Powder Filler: The Complete Buying Guide In 2025

Running a successful business is something that require persistence, vigilance, and relevant knowledge in the field. Even though the world has been arrived at the phase where technology is the answer to most tricky problems still its users are facing difficulty to deal with the complexities this technology has brought with it. Similar is the case with Powder Filler.

Manufacturers are struggling to opt the right powder filler, so, that they can benefited from it. But, in the world of machines how you will you know what powder filler is the most suitable one? How to operate it? And how to diagnose the common errors? All these questions along with much other aspects of a powder filler will be disclosed in this comprehensive buying guide. So, stay tuned and make sure to read it thoroughly!

1.What Is A Powder Filler?

1-10kg Semi Automatic High Accurancy Powder Filling Machine

Powder filler is a type of innovative machine designed with ergonomic features and distinct structure to facilitate the packaging of various dry powders and granules. It uses an automatic technology to measure the quantity of powders before their filling into bags and containers.

Powder filler is easy-to-use and multifunctional in its core due to its resilience to process all kinds of free flowing and cohesive powders. Therefore, its significance is more in pharmaceutical industry, food industry, and cosmetic industry etc.

2.What Benefits Can You Get By Using A Powder Filler?

A powder filler is cutting edge machine that brings along with it multifarious benefits for your business. Some of these advantages are as follows:

Production Growth

It is for sure that every manufacturer wants to increase the production. Now, this goal can be easily achieved by using a powder filler that provides you outstanding output by working automatically.

Accuracy

Fruit & vegetable powders- Picture Courtesy: trail.recipes

Manually filling your powders into bags and containers is not only difficult but uncertain as well. It is because powders come in different nature, so, the quantity become inaccurate. However, the newly developed powder fillers such as auger filler maintain high filling accuracy.

Product Safety

Milk powder in safe stainless steel can- Picture Courtesy: tichgop.vn

Product safety is the prime importance of producers who value customer satisfaction. In this way, a powder filler greatly assists in fulfilling these prerequisites by providing corrosion resistant stainless steel and antibacterial body where material is processed in an safe environment free from pollution.

Easy-to-use

Operator using PLC control panel- Picture Courtesy: huadapharma.com

Powder filler is extremely convenient in its operation. It follows simple working mechanism which can be easily understand by a layman and does not require high technical training. In addition, the touch screen penal has made its operation a piece of cake.

Reduce Waste

Wasted powder- Picture Courtesy: self.com

Another crucial benefit of a powder filler is that it helps in reducing the possible waste of powders that occurs during manual filling. Moreover, it is also proved by another feature of the machine where it controls the filling amount of material and avoid overfilling.

3.Enlist The Products Which A Powder Filler Can Process?

Below enumerated products are some of the prominent ones which a powder filler is capable to process:

Spices

Multiple powdered and granulated spices- Picture Courtesy: hubpages.com

Spices are popularly delivered in powdered form to add color and flavor to food. As they are in powder form their minute particles can get into eyes, if processed in air, and can be dangerous. Therefore, a powder filler is always suitable to process various spices and condiments in an enclosed environment.

Milk Powder

Milk glass and milk powder bowl- Picture Courtesy: alphafoodie.com

Milk powder is another product which can be easily processed by this machine. Whether it is baby milk powder or daily use instant milk powder, powder filler is the best capable machine to fill it.

Detergent Powder

Detergent powder with spoon- Picture Courtesy: jazzyshirt.de

Similar to spices, the inhalation of detergent powders is also hazardous for health because it contains chemical substances. Hence, different types of detergent powder, dish washing powder, and flour cleaning powdered agents can be measured and filled by the powder filler.

Herbal Powder

Herbal powder in bottle- Picture Courtesy: natures-dr.com

Herbs are natural entities due to which they have minimum or no side effects when consumed. Therefore, most of the herbal powders are now used for medical purpose to treat acute to chronic diseases. In this way, a powder filler can be employed to undertake its packaging step.

Flour

Wheat flour sack & grains- Picture Courtesy: inspirehealthmag.com

Flour is a fine powder made from crushing wheat, raw grains, legumes, and beans etc. As, the use of flour is frequent in daily life, so, it is often delivered in large bags with capacity of 5kg to 25kg. Hence, a powder filler can fill such large volume of flour into bags.

Coffee & Coco Powder

Chocolate protein powder- Picture Courtesy: biotrust.com

Other products that a powder filler can process include raw coffee powder, instant coffee powder, chocolate powder, and tea powder etc.

4.Differentiate Between Free-flowing And Non-Free Flowing Powder?

Powders can be classified into two categories based on their flow such as free-flowing powder and non-free-flowing powder. Below table is clearly demarcating the differences that exist between these two types of powders:

| No | Factors | Free-flowing Powder | Non Free-flowing Powder |

| 1 | Definition | Free flowing powders refers to powders which moves freely and do not get stick together to make shape. | While as non free flowing powders are sticky that tend to form specific shape if compacted. |

| 2 | Size | The size of free-flowing powders is large compared to non-free-flowing powders. | Non-free-flowing powders are extremely small in size due to which they easily get attached to each other. |

| 3 | Cohesiveness | They are not cohesive. | They are cohesive in nature. |

| 4 | Porosity | Free flowing powders are smooth and flow freely. | In contrast, non-free-flowing powders are highly porous. |

| 5 | Example | Sugar, salt, breadcrumbs etc. | Custard powder, talc powder, and corn flour etc. |

| 6 | Picture |

Crushed rice in bowl- Picture Courtesy: lacademie.com |

Corn flour presentation idea- Picture Courtesy: tipsbulletin.com |

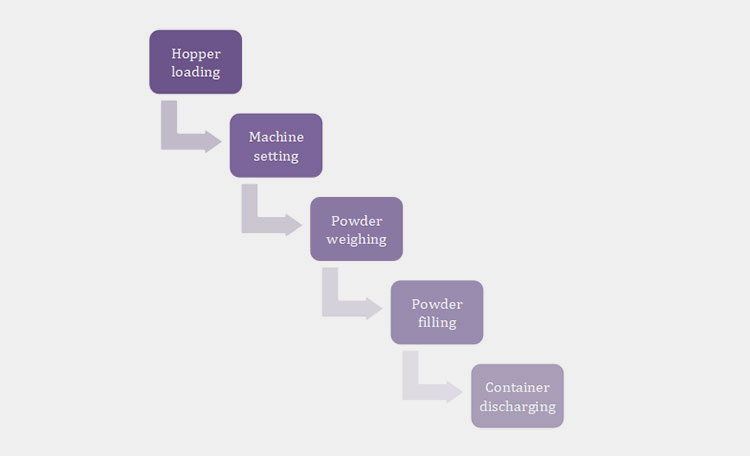

5.Explain The Working Principles Of A Powder Filler?

The working principles of a powder filler has been explained below:

Hopper Loading

Hopper loading- Picture Courtesy: huadapharma.com

Firstly, the user is required to load the feed hopper of a powder filler with adequate amount of material that can be powder or small granules. This feed hopper is integrated with the main machine for supplying material during operation.

Machine Setting

Operator setting machine through touch screen penal- Picture Courtesy: huadapharma.com

Secondly, the operator will adjust basic parameters of a powder filler through touch screen control panel. This panel provide multiple information regarding the powder dosage, speed of auger, and position of agitator blade etc.

Powder Weighing

Powder weighing in hopper- Picture Courtesy: huadapharma.com

In third stage, the operator will start the machine after which the empty bottles will be conveyed under the filling head in one hand, while as, powder is measured through auger on the other.

Powder Filling

Powder filling into bottle- Picture Courtesy: huadapharma.com

In fourth step, the accurately weighed amount is stored in straight funnel located right above the filling head. When the presence of containers is detected by the sensor, it communicated the message to machine in response the filling nozzle start distributing consistent amount of powder into each passing container.

Container Discharging

Bottles discharging- Picture Courtesy: huadapharma.com

At last, when all the bottles are filled with powder, their automatic discharging is taken place by the machine.

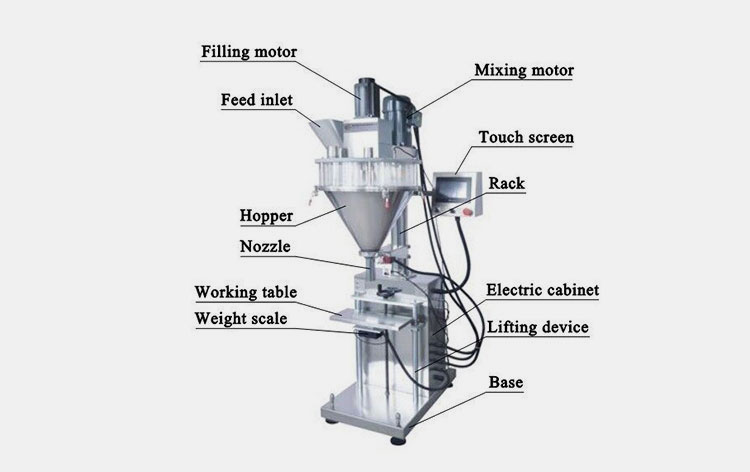

6.Describe The Structure Of A Powder Filler?

The structure of a powder filler is comprehensively explained in the upcoming paragraphs:

Structure of a powder filler- Picture Courtesy: ipharmachine.com

Filling Motor

Powder filler has separate motors for powder filling and mixing. In this way, servo motor plays a key role in the accurate dosing of powder which is attached to the top of machine. It administers and controls the auger filler.

Mixing Motor

Sew motor performs the mixing of powder inside hopper by continuously rotating the scrapper.

Feed Inlet

Feed inlet is hose like open area on hopper lid through which powder is fed into the hopper. In fully automatic powder filler, a feed conveyor is integrated to the auger filler where this feed inlet plays an instrumental role in supplying the powder to hopper.

Hopper

Hopper is another important part of a powder filler made from stainless steel. It is used to hold the powder and process it before filling into containers. The design of the hopper is extremely easy to open and clean. Inside hopper is an agitation blade that scrape the powder from corners to mid and a spiral through which powder is transferred from hopper to nozzle.

Rack

Rack is the framework that constitute the overall supporting structure of a powder filler. All other components are attached to it.

Nozzle

Nozzle is a long narrow tube type device attached to the lower end of hopper. It is responsible to dispense the precise dosage of powder into assigned containers and bags.

Working Table

Working table is a flat stainless-steel tray where bottles are placed before the filling head. Its height can be adjusted as per the size of containers.

Weight Scale

Weight scale is a device used to measure the weight and mass of filled containers. It is integrated with a powder filler to check the weight of each container after it is filled with powder.

Touch Screen

Touch screen is an intuitive display that allows user to contact with the machine and fix all desirable parameters in machine through this device.

Electric Cabinet

Electric cabinet is an enclosure that houses all the electrical components of a powder filler in one place.

Lifting Device

Lifting device refers to the stainless-steel tools with the help of which a working table is fitted. These tools help in the structural adjustment of a working table according to the varying height of containers.

Base

The base of a powder filler is located at the bottom of machine which is made from durable stainless steel. It greatly supports the smooth functioning of a powder filler during operation.

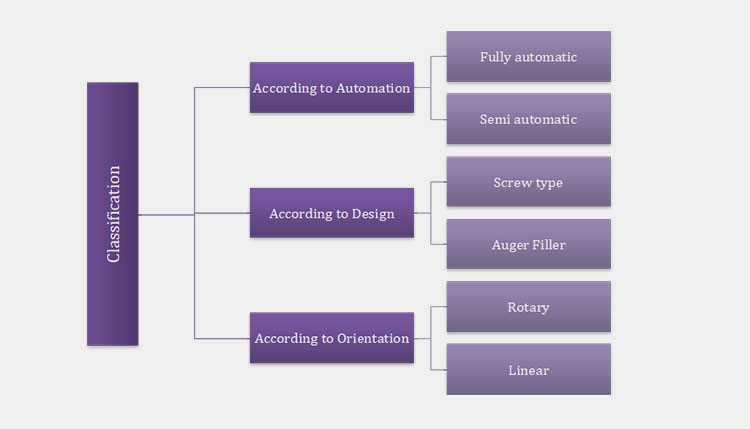

7.What Is The Classification Of A Powder Filler?

Powder filler can be classified into many types due to the growing diversities in need of manufacturers. Hence, below provided information depicts the broad classification of a powder filler. Look at them!

According to Automation

Fully Automatic Powder Filling Machine

High-Precision Double-Head Automatic Screw Feeding Powder Filling Machine

High precision automatic powder filling machine is a fully automatic machine that undertake the entire processing of powder filling independently. The machine is best fitted to fill different kinds of bottles, jars, and cans with varying sizes and shapes while maintaining the speed of filling 50 containers per minute.

Structure

The machine has comparably a complex structure comprising feed hopper, screw conveyor, and double head powder filling machine. It is made up of corrosion resistant stainless steel with a transparent window for clear observation along with smooth running drive mechanism and multiple motors etc.

Working Process

It follows automatic working process where screw conveyor take powder from feed station and transfer it to the hopper. Similarly, the hopper process it and dispense it into containers in a sequential order to avoid spillage and waste of product by taking help from sensors. These loaded containers are then discharged by the machine.

Semi-Automatic Auger Filler Machine

Semi Automatic Auger Filler Machine For powder

Semi-automatic powder filler is low cost and precise body machine which can be used for filling all kinds of powders. It has the capacity to fill up to 30 bags and bottles per minute, therefore, the machine is suitable to accomplish the daily production targets of small to medium industries in health, beauty, and food sectors.

Structure

The structure of machine is small with one auger filler and attached weight scale device. It consists of dual motors, PLC control panel, hopper, filling head, main frame, and working table.

Working Process

The working process of semi-automatic powder filling machine is quite simple with electric weighing and automatic filling. The execution requires one operator for loading hopper and placing container under the filling head. Afterwards, the machine automatically weigh powder, fill into container, and operator manually scale it after picking the container from working table.

According to Design

Screw Powder Filling Machine

Screw Blanking Powder Filling Machine / FLG-500A

Screw powder filling machine is an economical solution that process powders and granules in simplest way. The capacity of machine stood at filling 40 containers in a single minute. Moreover, the machine has low power consumption due to the absence of heavy-duty motors.

Structure

It has a small footprint with robust stainless steel body, screw hopper, touch screen display, electric sensor, 360° universal wheels, and filling nozzle.

Working Process

Its working principles involve setting machine parameters and loading the hopper with desired bulk powder. Along with that, when machine is powered on, the screw start rotating taking the powder in its blank spiral place towards bottom. Once, the filling head get filled with powder, and machine detect the presence of container, it automatically discharge the powder into it.

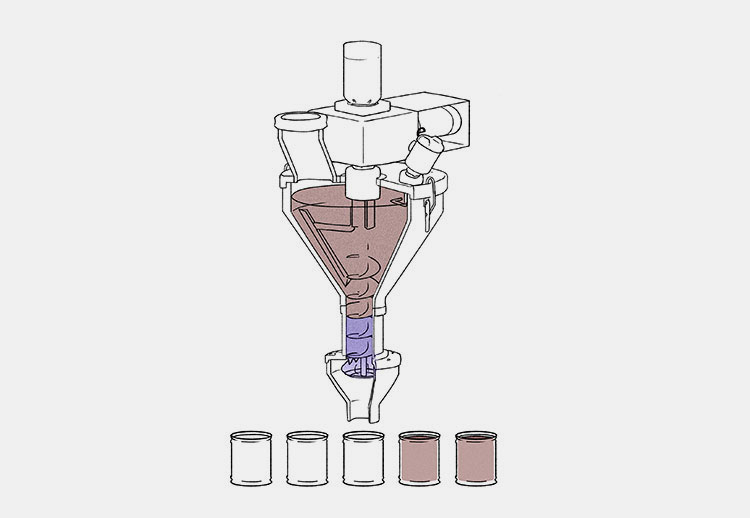

Auger Filler Machine

1-10kg Semi Automatic High Accurancy Auger Filler Machine

Auger Filler machine is one of the significant types of powder filler that uses advance technology of auger filling to fill powders of varying nature such as free-flowing and non free-flowing powders. The machine come in various capacities, models, and designs to facilitate diverse sectors in meeting their powder filling requirements.

Structure

It consists of a filling motor, mixing motor, auger shaft, side blender or mixer, hopper, control system, foot switch, and support frame etc.

Working Process

Auger filling process- Picture Courtesy: spee-dee.com

It follows an unconventional method where powder is both weighed and then filled into containers. Firstly, powder is processed inside hopper through a scrapper and an auger device. Secondly, the rotation of auger leads powder to move downward and collected in a straight funnel for weighing. Thirdly, the precisely weighed powder is dispensed into containers.

According to Orientation

Rotary Powder Filler

CVC 6088-2R24 Rotary Powder Filler- Picture Courtesy: cvctechnologies.com

Rotary powder filler is a sophisticated machine employed to enhance the efficiency of powder filling and reduce the time spent on it. The machine can hold 14 liters of product volume in its hopper and the filling rate is 140 bottles per minute.

Structure

The machine is composed of a heavy-duty machinery including nitrogen purging device, star wheel assembly for infeed and outfeed, vacuum dust collector, conveying mechanism, servo motor driven dual auger fillers, and rotary funnels.

Working Process

The working process of a powder filler is based on rotary system where bottles are fed onto conveyor and then transported to the rotary star wheels. These wheels then combined to a single large star wheel where the nitrogen purging of bottles takes place. Afterwards, with the help of rotary funnels, powder is dispensed into individual bottles. Filled bottles are then transferred from the machine.

Linear Powder Filling Machine

Automatic linear powder filling machine

This linear powder filling machine is designed to fill different types of dry powders into rigid containers including bottles, cans, and jars. It provides dual functions of metering as well as filling in a straight line. Therefore, the additional complexity of bottles is absent here.

Structure

This linear powder filling machine is made up of a a feed hopper, screw conveyor, linear conveyor belt, auger filler, control system, and regulating motors.

Working Process

The working process starts from automatic bottles unscrambling and powder conveying to hopper. Proceeding further, the bottles are conveyed in a linear manner until they reach under the filling head. Similarly, powder is measured and then delivered into bottles after which they get discharged.

8.Highlight The Applications Of A Powder Filler?

The need of a powder filler is not restricted to pharmaceutical industry, condiments industry, or chemical industry, rather its sphere of application is broad enough. Below given description will provide a more particularistic view in this respect:

Healthcare Industry

Herbal powder & tablets- Picture Courtesy: dailydose.co

Healthcare industry revolves around the major aim of treating illness. For this reason, different techniques have been employed to deliver medicine dosage among which powder is popular one. Different herbal powders, calcium powder, and protein powders are now delivered in bottles for which a powder filler is used.

Food Industry

Milk powder cans- Picture Courtesy: Behance

Another notable application of a powder filler can be easily find in food sector where milk powder, drink powders, coffee powder, condiments, and coco powder are the common examples which are processed by this machine.

Agricultural Industry

Agricultural seeds- Picture Courtesy: sacbee.com

Agriculture is a sector where thousands of seeds and grains are processed. Along with that, fertilizers are also used in the same place. Therefore, packing such a large volume of powders and granules require heavy-duty machinery which a powder filler can provide with exceptional material holding capacity.

Daily Chemical Industry

Detergent powder presentation idea- Picture Courtesy: hellonaturalliving.com

Whether is it chemical industry or daily chemical industry the manufacturing and packaging of powders is inevitable. Hence, a powder filler becomes applicable here.

Cosmetic Industry

Cosmetic powder boxes- Picture Courtesy: popsugar.com

A powder filler has also good demand in cosmetic industry where multiple types of dry powders are processed. Talc powder is the common powder in this way that has been used in face powder, eye shadow, and foundation etc.

Dyes & Pigment Industry

Multi color dyes- Picture Courtesy: kaliko.co

Dyes and pigments can also be filled by a powder filler into range of containers and small to large sacks. This indicates the applicability of the machine in colorants industry.

9.How To Setup And Install A Powder Filler?

After purchasing a powder filler, it is important that you follow the right way for its successful installation and setup. In this way, we have provided few important points for your help. Consider them below:

Installation icon- Picture Courtesy: appliancesonline.com.au

Firstly, all the components of a powder filler must be carefully attached in order to work smoothly. It will include the right placement of hopper, auger shaft, mixer, filling nozzle, weight scale, working table, and electronic sensor.

Secondly, when the structural adjustment of machine is completed, it is significant that you place the machine in a safe environment having access to air. It is beneficial, as powders like spices and herbs need to be processed in place with no suffocation.

Thirdly, the ground wire located in electric cabinet must be attached safely. Along with that, you need to make sure the level of surface is even and the machine has adequate availability of electricity.

10.What Is The Cleaning And Maintenance Requirements Of A Powder Filler?

Regular cleaning and maintenance of a powder filler ensure that your machine will have a good longer service life and will perform smooth functioning. So, make sure you are also cleaning and maintaining your powder filler according to below mentioned steps:

Surface cleaning- Picture Courtesy: www.angi.com

Cleaning

Cleaning includes washing the different parts of machine which are in direct contact with powder like hopper, filling nozzle, auger, and scrapper etc. Apart from this, other components of machine such as conveyor, working table, control panel, and electronic sensor must be cleaned with dry cloth to remove the accumulated dust and make the machine function in an uninterrupted way.

Maintenance

Maintenance of a powder filler encompasses the examination of machine tools during and after operation to make sure all the screws are tight. You also need to replace the damaged and worn-out parts when found. Moreover, the lubrication of transmission parts and motors is also necessary to reduce friction caused during operation.

11.What Is The Troubleshooting Of A Powder Filler?

A powder filler may show inconsistencies at any point that might trigger you. But, there is no need to worry about them, because such problems occur due to technical errors which, if examined, can be corrected. So, let's discover some of the common troubleshooting of a powder filler!

| No | Error | Cause | Solution | Picture |

| 1 | Inaccurate powder fill level | It may be due to clogged nozzle, the change in product properties, or | The problem can be fixed by cleaning the nozzle, recalibration, and adjusting machine according to product properties. |

Clogged nozzle- Picture Courtesy: ipharmachine.com |

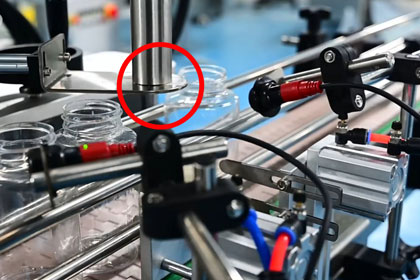

| 2 | Auger filler is jammed and does not move | It is a serious problem causing damage to machine as well as product that is caused by accumulation of powder. | You need to disassemble the hopper and auger, clean the lower funnel, and make sure that all parts are fixed and tight on their own place. |

Encircled jammed powder filling nozzle- Picture Courtesy: All-Fill Inc |

| 3 | Machine tripping | The tripping is resulted from inadequate power supply or poor connection to electricity. | So, replug the machine and ensure the board is providing required voltage. |

Machine tripping display- Picture Courtesy: whitegoodshelp.co.uk |

| 4 | Unusual noise during operation | Loose parts, friction, and misaligned components cause vibration and noise during filling. | It can be solved by deeply examining the parts of machine, lubricate the movable parts, and tighten loose nuts. |

Unusual icon |

| 5 | Fluctuating filling | Overloading hopper lead the auger to intermittent powder filling. | Make sure 1/3 area of hopper is empty for ensuring consistent powder filling. |

Overfilled hopper- Picture Courtesy: All-Fill Inc |

12.Factors To Consider When Choosing A Powder Filler?

Every manufacturer desire to have an effective powder filler, so, that the process of powder packaging will be efficient. However, fulfilment of this wish requires some vigilant considerations on part of the buyer. So, make sure you follow all of them!

Type of Product

Food powder- Picture Courtesy: hedgecombers.com

When choosing any specific powder filler, it is significant that you have proper information regarding the type of product you are processing. For instance, it could be free-flowing, non-free-flowing, or granulated. So, determining this will help you choose the machine that is fulfilling the basic criteria for product properties.

Production Speed

Another crucial factor to look for is the speed and capacity of a powder filler per minute. Now, this will be determined by your existing production line. In addition, if your daily production rate is small to medium size, it will be a better choice to go for a semi-automatic powder filler with single head. In contrast, large scale production will require fully automatic powder filler with double or multiple heads.

Cost

Costs icon- Picture Courtesy: catalpha.com

Considering cost of a powder filler is important as you are about to spend your good share of money on capital. In this way, if you hesitate to pick up expensive machine but want to have advance technology powder filler, then you can go for second hand sophisticated powder filler which will be a suitable option.

Quality Assurance

Quality assurance icons- Picture Courtesy: sassofia.com

Quality assurance is also an obligatory aspect of a powder filler which must be considered. It can be done by checking the machine compliance to national and international quality standards such as ISO, FDA, and cGMP etc., along with warranty policy.

Conclusion

In a nutshell, this buying guide about a Powder Filler entails a broader view from every angle. It showcases how powder filler is becoming popular in every sector whether food, non-food, or medical. Not only that, but this machine can help you meet your highest production targets while maintaining product safety. So, if you want to be the beneficiary of a powder filler, don't forget to contact us! As, we are offering the world's best powder fillers with one year of warranty. For further information, click on the given link!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine