The Ultimate Guide to Selecting an Integrated Powder Filling Line for Supplement Contract Manufacturers

Are you a contract manufacturer struggling with changing bottle sizes and dusty powders? You are not alone. Finding flexible equipment is the hardest part of scaling up your production business.

An integrated powder filling line for OEMs must handle multiple bottle sizes and prevent cross-contamination. The best solution includes a double-head linear filler for speed, a lifting conveyor to reduce dust, and modular add-ons like scoop inserters and metal detectors. This flexibility ensures high efficiency for diverse client needs.

Integrated powder filling line factory floor

Many factory owners think they just need a simple machine to put powder in a jar. But then they get an order for a different bottle shape, or a sticky powder, and the whole line stops working well. I want to share a story about a recent client. This story will show you exactly what to look for when buying this equipment.

1.How Do You Handle Multiple Bottle Sizes and Fill Weights?

Contract manufacturers often face a big problem. You have too many different bottle shapes and sizes from your customers. This makes buying a single machine very difficult and confusing.

To handle multiple sizes, you need a machine with quick-change parts. A linear filling system is usually better than a rotary one for this. It allows you to adjust rails and heads quickly for bottles ranging from 16oz to 70oz without buying a new machine for every size.

Assorted supplement bottles on conveyor

Powder filling machine inquiry

I recently received an email from a client. He asked for a video and a quote for a fully automatic powder filling line. I sent him the standard video, but I knew I needed to ask more questions. I asked about his bottle sizes, filling weights, speed requirements, and how the powder flows.

His reply changed everything. He is an OEM contract manufacturer. This means he does not just make one product. He listed a huge range of bottle sizes: 16oz, 20oz, 25oz, 32oz, 40oz, 44oz, 55oz, 60oz, and even 70oz. He also had three different cap diameters: 89mm, 110mm, and 120mm. His fill weight ranged from 300g to 1000g.

Bottle size from this customer

If you are in the same business, you know this is a challenge. He initially asked for a speed of 12-15 bottles per minute. The powder was different types of vitamin supplements.

When you have this much variety, you cannot use a rigid system. You need a line where you can change the "change parts" (like star wheels or guide rails) very fast.

I looked at his list and knew that a standard fixed setup would fail. We had to design a system where the filling height and the conveyor width could change easily. This is the first thing you must look for. If the machine takes four hours to switch from a 16oz bottle to a 70oz bottle, you will lose money. We aimed for a solution that handles this variety without trouble.

2.How Can You Prevent Powder Dust from Dirtying the Bottles?

Dust is the enemy of supplement packaging. If powder gets on the bottle neck/thread, the cap will not seal right. This looks bad and can ruin the product quality quickly.

The best way to stop dust is a three-step approach. First, use a lifting conveyor to fill from the bottom up. Second, use an air-blowing device at the mouth. Third, use a bottle-cleaning machine after capping to ensure the final product is spotless.

Powder filling nozzle inside bottle

After I sent the first quote, the client had a big worry. He was afraid the powder would spread to the bottle neck during filling. If the neck is dirty, the seal is bad. The customer receives a messy bottle. This is a disaster for his reputation.

I analyzed his material. He said the powder flows well. Surprisingly, good flow often means more dust. It flies everywhere. I told him we have a specific "Triple Insurance" solution for this.

First, we do not just drop powder from the top. We make the bottle conveyor lift up. The filling nozzle goes deep into the bottle. We fill from the bottom as the bottle goes down. This keeps the dust inside.

Second, we add a special device at the bottle mouth. It blows air and sucks dust at the same time. This cleans the rim before the cap goes on.

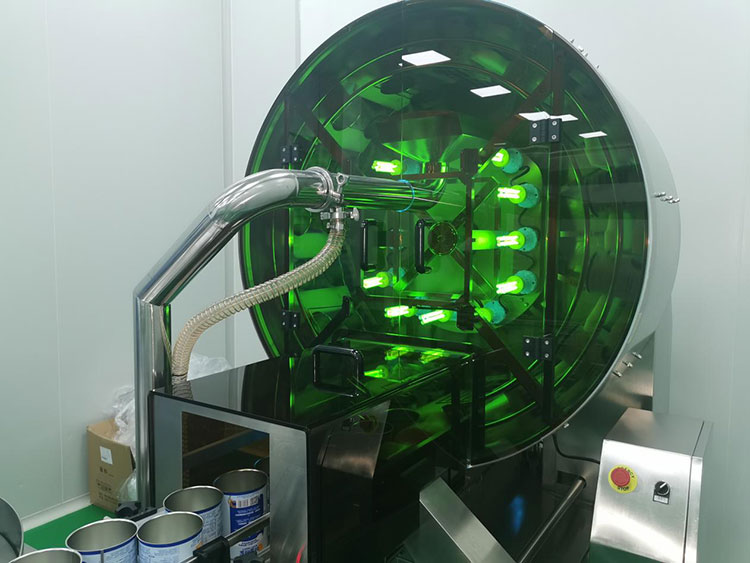

Bottle outside cleaning machine

Third, we add a "Bottle Outside Cleaning Machine" at the end. Even with the first two steps, some dust might settle on the shoulder of the jar. This machine brushes and wipes the outside.

I sent him videos of these three solutions working in our factory. He accepted all three immediately. He saw that we understood his pain point. When you choose a machine, do not just look at speed. Look at how clean it keeps your package.

3.Single Head vs. Double Head: Which Speed is Right for You?

Speed determines your profit. But you also need accuracy. Choosing between a single head and a double head filler depends on your volume and how fast you want to grow.

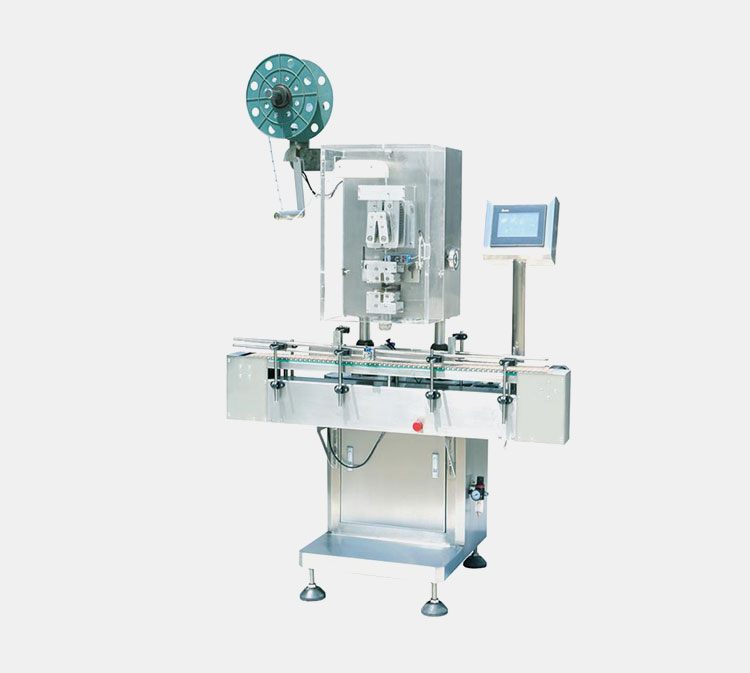

Double head powder filling machine

A single head filler is good for 15-20 bottles per minute. For higher speeds like 60 bottles per minute, you need a double head linear machine. This doubles your output without doubling the space, making it ideal for growing manufacturers.

The client told me he would come to China for the CPHI exhibition. This was the perfect chance. I invited him to our factory. I always tell clients: bring your actual bottles and powder.

He came in June after the show. We did a FAT (Factory Acceptance Test) right there. We used his powder on a Single Head Filling Machine. I showed him the accuracy. It was within ±1%. He was happy with the precision, but he changed his mind about speed.

He originally wanted 12-15 bottles per minute. But after seeing the machine, he wanted more efficiency. He asked for 60 bottles per minute.

I showed him four options:

1.Single Head Filler (Too slow for his new goal).

2.Single Head with Weighing (Very accurate, but still slow).

3.Double Head Rotary Filler (Fast, but harder to change parts for his many bottle sizes).

4.Double Head Linear Filler.

Option 4 was the winner. It is a straight line, so changing bottle sizes is easy. But it has two nozzles, so it hits the 60 bottles per minute target. We updated the quote to the **APC-2BG-2 double head powder filling machine**. It was the perfect balance of speed for his new goal and flexibility for his many bottle sizes.

4.What Auxiliary Equipment Do You Need for a Complete Line?

A filler is not enough. To sell a finished product, you need to treat the bottle, add scoops, seal it, and check for safety. A complete line handles everything automatically.

A full line includes a bottle unscrambler, UV sterilization, scoop inserter, desiccant inserter, capper, induction sealer, and metal detector. These machines ensure your product meets GMP standards and consumer expectations for safety and convenience.

During the factory visit, we walked past other machines. The client realized he needed more than just a filler. He saw a **Scoop Inserter** and said, "Yes, some of my customers need scoops inside." He saw a **Desiccant Inserter** and said, "We need that for shelf life."

Scoop Inserter

Desiccant inserter

Empty Bottle Sterilizer(UV light)

Metal detector

We also discussed safety. He added an **Empty Bottle Sterilizer** (UV light) to clean the jars before filling. He also added a **Metal Detector** at the end of the line. This is critical for export markets. If a tiny piece of metal is in the powder, you need to know before it ships.

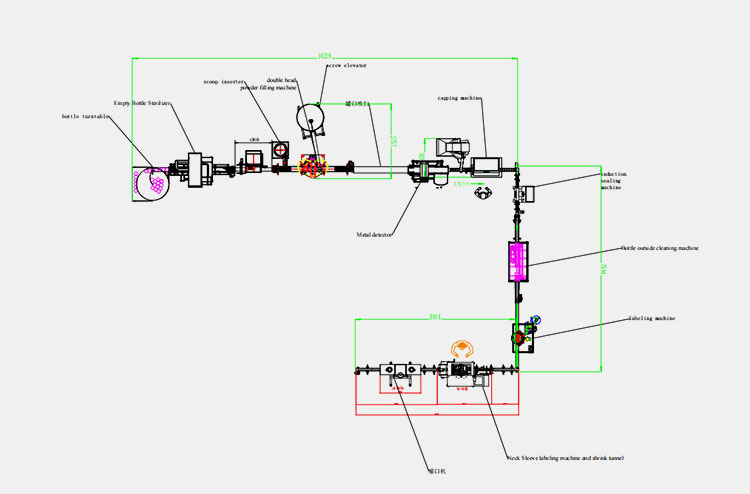

He also had a space limit. He asked for a U-shaped layout to fit his room. I told him we could do that easily.

Here is the final list of the line we designed for him. It shows how complex a real line is:

| Item | Machine Name | Function |

| 1 | Bottle Turntable (Φ1200) | Feeds bottles into the line |

| 2 | Empty Bottle Sterilizer | Kills bacteria with UV |

| 3 | Desiccant Insert Machine | Puts moisture absorbers in |

| 4 | Automatic Scoop Inserter | Drops the scoop in correctly |

| 5 | APC-2BG-2 Double Head Filler | Fills powder with dust control |

| 6 | Screw Powder Elevator | Lifts powder to the filler |

| 7 | Metal Detector | Checks for contamination |

| 8 | APCXS-X160 Capping Machine | Tightens the caps |

| 9 | Induction Sealing Machine | Seals the foil to the rim |

| 10 | Bottle Outside Cleaning Machine | Removes dust from the jar |

| 11 | Labeling Machine | Applies the sticker label |

| 12 | Neck Sleeve & Shrink Tunnel | Adds the safety seal on the neck |

Updated layout to customer

The client was very happy. He saw the layout and the updated quote within two days. He returned to the USA and signed the deal.

Conclusion

Choosing the right line requires looking at bottle variety, dust control, and future speed needs. A flexible, integrated system ensures you can say "yes" to any customer order.

Don't forget to share this post!

Integrated Powder Filling Solutions for Contract Manufacturing

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine