number and the serial number. These details are usually found on identification plate of the machine unit, which are specific to every unit.

5.If buyer made any alteration to machine without previous written permission of foil sealing machine manufacturing company then warranty should be considered void.

6.Following stipulations must be complied with for warranty:

-

- Maintenance of machine parts should be performed according to the schedule described in the machine manual. This schedule operation should be executed by properly trained and competent workforce at specific time interval as mentioned in the manual.

- Machine operation must be carried out exactly according to instruction detailed in machine handbook and machine should not be operated beyond parameters mentioned in manual.

If these conditions are not met then warranty will be automatically cancelled.

16.What to do when foil sealing machine has spent its operational years?

There are many options to consider if the machine has met the limit of its operational life such as:

- Prospect of buy-back can be considered by contacting the manufacture for whom machine was purchased.

- Whole unit can be sold in market with aid of proficient metal dealer. Similarly individual parts can be retailed in one piece by dismantling them.

Safe environmental conditions must be retained by following instructions detailed in manual when disposing of parts of machine. Few such instructions for proper disposal of machine parts are:-

- By using conventional techniques, metals such as stainless steel should be recycled.

- Plastic used in Gear wheels and guard doors does not require specific instructions for recycling.

- Proper precautions should be taken when disposing of lubrication materials within machine. Otherwise, other materials employed in manufacturing of machine does not require specific instructions.

- Follow Policy and Law when discarding or recycling of electronic components of machine.

Conclusion

Hope this blog has brought you valuable information related to foil sealing machine. The blog was specifically written to make the reader understand ins and outs, pros and cons of a foil sealing machine and self-assessment and analysis of one’s own needs. Now you are in a better position of selecting the best foil sealing machine from the market according to your needs and requirements. HAPPY SHOPPING.

Induction Sealing Machine Related Products

Induction Sealing Machine Related Posts

Induction Sealing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours